Professional Documents

Culture Documents

Guide to Toyota U240E and U341E Automatic Transaxles

Uploaded by

Manuel CastilloOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Guide to Toyota U240E and U341E Automatic Transaxles

Uploaded by

Manuel CastilloCopyright:

Available Formats

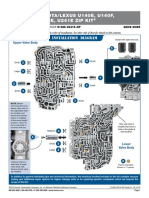

CHASSIS U240E AND U341E AUTOMATIC TRANSAXLES U240E AND U341E AUTOMATIC TRANSAXLES

JDESCRIPTION

D The U240E and the U341E are compact, lightweight, and high-capacity 4-speed automatic transaxles equipped with the [Super ECT (Electronically Controlled Transaxle)]. The U240E automatic transaxle has been newly adopted on the 2ZZ-GE engine models, and the U341E automatic transaxle on the 1ZZ-FE engine models. D Both the U240E and U341E automatic transaxles have adopted a planetary gear unit with a new gear layout. D The U240E automatic transaxle has adopted the E-Shift system, which has transmission shift switches located on the steering wheel to enable the driver to manually shift the gears without taking the hands off the steering wheel, provided that the floor shift lever is engaged in the M position. D A shift lock mechanism is incorporated to minimize the possibility of incorrect operation of the automatic transaxle. D The overdrive switch has been changed from the previous ON/OFF lock type to the momentary type switch. D Automatic transaxle fluid is used T-IV.

169CH12

169CH13

U240E Automatic Transaxle

"

U341E Automatic Transaxle

Specifications A Transaxle Type Engine Type 1st 2nd U240E 2ZZ-GE 3.944 2.197 1.413 1.020 3.145 1.020 3.120 7.6 (8.0, 6.7) ATF Type T-IV U341E 1ZZ-FE 2.847 1.552 1.000 0.700 2.343 1.019 3.924 6.88 (7.3, 6.1) z

Gear Ratio

3rd 4th Reverse

Counter Gear Ratio Differential Gear Ratio Fluid Capacity Fluid Type Liters (US qts, Imp. qts)

CHASSIS U240E AND 7341E AUTOMATIC TRANSAXLES

JPLANETARY GEAR UNIT 1. General

U240E Automatic Transaxle The U240E automatic transaxle has adopted a new gear layout. In the new gear layout, the counter drive and driven gears are placed in front of the front planetary gear and the under drive (U/D) planetary gear unit is placed above the counter shaft. Furthermore, the force transmission method has been changed by eliminating the brake and the one-way clutch. As a result, torque capacity that accommodates the high output engine has been attained, while realizing a compact gear unit. Front Planetary Gear B1 C2 F1 Rear Planetary Gear B3 Under Drive (U/D) Planetary Gear F2 C3 Counter Driven Gear Differential Drive Pinion Input Shaft B2 Counter Drive Gear C1

169CH14

"

Specifications A Forward Clutch Direct Clutch U/D Direct Clutch 2nd Brake 1st & Reverse Brake U/D Brake No.1 One-Way Clutch U/D One-Way Clutch 4 4 3 4 5 3 28 15 43 17 77 31 19 69 32 26 83 50 51

C1 C2 C3 B1 B2 B3 F1 F2

The No of Discs No.

The No of Sprags No. The No. of Sun Gear Teeth The No. of Pinion Gear Teeth The No. of Ring Gear Teeth The No. of Sun Gear Teeth The No. of Pinion Gear Teeth The No. of Ring Gear Teeth The No. of Sun Gear Teeth The No. of Pinion Gear Teeth The No. of Ring Gear Teeth The No. of Drive Gear Teeth The No. of Driven Gear Teeth

Front Planetary Gear

Rear Planetary Gear

U/D Planetary Gear

Counter Gear

CHASSIS U240E AND U341E AUTOMATIC TRANSAXLES

U341E Automatic Transaxle The U341E automatic transaxle has adopted a new gear layout. This automatic transaxle effects the shifting of all speeds using 2 sets of planetary gear unit. Also, through the adoption of the clutch-to-clutch pressure control, the number of brakes have been reduced from 4 to 3, and the number of one-way clutches from 3 to 2 in comparison to the A140E automatic transaxle.

169CH15

"

Specifications A Forward Clutch Direct Clutch Reverse Clutch OD & 2nd Brake 2nd Brake 1st & Reverse Brake No.1 One-Way Clutch No.2 One-Way Clutch The No. of Sprags The No. of Rollers The No. of Sun Gear Teeth The No. of Pinion Gear Teeth The No. of Ring Gear Teeth The No. of Sun Gear Teeth The No of Discs No. 4 3 3 2 4 4 16 15 46 21 85 32 21 75 52 53

C1 C2 C3 B1 B2 B3 F1 F2

Front Planetary Gear y

Rear Planetary Gear y

The No. of Pinion Gear Teeth The No. of Ring Gear Teeth The No. of Drive Gear Teeth The No. of Driven Gear Teeth

Counter Gear

CHASSIS U240E AND U341E AUTOMATIC TRANSAXLES

3. Motive Power Transaxle

U240E Automatic Transaxle

"

Operating Conditions A Gear Park Reverse Neutral 1st D 2nd 3rd 4th 2 L 1st 2nd 1st Solenoid Valve SL1 ON ON ON ON OFF *OFF/ON* *OFF/ON* ON OFF ON Solenoid Valve SL2 ON OFF ON ON ON OFF OFF ON ON ON Solenoid Valve S4 OFF OFF OFF OFF OFF OFF ON OFF OFF OFF Solenoid Valve DSL OFF OFF OFF OFF OFF OFF OFF OFF OFF ON f f f f f f f f f f f f f f f f f f f f f f C1 C2 C3 B1 B2 B3 F1 F2 f f f f f f f f f f f

Shift Lever Position P R N

*: Lock-up ON

CHASSIS U240E AND U341E AUTOMATIC TRANSAXLES

1) 1st Gear (D or 2 Position) Counter Drive Gear

B1 C2

F1

B2 Front Planetary Gear

C1

Input Shaft

Rear Planetary Gear

C3

Sun Gear

Intermediate Shaft Differential Drive Pinion

Sun Gear

F2

B3

U/D Planetary Gear Counter Driven Gear

Ring Gear

161ES09

2) 2nd Gear (D or 2 Position) Counter Drive Gear

B1 C2

F1

B2 Front Planetary Gear

C1

Input Shaft

Rear Planetary Gear

C3

Sun Gear

Intermediate Shaft Differential Drive Pinion

Sun Gear

F2

B3

U/D Planetary Gear Counter Driven Gear

Ring Gear

161ES10

3) 3rd Gear (D Position)

Counter Drive Gear

B2 Front Planetary Gear C1

B1 C2

F1

Input Shaft

Rear Planetary Gear

C3

Sun Gear

Intermediate Shaft Differential Drive Pinion

Sun Gear

F2

B3

U/D Planetary Gear Counter Driven Gear

161ES11

Ring Gear

CHASSIS U240E AND U341E AUTOMATIC TRANSAXLES

4) 4th Gear (D Position) Counter Drive Gear

B1 C2

F1

B2 Front Planetary Gear

C1

Input Shaft

Rear Planetary Gear

C3

Sun Gear

Intermediate Shaft Differential Drive Pinion

F2

B3

Sun Gear U/D Planetary Gear Counter Driven Gear Counter Drive Gear

Ring Gear

161ES12

5) 1st Gear (L Position)

B1 C2

F1

B2 Front Planetary Gear

C1

Input Shaft

Rear Planetary Gear

C3

Sun Gear

Intermediate Shaft Differential Drive Pinion

Sun Gear

F2

B3

Ring Gear

161ES13

U/D Planetary Gear Counter Driven Gear Counter Drive Gear Front Planetary Gear C1

6) Revers Gear (R Position)

B1 C2

F1

B2

Input Shaft

Rear Planetary Gear

C3

Intermediate Shaft Sun Gear Differential Drive Pinion Sun Gear

F2

B3 U/D Planetary Gear

Ring Gear

161ES14

Counter Driven Gear

CHASSIS U240E AND U341E AUTOMATIC TRANSAXLES

U341E Automatic Transaxles

"

Operating Conditions A Gear Park Reverse Neutral 1st D 2nd 3rd 4th 2 L 1st 2nd 1st Solenoid Valve No.1 ON ON ON ON ON OFF OFF ON ON ON Solenoid Valve No.2 ON ON ON ON OFF OFF ON ON OFF ON f f f f f f f f f f f f f f f f f f f f f f C1 C2 C3 B1 B2 B3 F1 F2

Shift Lever Position P R N

1) 1st Gear (D or 2 Position)

Rear Planetary Gear

F2

B3

C2

C1

Intermediate Shaft

C3

F1

Counter Drive Gear Sun Gear Front Planetary Gear

B1

B2

Counter Driven Gear

171CH05

CHASSIS U240E AND U341E AUTOMATIC TRANSAXLES

2) 2nd Gear (D Position)

Rear Planetary Gear

F2

B3

C2

C1

Intermediate Shaft

C3

F1

Counter Drive Gear Sun Gear Front Planetary Gear Counter Driven Gear

171CH06

B1

B2

3) 3rd Gear (D Position) Rear Planetary Gear

F2

B3

C2

C1

C3

Intermediate Shaft Counter Drive Gear

F1

B1

B2

Sun Gear Front Planetary Gear

Counter Driven Gear

171CH07

4) 4th Gear (D Position)

Rear Planetary Gear

F2

B3

C2

C1

Intermediate Shaft

C3

F1

Counter Drive Gear Sun Gear Front Planetary Gear

171CH08

B1

B2

Counter Driven Gear

CHASSIS U240E AND U341E AUTOMATIC TRANSAXLES

5) 2nd Gear (2 Position) Rear Planetary Gear

F2

B3

C1

C2

C3

Intermediate Shaft Counter Drive Gear

F1

B1

B2

Sun Gear Front Planetary Gear

Counter Driven Gear

171CH09

6) 1st Gear (L Position) Rear Planetary Gear

F2

B3

C2

C1

C3

F1

Intermediate Shaft Counter Drive Gear Sun Gear Front Planetary Gear Counter Driven Gear

B1

B2

171CH10

7) Reverse Gear (R Position)

Rear Planetary Gear

F2

B3

C2

C1

C3

F1

Intermediate Shaft Counter Drive Gear Sun Gear Front Planetary Gear Counter Driven Gear

B1

B2

171CH11

CHASSIS U240E AND U341E AUTOMATIC TRANSAXLES

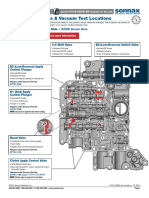

JHYDRAULIC CONTROL SYSTEM 1. General

The hydraulic control system is composed of the oil pump, the valve body, the solenoid valves, the accumulators, the clutches and brakes as well as the fluid passages which connected all of these components. Based on the hydraulic pressure acting on the torque converter clutch, clutches and brakes in accordance with the vehicle driving conditions.

HYDRAULIC CONTROL SYSTEM

ACCUMULATORS

VALVE BODY

Hydr. pressure control

OIL PUMP

Fluid passage switching & Hydr. pressure control

CLUTCH & BRAKE

Planetary gear units

Torque converter clutch

ECM

SOLENOID VALVES

165CH56

2. Oil Pump (U341E Automatic Transaxle)

An oil pump, in which the shape of the teeth has been changed and the crescent has been discontinued, has been adopted. As a result, the oil pump has been made more compact, and the driving torque has been reduced, thus realizing excellent volumetric efficiency during low-speed operation. Cresent

U341E

Conventional Model

165CH10

3. Valve Body

The valve body has a two-stage construction. Also, a compact, lightweight, and highly rigid valve body has been realized. All the solenoid valves are installed in the lower valve body.

CHASSIS U240E AND U341E AUTOMATIC TRANSAXLES

JELECTRONIC CONTROL SYSTEM 1. Construction

The configuration of the electronic control system in the U240E and U341E automatic transaxles are as shown in the following chart.

SENSORS CRANKSHAFT POSITION SENSOR NE SL1 ACTUATORS SOLENOID VALVE SL1*1

ENGINE COOLANT TEMP. SENSOR

THW

S1

SOLENOID VALVE No.1*2

THROTTLE POSITION SENSOR

VTA

SL2

SOLENOID VALVE SL2*1

PARK/ NEUTRAL POSITION SWITCH

P, N

R, D, 2, L

S2

SOLENOID VALVE No.2*2

TRANSMISSION SHIFT SWITCH*1

SFTU

SLT

SOLENOID VALVE SLT

TRANSMISSION SHIFT SWITCH*1

SFTD ECM

ST

SOLENOID VALVE ST*2

VEHICLE SPEED SENSOR COMBINATION METER SPD

S4

SOLENOID VALVE S4*1

SL COUNTER GEAR SPEED SENSOR*1 NC DSL INPUT TURBINE SPEED SENSOR NT

SOLENOID VALVE SL*2

SOLENOID VALVE DSL*1

STOP LIGHT SWITCH

STP

MALFUNCTION INDICATOR LAMP

FLUID TEMPERATURE SENSOR

THO

ODLP

O/ D OFF INDICATOR

OVER DRIVE SWITCH

ODMS

SIL TC

DATA LINK CONNECTOR 3

*1: Only for the U240E Automatic Transaxle *2: Only for the U341E Automatic Transaxle

CHASSIS U240E AND U341E AUTOMATIC TRANSAXLES

2. Solenoid Valves

U240E Automatic Transaxle 1) Solenoid Valves SL1, SL2 and SLT a. General In order to provide a hydraulic pressure that is proportion to current that flows to the solenoid coil, the solenoid valve SL1, SL2 and SLT linearly controls the line pressure based on the signals it receives from the ECM. The solenoid valves SL1, SL2 and SLT have the same basic structure. Sleeve Solenoid Coil

Hydraulic Pressure " Valve ! Current

161ES22

b. Functions of Solenoid Valve SL1, SL2 and SLT Solenoid Valve SL1 SL2 SLT Action For clutch engagement pressure control For line pressure control Function D B1 brake pressure control D Lock-up clutch pressure control C2 clutch pressure control D Line pressure control D Secondary pressure control

CHASSIS U240E AND U341E AUTOMATIC TRANSAXLES

2) Solenoid Valves S4 and DSL a. General The solenoid valves S4 and DSL use a three-way solenoid valve.

Control Pressure Line Pressure

Drain

Solenoid Valve ON

161ES65

Solenoid Valve OFF

161ES64

b. Function of Solenoid Valve S4 The solenoid valves S4 when set to ON controls the 3-4 shift valve to establish the 4th by changing over the fluid pressure applied to B3 brake and C3 clutch. Solenoid Valve S4 B3 Accumulator

Except 4th # B3 Brake ON S4 OFF Line Pressure S4 ON C3 4th # C3 Clutch ON B3

3-4 Shift Valve

161ES23

C3 Accumulator

CHASSIS U240E AND U341E AUTOMATIC TRANSAXLES

c. Function of Solenoid Valve DSL The solenoid valve DSL controls the B2 control valve when the transaxle is shifted in the R or L position. During lock-up, the lock-up relay valve is controlled via the C2 lock valve.

Lock-up Relay Valve R Lock-up ON Chamber Secondary Pressure Solenoid Valve DSL

Lock-up OFF Chamber

R L Secondary Pressure C2 Lock Valve B2 Control Valve

161ES24

B2

U341E Automatic Transaxle D In order to provide a hydraulic pressure that is proportion to current that flows to the solenoid coil, the solenoid valves SLT linearly controls the line pressure based on the signals it receives from the ECM. D The solenoid valves No.1 and No.2 control the hydraulic pressure during shifting, and the solenoid valve ST operates only when shifting from the 3rd gear to the 4th gear, and from the 4th gear to the 3rd gear.

3. Fluid Temperature Sensor

A fluid temperature sensor is installed inside the valve body for direct detection of the fluid temperature.

4. Speed Sensors

The U240E and U341E automatic transaxles have adopted an input turbine speed sensor (for the NT signal), and the U240E automatic transaxle has adopted a counter gear speed sensor (for the NC signal). Thus, the ECM can detect the timing of the shifting of the gears and appropriately control the engine torque and hydraulic pressure in response to the various conditions.

CHASSIS U240E AND U341E AUTOMATIC TRANSAXLES

JAUTOMATIC TRANSAXLE CONTROL SYSTEM 1. General

The automatic transaxle control system of the U240E and U341E automatic transaxles are compared below. System Function D Controls the pressure that is applied directly to B1 brake and C2 clutch by actuating the shift solenoid valve in accordance with the ECM signals. D The solenoid valves SL1 and SL2 minutely controls the clutch pressure in accordance with the engine output and driving conditions. Clutch Pressure Control D Controls the pressure that is applied directly to B1 brake and C1 clutch by actuating the shift solenoid valves ST and SLT in accordance with the ECM signals. D The solenoid valve SLT minutely controls the clutch pressure in accordance with the engine output and driving conditions. The apply orifice control valve varies the apply orifice to control the flow volume supplied to the B3 brake. Applies an equal pressure from the opposite side to cancel the influence of the pressure that is created by centrifugal force. Actuates the solenoid valve SLT to control the line pressure in accordance with information from the ECM and the operating conditions of the transaxle. Retards the engine ignition timing temporarily to improve shift feeling during up or down shifting. Controls to restrict the 4th upshift by using the ECM to determine whether the vehicle is traveling uphill. The shift time lag has been reduced to half by the centrifugal fluid pressure cancelling mechanism and clutch pressure optimal control. The ECM sends current to the solenoid valve No.1 and/or No.2 based on signals from each sensor and shifts the gear. The ECM sends current to the solenoid valve SL1 and/or SL2 based on signals from each sensor and shifts the gear. The ECM sends current to the shift solenoid valve based on signals from each sensor and engages or disengages the lock-up clutch. When the shift lever is shifted from N to D range, the gear is temporarily shifted to 3rd and then to 1st to reduce vehicle squat. U240E U341E

Apply Orifice Control Centrifugal Fluid Pressure Cancelling Mechanism Line Pressure Optimal Control Engine Torque Control Shifting Control in Uphill Traveling High Response Shift Control

f f f f

f f f f

Shift Timing Control

Lock-Up Timing Control

N to D Squat Control

CHASSIS U240E AND U341E AUTOMATIC TRANSAXLES

2. Clutch Pressure Control

Clutch to Clutch Pressure Control 1) U240E Automatic Transaxle A direct clutch pressure control has been adopted for shifting from the 1st to 2nd gear, and from the 2nd to 3rd gear. Actuates solenoid valves SL1 and SL2 in accordance with the signals from the ECM, and guides this output pressure directly to control valves B1 and C2 in order to regulate the line pressure that acts on the B1 brake and C2 clutch. As a result, compact B1 and C2 accumulators without a back pressure chamber have been realized. Signals from ECM Individual Sensors SL1 SL2 C2 Accumulator B1 Accumulator Solenoid Valve SL2 OFF Solenoid Valve SL1 OFF # # C2 Clutch ON B1 Brake ON B1 C2

B1 Control Valve 2) U341E Automatic Transaxle

C2 Control Valve

161ES15

A clutch to clutch pressure control has been adopted for shifting from the 3rd to 4th gear, and from the 4th to 3rd gear. Actuates solenoid valves ST and SLT in accordance with the signals from the ECM, and guides this output pressure directly to 4-3 timing valve and 3-4 timing valve in order to regulate the line pressure that acts on the B1 brake and C1 clutch. As a result, compact B1 and C1 accumulators without a back pressure chamber have been realized. By enabling the solenoid valve ST to switch the orifice of the 4-3 timing valve and the 3-4 timing valve, a smooth shifting has been realized. Linear Solenoid SLT 3-4 Shift Valve 3-4 Timing 4-3 Timing Valve Valve Accumulator Control Valve

C1

Solenoid Valve ST B1

171CH12

CHASSIS U240E AND U341E AUTOMATIC TRANSAXLES

Clutch Pressure Optimal Control Solenoid valves SL1, SL2 (U240E) and SLT (U341E) are used for optimal control of clutch pressure. The ECM monitors the signals from various types of sensors such as the input turbine speed sensor, allowing shift solenoid valves SL1, SL2 (U240E) and SLT (U341E) to minutely control the clutch pressure in accordance with engine output and driving conditions. As a result, smooth shift characteristics have been realized.

"

U240E Automatic Transaxle A

Input Shaft rpm Torqueted rpm Change Ratio

ECM

Input Turbine Speed Sensor

Signals from Various Sensors Engine rpm Engine Torque Information Fluid Temperature

Practical rpm Change Ratio

Time Engine

SL1

Clutch/Brake Pressure

SL2

Solenoid Drive Signal

Output Shaft Torque

169CH16

Time

"

U341E Automatic Transaxle A

Input Shaft Speed Torqueted rpm Change Ratio

ECM

Signals from Various Sensors Engine Speed Engine Torque Information Fluid Temperature

Practical rpm Change Ratio

Time Engine

Input Turbine Speed Sensor

SLT

Clutch/Brake Pressure

Solenoid Drive Signal

Output Shaft Torque

Time

165CH14

CHASSIS U240E AND U341E AUTOMATIC TRANSAXLES

3. Apply Orifice Control (U240E Automatic Transaxle)

The B3 orifice control valve has been provided for the B3 brake, which is applied when shifting from 4th to 3rd. The B3 orifice control valve is controlled by the amount of the throttle pressure in accordance with shifting conditions, and the flow volume of the fluid that is supplied to the B3 brake is controlled by varying the size of the control valves apply orifice. Throttle Pressure

Except 4th # B3 Brake ON B3 B3 Orifice Control Valve

B3 Apply Fluid Pressure

B3 Accumulator

157CH19

CHASSIS U240E AND U341E AUTOMATIC TRANSAXLE

4. Centrifugal Fluid Pressure Cancelling Mechanism

A centrifugal fluid pressure canceling mechanism has been adopted in the clutches. On the U240E automatic transaxle, this mechanism is provided in the C1, C2 and C3 clutches for 2nd/3rd and 3rd/4th gear shifting, and on the U341E automatic transaxle, this mechanism is provided in the C1 clutch for 4th/3rd and 4th/2nd gear shifting. In the conventional clutch mechanism, to prevent the generation of pressure by the centrifugal force that is applied to the fluid in the piston fluid pressure chamber when the clutch is released, a check ball is provided to discharge the fluid. Therefore, before the clutch can be subsequently applied, it took time for the fluid to fill the piston fluid pressure chamber. During shifting, in addition to the pressure that is controlled by the valve body, the pressure that acts on the fluid in the piston fluid pressure chamber also exerts influence, which is dependent upon rpm fluctuations. In order to eliminate this influence, a canceling fluid pressure chamber is provided opposite to the piston fluid pressure chamber. By utilizing the lubrication fluid such as that of the shaft, the same amount of centrifugal force is applied, thus canceling the centrifugal force that is applied to the piston itself. Accordingly, it is not necessary to discharge the fluid through the use of a check ball, and a highly responsive and smooth shifting characteristic has been achieved. C2 Clutch Piston

Canceling Fluid Pressure Chamber

C2 Clutch

Piston Fluid Pressure Chamber

Clutch Fluid Pressure Centrifugal Fluid Pressure

C3 Clutch

169CH47

U240E Automatic Transaxle Centrifugal Fluid Pressure Applied to the Piston Fluid Pressure Chamber Target Fluid Pressure

Centrifugal Fluid Pressure Applied to Canceling Fluid Pressure Chamber

Centrifugal Fluid Pressure Applied to the Piston Fluid Pressure Chamber Clutch Target Fluid Pressure

Centrifugal Fluid Pressure Applied to Canceling Fluid Pressure Chamber

Fluied Pressure Applied to piston

Piston Fluid Pressure Chamber

157CH16

Canceling Fluid Pressure Chamber

157CH17

Shaft Side Target fluid pressure

Centrifugal fluid pressure Fluid pressure applied to canceling fluid applied to piston pressure chamber

= (original clutch pressure)

CHASSIS U240E AND U341E AUTOMATIC TRANSAXLES

5. Line Pressure Optimal Control

The line pressure is controlled by using a solenoid valve SLT. Through the use of the solenoid valve SLT, the line pressure is optimally controlled in accordance with the engine torque information, as well as with the internal operating conditions of the torque converter and the transaxle. Accordingly, the line pressure can be controlled minutely in accordance with the engine output, traveling condition, and the ATF temperature, thus realizing smooth shift characteristics and optimizing the workload on the oil pump.

Line Pressure

Primary Regulator Solenoid Valve SLT Solenoid Drive Signal

Fluid Pressure

Current

Input Turbine Speed Sensor

Transaxle

Fluid Temperature Shift Position

Pump

Throttle Pressure

Engine

Throttle Valve Opening

Intake Air Volume Engine Coolant Temperature Engine rpm

ECM

161ES26

CHASSIS U240E AND U341E AUTOMATIC TRANSAXLES

6. Shifting Control in Uphill Traveling

General With shifting control in uphill traveling, the ECM calculates the throttle opening angle and the acceleration rate to determine whether the vehicle is in the uphill state. While driving uphill on a winding road with ups and downs, the 4th upshift is restricted to ensure a smooth drive.

Uphill Corner

Without Control With Control

3rd 3rd

4th

3rd

Shifting up to the 4th speed after down shifting to the 3rd speed is prohibited while uphill traveling is judged.

169CH53

7. High Response Shift Control

Due to the use of the previously mentioned centrifugal fluid pressure canceling mechanism and the clutch pressure optimal control, not only smooth shifting has been achieved, but the shift time lag has been halved to realize excellent response.

CHASSIS U240E AND U341E AUTOMATIC TRANSAXLES

JE-SHIFT (U240E Automatic Transaxle) 1. General

The E-Shift system allows the driver to manually shift the gears by operating the transmission shift switches located on the steering wheel. This enables the driver to shift the gears by operating the transmission shift switches located on the steering wheel without taking the hands off the steering wheel, thus minimizing the amount of time required to shift gears, provided that the floor shift lever is engaged in the M position. The gear position that has been selected by operating the transmission shift switch is fixed, it enables a manual shift-like feel. However, when the vehicle is brought to a stop, it automatically down-shifts to the 1st gear.

2. Construction

Transmission Shift Switch The transmission shift switches for down-shift are located on the top side of the steering wheel and the transmission shift switches for up-shift are located on the back side of the steering wheel. Transmission Shift Switches (Down) Transmission Shift Switches (Up)

Top Side

169CH17

Back Side

169CH18

CHASSIS U240E AND U341E AUTOMATIC TRANSAXLES

Shift Position and Gear Position Indicators D The driver selects the M position by engaging the shift lever. At that time, the M mode indicator illuminates in the combination meter. D The gear position indicator illuminates at the respective shift position (L, 2, D, and M).

169CH19

M Mode Indicator Gear Position Indicator Combination Meter Operation The usable gears are shown in the chart below. Shift Position L 2 D M Transmission Shift Switch Inactive Inactive Inactive Active O/D ON O/D OFF O/D ON O/D OFF Usable Gear 1st 1st, 2nd 1st X 4th 1st X 3rd 1st X 4th 1st X 3rd Shift Indicator Gear Position Indicator ON ON ON ON M Mode Indicator OFF OFF OFF ON

169CH20

CHASSIS U240E AND U341E AUTOMATIC TRANSAXLES

JFAIL SAFE FUNCTION

This function minimizes the loss of operability when any abnormality occurs in each sensor or solenoid. Control is effected as follows if a malfunction occurs in the sensors and solenoids:

1. U240E Automatic Transaxle

D During a speed sensor malfunction, the vehicle speed is detected through the signals from the counter gear speed sensor to effect normal control. D During a counter gear speed sensor malfunction, 4th upshift is prohibited. D During an ATF temperature sensor malfunction, 4th upshift is prohibited. D During a malfunction in the solenoid valve SL1, SL2, or S4, the current to the faulty solenoid valve is cut off and control is effected by operating the normal solenoid valves. Shift control is effected as described in the table below, depending on the faulty solenoid.

When all solenoids are normal Solenoid SL1 ON SL2 ON S4 OFF Gear SL1 x When shift solenoid SL1 is abnormal Traveling 3rd or 4th Solenoid SL2 ON # OFF ON # OFF OFF S4 OFF Gear SL1 x*2 Traveling 1st or 2nd Solenoid SL2 ON S4 OFF Gear SL1 ON # OFF OFF OFF / ON *1 OFF / ON *1 When SL2 is abnormal Solenoid SL2 x S4 OFF Gear SL1 ON When S4 is abnormal Solenoid SL2 ON S4 x Gear

1st

3rd

2nd

3rd

1st

OFF

ON

OFF

2nd

OFF

3rd

x*2

ON OFF # ON OFF # ON

OFF OFF # ON ON

2nd

OFF

3rd

OFF OFF / ON *1 OFF / ON *1

ON

2nd

OFF / ON OFF *1 OFF / ON OFF *1

OFF

3rd

OFF

3rd

x*2

3rd

OFF

3rd

OFF

3rd

ON

4th

OFF

ON

4th

x*2

3rd

ON

4th

OFF

3rd

When SL1 and SL2 are abnormal Solenoid SL1 x SL2 x S4 OFF Gear

When SL1 and SL4 are abnormal Traveling 3rd or 4th Solenoid SL1 x SL2 ON # OFF ON # OFF OFF S4 x Gear SL1 x Traveling 1st or 2nd Solenoid SL2 ON S4 x Gear

When SL2 and S4 are abnormal Solenoid SL1 ON # OFF OFF OFF / ON *1 OFF / ON *1 SL2 x S4 x Gear

When SL1, SL2 and S4 are abnormal Solenoid SL1 x SL2 x S4 x Gear

3rd

3rd

2nd

3rd

3rd

OFF

3rd

3rd

ON OFF # ON OFF # ON

2nd

3rd

3rd

OFF

3rd

3rd

2nd

3rd

3rd

ON

4th

OFF

3rd

2nd

3rd

3rd

*1: Lock-up ON *2: B1 is constantly operating.

CHASSIS U240E AND U341E AUTOMATIC TRANSAXLES

2. U341E Automatic Transaxle

D During a vehicle speed sensor malfunction, 4th upshift prohibited. D During a input turbin speed sensor malfunction, 4th upshift prohibited. D During on fluid temperature sensor malfunction, 4th upshift prohibited. D During a solenoid valve SLT malfunction, 4th upshift prohibited. D During a solenoid valve ST malfunction, 4th upshift prohibited. D During a water temp. sensor, knock sensor, or throttle position sensor malfunction, 4th upshift prohibited. D During a malfunction in the solenoid valve S1 or S2 the current to the faulty solenoid valve is cut off and control is effected by operating the normal solenoid valves. Shift control is effected as described in the table below, depending on the faulty solenoid. When all solenoids are normal Solenoid S1 ON S2 ON Gear When shift solenoid S1 is abnormal Solenoid S1 x S2 ON # OFF OFF Gear When shift solenoid S2 is abnormal Solenoid S1 ON S2 x Gear When shift solenoid S1 and S2 are abnormal Solenoid S1 x S2 x Gear

1st

3rd

2nd

3rd

ON

OFF

2nd

3rd

ON

2nd

3rd

OFF

OFF

3rd

OFF

3rd

OFF

3rd

3rd

OFF

ON

4th

ON

4th

OFF

3rd

3rd

You might also like

- U341E GearDocument18 pagesU341E Gearpalaboy88875% (12)

- U140eand U241Document25 pagesU140eand U241yosergey80% (5)

- A340E and A343E automatic transmission specifications and operationDocument8 pagesA340E and A343E automatic transmission specifications and operationcalixtoruas75% (4)

- Aw60 41sn Zip BookDocument8 pagesAw60 41sn Zip BookRiki Nurzaman100% (3)

- U340 441E DescriptionDocument25 pagesU340 441E Descriptionruslan1580No ratings yet

- A 340 e 343Document8 pagesA 340 e 343Mauricio Exequiel Chavez100% (1)

- Honda Accord, Acura RSX, TSX, CR-V Transmission SpecsDocument8 pagesHonda Accord, Acura RSX, TSX, CR-V Transmission Specshidraulic100% (5)

- Dokumen - Tips - Technical Service Information Atsg Toyotalexus U150u250 Preliminary Information PDFDocument5 pagesDokumen - Tips - Technical Service Information Atsg Toyotalexus U150u250 Preliminary Information PDFAleksandr Kuznichenko0% (1)

- A 240Document89 pagesA 240Mario Diaz Lopez100% (1)

- BL Aisin (30-40lei) atDocument112 pagesBL Aisin (30-40lei) atmangyan100% (3)

- U140e U241e Zip PDFDocument8 pagesU140e U241e Zip PDFossoski100% (1)

- Automatic Transaxle Components and OperationDocument140 pagesAutomatic Transaxle Components and OperationRadu Xnx100% (6)

- JR405EDocument8 pagesJR405ELalo Barajas Garcia100% (2)

- A541e Automatic TransaxleDocument132 pagesA541e Automatic TransaxleHuey_7480% (10)

- Toyota U151E-U250E Zip Kit: Electronic CautionsDocument8 pagesToyota U151E-U250E Zip Kit: Electronic CautionsMajdy Alsobhi100% (2)

- Baxa Resumen PDFDocument12 pagesBaxa Resumen PDFChepe Camacho100% (3)

- Re4f03b Re4f04bDocument756 pagesRe4f03b Re4f04bdenis100% (3)

- A760EDocument47 pagesA760ENeqcer Martínez100% (3)

- A40Document15 pagesA40Ale100% (3)

- U151E ComponentsDocument203 pagesU151E ComponentsAndres Chavez Barrios100% (3)

- Toyota U660 Transmission Exploded ViewDocument5 pagesToyota U660 Transmission Exploded ViewMarkus of Tau86% (7)

- U-340 Valve BodyDocument19 pagesU-340 Valve BodyAle100% (4)

- Auto Trans U241e PDFDocument396 pagesAuto Trans U241e PDFmasakp94% (16)

- Hyundai A4AF1-2 - A4BF1-1Document4 pagesHyundai A4AF1-2 - A4BF1-1Tal Benyamin67% (6)

- A750E and A750F Automatic TransmissionsDocument41 pagesA750E and A750F Automatic TransmissionsIzabela Mądzelewska100% (4)

- U140e U241e Zip inDocument10 pagesU140e U241e Zip inAnonymous DNM4ZI100% (4)

- Location Valve Body U151EDocument5 pagesLocation Valve Body U151EgabotoyoNo ratings yet

- 3040LE Cable-CompleteDocument13 pages3040LE Cable-CompleteZafer IlhanNo ratings yet

- U341e PDFDocument18 pagesU341e PDFmaq8048100% (2)

- Overhaul A240eDocument140 pagesOverhaul A240eSamuel83% (6)

- Toyota U660E FWD 6-speed transmission rebuild kit guideDocument4 pagesToyota U660E FWD 6-speed transmission rebuild kit guidemickabd2002100% (1)

- Import Checkball Vol III 82-92 PDFDocument11 pagesImport Checkball Vol III 82-92 PDFJulio Chalbaud100% (1)

- A340 VB ID PDFDocument5 pagesA340 VB ID PDFleeroy381No ratings yet

- 變速箱 A245E,A246E ZZE121Document136 pages變速箱 A245E,A246E ZZE121esquisof67% (9)

- Technical Service Information: Jatco Jr710EDocument5 pagesTechnical Service Information: Jatco Jr710EUrszula Walczewska100% (2)

- U660 AtsgDocument63 pagesU660 Atsgevgeny91% (54)

- Nissan RE4F04AV Overhaul PDFDocument91 pagesNissan RE4F04AV Overhaul PDFpedro melendez100% (2)

- Re 4 Fo 4 ADocument116 pagesRe 4 Fo 4 AWissem RatelNo ratings yet

- Toyota U151ef U250eDocument1 pageToyota U151ef U250eMauricio Exequiel Chavez100% (1)

- Automatic Transmission Terms and Components GuideDocument155 pagesAutomatic Transmission Terms and Components GuideFelipe MarquesNo ratings yet

- U 140Document163 pagesU 140mauricio_ch_91100% (6)

- Hyundai 6 SPDocument6 pagesHyundai 6 SPjagaca86% (14)

- AUTOMATIC TRANSAXLE COMPONENTSDocument19 pagesAUTOMATIC TRANSAXLE COMPONENTSWissem RatelNo ratings yet

- Automatic A245E, A246EDocument17 pagesAutomatic A245E, A246EAntonio Carlos Santos77% (13)

- Automatic Transaxle GuideDocument194 pagesAutomatic Transaxle Guidebravo6d78% (9)

- Auto 4HP16 (0 30)Document31 pagesAuto 4HP16 (0 30)Jose David Huanca Taype67% (3)

- At PDFDocument200 pagesAt PDFchory_1100% (1)

- Aa80e Intergration pt1 PDFDocument9 pagesAa80e Intergration pt1 PDFMothana Husban100% (4)

- U151e PDFDocument155 pagesU151e PDFAlejandro Roldan Valle88% (8)

- Attn 0205 AjDocument35 pagesAttn 0205 AjFelix TecateNo ratings yet

- 4f27e 2006 Workshop ManualDocument23 pages4f27e 2006 Workshop ManualTransmisiones Automáticas Chepe100% (5)

- I-Shift Transmission, Design and FunctionDocument38 pagesI-Shift Transmission, Design and Functionghostrpg88% (68)

- Workshop Repair ManualDocument36 pagesWorkshop Repair Manualbogdanxp2000100% (3)

- DC 5-SpeedDocument118 pagesDC 5-SpeedНазар Зафійовський100% (1)

- Automatic Transaxle Repair Manual Section TermsDocument132 pagesAutomatic Transaxle Repair Manual Section TermsRoman Filatov83% (6)

- TeriosDocument1,009 pagesTeriosmohhizbar100% (15)

- Aw55 51leDocument369 pagesAw55 51leJuanortega92% (37)

- Steering SystemDocument22 pagesSteering SystemAlexanderNo ratings yet

- Top AWS Architect Interview Questions in 2019Document23 pagesTop AWS Architect Interview Questions in 2019vasilirajeshNo ratings yet

- 5cd6d9a3a16/certificate PDFDocument4 pages5cd6d9a3a16/certificate PDFIzotopСчастьяNo ratings yet

- Resistance Meter: Operation GuideDocument2 pagesResistance Meter: Operation GuideEko SutjiptoNo ratings yet

- Holiday Accident Reduction Program: SSGT 32 Comm/ElectDocument3 pagesHoliday Accident Reduction Program: SSGT 32 Comm/ElectSteven GarrisNo ratings yet

- Resume Test AutomationDocument4 pagesResume Test AutomationAbhinav DesaiNo ratings yet

- HM TRDocument6 pagesHM TRrafersa100% (2)

- Final PPT Project ReportDocument21 pagesFinal PPT Project ReportAman GuptaNo ratings yet

- 3HAC049194 AM Lincoln ArcLink Interface and Weld Editor-EnDocument48 pages3HAC049194 AM Lincoln ArcLink Interface and Weld Editor-EnRosmery MilagrosNo ratings yet

- Personal branding worksheet to define your brand identityDocument5 pagesPersonal branding worksheet to define your brand identityՀայկուհի Գրիգորյան100% (3)

- Vishwakarma Institute E&TC curriculumDocument37 pagesVishwakarma Institute E&TC curriculumAbhijeet KadamNo ratings yet

- 5th Sem SyllabusDocument28 pages5th Sem SyllabusSUHOTRA guptaNo ratings yet

- Control Gear Fluorescent Electronic EB-ECONOMY Electronic Ballasts For TLD LampsDocument6 pagesControl Gear Fluorescent Electronic EB-ECONOMY Electronic Ballasts For TLD LampsGary LauNo ratings yet

- College Diploma Theme With Art Deco Borders and Frames by SlidesgoDocument47 pagesCollege Diploma Theme With Art Deco Borders and Frames by SlidesgoJigyasu DinodiaNo ratings yet

- The Effect of Technology To The Everyday Living of A First Year Nursing Student in Terms of Academic PerformanceDocument18 pagesThe Effect of Technology To The Everyday Living of A First Year Nursing Student in Terms of Academic PerformanceVanessa Mae IlaganNo ratings yet

- PT INTI (Persero) Company Profile 2022Document32 pagesPT INTI (Persero) Company Profile 2022novitaNo ratings yet

- ANALYSISTABS Sample Dashboard Sales DataDocument232 pagesANALYSISTABS Sample Dashboard Sales Datapuran1234567890No ratings yet

- The Ages of Globalization Geography Technology and Institutions by Jeffrey D. SachsDocument316 pagesThe Ages of Globalization Geography Technology and Institutions by Jeffrey D. SachsJesus Rubio50% (2)

- Cigré2016 Experiencesandinnovationsinpowertransformershort Circuitcurrentwithstandtesting A2 304Document11 pagesCigré2016 Experiencesandinnovationsinpowertransformershort Circuitcurrentwithstandtesting A2 304cisnatelNo ratings yet

- 034 PhotogrammetryDocument19 pages034 Photogrammetryparadoja_hiperbolicaNo ratings yet

- Introduction to TelecommunicationsDocument39 pagesIntroduction to TelecommunicationsepisodbaruNo ratings yet

- Labview & MatlabDocument7 pagesLabview & MatlabSuneet SahuNo ratings yet

- Physics 03-04 PowerDocument2 pagesPhysics 03-04 PowerMacmillanNo ratings yet

- WachsDocument64 pagesWachsJorgeNo ratings yet

- HD 110 / HD 110K: - Articulated Tandem Roller With Two Vibratory Drums - Articulated Combi Roller With Vibratory DrumDocument2 pagesHD 110 / HD 110K: - Articulated Tandem Roller With Two Vibratory Drums - Articulated Combi Roller With Vibratory DrumSanNo ratings yet

- Writing For The Technical ProfessionsDocument557 pagesWriting For The Technical Professionsnewfut93% (14)

- Sun Tzu and Information Warfare PDFDocument178 pagesSun Tzu and Information Warfare PDFtazman10102458100% (4)

- Vehicle Running Account (Vra) December 2022 RCCKDocument12 pagesVehicle Running Account (Vra) December 2022 RCCKm.fadhlyaugustami fadhlyNo ratings yet

- Multi-Function Steering Wheel: Wiring DiagramDocument6 pagesMulti-Function Steering Wheel: Wiring DiagramHaji RashidNo ratings yet

- EE021 - Sub-Station Earth Grid DesignDocument4 pagesEE021 - Sub-Station Earth Grid DesignbhavikNo ratings yet

- Silibus Dum 20022Document266 pagesSilibus Dum 20022lyssa daudNo ratings yet

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyFrom EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNo ratings yet

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- The Rare Metals War: the dark side of clean energy and digital technologiesFrom EverandThe Rare Metals War: the dark side of clean energy and digital technologiesRating: 5 out of 5 stars5/5 (2)

- Transmission Pipeline Calculations and Simulations ManualFrom EverandTransmission Pipeline Calculations and Simulations ManualRating: 4.5 out of 5 stars4.5/5 (10)

- Implementing an Integrated Management System (IMS): The strategic approachFrom EverandImplementing an Integrated Management System (IMS): The strategic approachRating: 5 out of 5 stars5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- ISO 50001: A strategic guide to establishing an energy management systemFrom EverandISO 50001: A strategic guide to establishing an energy management systemNo ratings yet

- Energy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksFrom EverandEnergy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksNo ratings yet

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeFrom EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeRating: 4 out of 5 stars4/5 (130)

- Air-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&AFrom EverandAir-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&ARating: 5 out of 5 stars5/5 (1)