Professional Documents

Culture Documents

Paper Forests

Uploaded by

DaisyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Paper Forests

Uploaded by

DaisyCopyright:

Available Formats

Paper Forests Billions of trees are being planted to meet the

world’s soaring appetite for paper, but pulp

plantations are hardly forests.

b y A s h l e y T. M a t t o o n

O

pen up International Paper’s web page and world’s entire pulpwood demand could be met by a

the first thing you see, in large bold print, relatively small area of plantations. One recent study,

is: “We Plant an Average of 50 Million based on 1993 data, concluded that plantations cov-

Trees Annually.” International Paper bills ering 40 million hectares could have met the world’s

itself as the world’s largest private seedling total wood fiber demand for pulp in that year. That’s

grower: the company produces more than 300 mil- an area less than 30 percent the amount of cropland

lion “genetically-improved” SuperTree® seedlings usually planted in corn (about 140 million hectares).

per year. Those aren’t just trees they’re planting— Pulp and paper companies are not alone in their

they’re super trees. IP may be the biggest planter, but high expectations for industrial tree plantations.

it is hardly unique in either word or deed. All over the Many forestry consultants, governments, and even

world, large pulp and paper operations are cutting— environmental groups see large-scale plantation

and planting—trees at a record pace. And in an effort forestry as the key to a sustainable wood supply for

to convince the public that they are not only using what is the most rapidly growing portion of the for-

forests responsibly, but improving them, the compa- est products sector: the production of woodchips and

nies are continually churning out feel-good slogans pulp to make paper, particle board, and other recon-

like: “for every tree harvested, two are planted,” stituted wood products. Some argue that the global

“there are 20 percent more trees in the United States shift to tree farming is the forester’s equivalent to the

today than there were in 1970,” “managed forests agricultural “Green Revolution” which favored high-

will help prevent global warming by absorbing car- yield crop varieties and large, mechanized farms at

bon,” and so on. the expense of smaller, more diverse operations.

The claims go even further than that. Even as the The planting of trees as crops is hardly a recent

Earth’s natural forest area continues to shrink by as phenomenon. Brazil, which now boasts the world’s

much as 16 million hectares per year, the major pulp largest planted area of eucalyptus (a group of popular

and paper companies present themselves as a sort of plantation trees native to Australia), undertook its Growing simple monocultures where

antidote to the trend. The industry, which posted first extensive eucalyptus plantings around the turn of

1995 sales in excess of $337 billion, argues that it’s the century, as a fuel supply for the São Paulo railway.

natural ecosystems once stood may

actually creating forests. And while it sometimes And given the pressures on the world’s surviving nat- increase immediate profits, but with

acknowledges that these artificial forests house very ural forests, it’s obvious that plantations must play a

little biological diversity, it generally claims that the major role in the industrial wood supply. But there is

dangerous long-term consequences.

spread of intensively managed tree plantations is growing evidence that the prevailing methods of

good news for the natural forests that remain. plantation development are doing serious damage—

Plantations, the argument goes, are potentially so both to natural forests and to the people who live in

productive that they could largely satisfy the demand or around them.

for wood products, thereby relieving pressure on nat- To understand the problem, it’s necessary first to

ural forests. Proponents of this view argue that the grasp the rate and scale of current developments. In

✦

20 WORLD•WATCH March/April 1998 ILLUSTRATION BY BRIAN BATTLES

the past, the world’s pulp mills got their pulpwood About three-quarters of that area is planted in rela- turn, have allowed the industry to penetrate the

primarily from old-growth forests and second growth

stands in the northern United States, Canada, and

tively slow growing species—everything from the

slower growing pines to teak. These stands are used

forests in ways that had not previously been prof-

itable—shipping whole logs out of forests can be

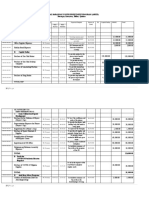

The Global Pulp Stream: Where is

Scandinavia. Over the past 20 years, however, the

wood fiber supply has begun to shift southward, to

primarily for producing timber in the ordinary sense

of the term—the sawnwood and panels used in build-

expensive, but transporting chips is relatively cheap.

The insatiable appetite of these 140 log-chewing

the Fiber Coming From?

the southern United States and to a group of rela- ing construction and furniture making. (Their prima- behemoths has transformed the landscape of the

tively new players, such as New Zealand, Indonesia, ry contribution to the pulp market is through scrap region, consuming more than 485,000 hectares of W O R L D F I B E R S U P P LY

Chile, Brazil, and South Africa. In many southern wood.) The remaining quarter of plantation area is plantation and natural forest per year. Experts predict

Nonwood: 7%

countries, the prospect of a pulp and paper bonanza planted in fast-growing species, mostly eucalyptus that in order to meet the industry’s increasing

has resulted in lavish government subsidies and a rush and the faster-growing pines. These are used mainly demand for fiber, 70 percent of the native pine

of foreign investment. Of course, the underlying goal for pulpwood, and to a lesser extent for fiberboard forests in the southern United States will be convert-

of the investments—both public and private—is not and other reconstituted wood products. ed to monoculture pine plantations by 2020—a dou-

to save forests but to make money, by producing bling of the region’s current plantation area. The cur- Recycled: 36%

wood fiber as quickly and cheaply as possible. Ready From Timber to Fiber, From North to South rent harvesting rate of pine is probably surpassing the

money and an apparently insatiable market have led growth rate by 12 to 14 percent. And as the pine sup-

to enormous increases in plantation cover. In Latin Even though the fast-growing plantations thus far ply diminishes, the industry has increased its reliance

America, for example, plantation area has increased comprise only a quarter of total industrial plantation on hardwood pulp. At mid-century, hardwoods

50 percent in just the last 12 years, to a current total cover, they are, for a couple of reasons, the trend-set- accounted for 13 percent of the region’s pulpwood; Old growth temperate

hardwood: 1%

of 7.5 million hectares—an area slightly larger than ting sector of the forest products industry. There is, today they account for 37 percent, and the hardwood

Panama. Many countries with large plantation estates first of all, the continuing growth in the paper and harvesting rate is expected to overtake the growth

Old growth boreal: 15%

plan to double their plantation area by the year 2010. reconstituted wood products markets. While the pro- rate by 2010. In the meantime, an increasing share of

Indonesia is planning to triple its plantation area duction of sawnwood has roughly plateaued since the the chips is being exported, to feed pulp mills in

within the next 15 years. 1970s, wood pulp production has grown by almost Japan. Between 1989 and 1995, southern hardwood Unmanaged second growth: 17%

Despite the huge amounts of land involved, actu- two-thirds and particle board production has chip exports increased five-fold.

Virgin: 57%

ally quantifying plantation extent is not an easy task. increased nearly three-and-a-half times. In addition, On the whole, however, northern countries have

see breakdown

The global data on forest cover and land-use patterns manufacturing improvements now allow the use of grown increasingly less hospitable to that kind of at right Fast-growing plantations: 29%

are incomplete and often unreliable—the term “plan- lower-quality immature woods—and in some cases, wholesale exploitation (with the exception of the

tation” itself has no universally accepted definition. even wood fiber—in furniture and construction chaotic logging in eastern Siberia, the extent of which

But a rough picture is available from the United material, without compromising the strength or is very difficult to determine). That reticence has cre-

Nations Food and Agriculture Organization, the only durability of the products. Forest management is ated an opening for southern producers, who are also

institution that regularly attempts to assess the extent therefore shifting away from its old focus on high capitalizing on a natural advantage: warmer climates. Managed second growth: 37%

of natural and plantation forest on a global scale. In quality timber and increasingly towards the produc- In the moist tropics, where tree growth is continual

its most recent survey, State of the World’s Forests tion of high quantities of fiber. year-round, large pulp mills can be supported by a

1997, the FAO estimated that between 1980 and Currently, approximately 57 percent of the fiber much smaller land base than in the North. Annual

1995, global plantation cover doubled in size, used in paper production comes from virgin wood growth rates of 3 to 5 cubic meters per hectare

expanding from approximately 90 million hectares to pulp; the rest comes from recovered paper (37 per- (m3/ha) in eastern Canada and 10 m3/ha in the Virgin wood pulp accounts for roughly 40% of the industrial

180 million hectares—just 10 million hectares less cent) and nonwood fibers such as wheat straw (6 per- southern United States pale in comparison to rates as wood harvest. (The other 60% goes mainly for lumber.)

than the total land area of Mexico. cent). Roughly one-quarter of the world’s industrial high as 25 m3/ha in Indonesia and 30 to 40 m3/ha About 25% of industrial wood is cut directly for pulp; the

Certain limitations in the FAO survey, however, wood harvest goes directly for pulpwood, but the in Brazil. And while it takes at least 15 years to grow remainder of the virgin pulp stream consists of scrap from

mean these numbers must be handled with care. The pulp stream absorbs an additional 15 percent of the pine large enough to cut in Alabama, rotations of other processes.

survey provides only very rough estimates of planta- harvest as waste from other processes. At present only eucalyptus in Brazil can be as short as six to eight

tion cover in developed countries, for example, about 29 percent of virgin pulp is coming from the years. The plantation area required to feed a 500,000

because of the difficulty of distinguishing natural fast-growing plantations, according to a 1996 study ton-per-year pulp mill in a Nordic country may be up

forests from plantations in those regions. In develop- by the International Institute for Environment and to 16 times the area required in Brazil.

ing countries, the survey doesn’t include the extensive Development (IIED), a London-based research In addition to the faster growth rates, both land

agricultural tree plantations, such as palm oil or rub- group (see figure, page 23). But the enormous and labor are often much cheaper in southern coun-

ber crops. Nor are industrial plantations distinguished increases in plantation cover virtually guarantee that tries—a combination that can greatly reduce overall

from those that serve non-industrial purposes, such as the percentage will rise rapidly over the next decade. production costs. In September 1997, it cost $449 to Scrap: 15%

community fuelwood supply, agroforestry, and envi- The pulp boom is not just a forestry trend; it is produce a ton of bleached hardwood pulp in the

ronmental protection (through erosion control, also an expansion of heavy industry. The southeastern United States, while in Brazil the average is $357.

watershed management, and so on). Also omitted is a United States, for example, is rapidly expanding its One Brazilian company, Aracruz Celulose S.A., the

key factor for understanding current trends: the dis- pulp mill capacity: the expanded mills—some of world’s largest producer of bleached eucalyptus mar- Direct: 25%

tinction between plantations established in areas which cost over $1 billion—have boosted the ket pulp, has reduced its production costs to just

deforested long ago and those established in areas region’s pulp production nearly 20 percent over the $279 per ton. With costs as low as this, it is no sur- Source: Forest type percentages are from IIED (see text). Other percentages

deforested as a prelude to plantation development. last decade. In response to the new pulp capacity, the prise that industry giants from the North are rapidly are from a variety of sources. All percentages are approximate.

But it is clear that as much as 100 million hectares number of wood chipping mills has increased from flocking to the South to buy up land and engage in

of the global plantation estate is for industrial use. 40 to 140 over the same period. The chip mills, in joint-venture projects with southern companies.

✦ ✦

22 WORLD•WATCH March/April 1998 WORLD•WATCH March/April 1998 23

Between 1995 and 2000, woodpulp capacity in the stantial share of their natural forests to feed the inter- plantations have been installed immediately after the backhanded compliment to brand an area that has

United States and Canada is projected to increase by national woodchip market. In Chile, for instance, the felling of native forests, although few governments been occupied for thousands of years by indigenous

a mere 1.5 percent and 3.5 percent respectively, while forest products export sector has grown from $334 admit that such activities are a matter of policy. peoples as “unused”—an unintentional recognition

in Thailand this increase is expected to be 166 per- million in 1985 to $2 billion by 1995, largely on the Indonesia, however, is an important exception. A of how well used such areas actually are. But when

cent, in Indonesia 123 percent, and Chile 51 percent. strength of a heavily subsidized plantation program. 1995 report by the World Wide Fund for Nature the lands end up as plantations, the former occupants

Brazil, already a well-established producer, nearly Monterey pine (Pinus radiata), the plantation tree of observes that “Indonesia is perhaps the only country are often displaced. Their new homes are likely to be

doubled its pulp exports in the first half of the choice in Chile, now covers an estimated 1.3 million where the planned expansion of the pulp and paper either urban shanty towns or much smaller areas of

decade, from 1,035,000 tons to 1,950,000 tons. The hectares. Yet much of the chips and pulp exported industry openly involves the clearfelling of substantial surviving natural forest where, eventually, even tradi-

country’s 5 million hectares of plantation now thus far have come, not from plantation wood, but areas of rainforest.” As much as 60 percent of tional use may reach an intensity too great for the

account for approximately 60 percent of its industri- from the natural forests displaced by the plantations. Indonesia’s roughly 2 million hectares of plantation land to bear.

al wood production. According to journalist Bill Between 1978 and 1987, approximately 48,600 is thought to have directly displaced natural forest. Take the case of Aracruz Celulose, the Brazilian

Finch, “the joke in the forest industry is that the hectares of native forest were clearcut or burned so The country plans to increase its pulpwood planta- company producing the extremely low-cost pulp.

lobby of the Rio de Janeiro airport looks like a con- that plantations could be installed. In recent years, an tion area to about 6 million hectares by 2010. Aracruz began developing its plantations in the mid-

vention of the Society of American Foresters.” estimated 20,000 hectares of native forest have been This issue gained some international prominence 1960s, on the strength of a government decree that

Leaf through any of the industry journals these logged each year, largely to make way for pulp plan- in the fall of 1997, when fires set to clear land for called for the “afforestation” of 80,000 hectares of

days, and you’ll find all sorts of examples of this tations. Two exotic pine and eucalyptus species now palm oil and pulpwood plantations resulted in a con- the state of Espírito Santo. By 1994, Aracruz owned

North-South consolidation. The Japanese New Oji cover close to one fifth of Chile’s total forest area. flagration that consumed an estimated 2 million 15 percent of Espírito Santo’s fertile coastal plain and

Paper Co. has recently invested in plantations in The same trend is apparent in some parts of the devel- hectares of forest. The Indonesian government ini- had installed 132,000 hectares of eucalyptus in that

Vietnam, Fiji, and New Zealand. By the year 2000, oped world as well, such as the southern United tially laid the blame for the fires on slash-and-burn state and in the neighboring state of Bahia. The land

New Oji’s investments in “Australasian” tree planta- States, or the Australian island of Tasmania, where farmers, but satellite images showed that approxi- Aracruz appropriated in the 1960s was initially said

tions are expected to reach approximately $218 mil- 140,000 hectares of pine and eucalyptus plantation mately 80 percent of the fires originated in lands con- to be uninhabited, but it has now been established

lion. Champion International of Stamford, have been installed, much of it after native old growth trolled by industry. The fires are apparently being that nearly 7,000 families were displaced—in some

Connecticut, recently added to its Brazilian holdings forests were felled and chipped. About 80 percent of used to circumvent regulations that restrict planta- cases forcibly—when Aracruz took control of the

with a purchase of a 174,000-hectare tree farm in the Tasmania’s wood chips are shipped to Japan. tion development to lands containing fewer than 20 land. Many of these people received no compensation

state of Amapa. In addition to providing a supply of cubic meters of merchantable timber per hectare— for the lands they lost. The Tupinikim and Guarani

woodchips to Champion’s paper mills in Florida and

Alabama, the newly acquired lands will also supply

How green is the plantation economy? once burnt, the forest is “degraded” and available for

development. In part, the Indonesian pulp crisis is

indigenous peoples, two groups that lost land to

Aracruz, have since launched an international cam-

woodchips to the global market. Champion is con- Plantations, for pulp and for other purposes, are driven by mill over-capacity: the plantations estab- paign to have their traditional territories restored.

sidering investing another $1.5 billion in pulp and now a necessary and permanent part of the forest lished to feed the country’s new mills are not yet In some cases, plantations have displaced not tra-

paper capacity in Brazil. And as the money flows in, economy. But a number of factors associated with the mature and mill owners are reported to be purchas- ditional but modern agricultural regimes. Spain, for

the wood chips and pulp flow out. Over the past four current boom—the loss of native forest in countries ing an average of 25 percent of their fiber from example, experienced a plantation boom following its

decades, international trade in wood fiber has like Chile, the tremendous growth of the interna- sources that may be operating—in one way or anoth- entry into the European Community in 1985. The

quadrupled. Today, approximately 20 percent of pulp tional paper market, the pulp and chip mill building er—outside the law. country now has more than 5 million hectares of pulp

production, and 25 percent of paper production is frenzy—all of these factors invite a critical reassess- On a global level, it’s very difficult to assess what plantation, much of it growing on former farmland.

traded internationally. ment of the industry’s current practices. Here are proportion of plantation area is a direct, immediate In Hawaii, Japan’s New Oji Paper Company is inter-

Few countries illustrate the trend toward global- some of the standard industry claims: displacement of natural forest. Such developments ested in taking a 55-year lease for 10,000 hectares of

ized markets better than Japan. Japan is second only often involve some sort of subterfuge like burning or an old sugar cane plantation (the pro-

to the United States as a producer and consumer of Claim 1: Plantations ease the pressure on pirate logging, to bring a tract of land out of pro- posal is currently on hold due

paper and paperboard: in 1995, the most recent year remaining natural forests. tected status. But according to some conservative to public opposition).

for which figures were available, Japan accounted for The industry and governments involved in plan- estimates, 15 percent of all tropical plantation area Plantation encroachment

10.7 percent of world paper production and 10.9 per- tation development frequently claim that most, or all, was established directly over natural forest. on productive farmland

cent of consumption. Yet unlike the United States, or at least a substantial portion of their plantations is likely to increase the

which produces the majority of its own fiber, Japan’s are installed on lands that are already degraded, and Claim 2: Plantations allow unused land pressure that agri-

raw material production is practically insignificant. It that by bringing these lands into production, less cut- to be productive. culture is putting

is not surprising, then, that the country is the world’s ting will be necessary in surviving natural forests. Industry officials often claim that planta- on natural forests.

biggest importer of wood chips (accounting for 70 Some plantations are indeed growing on previously tions have been established on land that was According to the

percent of the international market in 1994), and a degraded sites, but the suggestion that the industry not being “used.” Often, the argument is FAO, an addi-

major importer of pulp (almost 12 percent of the generally seeks out degraded land to grow trees is advanced with reference to forests or mixed tional 90 million

international trade). In addition to importing from simply not credible. In the first place, the logic of landscapes inhabited by peoples who are hectares of crop-

the United States and Canada (its traditional sources), high-volume investment wouldn’t permit this: no not fully integrated into the mainstream land will be need-

Japan is now buying more and more fiber from executive who wants to keep his job is going to tie a economy. To the executives of a large com- ed by 2010 to feed

Australia, Chile, Indonesia, South Africa, and Brazil. billion-dollar pulp mill to the fate of degraded land if pany, whose operation requires the planting the world’s grow-

Had this article been published on Japanese paper, he can avoid doing so. Instead, he’s likely to look for and harvesting of trees over thousands of ing population; at

you might now be holding in your hands a piece of the best soils and the best water supply available— hectares, the degree of “use” imposed upon least half of that is

material woven from the forests of perhaps half a even if they happen to be underneath natural forests. a landscape by small-scale farmers and already expected to

dozen different countries on at least three continents. In the second place, there is plenty of hard, on- hunters may well seem hardly worth notice. come from the con-

Many southern countries are liquidating a sub- the-ground evidence from countries like Chile that Indeed, in some cases, it could be a kind of Cedrus Atlantica (Atlas Cedar) version of forest.

✦ ✦

24 WORLD•WATCH March/April 1998 WORLD•WATCH March/April 1998 25

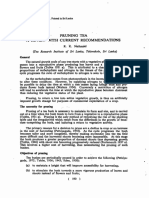

Claim 3: Plantations create jobs and help local the University of Alabama in Huntsville, on the situ- eye is nearly impossible…. Areas missed have to be consumption in industrialized countries is 158 kilo-

communities. ation: “‘We’ve got another 20 to 40 years of pine reflown, adding to chemical costs and flying time.” grams per year—over eight times the developing

The industry frequently claims that industrial cropping before we are blown out of the water by In addition to the pesticides, chemical fertilizers world average of 18 per year. The United States, with

plantations create jobs for local people and generate cheap cropping in the tropics’…In the game of low- are required to compensate for the nutrients lost approximately 4.7 percent of the world’s population,

much-needed income for local communities. Given quality, high-volume production, ‘Alabama is gonna when whole trees are removed from the system every consumes over 31 percent of the world’s paper and

the number of operations required to run a planta- get its pants beaten off.’” ten years or so. Site preparation and harvesting is paperboard. The United States, Japan, and Western

tion—preparing land, planting, tending the trees, done by heavy equipment that compacts soils,

operating the mills—it’s not hard to understand why Claim 4: Plantations are “sustainable.” increasing runoff and erosion. While a company may

many governments have been willing to accept this One of the most common and seductive sugges- endorse the need to manage its lands sustainably, Kilograms per person per year

argument, and to offer substantial financial incentives tions that the industry offers in favor of plantation profit, not ecological health, is the bottom line. And 250

to plantation developers in the hope of economic Industrialized Countries

development is that plantations are essentially forests. in many countries, the current regulatory and social

Developing Countries

growth. But plantation work is generally grueling, If a plantation is like a natural forest, then it is essen- climate offers the biggest profit to operations that 200

dangerous, and very low-paying; the hours are long tially a healthy ecosystem, and it should therefore be crop trees as intensively as possible, with the prospect

and job security is often minimal. Yet where planta- possible to maintain that health indefinitely. It should, of moving on to fresh soils once the current land is

150

tions have displaced communities—thereby creating in other words, be “sustainable.” But the ecological exhausted.

a class of landless, jobless poor—plantation labor may differences between industrial plantations and natural

be the only remaining option. On the Aracruz plan- forests are so vast that comparing them in detail Rethinking the Paper Economy 100

tations, for instance, some of the displaced people would be pointless: apart from the presence of trees,

opted to return to their lands as Aracruz employees. plantations bear almost no resemblance to real forests. Industrial plantations could do much to reduce

50

As far as employment is concerned, industry The key difference, of course, is diversity. Natural the environmental impacts associated with the pro-

trends are not encouraging. Increasing mechaniza- forests are some of the most diverse ecosystems on duction of raw material for industry. Farming trees in

tion is steadily reducing the labor force. From earth, but plantations—especially industrial planta- a concentrated area, in a sustainable way, is clearly 0

installing the trees, to felling them, to producing tions—are generally monocultures. Obviously, plan- preferable to mining the world’s last remaining old- 1975 1980 1985 1990 1995 2010

pulp—all the new equipment is engineered to require tations have virtually no plant diversity; they have lit- growth stands. But in their present form, pulp plan-

Per Capita Consumption of Paper and Paperboard,

as few people as possible. Since 1993 Aracruz has tle wildlife value either because they lack habitat tations are driven almost entirely by short-term com-

with FAO Projections to 2010

reduced its workforce from 7,000 to 2,700 employ- diversity and forage. Natural forests offer a huge mercial considerations, at tremendous social and eco-

ees (including the loss of 2,500 jobs that were con- range of “natural goods and services”—everything logical costs. Reforming plantation management is

tracted out). Bahia Sul Celulose, another Brazilian from fruit production, to habitat for crop pollinators, therefore crucial to the survival of the real forests. Europe combined represent less than 20 percent of

pulp giant, employs one plantation worker for every to flood control (see Janet Abramovitz, “Putting a Several “stakeholder” coalitions are developing plans the world’s population and account for nearly 70 per-

45 hectares of trees, while local diversified agriculture Value on Nature’s ‘Free’ Services,” January/ for better plantation management; they include the cent of its paper consumption. Even so, it is in the

provides 18 jobs per hectare, according to a 1993 February). These aspects of a natural forest are also Forest Stewardship Council’s “Principles and Criteria industrialized countries that most of the growth in

study. In terms of investment capital, each of the largely absent from plantations. for Forest Stewardship” and the International consumption is expected to occur. By 2010, per capi-

5,500 jobs provided by Bahia Sul in the early 1990s It is true that in recent years, some companies Tropical Timber Organization’s “Guidelines for the ta consumption in the world’s richest countries is

cost between $226,000 and $338,000—and much of (Aracruz among them) have taken steps to reduce Establishment and Sustainable Management of expected to reach 241 kg per year (see figure above).

that investment was public. In Indonesia, robots are their environmental impacts, but industrial planta- Planted Tropical Forests.” Plans such as these gener- Timber industry analysts generally treat the

being designed to handle seedling operations. tions still generally inflict a huge insult on the land. ally emphasize conservation, local economic health, prospect of consumption increases as a sign of

The same labor trends are at work in developed Like virtually all large-scale monocultures, planta- integrated land-use planning, watershed protection, healthy economic growth—as an improvement in the

countries. In the United States, a recent tions are susceptible to disease and the need to reduce fertilizer and pesticide use, and quality of life. But in real life, the quality isn’t always

study of Alabama pulp mills deter- pest outbreaks, so they commonly clearer definitions of loaded terms like “degraded so obvious. In the United States, the world’s biggest

mined that only one job is creat- require heavy applications of insec- lands.” paper consumer, per capita consumption increased

ed for every million dollars ticides and fungicides. Herbicides But no matter how carefully crafted it is, no plan from 312 kg in 1990 to 332 kg in 1995, the most

invested in pulp mills. In are also frequently used to pre- has much of a chance if the world’s growing appetite recent year for which figures were available. Yet that

contrast, for every million vent invasion of competing veg- for wood fiber is not reduced. At least as important as 20-kg increase, which boosted U.S. per capita con-

invested in sawmills, nine etation. New Zealand’s planta- forest management is the management of consump- sumption to nearly seven times the global average,

jobs are created, and for every tion managers have used over 30 tion. If it is hard to believe that consumption can (or would probably be regarded by much of the U.S.

million invested in the furniture different pesticides, including should) be managed, that’s testimony to the power of population as, on reflection, a mild deterioration in

industry, 40 jobs are created. In highly toxic organochlorines (the three assumptions, which are largely guiding the pre- the quality of life. If you doubt this and you live in

Hawaii, a 10,000 hectare pulp plan- class of chemicals that includes sent course of development—and which are toxic to the United States, try an experiment: save a week’s

tation would produce 40 to 60 jobs, DDT). The pesticides are generally natural forests. worth of junk mail, weigh it, and multiply the results

while the same amount of land used for broadcast from airplanes or helicopters, The most dangerous assumption is that growth in by 52. (The average U.S. household receives 553

diversified agriculture would create over and aerial spraying virtually insures that paper demand is inevitable. The FAO projects that pieces of junk mail in a year.)

4,000 jobs. Even at its present employment neighboring land will be contaminated. global consumption of paper and paperboard will rise While the prevailing economic view still envisions

level, many observers of the Alabama indus- “No pilot can really fly a straight line,” from 276 million tons per year in 1995 to 480 million consumption increasing ad infinitum, there is

try fear that the sector is setting itself up explains one New Zealand helicopter pilot. tons in 2010. While developing countries are begin- already a small but growing body of literature devot-

for major job losses. An article in the “‘Wandering’ is a recognized part of heli- ning to absorb a larger share of the world’s paper, ed to the practical problems of reducing consump-

Mobile Register newspaper quoted copter work and complete accuracy with industrialized countries still account for over 75 per- tion. And the consensus is that reduction—even rad-

Arenga saccharifera

Robert Lawton, an ecology professor at spray coverage or seeding when flying by cent of global consumption. On average, per capita ical reduction—is possible. For example, a 1994 con-

✦ ✦

26 WORLD•WATCH March/April 1998 WORLD•WATCH March/April 1998 27

ference on the issue, held in Tomales Bay, California, lar way. L I F E C Y C L E S

suggested a goal of a 75 percent reduction in U.S. Nonwood fibers—including agricultural residues

wood consumption over the course of a decade. (See such as wheat straw and crops such as kenaf and

Atossa Soltani and Penelope Whitney, eds., Cut hemp—currently account for close to 7 percent of

Waste, Not Trees, San Francisco: Rainforest Action

Network, 1995.) A broader assessment is available in

the work of analysts like Friedrich Schmidt-Bleek, an

fiber input as a global average, but the proportion

varies dramatically from one country to another. In

the United States, for example, nonwoods contribute

The Story of a Shoe

economist with the Wuppertal Institute, a German less than 1 percent to total fiber, while in China, they

think tank, who argues that industrialized countries contribute 60 to 65 percent (primarily in the form of

could ultimately cut their materials consumption in straw). There are a number of serious questions by John C. Ryan and Alan Thein Durning,

general by 90 percent. (Schmidt-Bleek was a member about the role that nonwood fibers should play in excepted from Stuff: The Secret Lives of Everyday Things

of the “Factor 10 Club,” which developed this thesis paper production. Should crop residues, for example,

in 1994.) These theories have received relatively little be diverted to the mills instead of being recycled on

public attention, but they merit serious attention the farm? How much cropland is it reasonable to

from policymakers looking for a fresh approach to divert into paper production? Nonwood fibers prob- Editor’s Introduction: Since the days when and labor assessments—documenting many unsafe

economic and environmental problems. And in the ably shouldn’t replace wood fiber entirely—far too Nike Corporation co-founder Phil Knight sold shoes conditions at a plant in Vietnam—has seriously called

current context, it’s hardly a question of radical much cropland would have to be used, and the pro- out of the trunk of his car at track meets, his high-fly- Young’s findings into question. In a sobering refuta-

reduction: even stabilizing paper demand would be duction wouldn’t necessarily be kinder to the land tion of Young’s report in the New Republic, Stephen

ing sports-shoe company has developed a reputation as

an enormous improvement over the status quo. than the current pulp plantations are. Nevertheless,

one of the United States’ more progressive corporations. Glass avers that in order to soothe labor critics, “the

The second toxic assumption guiding present it’s clear that in some circumstances, nonwood fibers

development is that virgin wood fiber must continue can make sense for particular farming communities— But this reputation—based on the company’s strong world’s largest sneaker company did what it did best:

to be the primary raw material source for the paper and they can be used effectively to take some of the leadership in supporting equal participation for it purchased a celebrity endorsement.”

industry. Two other readily available sources of fiber, pressure off the forests. Maureen Smith, an indepen- women in sports, for example, or on the wooded run- Nike’s ability to reconfigure its public image

recycled paper and nonwood fibers, have yet to be dent paper analyst based in California, argues that the ning trails it provides for its U.S. employees—contrasts through advertising and celebrity endorsements points

tapped at anywhere near their full potential. The use U.S. industry, now dependent on wood pulp for sharply with reports of its operations in Asia, where to another troubling aspect of the company’s

of recycled paper has increased substantially, from 23 roughly 70 percent of its fiber, could eventually work growing scrutiny has revealed wide- success. Perhaps as much a matter of concern

percent as a global average in 1970, to 36 percent in with a fiber stream that is at least 50 percent wastepa- as Nike’s exploitation of its factory workers, is

spread labor abuses.

1994, but there is still plenty of room for growth. per and 20 percent agricultural residues.

By employing subcontractors in Asia the shoe company’s ability to manipulate its

The rap against recycled fiber is that it’s substantially The third toxic assumption might be called the

weaker than virgin fiber, which limits the recycled “SuperTree” ideal. This is the notion that intensively to assemble shoes, Nike has made big consumers, the people who purchase and wear

content of a blend. But of course, not all papers managed plantations covering a relatively small area profits—$800 million on sales of $9.2 its shoes. The human rights organization

require great strength. Germany and Japan have will provide a sustainable source of pulp for genera- billion in 1996. But the company’s suc- Christian Aid estimates that the labor com-

already shown that it is feasible to push the recycled tions to come. They won’t, because no soil on earth cess, and the disparity between its profits ponent of athletic shoes manufactured in

contribution to the fiber stream, as a national aver- can take that kind of repeated depletion, and because and the wages it pays its subcontracted Asia is roughly equivalent to 6 percent of the

age, above 50 percent, and there pulp demand is continually growing. These “40 mil- labor force, has made it a target for crit- price Nike pays for them, or about 3 percent

may not be any reason lion hectare solutions” have a kind of sound-bite of the price they fetch in stores. Since Nike

ics who say the company has a double

to stop there. glibness to them. They suggest that there is some

standard. Last spring thousands of spent $978 million on advertising in 1997—

After all, it sort of collective decision-making process that

required signifi- neatly divvies up portions of the earth’s land Indonesian workers, complaining that they were not more than 10 percent of its earnings—it appears that

cant engineer- cover for different uses. This is clearly mislead- receiving the required minimum wage of $2.50-a-day, the company spends significantly more marketing its

ing know- ing and results in a false sense that there are “ransacked” their factory. In Vietnam, where workers shoes than it does paying its labor force to make them.

how to make no practical limits to the supply of “renew- churn out a million pairs of shoes every month for a Along with countless other businesses and advertising

a consistently able” resources such as trees. minimum monthly wage of $42, 800 workers recently companies, Nike is working to create needs, rather

strong pulp The pulp plantation boom is likely to walked off the job to protest poor working conditions. than meet existing ones—the satisfaction of which

out of eucalyp- encourage a dangerous complacency in exacts unnecessary social and environmental costs.

Wages are nearly as low in China and Indonesia,

tus fiber, so per- industrialized societies—an ignorance of the

where 70 percent of all Nike shoes are made. As John Ryan and Alan Thein Durning have

haps additional true costs of paper production. As more and

attention to recy- more chipping and pulp operations move to Last year, in response to growing criticism Nike documented in their book Stuff: The Secret Lives of

cled fiber would southern countries, consumers in the north are hired noted civil rights activist Andrew Young to Everyday Things, consuming goods has come to play a

pay off in a simi- less and less likely to be aware of the negative draft a report on the state of Nike’s labor practices— different role in our lives than anyone, even econo-

impacts of wasteful overconsumption. Before though Young admittedly has no labor expertise. Based mists, ever imagined it would. For many, the con-

No plantation tree will

we can get pulp plantations on a really sustain- on a two-week, whirlwind tour through 12 different sumer culture has become an ideology “where buying

ever look like this. The able footing, we will have to reduce the demands factories in Indonesia, China, and Vietnam, Young things is believed to provide the sort of existential satis-

Baobab tree of Mada- that we make of them. faction that, say, going to church once did,” as Thomas

gascar (Adansonia concluded that there was no “widespread or systematic

Madagascariensis) was illustrated in a dictionary entry a centu- abuse or mistreatment of workers” at these operations. Frank puts it in an essay in the book Commodify

ry ago, but wonders that were commonplace then are rare or

Ashley T. Mattoon is a staff researcher at the

Worldwatch Institute. But the leak of one of Nike’s internal human rights Your Dissent. Businesses now spend staggering

nonexistent today.

✦ ✦

28 WORLD•WATCH March/April 1998 WORLD•WATCH March/April 1998 29

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- One Thousand Magical Herbs and FungiDocument16 pagesOne Thousand Magical Herbs and FungiSayanSanyal100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Forty Rules of LoveDocument41 pagesForty Rules of LoveDaisy100% (8)

- Family Toolkit Healthy LivingDocument73 pagesFamily Toolkit Healthy LivingDaisy100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Kelty - ProfToolkit - Healthy Living Healthy MindDocument149 pagesKelty - ProfToolkit - Healthy Living Healthy MindDaisy100% (2)

- Macadamia Description PDFDocument32 pagesMacadamia Description PDFAndres Giraldo GomezNo ratings yet

- Systems Intelligence 2004Document320 pagesSystems Intelligence 2004Daisy100% (1)

- The Eucalyptus A Natural and Commercial History of The Gum TreeDocument257 pagesThe Eucalyptus A Natural and Commercial History of The Gum Treeaniara rNo ratings yet

- ORCHARD GARDENING LAYOUT GUIDEDocument16 pagesORCHARD GARDENING LAYOUT GUIDEMaribeth Tangco FrondaNo ratings yet

- Building Sustainability in An Urbanizing World - WB 2013Document216 pagesBuilding Sustainability in An Urbanizing World - WB 2013DaisyNo ratings yet

- 3rd Grade Plant and Flower Science ReviewDocument4 pages3rd Grade Plant and Flower Science ReviewAlex BuycoNo ratings yet

- Joy of Learning - Lesson Plans On Hygiene, Sanitation, Water, Health and EnvironmentDocument98 pagesJoy of Learning - Lesson Plans On Hygiene, Sanitation, Water, Health and EnvironmentDaisy80% (5)

- Class 2 NSTSE PQP 10-Papers 2019-20 2-In-A4 PDFDocument77 pagesClass 2 NSTSE PQP 10-Papers 2019-20 2-In-A4 PDFShyamNo ratings yet

- Companion To Philosophy of ScienceDocument465 pagesCompanion To Philosophy of ScienceMario de Turey93% (15)

- Sustainable Everyday ENGDocument276 pagesSustainable Everyday ENGDaisy100% (4)

- Paving The Way For Climate Resilient InfrastructureDocument148 pagesPaving The Way For Climate Resilient InfrastructureDaisyNo ratings yet

- How To Design Our World For HappinessDocument69 pagesHow To Design Our World For HappinessDaisy100% (1)

- The Ecosystem Approach - 5 Steps To ImplementationDocument39 pagesThe Ecosystem Approach - 5 Steps To ImplementationDaisyNo ratings yet

- Investing in Resilience: Ensuring A Disaster-Resistant FutureDocument188 pagesInvesting in Resilience: Ensuring A Disaster-Resistant FutureAsian Development BankNo ratings yet

- Steam Curriculum Guide For Nursery and Primary School PDFDocument49 pagesSteam Curriculum Guide For Nursery and Primary School PDFLamiNo ratings yet

- Jessican Conrad Sharing RevolutionDocument81 pagesJessican Conrad Sharing RevolutionZaq MosherNo ratings yet

- The New Sharing EconomyDocument13 pagesThe New Sharing EconomyDaisy100% (4)

- Social Dimensions Climate ChangeDocument16 pagesSocial Dimensions Climate ChangeSamrerng KriengprathanaNo ratings yet

- ADB Climate Change Assessment CooDocument28 pagesADB Climate Change Assessment CooDaisyNo ratings yet

- ADB Green Growth Resources ResilienceDocument157 pagesADB Green Growth Resources ResilienceDaisyNo ratings yet

- ADB Flood Risk ManagementDocument206 pagesADB Flood Risk ManagementDaisyNo ratings yet

- ADB Flood Risk ManagementDocument206 pagesADB Flood Risk ManagementDaisyNo ratings yet

- ADB Climate Change Assessment CooDocument28 pagesADB Climate Change Assessment CooDaisyNo ratings yet

- Global Food Policy Report 2012Document142 pagesGlobal Food Policy Report 2012DaisyNo ratings yet

- ADB Building Climate Resilience Agriculture SectorDocument322 pagesADB Building Climate Resilience Agriculture SectorDaisyNo ratings yet

- ADB Building Climate Resilience Agriculture SectorDocument322 pagesADB Building Climate Resilience Agriculture SectorDaisyNo ratings yet

- Value - Counting Ecosystems As Water InfrastructureDocument90 pagesValue - Counting Ecosystems As Water InfrastructureDaisyNo ratings yet

- Soc Trang ICAM ReportDocument74 pagesSoc Trang ICAM ReportDaisyNo ratings yet

- Share - Managing Water Across Boundaries IUCN 2008Document97 pagesShare - Managing Water Across Boundaries IUCN 2008DaisyNo ratings yet

- Mekong Basin Planning Story 2013Document68 pagesMekong Basin Planning Story 2013DaisyNo ratings yet

- Mekong Environmental Symposium 2013 - Abstract VolumeDocument282 pagesMekong Environmental Symposium 2013 - Abstract VolumeDaisy100% (1)

- Pay - Establishing Payments For Watershed ServicesDocument105 pagesPay - Establishing Payments For Watershed ServicesDaisyNo ratings yet

- Mangroves - Soldiers of Our CoastsDocument17 pagesMangroves - Soldiers of Our CoastsDaisyNo ratings yet

- Alice Park SWOT Strengths Weaknesses Opportunities Threats AnalysisDocument13 pagesAlice Park SWOT Strengths Weaknesses Opportunities Threats AnalysisTine DiosoNo ratings yet

- Annual Barangay Youth Investment Program (Abyip) Barangay Liwayway, Diffun, QuirinoDocument8 pagesAnnual Barangay Youth Investment Program (Abyip) Barangay Liwayway, Diffun, QuirinoKrisna Criselda SimbreNo ratings yet

- Melia Dubea BrouchureDocument2 pagesMelia Dubea Brouchuremoham_idrisNo ratings yet

- 1-Bioclimatic Landscape Design in Arid ClimateDocument6 pages1-Bioclimatic Landscape Design in Arid ClimatevabsNo ratings yet

- SST All in One Class9Document14 pagesSST All in One Class9SumitNo ratings yet

- Daily Lesson Plan: in Technology and Livelihood EducationDocument6 pagesDaily Lesson Plan: in Technology and Livelihood EducationReyg LamonioNo ratings yet

- Lagundi Herbal Medicine - Health Benefits of Philippine ShrubDocument2 pagesLagundi Herbal Medicine - Health Benefits of Philippine ShrubGunongEmylDale100% (1)

- Sanford Ferguson Project2 PRDocument2 pagesSanford Ferguson Project2 PRapi-360234881No ratings yet

- Screenshot 2023-08-02 at 6.53.58 PMDocument26 pagesScreenshot 2023-08-02 at 6.53.58 PMNou BeangNo ratings yet

- Domestica (Apple) in Hypercholestremia andDocument3 pagesDomestica (Apple) in Hypercholestremia andForam JethwaNo ratings yet

- Building Material and Construction-Iii: Lecture By: Prof. Dr. Sajjad MubinDocument44 pagesBuilding Material and Construction-Iii: Lecture By: Prof. Dr. Sajjad MubinAleena AsifNo ratings yet

- Effects of Mulch Treatments On Lateral Branching of Sweet Cherry TreesDocument8 pagesEffects of Mulch Treatments On Lateral Branching of Sweet Cherry TreesiplascakNo ratings yet

- Norway Spruce Fact SheetDocument4 pagesNorway Spruce Fact SheettdrnkNo ratings yet

- Orchid Fever: by Susan Orlean The New Yorker January 23, 1995Document5 pagesOrchid Fever: by Susan Orlean The New Yorker January 23, 1995Jane GaijinNo ratings yet

- Morfologi Pinus Aceh (Pinus Merkusii)Document12 pagesMorfologi Pinus Aceh (Pinus Merkusii)tjahjo trihartonoNo ratings yet

- Building Bulk GuidelinesDocument14 pagesBuilding Bulk GuidelinesmitualvesNo ratings yet

- Humans and Natural Environment (1) CharanDocument19 pagesHumans and Natural Environment (1) CharantejNo ratings yet

- The Tale of Three TreesDocument3 pagesThe Tale of Three TreesJhonaNo ratings yet

- Acacia BookDocument48 pagesAcacia BookAhmad SolimanNo ratings yet

- How to write an article: format, structure and tipsDocument8 pagesHow to write an article: format, structure and tipsSunilDwivediNo ratings yet

- Workbook: Curriculum Integration Reading ProgramDocument19 pagesWorkbook: Curriculum Integration Reading Programionescu9No ratings yet

- Tea Pruning Current MethodsDocument16 pagesTea Pruning Current MethodsChanaka Mallikarachchi100% (1)

- Aldinga Bay's Coastal Views September 2015Document40 pagesAldinga Bay's Coastal Views September 2015Aldinga BayNo ratings yet