Professional Documents

Culture Documents

D.F.stamatialis - Structure and Permeation Properties of Cellulose Esters Asymmetric Membranes

Uploaded by

Muruganandam LoganathanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D.F.stamatialis - Structure and Permeation Properties of Cellulose Esters Asymmetric Membranes

Uploaded by

Muruganandam LoganathanCopyright:

Available Formats

564

Biomacromolecules 2000, 1, 564-570

Structure and Permeation Properties of Cellulose Esters Asymmetric Membranes

Dimitrios F. Stamatialis, Cristina R. Dias, and Maria Norberta de Pinho*

Department of Chemical Engineering, Instituto Superior Tecnico, Av. Rovisco Pais, 1049-001 Lisbon, Portugal Received February 7, 2000

The permeation properties of a series of membranes of cellulose esters, presenting a wide range of characteristics, were studied and correlated to the structure of water in the pores, to the polymer hydrophilicity/ hydrophobicity, and to the morphology of the surface of the active layer. Asymmetric membranes of cellulose acetate, cellulose acetate propionate, and cellulose acetate butyrate were prepared by the phase inversion method and their preferential permeation performance tested. The surface morphology and the structure of the water in the pores of the active layer were studied by atomic force microscopy (AFM) and attenuated total reflectance Fourier transform infrared (ATR-FTIR) spectroscopy, respectively. Results show that higher rejection to NaCl and low fluxes are generally associated with smaller clusters of water in the pores. On the other hand, the surface of the membranes presenting smaller clusters of water in the active layer show generally surfaces with lower roughness as measured by AFM. 1. Introduction The development by Loeb and Sourirajan1 of cellulose acetate (CA) asymmetric membranes made possible the use of ultrafiltration (UF), nanofiltration (NF), and reverse osmosis (RO) at industrial scale. In fact, these membranes present a unique combination of selective characteristics and high permeation rates. This is associated with the crosssection asymmetry consisting of a thin (ca. 0.1-1 m) dense skin layer (the active layer) integrally bounded, in series, with a thick (ca. 100 m) porous structure. The casting of these membranes is carried out by the phase inversion method that allows the variation of the casting solution composition (polymers, system of solvents, and additives) and of the casting parameters (evaporation time, coagulation media, etc.) to create different structures of the active layers (average pore size and pore size distribution). Thus, the final asymmetric membrane can be tailored to a given separation task. The selective separation characteristics are essentially attributed to molecular sieving mechanisms in UF, diffusion mechanisms in RO, and both of them in NF. However, these separation mechanisms are not only determined by the structure of the active layer but also by the characteristics of the water clusters in their pores and of the polymer hydrophobicity/hydrophilicity. Different permeation properties result from the interplay of all these components. Studies aiming the correlation between the structure of the membrane active layer, the surface morphology and the permeation characteristics have been performed since early 1970s. Using electron microscopy, Schultz and Asunmaa2 observed the presence of spherical micelles in the skin of

* Author for correspondence. Telephone: (+ 351) 21 84 17 488. Fax: (+351) 21 84 99 242. E-mail: io39@alfa.ist.utl.pt.

CA asymmetric membranes. It was assumed that the mass transport in these membranes occurred through the interstitial spaces between the micelles. The presence of nodules or polymer aggregates has been also mentioned by other authors in membranes of different polymers.3,4 For integrally skinned phase inversion membranes, Kesting5 proposed a model consisting on: macromolecules (functionally submacromolecules), nodules (approximately 20 nm in diameter), nodule aggregates (40-100 nm in diameter) and super nodular aggregates. The recent development of atomic force microscopy (AFM) allowed the thorough characterization of the surface morphology of membranes. Matsuura et al.6-11 have been reporting extensive AFM studies on the characterization of the surface morphology of poly(2,6-dimethyl-1,4-phenylene)oxide (PPO) integrally skinned gas permeation membranes casted under different conditions. They observed the presence of both merged and discrete nodules11 and studied the importance of roughness and nodule size parameters on the gas permeation properties. Generally, membranes with smaller and merged nodules resulted in higher pure gas permeate ratios for O2/N2 and CO2/CH4. Using AFM, NF membranes have been also characterized by Bowen et al.12 and Stamatialis et al.13 The latter reported on the influence of different casting conditions on the surface roughness of NF/RO asymmetric membranes of CA and cellulose acetate butyrate (CAB). For CA membranes higher apparent rejection and lower fluxes, obtained by preparing membranes with increasing evaporation times and organic-pore formers, could be always associated with lower values of the roughness parameters of the surface. The CAB membranes always displayed much higher apparent rejection than the CA membranes prepared under the same casting conditions and

10.1021/bm000002b CCC: $19.00 2000 American Chemical Society Published on Web 10/21/2000

Cellulose Esters Asymmetric Membranes

Biomacromolecules, Vol. 1, No. 4, 2000 565

Table 1. Casting Solutions and Casting Conditions for Membrane Preparation

method I Casting Solution (wt %) polymer (CA, CAB, or CAP) acetone (p.a., Merck) Mg(ClO4)2xH2O (83% dry wt, Merck) water glycerol (Merck) n-propanol (p.a., Merck) triethyl phosphate (99%, Acros) Film Casting Conditions temp of casting solution (C) solvent evaporation time, tevap (min) gelation medium 13.95 79.07 3.49 3.49 20 45 2 2 6 25 IV

such higher apparent rejections could be correlated to lower roughness parameters of the surface. In what concerns the study of the structure of the water in the pores of membranes, spectroscopy is the most used technique. Since in asymmetric membranes the dense active layer determines the separation characteristics, instead of the more common transmission spectroscopy, attenuated total reflection-Fourier transform infrared (ATR-FTIR) spectroscopy is particularly suited. In fact, in ATR-FTIR spectroscopy, the depth of the IR beam into the sample can be adjusted by varying parameters such as the beam incidence angle, allowing the analysis of the surface layer only. Water in membrane pores can present distinct structures: monomeric, weakly or strongly H-bonded clusters. Bands corresponding to the OH bonds stretching are generally detected in the 3500-3100 cm-1 range.14,15 Water trimers and other oligomers are expected to have stronger waterwater hydrogen bonds than dimers and yield absorption bands at 3400 cm-1 (which is the band center in the spectrum of liquid water), whereas monomeric water species show a shoulder at ca. 3600 cm-1.14,15 The structure of water in the pores is determined by factors such as the hydrophobicity/hydrophilicity of the polymer membrane, the time and conditions of exposure to water, and the pore size.16 After relatively short exposure to water vapor or to liquid water, small predominantly hydrophobic pores contain mobile clusters of weakly bonded molecules, leading with prolonged soaking to the formation of stretched water; whereas the larger and predominantly hydrophilic pores contain generally liquid water.16 The effects of the pore size and of the hydrophilicity/ hydrophobicity of the polymer in the water structure have been studied by ATR-FTIR spectroscopy.17-19 For a series of CA membranes, Murphy and de Pinho17 concluded that, in the RO range, there are lightly clustered water species, weakly hydrogen bonded to the polymer hydroxyl groups, whereas UF membranes contain predominantly bulklike water clusters. ATR-FTIR spectroscopy was also applied to a series of CA and CAB membranes prepared using different pore formers and different casting conditions.18 Results showed that a larger and more hydrophobic substitute, such as butyryl, leads to higher values of OH, which has been associated with the presence of weakly H-bonded water clusters. A relation between the permeation properties and the structure of the water in the active layer was observed, lower values of apparent rejection being obtained for increasing size of the water clusters. This has been supported by the deconvolution and simulation of the ATIRFTIR spectra of the CA and CAB membranes.19 ATR-FTIR spectroscopy has been also used in the study of the polymer/water interaction in films.20,21 For thin sulfonated poly(ether sulfone) films of different thickness, the spectrum of a dry sample, which was analyzed after being kept in a desiccator, presented a band in the OH stretching region at ca. 3500 cm-1. This is higher than the absorption band for liquid water (ca. 3400 cm-1) and has been ascribed to a weakly hydrogen-bonded OH group on the sulfonic acid present on the dry membrane or some

10 25 1-10 1-10 ice cold water water at 25 C

water molecules whose hydrogen bonding is weaker than in pure liquid water. As the water content increased, two new bands appeared at 3250-3400 cm-1. The analysis of the OH band showed that the average hydrogen-bonding strength of the sorbed water is considerably lower than in liquid water. In the present work, a series of cellulose acetate propionate (CAP) membranes are prepared by the phase inversion method using different casting conditions and casting solutions. The structure of the water in the pores of the active layer is characterized by ATR-FTIR, the surface morphology is characterized by AFM, and the permeation performance of the membranes is tested with a solution of NaCl and with water. Results are compared and correlated with those previously obtained for CA and CAB membranes.13,18 For the three polymers, the structure of the water in the pores of the active layer is correlated to the polymer hydrophobicity/hydrophilicity and to the surface morphology. The permeation performance is in turn analyzed as a function of these membrane characteristics. 2. Experimental Section 2.1. Membrane Preparation. Membranes were prepared by phase inversion using the wet process as described by Kunst and Sourirajan.22 The cellulose esters used were (i) cellulose acetate, CA (39.8% acetyl content, MW ) 30 270), supplied by Eastmann Kodak, (ii) cellulose acetate butyrate, CAB (17% butyryl content, MW ) 65000), supplied by Aldrich, Steinheim, Germany, and (iii) cellulose acetate propionate, CAP (46% propionyl content, MW ) 75 000) supplied by Aldrich, Steinheim, Germany. Two methods, corresponding to different casting solutions and film casting conditions, referred to as I and IV, were followed and described in detail in Table 1. The membranes are identified in this text by a three-area code: the first area is relative to the polymer used (CA, CAB, and CAP), the second is relative to the method (I and IV), and the third is relative to the solvent evaporation time expressed in minutes. The asymmetric membranes were gently dried by solvent exchange as described by Lui et al.23 The wet membranes were immersed in aqueous isopropyl alcohol solutions of successively increasing alcohol contents (25, 50, 75, and 100 vol. % isopropyl alcohol) for at least 24 h at each successive step. The alcohol was then removed by repeating the previous procedure with isopropyl alcohol-hexane solutions of suc-

566

Biomacromolecules, Vol. 1, No. 4, 2000

Stamatialis et al.

Table 2. Permeation Parameters Estimated from Permeation Experiments and Values of the OH Estimated from ATR-FTIR Spectra of Asymmetric Membranes of Cellulose Esters membrane Jw (Kg m-2 h) Jv (Kg m-2 h) CA-I-1 CA-I-2 CA-I-3 CA-I-10 CAB-I-1 CAB-I-2 CAB-I-3 CAP-I-1 CAP-I-2 CAP-I-10 CA-IV-1 CAB-IV-1 29 ( 8 28 ( 8 4(2 3(2 0.41 ( 0.08 0.35 ( 0.08 0.32 ( 0.03 0.29 ( 0.01 19 ( 6 14 ( 1 0.7 ( 0.3 0.73 ( 0.07 0.02 ( 0.01 0.01 ( 0.01 18 ( 1 9(1 0.4 ( 0.1 0.6 ( 0.2 0.3 ( 0.2 17 ( 6 12 ( 1 0.6 ( 0.3

cessively higher hexane contents (25, 50, 75, and 100 vol % hexane). The hexane was removed by gentle evaporation in a desiccator, at ambient temperature, for 15 days. Dense membranes were prepared by casting a solution of 20 wt % polymer in acetone solution on a clean glass surface. Acetone evaporation was completed in an atmosphere nearly saturated with acetone vapor for 3 days. Membranes were then kept in a desiccator for 15 days. 2.2. Permeation Experiments. The permeation experiments were carried out with deionized water to determine the membrane pure water flux, Jw, and with a reference solution of NaCl p.a. to determine the apparent rejection to NaCl, fNaCl, and the permeate flux, Jv. The apparent rejection to NaCl, fNaCl, is defined as fNaCl ) (C)feed - (C)permeate (C)feed 100 (1)

fNaCl (%)

30 ( 10 79 ( 9 95.9 ( 0.8 97.75 ( 0.07 94 ( 1 94 ( 2 97 ( 3

OH (cm-1) 3372 3394 3400 3458 3400 3400 3396 3390 3440 3431 3390 3398 3397 3395 3400

0.4 ( 0.1 92 ( 2 0.01 ( 0.01 98 ( 1 0.01 ( 0.01 99 ( 1 19 ( 3 8(1 53 ( 7 98.2 ( 0.4

where (C)feed and (C)permeate are the concentrations of NaCl in the bulk of the feed solution and of the permeate solution, respectively. The permeation cell is a flat plate cell with two detachable parts separated by a porous plate (membrane support). The membrane surface area is 13.2 10-4 m2. The wet membranes were first compacted by circulating deionized water (conductivity below 0.2 S/cm) at 40 bar, 25 C, and 0.6 dm3 min-1 for at least 8 h. The stabilization time for each experiment run was 30 min. The initial feed concentration of NaCl was 3500 mg/L, and the concentration of NaCl in the feed and in the permeate solutions was determined, at 25 C, by conductivity measurements using a Crison apparatus (model 525). Details about the laboratory setup used in the permeation experiments were given elsewhere.18 2.3. ATR-FTIR Spectroscopy. ATR-FTIR spectroscopy was performed by means of a Perkin-Elmer 1600 spectrometer. Data were collected over 100 scans using a variable-angle ATR unit (Graseby Specac Ltd.) set at a nominal incident angle of 45. A KRS-5 crystal was used. The spectra were recorded at 25 C and samples were taken at random from flat sheet membranes, cut to ATR crystal size (20 mm 50 mm) and mounted on both sides of the trapezoid crystal. For wet samples, the spectra were recorded immediately upon withdrawing the membrane from water and removing the excess of water with filter paper. 2.4. AFM Images. The atomic force microscope used to image the membrane surfaces was a Multi Mode Scanning Probe microscope with a Nanoscope IIIa controller, supplied by Digital Instruments. The membrane surface was scanned in tapping mode (TM) with an oscillating tip. This eliminates shear forces, which can damage soft samples and reduce the image resolution. Details about the AFM measurements have been previously described.13 The TM AFM images shown were obtained at room temperature for solvent-dried membranes. Differences in the membrane surface morphology can be expressed in terms of various roughness parameters, such as the following. (i) The mean roughness (Ra). It represents the mean value of the surface relative to the center plane, the plane for which

CAP-IV-1 CAP-IV-2 CAP-IV-10

0.16 ( 0.05 94 ( 2 0.25 ( 0.08 95 ( 3 0.19 ( 0.05 94 ( 2

the volume enclosed by the image above and below this plane are equal, and is calculated as Ra ) 1 Lx Ly

0L 0L |f(x,y)| dx dy

x y

(2)

where f(x,y) is the surface relative to the center plane and Lx and Ly are the dimensions of the surface. (ii) The z range. It represents the difference between the highest and the lowest points within the given area. (iii) The root-mean-square of z values (Rq). It represents the standard deviation of the z values within the given area and is calculated as Rq )

(zi - zavg)2

Np

(3)

where zi is the current z value, zavg is the average of the z values within the given area, and Np is the number of points within the given area. The roughness parameters depend on the curvature and the size of the tip as well as on the treatment of the captured surface data (plane fitting, flattening, etc.). Therefore, the roughness parameters should not be considered as absolute roughness values. In the present study the same type of tip was used for all membranes and all captured surfaces where treated in the same way. The diameter of the nodules was estimated from crosssectional profiles of the data along a reference line and is based on the average of at least 50 measurements. 3. Results and Discussion 3.1. Structure of water and hydrophobicity/hydrofilicity of the polymer. The permeation characteristics of CA, CAP and CAB membranes prepared using different casting conditions and different casting solutions are listed in Table 2. In the same table, the average values corresponding to the maximum of the OH band in the ATR-FTIR spectra of the membranes are shown. As examples, the ATR-FTIR

Cellulose Esters Asymmetric Membranes

Biomacromolecules, Vol. 1, No. 4, 2000 567

Figure 1. ATR-FTIR spectra of the hydrated asymmetric membranes.

spectra in the 4400-2400 cm-1 range of some of the membranes are presented in Figure 1. The comparison of the permeation properties of the membranes shows that when acetyl is replaced by a larger and more hydrophobic group, such as butyryl or propionyl, a strong variation of the permeation properties is observed. As the hydrophobicity of the polymer increases the values of fNaCl increase and those of Jw and Jv decrease. The high degree of substitution of the CAP used in the preparation of membranes (46% propionyl) compared to that of CAB (17% butyryl) leads to very hydrophobic CAP membranes. This may explain the higher f and lower Jw and Jv values observed for CAP membranes when compared with the homologous CAB membranes. The very different casting conditions used allow the preparation of CA membranes with a wide range of permeation properties. However, the use of the same conditions for the preparation of the CAB and CAP membranes leads always to membranes presenting higher rejections to NaCl (>92%). Furthermore, CAP membranes always present very low values of flux (<1 K g m-2 h). In the ATR-FTIR spectra of the CA, CAP and CAB membranes the OH band is centered in the 3460-3330 cm-1 range (see Table 2). As previously mentioned, larger clusters of water in the pores are expected to have stronger waterwater hydrogen bonds and to yield absorption bands at lower wavenumbers than monomeric water species. The comparison of membranes prepared using the same method, the same polymer but different evaporation time allows the study of the effect of the pore size. For the CAB and CAP membranes that present very high rejection (>92%) such effect is not important, however is particularly evident for the CA membranes. In the CA-I series, the increase of tevap from 1 to 10 min leads to the shift of the maximum of OH from 3372 to 3458 cm-1, showing that at higher evaporation time smaller clusters of water are present in the pores. The presence of such smaller clusters is always associated with higher rejection to NaCl and lower fluxes (see Table 2). The comparison of the spectra of membranes prepared using the same method and the same evaporation time but different polymers allows the study of the effect of the hydrophobicity/hydrophilicity of the polymer. Results show that the substitution of acetyl by more hydrophobic groups

Table 3. AFM Parameters for the Active Layer of CAP Asymmetric Membranes membrane CAP-I-1 CAP-I-2 CAP-I-10 CAP-IV-1 CAP-IV-2 CAP-IV-10

Ra (nm)

2.8 2.4 2.1 2.7 2.7 2.9

z (nm)

24.1 23.3 19.2 27.6 26.15 26.2

Rq (nm)

3.6 3.1 2.7 3.4 3.2 3.6

nodule diameter (nm) 72.9 39.5 43.9 36.6 38.2 39.4

leads to smaller water clusters in the active layer of the membranes. In fact, the OH values in ATR spectra of CAB and CAP membranes are generally higher than those for the homologous CA membranes. This is particularly evident for the CA, CAP and CAB membranes prepared by method I and using 1 min as evaporation time, i.e., CA-I-1, CAP-I-1 and CAB-I-1, which show the OH stretching band centered at ca. 3372, 3390, and 3400 cm-1, respectively. The methods I and IV correspond to the use of two types of pore former additives. In method I, the pore former additive is an electrophilic salt, Mg(ClO4)2 whereas in method IV is a mixture of organic solvents of different polarities. Particularly, for CA membranes, the use of these two methods leads to membranes with different permeation characteristics. In fact, CA-IV-1 shows higher f NaCl and lower Jw and Jv than CA-I-1. The comparison of the ATR-FTIR spectra of the two membranes shows that in the pores of the active layer of CA-IV-1 smaller clusters of water are present. Thus, for all the membranes tested, irrespective of the casting conditions and casting solutions used, a correlation between the structure of the water and the permeation properties is observed, larger water clusters corresponding to lower values of fNaCl and, generally, to higher values of the flux. 3.2. Surface Morphology. The surface morphology of the active layer of CA and CAB membranes studied by AFM has been thoroughly described elsewhere.13 Thus, in Table 3 and Figure 2 only the roughness parameters and the AFM images of CAP membranes, respectively, are shown. In the 3D AFM image of the active layer of the CAP-I-1 asymmetric membrane (Figure 2) large darker areas are observed. These areas are associated with depressions on the surface. They are generally surrounded by high elevation regions made of grains that probably correspond to nodule

568

Biomacromolecules, Vol. 1, No. 4, 2000

Stamatialis et al.

Figure 2. AFM images of the surface of the active layer of CAP membranes.

aggregates. The average diameter of these grains (ca. 73 nm) is in agreement with the average size of the nodule aggregates reported by Kesting (40-100 nm).5 The effect of the evaporation time on the surface morphology of the active layers, is clearly illustrated by comparing the AFM images and roughness parameters of the active layers of CAP-I-1 and CAP-I-10 (see Figure 2). In the latter, the average size of the depression areas is smaller and their concentration is lower than for the membranes casted at shorter evaporation times. The AFM parameters Ra, z, and the average nodule diameter are higher for CAP-I-1. For

these membranes a correlation between the roughness parameters and the permeation properties could be observed, higher values of Ra and z corresponding, generally, to lower fNaCl and higher values of flux. By comparing the permeation properties with the roughness parameters previously obtained for CA and CAB membranes13 it is possible to conclude that, for these membranes, the same correlation is applicable. The evaporation time has no strong influence in the permeation properties of the membranes prepared by method IV. This is in agreement with the similar AFM parameters (Table 3) and images obtained for the CAP-IV series. For this series, only the AFM image of CAP-IV-1 is shown, in Figure 2, as an example. CAP membranes prepared by methods I and IV show similar permeation properties and the roughness parameters are similar. However, it should be noticed that the AFM images (Figure 2) reveal very different surface morphologies where the concentration of darker areas on the surface of the active layer of CAP-IV-1 is higher than for CAP-I-1, but their size is smaller. For the three polymers used, a correlation between the permeation properties, the size of the water clusters in the pores of the active layer and the roughness parameters of the surface of the active layer can be achieved. In fact, generally, lower Jw and Jv and higher fNaCl are associated with smaller water clusters in the membrane pores and to lower values of the roughness parameters, Ra and z, and of the average nodule diameter. 3.3. Symmetric/Asymmetric Membranes. The AFM images and the corresponding roughness parameters are compared for the two surfaces of both symmetric and asymmetric membranes. As previously observed for the dense symmetric membranes of CA and CAB,13 the roughness parameters of the top and bottom faces of the symmetric CAP membrane are similar. The slight differences may be due to the different nature of the air/solution and of the glass plate/solution interfaces. For asymmetric membranes prepared by the phase inversion method the two surfaces show very different roughness parameters, those corresponding to the active layer being always lower than those of the support layer. The AFM images of the top and bottom surfaces of CAP-I-1 asymmetric membranes are shown in Figures 2 and 3, respectively. Those of the dense CAP membrane are shown in Figure 4. The AFM roughness parameters for both surfaces of the membranes are shown in Table 4. The support layers of CAP membranes always show lower surface roughness parameters than those of CA and CAB (Table 4). Furthermore, for CAP membranes the difference between the parameters of the active layer and those of the support is much narrower showing that CAP membranes are less asymmetric than CA and CAB membranes. Particularly interesting is the comparison of the CAB and CAP membranes. These show similar rejection to NaCl, however the less asymmetric CAP membranes present much lower fluxes, showing that different characteristics in asymmetry play a major role in the magnitude of the permeation fluxes.

Cellulose Esters Asymmetric Membranes

Biomacromolecules, Vol. 1, No. 4, 2000 569

Table 4. AFM Roughness Parameters of the Surfaces of Cellulose Ester Membranes membrane CA-I-1 active layer CA-I-1 support layer CAB-I-1 active layer CAB-I-1 support layer CAP-I-1 active layer CAP-I-1 support layer CAP dense symmetric top surface CAP dense symmetric bottom surface

Ra (nm)

5.1 16.7 0.87 10.8 2.8 8.3 1.2 1.3

z (nm)

53.3 204.6 6.7 147.4 24.1 52.2 8.8 13.2

Rq (nm)

1.2 22.1 1.1 14.6 3.6 10.1 1.4 1.5

Figure 3. AFM image of the surface of the support of CAP-I-1.

associated with increasing evaporation times, increasing hydrophobicity of the polymer and to the use of an organic pore former. The very different permeation fluxes shown by CAB and CAP membranes, despite the similar values of rejection to NaCl, may be associated with different characteristics of asymmetry and to different structures of the porous layers. For all the membranes, irrespective of the polymer, casting conditions, or casting solutions, it is possible to establish a correlation between the structure of the water in the pores of the active layer and the permeation properties of the membranes. In fact, higher values of rejection to NaCl and low values of flux are generally associated with smaller clusters of water in the pores. On the other hand, the membranes presenting smaller clusters of water in the active layer show surfaces with lower roughness parameters. Acknowledgment. The authors wish to thank Professor L. Ilharco (I.S.T.; Lisbon, Portugal) for the ATR unit. D.F.S. extends special thanks to the Institute of Science and Engineering of Materials and Surfaces, Instituto Superior Tecnico (ICEMS-IST), Lisbon, Portugal for the financial support. Nomenclature

(C)feed (C)permeate CA CAB CAP fNaCl Jv Jw NF Np RO ATR-FTIR SEM tevap TM AFM Ra z concentration of NaCl in the bulk of the feed solution (mg/L) concentration of NaCl in the permeate solution (mg/L) cellulose acetate cellulose acetate butyrate cellulose acetate propionate apparent rejection to NaCl (%) permeate flux (kg m-2 h) water permeate flux (kg m-2 h) nanofiltration number of points within the given area used in the calculation of Rq reverse osmosis attenuated total reflectance Fourier transform infrared scanning electron microscopy evaporation time used in the preparation of membranes (min) tapping mode atomic force microscopy mean surface roughness (nm) difference between the highest and the lowest points within the given area (nm)

Figure 4. AFM images of both surfaces of the dense CAP symmetric membrane.

4. Conclusions The versatility of the phase-inversion method allowed the preparation of membranes with a wide range of permeation properties varying from NF to RO. By varying the hydrophobicity of the polymer, the evaporation time, the poreformer and the casting conditions, membranes with very different permeation properties were synthesized. Higher rejection to NaCl and lower values of the flux can be

570

Biomacromolecules, Vol. 1, No. 4, 2000

Stamatialis et al.

(12) Bowen, W. R.; Mohammad, A. W.; Hilal, N. J. Membr. Sci. 1997, 126, 91. (13) Stamatialis, D. F.; Dias, C. R.; de Pinho, M. N. J. Membr. Sci. 1999, 160, 235. (14) Toprak, C.; Agar, J. N.; Falks, M. J. Chem. Soc., Faraday Trans. 1 1979, 75, 803. (15) Luck, W. A. P.; Schioberg, D.; Siemann, U. J. Chem. Soc., Faraday Trans. 2 1980, 76, 136. (16) Wiggins, P. M. Prog. Polym. Sci. 1988, 13, 1. (17) Murphy, D.; de Pinho, M. N. J. Membr. Sci. 1995, 106, 245. (18) Dias, C. R.; Rosa, M. J.; de Pinho, M. N. J. Membr. Sci. 1998, 138, 259. (19) Dias, C. R.; de Pinho, M. N. J. Mol. Liq. 1999, 80, 117. (20) Pereira, M. R.; Yarwood, J. J. Chem. Soc., Faraday Trans. 1996, 92, 2731. (21) Pereira, M. R.; Yarwood, J. J. Chem. Soc., Faraday Trans. 1996, 92, 2737. (22) Kunst, B.; Sourirajan, S. J. Appl. Polym. Sci. 1974, 18, 3423. (23) Lui, A.; Talbot, F. D. F.; Fouda, A.; Matsuura, T.; Sourirajan, S. J. Appl. Polym. Sci. 1988, 36, 1809.

Rq zavg

standard deviation of the z values within the given area (nm) average of the z values within the given area (nm)

References and Notes

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11) Loeb, S.; Sourirajan, S. AdV. Chem. Ser. 1963, 38, 117. Schultz, R.; Asunmaa, S. Rec. Prog. Surf. Sci. 1970, 3, 291. Kesting, R. E. J. Appl. Polym. Sci. 1973, 17, 1771. Panar, M.; Hoehn, H.; Herbert, R. Macromolecules 1973, 6, 777. Kesting, R. E. J. Appl. Polym. Sci. 1990, 41, 2739. Khulbe, K. C.; Kruczek, B.; Chowdhury, G.; Gagne, S.; Matsuura, T. J. Appl. Polym. Sci. 1996, 59, 1151. Khulbe, K. C.; Kruczek, B.; Chowdhury, G.; Gagne, S.; Matsuura, T.; Verma, S. P. J. Membr. Sci. 1996, 111, 57. Khulbe, K. C.; Chowdhury, G.; Kruczek, B.; Vujosevic, R.; Matsuura, T.; Lamarche, G. J. Membr. Sci. 1997, 126, 115. Khulbe, K. C.; Matsuura, T.; Lamarche, G.; Kim, H. J. J. Membr. Sci. 1997, 135, 211. Khulbe, K. C.; Matsuura, T.; Noh, S. H. J. Membr. Sci. 1998, 145, 243-251. Tan, J. M. A.; T. Matsuura, J. Membr. Sci. 1999, 160, 7.

BM000002B

You might also like

- Fuels and Combustion OverviewDocument28 pagesFuels and Combustion OverviewDrupad PatelNo ratings yet

- Properties of Coal Classification and AnalysisDocument7 pagesProperties of Coal Classification and AnalysisJaco KotzeNo ratings yet

- Revised Hydrolysisofcomplexhydridesforhydrogengeneration 130423222627 Phpapp02Document25 pagesRevised Hydrolysisofcomplexhydridesforhydrogengeneration 130423222627 Phpapp02Muruganandam LoganathanNo ratings yet

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Fuck Your LawnDocument86 pagesFuck Your Lawnhuneebee100% (1)

- Strauss Dental Catalog 2013Document74 pagesStrauss Dental Catalog 2013d3xt3rokNo ratings yet

- Chapter 3 - CT&VT - Part 1Document63 pagesChapter 3 - CT&VT - Part 1zhafran100% (1)

- HierbasDocument25 pagesHierbasrincón de la iohNo ratings yet

- FileDocument284 pagesFileJesse GarciaNo ratings yet

- Interface GSKTMTRLBRCHR A4 Int 4webDocument7 pagesInterface GSKTMTRLBRCHR A4 Int 4webROGERIO GUILHERME DE OLIVEIRA MARQUESNo ratings yet

- Challenges of Tourism Students in Commercial CookingDocument29 pagesChallenges of Tourism Students in Commercial CookingMaeve Anne JaimeNo ratings yet

- TDS Versimax HD4 15W40Document1 pageTDS Versimax HD4 15W40Amaraa DNo ratings yet

- The Girls Center: 2023 Workout CalendarDocument17 pagesThe Girls Center: 2023 Workout Calendark4270621No ratings yet

- Acc101Q7CE 5 3pp187 188 1Document3 pagesAcc101Q7CE 5 3pp187 188 1Haries Vi Traboc MicolobNo ratings yet

- B.Sc. (AGRICULTURE) HORTICULTURE SYLLABUSDocument31 pagesB.Sc. (AGRICULTURE) HORTICULTURE SYLLABUSgur jazzNo ratings yet

- Hinduism Today April May June 2015Document43 pagesHinduism Today April May June 2015jpmahadevNo ratings yet

- Funds Flow Statement ExplainedDocument76 pagesFunds Flow Statement Explainedthella deva prasad0% (1)

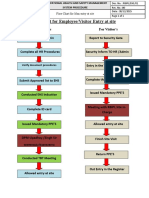

- fLOW CHART FOR WORKER'S ENTRYDocument2 pagesfLOW CHART FOR WORKER'S ENTRYshamshad ahamedNo ratings yet

- Biology (Paper I)Document6 pagesBiology (Paper I)AH 78No ratings yet

- Fluid Mechanics Sessional: Dhaka University of Engineering & Technology, GazipurDocument17 pagesFluid Mechanics Sessional: Dhaka University of Engineering & Technology, GazipurMd saydul islamNo ratings yet

- English III Module 2 Simple Present Job and Job VerbsDocument4 pagesEnglish III Module 2 Simple Present Job and Job VerbsAdrian CortesNo ratings yet

- EcR - 1 Leading and Lagging IndicatorsDocument10 pagesEcR - 1 Leading and Lagging IndicatorsMiloš ĐukićNo ratings yet

- Use Acupressure to Conceive FasterDocument15 pagesUse Acupressure to Conceive Fastersale18100% (1)

- Impact of Energy Consumption On The EnvironmentDocument9 pagesImpact of Energy Consumption On The Environmentadawiyah sofiNo ratings yet

- g21 Gluta MsdsDocument3 pagesg21 Gluta Msdsiza100% (1)

- Test Report OD63mm PN12.5 PE100Document6 pagesTest Report OD63mm PN12.5 PE100Im ChinithNo ratings yet

- Design and Built-A4Document2 pagesDesign and Built-A4farahazuraNo ratings yet

- Cement ReportDocument86 pagesCement ReportSohaibNo ratings yet

- Thee Correlational Study of Possittive Emotionons and Coping Strategies For Academic Stress Among CASS Studentts - updaTEDDocument23 pagesThee Correlational Study of Possittive Emotionons and Coping Strategies For Academic Stress Among CASS Studentts - updaTEDJuliet AcelNo ratings yet

- LAST CARGOES AND CLEANINGDocument1 pageLAST CARGOES AND CLEANINGAung Htet KyawNo ratings yet

- Tutorial 7: Electromagnetic Induction MARCH 2015: Phy 150 (Electricity and Magnetism)Document3 pagesTutorial 7: Electromagnetic Induction MARCH 2015: Phy 150 (Electricity and Magnetism)NOR SYAZLIANA ROS AZAHARNo ratings yet

- Sigma monitor relayDocument32 pagesSigma monitor relayEdwin Oria EspinozaNo ratings yet

- Quiz EmbryologyDocument41 pagesQuiz EmbryologyMedShare90% (67)

- Maximizing Oredrive Development at Khoemacau MineDocument54 pagesMaximizing Oredrive Development at Khoemacau MineModisa SibungaNo ratings yet