Professional Documents

Culture Documents

Paper 8

Uploaded by

RakeshconclaveOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Paper 8

Uploaded by

RakeshconclaveCopyright:

Available Formats

International Journal of Advances in Science and Technology, Vol. 4, No.

1, 2012

Influence of Geofabrics on California Bearing Ratio of Expansive Clayey Subgrades

Prof. A.V.Narasimha Rao1 and D.Neeraja2

1 2

Professor, Department of Civil Engineering, S.V.U.College of Engineering,Tirupati Assistant Professor(Sr) , Department of Civil Engineering, VIT University,Vellore (neerajadamarapati@gmail.com)

Abstract

Increasing demand for and decreasing availability of suitable base and subbase materials for modern highway construction has lead to a search for economic method of converting locally available troublesome soils to be utilized in construction by adopting various techniques like soil stabilization, adoption of reinforcement, use of geofabrics etc. In this paper, emphasis is given to investigate the feasibility of using abundantly available indigenous resources, coir and jute in road construction. In addition to the above mentioned natural fabrics, geogrid, a synthetic material is also considered. CBR method is employed for the design of flexible pavements in most of the design offices even though it is empirical in nature, since the method is simple and convenient to apply and the CBR value of the subgrade indirectly gives the strength of subgrade soil. Hence, the experimental study mainly deals with CBR values to determine the optimum location of reinforcement. In the present study, to determine the optimum depth, soil is tested for CBR with geofabrics like coir, jute and geogrid at different locations such as the top, H/6, 2H/6, 3H/6, 4H/6, 5H/6 from the top, H being the total thickness of the soil specimen. The results are analyzed effectively by introducing two non-dimensional factors namely, Effective Depth Ratio (EDR) and Strength Benefit Ratio (SBR). From the test results, it was observed that the optimum depth for placing the geofabrics( coir, jute and geogrid) were found at H/6, which gave a CBR value of 13.6% , 11.9% and 9.12% respectively, which is more than that of unreinforced soil. Based on the favorable results obtained, it can be concluded that expansive soil can be successfully stabilized using geofabrics.

Keywords: California Bearing Ratio, Effective Depth Ratio, Geofabrics, Expansive clay and Strength Benefit Ratio 1. Introduction

Design and construction of roads on expansive soils is a difficult task because of its low load carrying capacity, high compressibility, high swelling and shrinkage. With the reduction of available land resources, more and more construction of civil engineering structures is carried out over weak or soft soil, which leads to the establishment and development of various ground improvement techniques. The properties of these soils can be improved by stabilization with admixtures and geofabrics. But, in stabilization using admixtures technique, it is necessary to select proper stabilizer and it is very difficult to stabilize huge quantity of soil in the field. With the advent of synthetic fibres, soil reinforcement is found to be dynamic in improving load bearing capacity of soft soils. The geofabric reinforcement system prevents the failure of the pavement due to penetration of road crust into subgrade soil or intrusion of soft subgrade soils into base course and inadequate drainage of subbase and base course by acting as separator as well as drainer within the pavement apart from reinforcing function. The geofabrics include synthetic fibres like geogrid and natural fibres like jute and coir. In practice, the geofabrics are laid over weak sub grade soils and the aggregate is placed directly on it. But in this system sharp angular aggregates puncture through the fabric during the imposition of traffic loads. Moreover, the stressed soil tries to push the fabric into voids in between the aggregates. So, to avoid above discrepancies and to achieve positive contribution of geofabric, Shroff(1989) has suggested the placement of geofabric at optimum depth below the surface of weak

Special Issue

Page 67 of 99

ISSN 2229 5216

International Journal of Advances in Science and Technology, Vol. 4, No.1, 2012

subgrade. In the present study, to determine the optimum depth, soil is tested for CBR with geofabrics coir, jute and geogrid at different locations such as top, H/6, 2H/6, 3 H/6, 4 H/6, 5 H/6 from top, H being the total thickness of the specimen.

2. Materials and Methods

Soil

The soil used in this study was obtained from Gajulamandyam near Tirupati. Disturbed but representative soil samples were collected from trial pits at a depth of about 2.0 m from ground level. The soil collected from the site was pulverized with wooden mallet to break lumps and then air-dried. Subsequently it was sieved through 2.36 mm IS sieve and then dried in an oven at 105oC for 24 hours .The soil falls under the CH category i.e., clay of high compressibility as per I.S Classification System (IS 1498-1970). The soil passing through I.S 425 sieve has very high Liquid Limit and Plasticity Index. Based on Differential Free Swell Index, Liquid Limit and Plasticity Index, the soil comes under the category of high degree of expansiveness. The properties of soil are presented in Table 1.

Table 1 Properties of Soil CHARACTERISTICS Specific gravity Particle Size distribution a) Gravel (%) b) Sand (%) c) Silt+Clay (%) VALUE 2.69 Nil 12 88

Liquid limit (%) Plastic limit (%) Plasticity index (%) Differential Free Swell Index (%) Classification of soil Maximum dry unit weight (kN/m3) Optimum moisture content (%) Unconfined Compressive Strength (kN/ m2) Unsoaked CBR (%)

98 13 85 150 CH 17.99

14 145 6.84

Special Issue

Page 68 of 99

ISSN 2229 5216

International Journal of Advances in Science and Technology, Vol. 4, No.1, 2012

Coir

The coir fabric is obtained from door mats which are uniformly woven. Coir fabrics of 15 cm diameter circular pieces were used for the present study.

Jute

Jute is prepared from jute bags like sugar bags, rice bags etc, of 1.5 mm thick. 15cm diameter circular pieces are cut from the jute bag. A jute geofabric of 3mm thick is prepared by joining two pieces of jute bag.

Geogrid

Geogrid used in this study is a product of Netlon. This is immune to corrosive, chemical and biological attack in soils. Geogrid of 15 cm diameter circular pieces were used for the present study. 3. Tests conducted on Unreinforced Soil The compaction tests on unreinforced soil were conducted in accordance with I.S.2720:1980.UCC tests were conducted in accordance with I.S.2720:1991. CBR tests were conducted in accordance with I.S.2720:1987. 4. Tests conducted on Reinforced Soil The main emphasis in the present study is the influence of geofabrics on CBR values of expansive clays, since the thickness of pavement depends on CBR value. Hence CBR tests are conducted for determining optimum depth. The tests have been conducted for determining optimum depth (location effect). The locations chosen for this purpose were top, H/6, 2H/6, 3H/6, 4H/6 and 5H/6 respectively, H being the total thickness of the soil specimen. The CBR tests have been carried out as per I.S.2720-1987 with some modifications. In standard CBR tests, the soil is compacted in three layers at 55 blows per each layer for light compaction. The above procedure has been modified by compacting in six layers at 28 blows per layer, keeping the compactive effort as the same. 5. Results and Discussion The load-penetration curves for the soil reinforced with coir, jute and geogrid at different locations such as top, H/6, 2H/6, 3H/6, 4H/6, 5H/6 from the top, H being total thickness of the specimen are shown in Figures 1,2 and 3 respectively. The load-penetration curve for the unreinforced soil is also plotted in each of these figures. The results are analyzed effectively by introducing two non-dimensional factors namely, Effective Depth Ratio (EDR) and Strength Benefit Ratio (SBR). The Strength Benefit Ratio (SBR) is defined as the per cent increase in CBR value of soil due to the presence of reinforcement when compared to the CBR value of unreinforced soil.

SBR =

CBR Reinforced CBR Unreinforced CBR Unreinforced

X 100

The Effective Depth Ratio (EDR) is defined as the ratio of depth of reinforcing layer from the top to total height of soil specimen. EDR =

Depth of reinforcin g layer from the top Total height of soil specimen

The CBR values of the soil are tabulated in Table 2 for different locations of geofabrics. An analysis of test results presented in the table indicates that the effect of geofabric reinforcement with soil is to increase the value of CBR. It is interesting to note that the optimum value of CBR is obtained at an Effective Depth ratio (EDR) of 1/6 for all the fabrics considered in the present study. Beyond EDR of 1/6 the CBR values in all the cases are found to decrease, but remains always higher than the unreinforced soil. Hence, it can be concluded that the optimum depth of geofabric is at EDR of 1/6, which is nearly equal to half the diameter of the plunger. This implies that the optimum depth in the field is about half the maximum width of dual tyre assembly of a vehicle that is expected to ply on the

Special Issue

Page 69 of 99

ISSN 2229 5216

International Journal of Advances in Science and Technology, Vol. 4, No.1, 2012

pavement. The increase in CBR value at EDR of 1/6 may be due to the effect of increase in anchorage at H/6 rather at other locations. At H/6 the geofabric is sandwiched with the soil resulting in full lateral restrainment and better membrane reinforcement. Beyond H/6, even though the value is more than CBR value of unreinforced soil, it is less than H/6. The SBR values of the soil at optimum depth of H/6 from the top for the coir, jute and geogrid are 98.83%, 73.98% and 33 .33% respectively (Figure 4). The SBR values calculated from the CBR values obtained on testing at different EDR values are presented in Table 3. It is inferred that coir is more effective than jute due to the fact that the coir has more tensile strength and friction than jute. It is also observed from the above values that geogrid results in less CBR value when compared to natural fabrics like coir and jute. Actually, this is not correct since geogrid has more tensile strength than natural fabrics. But, to develop full tensile stress within the geogrid, it should interlock with the aggregates. Otherwise, it will slip due to its smooth nature resulting in low CBR value.

Figure 1 Load Vs penetration curves of soil reinforced with coir at different locations

Figure 2 Load Vs penetration curves of soil reinforced with jute at different locations

Special Issue

Page 70 of 99

ISSN 2229 5216

International Journal of Advances in Science and Technology, Vol. 4, No.1, 2012

Figure 3 Load Vs penetration curves of soil reinforced with geogrid at different locations

Figure 4 SBR (%) values for geofabrics with respect to effective depth ratio (EDR)

Special Issue

Page 71 of 99

ISSN 2229 5216

International Journal of Advances in Science and Technology, Vol. 4, No.1, 2012

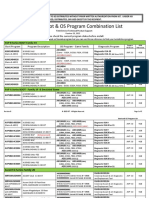

Table 2 CBR Values (%) for changing location of reinforcing layer

Type geofabric

of

CBR without fabric 6.84 6.84 6.84

GEOFABRIC AT TOP 9.12 8.7 8.8 H/6 13.6 11.9 9.12 2H/6 10 9.12 7.8 3H/6 8.2 7.3 7.3 4H/6 8.2 7 7.3 5H/6 7.3 7 7

COIR JUTE GEOGRID

Table 3 SBR Values (%) for different EDR Values Type of geofabric EDR values for Geofabric at 0 0.167 0.33 0.5 0.667 0.833

Coir Jute Geogrid

33.33 27.19 28.65

98.83 73.98 33.33

46.2 33.33 14.035

19.88 6.72 6.72

19.88 2.34 6.72

6.72 2.34 2.34

6. References

1. 2. 3. 4. 5. IS 1498-1970, Classification and Identification of Soils for General Engineering Purposes. IS 2720 (Part VII)-1980, Method of Test for Soils, Determination of Water Content-Dry Density relation using Light Compaction. IS 2720 (Part X)-1991, Method of Test for Soils, Determination of Unconfined Compressive Strength. IS 2720 (Part XVI)-1987, Method of Test for Soils, Laboratory Determination of CBR. Shroff A.V and. Singh G.N. (1989), Load-Deformation characteristics of fabric reinforced on weak soil subgrades, International workshop on geotextiles, pp 144-147.

Special Issue

Page 72 of 99

ISSN 2229 5216

International Journal of Advances in Science and Technology, Vol. 4, No.1, 2012

Authors Profile

Dr. A.V.Narasimha Rao received his Ph.D degree from IIT Madras in 1979. He published more than 105 papers in international and national journals and conferences and 3 text books in Geotechnical Engineering and Engineering mechanics. He has more than 32 years of teaching experience. He is the recipient of Engineer of the year 2007 by Institution of Engineers and Government of Andhra Pradesh.

D.Neeraja received her M.Tech from S.V.University, Tirupati. She published 28 papers in international and national journals and conferences. She has more than 10 years of teaching experience.

Special Issue

Page 73 of 99

ISSN 2229 5216

You might also like

- Stabilization of Sub-Grade Using Fly Ash and Geosynthetic MaterialDocument12 pagesStabilization of Sub-Grade Using Fly Ash and Geosynthetic MaterialSarabpreet SobtiNo ratings yet

- Effect of Plasticity Index and Reinforcement On The CBR Value of Soft ClayDocument7 pagesEffect of Plasticity Index and Reinforcement On The CBR Value of Soft Claygtarun22guptaNo ratings yet

- CBR Improvement of Clayey Soil With Geogrid ReinforcementDocument4 pagesCBR Improvement of Clayey Soil With Geogrid Reinforcementbkollarou9632No ratings yet

- Stabilization of Soil by Using Plastic Wastes: AbstractDocument6 pagesStabilization of Soil by Using Plastic Wastes: AbstractUmange Ranasinghe100% (1)

- Study On Geotechnical Properties of Stabilized Expansive Soil-Quarry Dust MixesDocument7 pagesStudy On Geotechnical Properties of Stabilized Expansive Soil-Quarry Dust MixesRVNLPKG6B VBL-GTLMNo ratings yet

- Field Plate Load Test To Investigate Stress Distribution in Soil Mass With and Without Reinforcement - United Arab EmiratesDocument15 pagesField Plate Load Test To Investigate Stress Distribution in Soil Mass With and Without Reinforcement - United Arab EmiratesSuraj MulikNo ratings yet

- Welcome To International Journal of Engineering Research and Development (IJERD)Document5 pagesWelcome To International Journal of Engineering Research and Development (IJERD)IJERDNo ratings yet

- 02 Article of Sanaullah 12 26Document15 pages02 Article of Sanaullah 12 26Ayanwale-cole pelumi AkeemNo ratings yet

- Reinforced Light Weight Geo MaterialsDocument9 pagesReinforced Light Weight Geo Materialsharishreddy1985No ratings yet

- Nanasaheb Mahadik College of Engineering 2Document8 pagesNanasaheb Mahadik College of Engineering 2Shramik ManeNo ratings yet

- Efficacy of Overlying Coarse Aggregate andDocument7 pagesEfficacy of Overlying Coarse Aggregate andInternational Journal of Research in Engineering and TechnologyNo ratings yet

- STABILIZING SOIL WITH INDUSTRIAL WASTESDocument15 pagesSTABILIZING SOIL WITH INDUSTRIAL WASTESvikas chawlaNo ratings yet

- Soil Improvement by Using Bamboo ReinforcementDocument7 pagesSoil Improvement by Using Bamboo ReinforcementShah Mohammad IqbalNo ratings yet

- Comparison of Effects of Using Geosynthetics ADocument9 pagesComparison of Effects of Using Geosynthetics ADũng HoàngNo ratings yet

- Major Project2Document43 pagesMajor Project2abhishekthapa311No ratings yet

- Effect of Soil Reinforcement On Shear Strength and Settlement of Cohesive-Frictional SoilDocument6 pagesEffect of Soil Reinforcement On Shear Strength and Settlement of Cohesive-Frictional SoilAbdikani SaidNo ratings yet

- Review Paper On Study On Properties of Black Cotton Soil Using Stone Dust and Sisal FiberDocument3 pagesReview Paper On Study On Properties of Black Cotton Soil Using Stone Dust and Sisal FiberEditor IJTSRDNo ratings yet

- Flexible PavementDocument18 pagesFlexible PavementarjunhrNo ratings yet

- GEOTEXTILE FOR SOIL STABILIZATIONDocument37 pagesGEOTEXTILE FOR SOIL STABILIZATIONRahman EfazNo ratings yet

- Effects If Depth of Footing and Water Table On Bearing Capacity of Soil PDFDocument4 pagesEffects If Depth of Footing and Water Table On Bearing Capacity of Soil PDFOkino CharlesNo ratings yet

- Geocell Rut TestDocument8 pagesGeocell Rut Testmspark futuristicNo ratings yet

- Key Words: Model Tests, Footing, Bearing Capacity, Granular Fill, Clays, Finite Elements, GeotextilesDocument14 pagesKey Words: Model Tests, Footing, Bearing Capacity, Granular Fill, Clays, Finite Elements, Geotextilesد.م أحمد رشديNo ratings yet

- An Experimental Study On Soil Strength E PDFDocument10 pagesAn Experimental Study On Soil Strength E PDFMarkanthony TatonNo ratings yet

- Enhancing The Bearing Capacity of B.c.soil by Using Shredded Rubber TyreDocument5 pagesEnhancing The Bearing Capacity of B.c.soil by Using Shredded Rubber Tyremukesh poundekarNo ratings yet

- Performance of Different Geosynthetic Reinforcement Materials in Sand FoundationsDocument9 pagesPerformance of Different Geosynthetic Reinforcement Materials in Sand FoundationsMariaPaulaMenesesNo ratings yet

- 21 - Chapter 13 PDFDocument11 pages21 - Chapter 13 PDFHồ ThắngNo ratings yet

- IMPROVEMENT IN BEARING CAPACITY OF SOIL BY GEOGRIDDocument4 pagesIMPROVEMENT IN BEARING CAPACITY OF SOIL BY GEOGRIDNabeel AL-HakeemNo ratings yet

- 1 s2.0 S1877042813045060 MainDocument10 pages1 s2.0 S1877042813045060 Mainkommanamanchi.vamsiNo ratings yet

- Stabilization of Black Cotton Soil Using Lime: Shailendra Singh, Hemant B. VasaikarDocument7 pagesStabilization of Black Cotton Soil Using Lime: Shailendra Singh, Hemant B. VasaikarPRADEEP100% (1)

- Effect of Polypropylene Fibers, Lime and Ceramic Additives On The Compressibility of Silty-Clay SoilDocument11 pagesEffect of Polypropylene Fibers, Lime and Ceramic Additives On The Compressibility of Silty-Clay SoilAsad HafudhNo ratings yet

- Geotextile As Foundtion Component in Constructing Road PavementDocument19 pagesGeotextile As Foundtion Component in Constructing Road PavementEdmar AngobNo ratings yet

- IJEAS0303031Document6 pagesIJEAS0303031erpublicationNo ratings yet

- Stabilization of Soft Soil by A Sustainable Binder Comprises Ground Granulated Blast Slag (GGBS) and Cement Kiln Dust (CKD)Document18 pagesStabilization of Soft Soil by A Sustainable Binder Comprises Ground Granulated Blast Slag (GGBS) and Cement Kiln Dust (CKD)Shaker QaidiNo ratings yet

- CBR Improvement of Clayey Soil With Geo-Grid ReinforcementDocument4 pagesCBR Improvement of Clayey Soil With Geo-Grid ReinforcementDipendra AwasthiNo ratings yet

- IJRESTS Published Paper PDFDocument5 pagesIJRESTS Published Paper PDFEr Sufyan AnsariNo ratings yet

- Geotextiles and Geomembranes: Technical NoteDocument6 pagesGeotextiles and Geomembranes: Technical NoteKari GalindoNo ratings yet

- 2023, Vinay Thakur, Experimental Evaluation On Behaviour of Geocell Geogrid Reinforced Sand Subjected Static and Cyclic LoadingDocument14 pages2023, Vinay Thakur, Experimental Evaluation On Behaviour of Geocell Geogrid Reinforced Sand Subjected Static and Cyclic Loadingkommanamanchi.vamsiNo ratings yet

- A Study On The Coefficient of Friction of Soil/geotextile InterfacesDocument12 pagesA Study On The Coefficient of Friction of Soil/geotextile InterfacesMalik RizwanNo ratings yet

- Coir Geotextiles For Paved Roads: A Laboratory and Field Study Using Non-Plastic Soil As SubgradeDocument17 pagesCoir Geotextiles For Paved Roads: A Laboratory and Field Study Using Non-Plastic Soil As SubgradeJungle BookNo ratings yet

- Geotextile Can Be Worth Their Cost in Pavement: Prof. Mayura M.Yeole, Dr.J.R.PatilDocument4 pagesGeotextile Can Be Worth Their Cost in Pavement: Prof. Mayura M.Yeole, Dr.J.R.PatilIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- Detail Phase 1Document15 pagesDetail Phase 1shobhitha shobhitha mNo ratings yet

- Plastic Waste ReinforcementDocument9 pagesPlastic Waste ReinforcementRoshna S BNo ratings yet

- Effect of Fiber On Fly-Ash Stabilized Sub Grade Layer ThicknessDocument8 pagesEffect of Fiber On Fly-Ash Stabilized Sub Grade Layer ThicknessEr Harshvardhan IngawaleNo ratings yet

- Laboratory Investigation of The Influence of Geotextile On The Stress-Strain and Volumetric Change Behavior of SandDocument10 pagesLaboratory Investigation of The Influence of Geotextile On The Stress-Strain and Volumetric Change Behavior of Sandعبد المالك قفيNo ratings yet

- Effect of Replacement Layers On Bearing Capacity of Silty Clay LayerDocument9 pagesEffect of Replacement Layers On Bearing Capacity of Silty Clay LayerPoonam KilaniyaNo ratings yet

- 1banasal 1652013Document78 pages1banasal 1652013rajubansalNo ratings yet

- Soil Stabilization Using Plastic WasteDocument16 pagesSoil Stabilization Using Plastic WasteAbdul Hoda67% (3)

- Performance Characteristic Study of Weak Subgrade Soil and Improving The Strength of Subgrade Soil by Stabilization TechniquesDocument62 pagesPerformance Characteristic Study of Weak Subgrade Soil and Improving The Strength of Subgrade Soil by Stabilization TechniquesJagadisha AcharNo ratings yet

- Large-Scale Drainage Behaviour Ofcomposite Geotextile and Geogrid in Residual SoilDocument14 pagesLarge-Scale Drainage Behaviour Ofcomposite Geotextile and Geogrid in Residual Soiljavad khosraviNo ratings yet

- Stabilization of Soil Using Crumb Rubber: Parveen Kumar, Dr. Rajesh Goel, Vishal YadavDocument5 pagesStabilization of Soil Using Crumb Rubber: Parveen Kumar, Dr. Rajesh Goel, Vishal YadavAli Saleh Saad ALiSAWiNo ratings yet

- Akbarimehr Et Al (2020) .Document34 pagesAkbarimehr Et Al (2020) .Alondra Martínez RojasNo ratings yet

- Transportation Geotechnics: SciencedirectDocument7 pagesTransportation Geotechnics: SciencedirectDipendra AwasthiNo ratings yet

- IRC ProposalDocument50 pagesIRC ProposalashwinmjoshiNo ratings yet

- Soil Stabiliisation Using Raw Plastic Bottles: December 2011Document5 pagesSoil Stabiliisation Using Raw Plastic Bottles: December 2011Muhammed Mohsin ShaikhNo ratings yet

- Effects of Polyester Geo - Textiles On CBR of Road Sub BaseDocument4 pagesEffects of Polyester Geo - Textiles On CBR of Road Sub BaseiisteNo ratings yet

- Iraqi Journal of Civil EngineeringDocument9 pagesIraqi Journal of Civil EngineeringAhMed SaMeerNo ratings yet

- Use of Shredded Tyre Waste in Improving The Geotechnical Properties of Expansive Black Cotton SoilDocument10 pagesUse of Shredded Tyre Waste in Improving The Geotechnical Properties of Expansive Black Cotton SoilNasasira DerrickNo ratings yet

- Stabilization of Expansive Soil Using Brick DustDocument8 pagesStabilization of Expansive Soil Using Brick DustRocky BhaiNo ratings yet

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsFrom EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNo ratings yet

- Soil Investigation and Foundation DesignFrom EverandSoil Investigation and Foundation DesignRating: 4.5 out of 5 stars4.5/5 (9)

- Paper 4Document8 pagesPaper 4RakeshconclaveNo ratings yet

- Paper 1Document6 pagesPaper 1RakeshconclaveNo ratings yet

- Paper 3Document7 pagesPaper 3RakeshconclaveNo ratings yet

- Galactic Chemical Evolution and Formation of The AtmosphereDocument16 pagesGalactic Chemical Evolution and Formation of The AtmosphereRakeshconclaveNo ratings yet

- Some Statistics of Rain Rate & Rain Attenuation For Tropical & Non Tropical CountriesDocument15 pagesSome Statistics of Rain Rate & Rain Attenuation For Tropical & Non Tropical CountriesRakeshconclaveNo ratings yet

- Paper 2Document6 pagesPaper 2RakeshconclaveNo ratings yet

- Arsenic and Heavy Metals in Waters of Oluyole NE, Ibadan SW, NigeriaDocument13 pagesArsenic and Heavy Metals in Waters of Oluyole NE, Ibadan SW, NigeriaRakeshconclaveNo ratings yet

- Paper 9Document9 pagesPaper 9RakeshconclaveNo ratings yet

- Performance Analysis of VBLAST MIMO-OFDM System For Intelligent Transportation SystemDocument9 pagesPerformance Analysis of VBLAST MIMO-OFDM System For Intelligent Transportation SystemRakeshconclaveNo ratings yet

- Noise Figure Measurement in Mobile Radio EnvironmentDocument7 pagesNoise Figure Measurement in Mobile Radio EnvironmentRakeshconclaveNo ratings yet

- Vibrational Pseudospin Solution (Triglycine Sulphate Crystal) For Computing TechnologyDocument10 pagesVibrational Pseudospin Solution (Triglycine Sulphate Crystal) For Computing TechnologyRakeshconclaveNo ratings yet

- Mesh - Encoding and Decoding: D. Srinivasa Reddy Dr. M. V. Subba Reddy and Dr. B. Jaya Rami ReddyDocument11 pagesMesh - Encoding and Decoding: D. Srinivasa Reddy Dr. M. V. Subba Reddy and Dr. B. Jaya Rami ReddyRakeshconclaveNo ratings yet

- Communications For Energy Conservation: Vineela Malae and Dr.M.V.Bhaskar ReddyDocument7 pagesCommunications For Energy Conservation: Vineela Malae and Dr.M.V.Bhaskar ReddyRakeshconclaveNo ratings yet

- Causes For Triggered Earthquakes - A Recent Review: R.Samuel Selvaraj and B.UmamaheswariDocument5 pagesCauses For Triggered Earthquakes - A Recent Review: R.Samuel Selvaraj and B.UmamaheswariRakeshconclaveNo ratings yet

- Design and Performance Analysis of 8-Bit RISC Processor Using Xilinx & Microwind ToolDocument10 pagesDesign and Performance Analysis of 8-Bit RISC Processor Using Xilinx & Microwind ToolRakeshconclaveNo ratings yet

- Applying Gene Grouping Genetic Algorithm For Solving Travelling Salesman ProblemDocument5 pagesApplying Gene Grouping Genetic Algorithm For Solving Travelling Salesman ProblemRakeshconclaveNo ratings yet

- A Highly Stable 8T SRAM Cell: P.Rama Koteswara Rao and D.Vijaya KumarDocument6 pagesA Highly Stable 8T SRAM Cell: P.Rama Koteswara Rao and D.Vijaya KumarRakeshconclaveNo ratings yet

- A Review On Invasion in Ad Hoc Networks and Its Detection ProceduresDocument10 pagesA Review On Invasion in Ad Hoc Networks and Its Detection ProceduresRakeshconclaveNo ratings yet

- Enabling Public Auditability For Cloud Data Storage SecurityDocument5 pagesEnabling Public Auditability For Cloud Data Storage SecurityRakeshconclaveNo ratings yet

- On The Security of An Efficient Time-Bound Hierarchical Key Management Scheme With BiometricsDocument3 pagesOn The Security of An Efficient Time-Bound Hierarchical Key Management Scheme With BiometricsRakeshconclaveNo ratings yet

- An Efficient Architecture For The Development of Open Cloud Computing BackboneDocument7 pagesAn Efficient Architecture For The Development of Open Cloud Computing BackboneRakeshconclaveNo ratings yet

- Mesh Completion Using Incomplete Mesh and Template Model: D. Srinivasa Reddy Dr. M. V. Subba ReddyDocument6 pagesMesh Completion Using Incomplete Mesh and Template Model: D. Srinivasa Reddy Dr. M. V. Subba ReddyRakeshconclaveNo ratings yet

- Enhanced Video Search Using Multimodal Fusion With CR RerankingDocument5 pagesEnhanced Video Search Using Multimodal Fusion With CR RerankingRakeshconclaveNo ratings yet

- ARM: Advanced File Replication and Consistency Maintenance in P2P SystemDocument5 pagesARM: Advanced File Replication and Consistency Maintenance in P2P SystemRakeshconclaveNo ratings yet

- Paper 12Document9 pagesPaper 12RakeshconclaveNo ratings yet

- Paper 11Document5 pagesPaper 11RakeshconclaveNo ratings yet

- Probabilistic Data Deduplication Using Modern Backup OperationDocument5 pagesProbabilistic Data Deduplication Using Modern Backup OperationRakeshconclaveNo ratings yet

- A Survey On Network Layer Attacks On Mobile Ad-Hoc NetworksDocument6 pagesA Survey On Network Layer Attacks On Mobile Ad-Hoc NetworksRakeshconclaveNo ratings yet

- Using Local Histogram and FCM Technique For Object Extraction in Semen Sample Microscopic Images, Based On Mathematical MorphologyDocument4 pagesUsing Local Histogram and FCM Technique For Object Extraction in Semen Sample Microscopic Images, Based On Mathematical MorphologyRakeshconclaveNo ratings yet

- Paper 4Document7 pagesPaper 4RakeshconclaveNo ratings yet

- EzraCohen TVMasterclass 2.0Document10 pagesEzraCohen TVMasterclass 2.0Pete PetittiNo ratings yet

- Washington State Employee - 4/2010Document8 pagesWashington State Employee - 4/2010WFSEc28No ratings yet

- SUTI Report - Metro ManilaDocument87 pagesSUTI Report - Metro ManilaIvan Harris TanyagNo ratings yet

- Yale Smart Door Locks GuideDocument50 pagesYale Smart Door Locks GuidejaganrajNo ratings yet

- Create Email Alerts For Mulitple People or Group - XpoDocument79 pagesCreate Email Alerts For Mulitple People or Group - XponiravmodyNo ratings yet

- Loctite 270™: Technical Data SheetDocument4 pagesLoctite 270™: Technical Data SheetM Jobayer AzadNo ratings yet

- Econometrics ProjectDocument17 pagesEconometrics ProjectAkash ChoudharyNo ratings yet

- Circulation in Vacuum Pans: January 2004Document18 pagesCirculation in Vacuum Pans: January 2004REMINGTON SALAYANo ratings yet

- Statement of Purpose Lanka Venkata Raghava Ravi TejaDocument2 pagesStatement of Purpose Lanka Venkata Raghava Ravi TejaRavi Teja LvrNo ratings yet

- Tool Catalog Ei18e-11020Document370 pagesTool Catalog Ei18e-11020Marcelo Diesel85% (13)

- S-S-, AXXX XXX 008 (BIA Sept. 15, 2017)Document7 pagesS-S-, AXXX XXX 008 (BIA Sept. 15, 2017)Immigrant & Refugee Appellate Center, LLCNo ratings yet

- Keystone - Contractors - Book 16 05 12 FinalDocument9 pagesKeystone - Contractors - Book 16 05 12 Finalfb8120No ratings yet

- Framing Business EthicsDocument18 pagesFraming Business EthicsJabirNo ratings yet

- Igt - Boot Os List Rev B 10-28-2015Document5 pagesIgt - Boot Os List Rev B 10-28-2015Hector VillarrealNo ratings yet

- What is Software Development Life Cycle (SDLC)? Key Phases and ActivitiesDocument11 pagesWhat is Software Development Life Cycle (SDLC)? Key Phases and ActivitiessachinNo ratings yet

- Garments & Tailoring Business: Submitted byDocument6 pagesGarments & Tailoring Business: Submitted bykartik DebnathNo ratings yet

- Efectele Crizei Economice Asupra Politicilor Pietei Muncii Din RomaniaDocument24 pagesEfectele Crizei Economice Asupra Politicilor Pietei Muncii Din Romaniacristian_incaltarauNo ratings yet

- Unit 3: The Catering Service Industry Topic: Catering Service Concept Digest (Discussion)Document5 pagesUnit 3: The Catering Service Industry Topic: Catering Service Concept Digest (Discussion)Justin MagnanaoNo ratings yet

- Tối Ưu Hóa Cho Khoa Học Dữ LiệuDocument64 pagesTối Ưu Hóa Cho Khoa Học Dữ Liệuminhpc2911No ratings yet

- How To Block Facebook in Mikrotik Using L7 Protocols (Layer 7) - Lazy Geek - )Document11 pagesHow To Block Facebook in Mikrotik Using L7 Protocols (Layer 7) - Lazy Geek - )oscar_198810No ratings yet

- G.R. No. 226140 - People Vs EspirituDocument24 pagesG.R. No. 226140 - People Vs EspirituAlfred Robert BabasoroNo ratings yet

- Smart Card PresentationDocument4 pagesSmart Card PresentationNitika MithalNo ratings yet

- Aesculap Qatar UniversityDocument3 pagesAesculap Qatar UniversityAl Quran AcademyNo ratings yet

- Learn About Intensifiers and How to Use Them Effectively in WritingDocument3 pagesLearn About Intensifiers and How to Use Them Effectively in WritingCheryl CheowNo ratings yet

- 47-Article Text-201-1-10-20180825Document12 pages47-Article Text-201-1-10-20180825kevin21790No ratings yet

- Rohini 43569840920Document4 pagesRohini 43569840920SowmyaNo ratings yet

- Manage Hospital Records with HMSDocument16 pagesManage Hospital Records with HMSDev SoniNo ratings yet

- English Speech Save Our Earth Save Our RainforestDocument3 pagesEnglish Speech Save Our Earth Save Our RainforestYeremia Billy100% (1)

- GE's Two-Decade Transformation: Jack Welch's Leadership: Amanda Rodriguez Patricia Robledo Brittany Culberson Yue JiangDocument34 pagesGE's Two-Decade Transformation: Jack Welch's Leadership: Amanda Rodriguez Patricia Robledo Brittany Culberson Yue JiangRishendra Singh RathourNo ratings yet

- Cs614-Mid Term Solved MCQs With References by Moaaz PDFDocument30 pagesCs614-Mid Term Solved MCQs With References by Moaaz PDFNiazi Qureshi AhmedNo ratings yet