Professional Documents

Culture Documents

Composite Slab Report

Uploaded by

Ahmed Moustafa AboelelaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Composite Slab Report

Uploaded by

Ahmed Moustafa AboelelaCopyright:

Available Formats

Composite Structures To Be Presented To Dr.

Hisham Fawzy Composite Slab

Name: Group Afaf Mohammed Level: 400 Subject: Composite Structure Code: STE 402 To Be Presented To Dr. Hisham Fawzy

Group Afaf Mohammed

Page 1 of 10

Composite Structures To Be Presented To Dr. Hisham Fawzy Composite Slab

Contents: Introduction Composite Structure Composite Slab Composite Slab Design Profile Design Design Calculation References Members of Group

1.1)

Introduction:

In this Report we will be discussing the design of composite slab using different corrugated sheet profiles, but first we will mention the idea of composite structure then we will discussing the concept of the composite slab and finally using the different corrugated sheet profile we will calculate the maximum resisting moment that each profile can withstand.

1.2)

Composite Structure:

Composite Structures are structures made up of more than 1 material that work together each material carries the type of stress that it is suited for; for example in composite slabs concrete carries compressive stress while steel (Corrugated sheet) carries the tensile stress. Composite Structures reduce labor cost but needs skilled labor to execute but the most beneficial use of composite structures is that is reduces construction time as it is faster to execute. Types of Composite structures: o Composite Slab which consists of corrugated deck and concrete. o Composite Beam which consists of steel section, shear connectors and solid/composite slab. o Composite Column and Frames like steel pipe filled with concrete or steel section enclosed within a concrete column. A composite material is basically a combination of two or more materials, each of which retains its own distinctive properties. The concept of composite materials is ancient. An example is adding straw to mud for building stronger mud walls. Most commonly, composite materials have a bulk phase, which is continuous, called the matrix; and a dispersed, noncontinuous, phase called the reinforcement. Some other examples of basic composites include concrete (cement mixed with sand and aggregate), reinforced concrete (steel rebar in concrete), and fiberglass (glass strands in a resin matrix). Page 2 of 10

Group Afaf Mohammed

Composite Structures To Be Presented To Dr. Hisham Fawzy Composite Slab

1.3)

Composite Slab:

Composite Slab which as we said before consisted a steel deck and a concrete slab with means of interlock between these 2 materials these interlocks can be either: o Mechanical Interlock where interlock is achieved via mechanical bonds due to different physical interlock mechanisms in the corrugated sheet via ribs in sheets. o Chemical Interlock where interlock is achieved via chemical bonds between 2 materials which act as the glue which keep material tacked with each other. o Frictional Interlock: natural bond occurring between any 2 materials.

1.4)

Composite Slab Design:

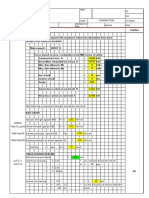

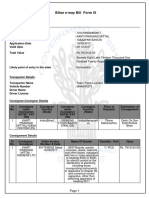

The fundamental design concept of composites is that the bulk phase accepts the load over a large surface area, and transfers it to the reinforcement material, which can carry a greater load. The Idea is to load each element with the type of stress it is design to withstand, where the steel reinforcement can withstand tension stress and the concrete is designed to withstand the compressive stress. In the design process we usually design on 2 stages; o The first stage is the construction stage during construction, the profiled steel deck acts alone to carry the weight of wet concrete, self weight, workmen and equipments. It must be strong enough to carry this load and stiff enough to be serviceable under the weight of wet concrete only. o The second stage is called the composite stage where the slab is permanently designed to carry the permanent loads which are expected to be carried by the composite slab which will consists of the corrugated sheet as well as the concrete part, the loads in this stage are the loads of hard concrete, finishing and false ceiling, partition loads as well as live load. In Our Example we used profiles from a company called TATA Steel which specializes in steel structures and one of which is the composite floor decking (ComFlor). The Profile type we used is called (ComFlor 46) which has the following properties which will be listed in the design calculations, also the whole brochure will be attached to the word file for checking of any information if required. Here is the part of the brochure from which the properties of section was acquired:

1.5)

Profile Design:

Group Afaf Mohammed

Page 3 of 10

Composite Structures To Be Presented To Dr. Hisham Fawzy Composite Slab

Group Afaf Mohammed

Page 4 of 10

Composite Structures To Be Presented To Dr. Hisham Fawzy Composite Slab

Group Afaf Mohammed

Page 5 of 10

Composite Structures To Be Presented To Dr. Hisham Fawzy Composite Slab

Group Afaf Mohammed

Page 6 of 10

Composite Structures To Be Presented To Dr. Hisham Fawzy Composite Slab

1.6)

Design Calculation:

Given:

o Moment of Resistance of Section Only (Mpa ) = 4.63 KN.m/m o Thickness of Concrete above Corrugated Sheet (T) = (hc) = 10 cm (Assumption) o Centroid of Corrugated Sheet (e) = 23 mm o Modulus of Elasticity of Corrugated Sheet (Ea) = 2100 t/cm2 o Inertia of Corrugated Sheet (Ip) = 41.5 cm4 o Yield Strength of Corrugated Sheet (Fybd) = 550 Mpa o Area of Corrugated Sheet per 1 meter (Ap) = 1137 mm2/m' o Width of Single Corrugation (b0) = (120+67)/2 = 93.5 mm o Width of Corrugation (b) = 225 mm o Yield Strength of Concrete (fcu) = 250 Kg/cm2 Calculations: o Ncf = 0.85 Fcbd* X * b = Ap* Fypd = 0.85 * (25/1.5) * X * 1 =1137 * (0.55/1.15) So X = 44.14 mm. Since Hc =100 mm (Assumed), So X < hc neutral axis in concrete o MRd = Ncf *( db 0.5 X ) where dp = h- e = 146 -23 = 133 mm MRd = 625.35 * (0.123 0.5 * 0.4414) = 63.11 KN.m/m (Resisting Moment of Section) o V min = 0.035 * 250.5 * ( VRd = ) (1.5) = 0.6 N/mm2, So

*123 * 0.6 = 30.7 KN/m (Resisting Shear of Section)

Group Afaf Mohammed

Page 7 of 10

Composite Structures To Be Presented To Dr. Hisham Fawzy Composite Slab

Group Afaf Mohammed

Page 8 of 10

Composite Structures To Be Presented To Dr. Hisham Fawzy Composite Slab

Group Afaf Mohammed

Page 9 of 10

Composite Structures To Be Presented To Dr. Hisham Fawzy Composite Slab

1.7)

References:

o http://www.wikipedia.org/ o http://www.tatasteelconstruction.com/en/about_us/panels_profiles/structural_products_systems/comflor/comflor _range/comflor210/

1.8)

Members: Ahmed Moustafa Mohammed ElSaid Mohammed Reda Afaf Mohammed May Ahmed Norhan Samir

Thank You for Reading By Group Afaf

Group Afaf Mohammed

Page 10 of 10

You might also like

- Book BindingDocument14 pagesBook Bindingpesticu100% (2)

- Composite Beams and Slabs1Document9 pagesComposite Beams and Slabs1rameshbabu_1979100% (1)

- StructuralDocument15 pagesStructuralMark James MateoNo ratings yet

- Week 7 & 8 Wind LoadsDocument43 pagesWeek 7 & 8 Wind Loadsmuhammad nuruddin che ab malikNo ratings yet

- Slab DesignDocument87 pagesSlab Designshamen amarasekaraNo ratings yet

- Construction EquipmentDocument41 pagesConstruction EquipmentAhmed Moustafa Aboelela100% (5)

- Calculation PDFDocument126 pagesCalculation PDFmohammed almahrooqiNo ratings yet

- Ce1302 Design of RC ElementsDocument22 pagesCe1302 Design of RC Elementsjs kalyana rama100% (1)

- Milviz F-15e Poh V 2Document499 pagesMilviz F-15e Poh V 2Jose Ramon Martinez GutierrezNo ratings yet

- W3 Deep FoundationDocument42 pagesW3 Deep FoundationTeoh Zhi TongNo ratings yet

- Timber Joist Design BS5268Document3 pagesTimber Joist Design BS5268Zheny FortinNo ratings yet

- Wind Load IntroductioDocument22 pagesWind Load IntroductioSougata DasNo ratings yet

- RAPT Beam AnalysisDocument16 pagesRAPT Beam Analysisvikramjain66No ratings yet

- MasterSeries Student Masonry Retaining EtcDocument21 pagesMasterSeries Student Masonry Retaining EtcekaNo ratings yet

- Steel Structures 3 - Composite Structures - Lecture Notes Chapter 10.7Document29 pagesSteel Structures 3 - Composite Structures - Lecture Notes Chapter 10.7iSoK11No ratings yet

- Structural Steel Design Project: Calculation SheetDocument30 pagesStructural Steel Design Project: Calculation SheetLynzerNo ratings yet

- Learn Flat Slab-Flat Slab Analysis Design and Drawing SoftwareDocument128 pagesLearn Flat Slab-Flat Slab Analysis Design and Drawing SoftwareMohammad FawwazNo ratings yet

- A Presentation On-: Dr. Nikhil Oza Intern BvdumcDocument43 pagesA Presentation On-: Dr. Nikhil Oza Intern BvdumcMaheboob GanjalNo ratings yet

- Beam To Column Connection ExampleDocument9 pagesBeam To Column Connection ExampleLuqman ZolkibliNo ratings yet

- Calculation Method of Punching ShearDocument2 pagesCalculation Method of Punching SheardilrangiNo ratings yet

- Sway Frame Steel Column DesignDocument1 pageSway Frame Steel Column DesignChirianu MarianNo ratings yet

- Gang-Nail Connectors - How They Work Gang-Nail Truss SystemDocument5 pagesGang-Nail Connectors - How They Work Gang-Nail Truss SystemAnonymous acaD5VNo ratings yet

- Chapter 6 BasementDocument51 pagesChapter 6 BasementMUHAMMAD IMAN ASYRAF AHMAD NIZANo ratings yet

- Ruj.: Kod: Subjek: No Helaian: Ruj. Lukisan: Disemak Tarikh: Direkabentuk Oleh: ProjekDocument5 pagesRuj.: Kod: Subjek: No Helaian: Ruj. Lukisan: Disemak Tarikh: Direkabentuk Oleh: ProjekHafiz Budean RahmanNo ratings yet

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Document7 pages1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12asuncionNo ratings yet

- Precast Concrete ConstructionDocument28 pagesPrecast Concrete ConstructionGirl in the CityNo ratings yet

- Structure Details FOR Foundation: Practical Architectural Training-Fun Begins (For Interns and Freshers)Document37 pagesStructure Details FOR Foundation: Practical Architectural Training-Fun Begins (For Interns and Freshers)Divya Varshney100% (1)

- Introduction To Construction ContractsDocument44 pagesIntroduction To Construction ContractsAhmed Moustafa Aboelela100% (2)

- Week 1 Legal SkillsDocument13 pagesWeek 1 Legal SkillsAweSumNess83% (6)

- Shear Walls - An OverviewDocument6 pagesShear Walls - An OverviewTabish IslamNo ratings yet

- Frame ExamplesDocument4 pagesFrame ExamplesXet FatNo ratings yet

- 09 Passport 7K 15K Performance Guidelines PCR 3 0Document44 pages09 Passport 7K 15K Performance Guidelines PCR 3 0thed719No ratings yet

- Example Problem Truss SupportDocument5 pagesExample Problem Truss Supportramu karriNo ratings yet

- Domes, ShellsDocument20 pagesDomes, ShellsTenzin Phenz100% (1)

- Advantages CFSTDocument14 pagesAdvantages CFSTprajjwal patidarNo ratings yet

- VI Semester Design of Steel and Timber StructureDocument5 pagesVI Semester Design of Steel and Timber Structuredinesh100% (1)

- Ghomes - Techincal Design - 25 Dec PDFDocument350 pagesGhomes - Techincal Design - 25 Dec PDFTanluan NguyenNo ratings yet

- Hinusdtan College of Science & Technology: ECE-064 Earthquake Resistant Design UNIT-5Document29 pagesHinusdtan College of Science & Technology: ECE-064 Earthquake Resistant Design UNIT-5Faraan KhanNo ratings yet

- Space Frame OptimisationDocument9 pagesSpace Frame OptimisationSreehari AshokNo ratings yet

- Topic 2 Alignment Geometry Design AaadsdDocument15 pagesTopic 2 Alignment Geometry Design AaadsdMohd HakimNo ratings yet

- SF10 and SF16Document22 pagesSF10 and SF16Shanil BussooaNo ratings yet

- Steel Plate Gate DesignDocument5 pagesSteel Plate Gate DesignvsnsfbNo ratings yet

- Bolted Bracket DesignDocument2 pagesBolted Bracket Designharoub_nasNo ratings yet

- Failure of Structures: by Ir. Tee Horng Hean, B.Eng. (Hons), MSC (Eng.), Mba, M.I.E.MDocument7 pagesFailure of Structures: by Ir. Tee Horng Hean, B.Eng. (Hons), MSC (Eng.), Mba, M.I.E.MRajarshi ChakrabortyNo ratings yet

- 3.000 X 1200m Flag Type (7+965)Document13 pages3.000 X 1200m Flag Type (7+965)UmesgNo ratings yet

- Technical Data Sheet For Hilti HIT HY 200 Injectable Mortar in Concrete Technical Information ASSET DOC 8258686 PDFDocument41 pagesTechnical Data Sheet For Hilti HIT HY 200 Injectable Mortar in Concrete Technical Information ASSET DOC 8258686 PDFiabdillahNo ratings yet

- Resistance Moment Calculations (Walls BS 8110) PDFDocument3 pagesResistance Moment Calculations (Walls BS 8110) PDFdhanya1995No ratings yet

- Deep FoundatioDocument49 pagesDeep FoundatioSanthosh PurushothamanNo ratings yet

- Tying Resistance of A Fin Plate ConnectionDocument9 pagesTying Resistance of A Fin Plate ConnectionSam Samoura0% (1)

- Learn Raft-RC Raft Foundation Analysis Design and Drawing SoftwareDocument108 pagesLearn Raft-RC Raft Foundation Analysis Design and Drawing SoftwareRahul Kumar100% (2)

- Chapter 2.1.2018 - Frame - Wind Load PDFDocument56 pagesChapter 2.1.2018 - Frame - Wind Load PDFHawaiiChongNo ratings yet

- Double Tee Ridge BeamDocument3 pagesDouble Tee Ridge BeamhuyxpkissNo ratings yet

- Giao An Thep 1Document33 pagesGiao An Thep 1Trinh Duy KhanhNo ratings yet

- Limit State Design Flanged BeamsDocument13 pagesLimit State Design Flanged BeamsRahulRandyNo ratings yet

- GF SlabDocument8 pagesGF Slabcheligp1981No ratings yet

- Cobicif-Reportdescription Eng PDFDocument700 pagesCobicif-Reportdescription Eng PDFĐạt Nguyễn TuấnNo ratings yet

- Steelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiesDocument56 pagesSteelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiessubamanivelNo ratings yet

- Project Title: East View Primary School Client CPG Designed by Trang Checked by BKT Code: BS 5950 - PART 1: 2000 Job: Purlin DesignDocument110 pagesProject Title: East View Primary School Client CPG Designed by Trang Checked by BKT Code: BS 5950 - PART 1: 2000 Job: Purlin DesignSơn Nguyễn-Lê100% (1)

- Sathya Consultants: For Thermal ComfortDocument10 pagesSathya Consultants: For Thermal ComfortJappu KumarNo ratings yet

- Mero Connector (Steel Ball) DesignDocument3 pagesMero Connector (Steel Ball) DesignParvez KhanNo ratings yet

- Short Term and Long Term Deflection CalculationsDocument4 pagesShort Term and Long Term Deflection CalculationsMahendra SuryavanshiNo ratings yet

- Design of Haunched Composite Connections For Long-Span Beam ConstructionDocument10 pagesDesign of Haunched Composite Connections For Long-Span Beam ConstructioncasanovavnNo ratings yet

- BS-5950-90 Example 001Document7 pagesBS-5950-90 Example 001Maribel Isaura Cunurana YapuchuraNo ratings yet

- CE 327 RConcrete Module 1Document7 pagesCE 327 RConcrete Module 1Niel John BaquilarNo ratings yet

- Reinforced Concrete NoteDocument9 pagesReinforced Concrete NotemodarthNo ratings yet

- RCC and PSCDocument50 pagesRCC and PSCradhakrishnangNo ratings yet

- Delay Analysis Methods For Construction Projects: Mathematical ModellingDocument10 pagesDelay Analysis Methods For Construction Projects: Mathematical ModellingAhmed Moustafa AboelelaNo ratings yet

- Critical ThinkingDocument6 pagesCritical ThinkingAhmed Moustafa AboelelaNo ratings yet

- Scott Wood Sharpening Your Legal Writing SkillsDocument2 pagesScott Wood Sharpening Your Legal Writing SkillsStanyslav CebanciucNo ratings yet

- Guidelines For Applicants: PrequalificationDocument19 pagesGuidelines For Applicants: PrequalificationAhmed Moustafa AboelelaNo ratings yet

- Guidelines For Applicants: PrequalificationDocument19 pagesGuidelines For Applicants: PrequalificationAhmed Moustafa AboelelaNo ratings yet

- To Do ListDocument1 pageTo Do ListAhmed Moustafa AboelelaNo ratings yet

- Factors Affecting ProductivityDocument5 pagesFactors Affecting ProductivityAhmed Moustafa AboelelaNo ratings yet

- ME 352 Design of Machine Elements: Lab ReportDocument5 pagesME 352 Design of Machine Elements: Lab ReportKeshav VermaNo ratings yet

- Biologically Active Compounds From Hops and Prospects For Their Use - Karabín 2016Document26 pagesBiologically Active Compounds From Hops and Prospects For Their Use - Karabín 2016Micheli Legemann MonteNo ratings yet

- Manual 35S EnglishDocument41 pagesManual 35S EnglishgugiNo ratings yet

- Chemistry Notes: SUBJECT: Leaving Cert Chemistry Level: TEACHER: Tara LyonsDocument5 pagesChemistry Notes: SUBJECT: Leaving Cert Chemistry Level: TEACHER: Tara LyonsSevinc NuriyevaNo ratings yet

- Chennai To Vishakhapatnam El6Vvd: Indigo 6E-6835Document3 pagesChennai To Vishakhapatnam El6Vvd: Indigo 6E-6835VENKATESH POONDRUNo ratings yet

- Aircraft Design Course PhillStocking 4.2Document48 pagesAircraft Design Course PhillStocking 4.2ugurugur1982No ratings yet

- Uji Efektivitas Mikroba Rumpun BambuDocument7 pagesUji Efektivitas Mikroba Rumpun BambuUse Real ProjectNo ratings yet

- Full Download Short Term Financial Management 3rd Edition Maness Test BankDocument35 pagesFull Download Short Term Financial Management 3rd Edition Maness Test Bankcimanfavoriw100% (31)

- Product Stock Exchange Learn BookDocument1 pageProduct Stock Exchange Learn BookSujit MauryaNo ratings yet

- GLP BmsDocument18 pagesGLP BmsDr.Subhashish TripathyNo ratings yet

- 412 X 7 Va CJ CSDocument1 page412 X 7 Va CJ CSRajesh KumarNo ratings yet

- FAJASDocument891 pagesFAJASCecilia GilNo ratings yet

- YellowstoneDocument1 pageYellowstoneOana GalbenuNo ratings yet

- ReviewerDocument3 pagesReviewerKristine SantominNo ratings yet

- 2 Contoh Narative TextDocument9 pages2 Contoh Narative TextRini RienzNo ratings yet

- Guidelines For The Management of Brain InjuryDocument26 pagesGuidelines For The Management of Brain InjuryfathaNo ratings yet

- 4 5803133100506483687Document245 pages4 5803133100506483687Malik HamidNo ratings yet

- Tran-Effects of Assisted JumpingDocument5 pagesTran-Effects of Assisted JumpingyoungjessNo ratings yet

- SAT Biochar Ethylene Poster 10 - 10b PDFDocument1 pageSAT Biochar Ethylene Poster 10 - 10b PDFsherifalharamNo ratings yet

- Of The Month Is Live. 100+ Subjects. Participate Now!: Sanfoundry Certification ContestDocument4 pagesOf The Month Is Live. 100+ Subjects. Participate Now!: Sanfoundry Certification ContestBaydaa QaidyNo ratings yet

- Generalized Anxiety DisorderDocument24 pagesGeneralized Anxiety DisorderEula Angelica OcoNo ratings yet

- Nicholas Hudson - From Nation To Race: The Origin of Racial Classification in Eighteenth-CenturyDocument19 pagesNicholas Hudson - From Nation To Race: The Origin of Racial Classification in Eighteenth-CenturyPedro IINo ratings yet

- Natural Disasters Vocabulary Exercises Fun Activities Games Icebreakers Oneonone Activiti 42747Document2 pagesNatural Disasters Vocabulary Exercises Fun Activities Games Icebreakers Oneonone Activiti 42747Andrea Tercero VillarroelNo ratings yet

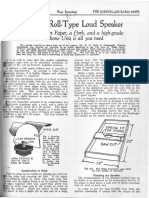

- Simple Roll-Type: A Loud SpeakerDocument1 pageSimple Roll-Type: A Loud SpeakerEudes SilvaNo ratings yet

- Firestone & Scholl - Cognition Does Not Affect Perception, Evaluating Evidence For Top-Down EffectsDocument77 pagesFirestone & Scholl - Cognition Does Not Affect Perception, Evaluating Evidence For Top-Down EffectsRed JohnNo ratings yet

- Modern Myth and Magical Face Shifting Technology in Girish Karnad Hayavadana and NagamandalaDocument2 pagesModern Myth and Magical Face Shifting Technology in Girish Karnad Hayavadana and NagamandalaKumar KumarNo ratings yet