Professional Documents

Culture Documents

Vacuum Box Testing

Uploaded by

ergyapOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vacuum Box Testing

Uploaded by

ergyapCopyright:

Available Formats

Job N: 268129 KASHAGAN DEVELOPMENT EXPERIMENTAL PROGRAMME PROJECT Page : 3 of 8 Hook-up and Commissioning of Complex D and Island A - Offshore

Facilities Doc. No.: 268129-SA-PR-8039-00 Rev. C01

REVISION RECORD SHEET Revision A01 P01 C01 Description Issued for internal Review Issued for Company Review / Approval Issued for Construction Page No.(s) 7 8 8

KE01-00-000-AN-Q-PR-0077-000-C01

PROCEDURE - VACUUM BOX TESTING PROCEDURE FOR TANKS

Page : 3 of 8

Job N: 268129 KASHAGAN DEVELOPMENT EXPERIMENTAL PROGRAMME PROJECT Page : 4 of 8 Hook-up and Commissioning of Complex D and Island A - Offshore Facilities Doc. No.: 268129-SA-PR-8039-00 Rev. C01 INDEX 1 2 3 4 5 6 7 8 9 SCOPE REFERENCE DOCUMENTS DEFINITIONS AND ABBRIVIATION PERSONNEL EQUIPMENT TESTING ACCEPTANCE CRITERIA REPORTING ATTACHMENT ANNEX VACUUM BOX TESTING REPORT 5 5 5 5 6 6 6 7 8

KE01-00-000-AN-Q-PR-0077-000-C01

PROCEDURE - VACUUM BOX TESTING PROCEDURE FOR TANKS

Page : 4 of 8

Job N: 268129 KASHAGAN DEVELOPMENT EXPERIMENTAL PROGRAMME PROJECT Page : 5 of 8 Hook-up and Commissioning of Complex D and Island A - Offshore Facilities Doc. No.: 268129-SA-PR-8039-00 Rev. C01

1.0

SCOPE This procedure describes the general requirements, method, technique and acceptance criteria for Vacuum Box Testing of welds in welded Storage tanks in accordance with API 650 and the extent shall be in accordance with an approved QCP

2.0

REFERENCES DOCUMENTS

[1]

KE01-00-000-KD-M-ST.0029-000 F01

Specification for Welded Steel Storage Tank.

[2] [3]

KE01-00-000-KD-V-SS-0010-000 D02 API 650

Welding of Storage Tank Welded Tank for Oil Storage.

3.0

DEFINITIONS and ABBREVIATION

Company Contractor Ndt Sub contractor API QCP Shall Should

AGIP KCO ERSAI NDT Laboratory (personnel and equipment) employed by ERSAI for Kashagan Experimental Development Program American petroleum institute Qulity Control Plan The word shall indicates a requirement The word should indicates recommendations

4.0

PERSONNEL

Personnel performing and witnessing Vacuum Box Testing shall have past experience in the activity. Specific Training to the Operators and Inspectors shall be given by NDT / QC Supervisor and shall be documented. Personnel performing Inspection / Interpretation / Evaluation shall have vision with or without correction to be able to read a Jaeger type 2 standard chart at a distance of not less than 300mm. This check shall be performed annually.

KE01-00-000-AN-Q-PR-0077-000-C01

PROCEDURE - VACUUM BOX TESTING PROCEDURE FOR TANKS

Page : 5 of 8

Job N: 268129 KASHAGAN DEVELOPMENT EXPERIMENTAL PROGRAMME PROJECT Page : 6 of 8 Hook-up and Commissioning of Complex D and Island A - Offshore Facilities Doc. No.: 268129-SA-PR-8039-00 Rev. C01

5.0

EQUIPMENT Following Equipment shall be used A. Vacuum Box of dimension 150mm wide by 750mm long with a clear window in the top with gaskets , seals etc B. Torch C. Soap Solution D. Vacuum Pump / Hoses E. Calibrated Vacuum Guage F. Calibrated Temperature guage G. Calibrated Light Intensity meter

6.0

TESTING Perform a good visual inspection of the surface / weld to be vacuum box tested. And check the temperature of the surface. Metal surface temperature shall be between 4C to 52C. Apply the soap solution on the area to be inspected. Place the open bottom portion of the vacuum box against the tank surface so that the weld to be inspected is in the centre of the box. Check for the proper fit and seal. Apply a partial vacuum of 650mBar, for a minimum period of 5 seconds or the time required to view the area under test. Ensure minimum light intensity of 1000 Lux at the point of examination. Look for any air bubbles in the area of interest. The test shall have at least 50mm overlap of previously inspected surface on each application.

7.0

ACCEPTANCE CRITERIA The presence of a through-thickness leak indicated by continuous formation or growth of a bubble(s) or foam, produced by air passing through the thickness, is Not Acceptable The presence of a large opening leak, indicated by a quick bursting bubble or spitting response at the initial setting of the vacuum box is Not Acceptable Leaks shall be repaired and retested.

KE01-00-000-AN-Q-PR-0077-000-C01

PROCEDURE - VACUUM BOX TESTING PROCEDURE FOR TANKS

Page : 6 of 8

Job N: 268129 KASHAGAN DEVELOPMENT EXPERIMENTAL PROGRAMME PROJECT Page : 7 of 8 Hook-up and Commissioning of Complex D and Island A - Offshore Facilities Doc. No.: 268129-SA-PR-8039-00 Rev. C01

8.0

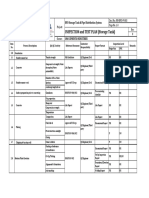

REPORTING After completion of the inspection of activity, prepare the report as the form in Annex 1

9.0

Attachment Annex - Vacuum Box Testing Report (268129-WELD-005-E-R)

KE01-00-000-AN-Q-PR-0077-000-C01

PROCEDURE - VACUUM BOX TESTING PROCEDURE FOR TANKS

Page : 7 of 8

Job N: 268129 KASHAGAN DEVELOPMENT EXPERIMENTAL PROGRAMME PROJECT Page : 8 of 8 Hook-up and Commissioning of Complex D and Island A - Offshore Facilities Doc. No.: 268129-SA-PR-8039-00 Rev. C01 Annex Vacuum Box Testing Report

KE01-00-000-AN-Q-PR-0077-000-C01

PROCEDURE - VACUUM BOX TESTING PROCEDURE FOR TANKS

Page : 8 of 8

You might also like

- Complete Resonance MathematicsDocument701 pagesComplete Resonance MathematicsRajendra Bisoi100% (6)

- GRE Pipes Inspection Test PlanDocument6 pagesGRE Pipes Inspection Test PlanMat RidhanNo ratings yet

- Index: Method Statement For Post Weld Heat TreatmentDocument8 pagesIndex: Method Statement For Post Weld Heat TreatmentsomiqatarNo ratings yet

- Water Fill Up Testing Procedure-R3 07.07.2011sohar 2Document7 pagesWater Fill Up Testing Procedure-R3 07.07.2011sohar 2AjeetKumarNo ratings yet

- Pneumatic Test ProcedureDocument10 pagesPneumatic Test ProcedureahmadNo ratings yet

- Vaccum Test MethodDocument4 pagesVaccum Test MethodMahmud AlamNo ratings yet

- Api 653 Report-Hydrolic Test PDFDocument12 pagesApi 653 Report-Hydrolic Test PDFnaoufel1706No ratings yet

- KYPipe Reference Manual GuideDocument76 pagesKYPipe Reference Manual GuideApril TrevinoNo ratings yet

- 6) Pneumatic Pressure TestDocument3 pages6) Pneumatic Pressure Testbacabacabaca100% (1)

- Oil Leak Test ProcedureDocument7 pagesOil Leak Test ProcedurekokoNo ratings yet

- Pipeline Systems Dewatering Method Statement and Work Procedure - Rev - A01Document7 pagesPipeline Systems Dewatering Method Statement and Work Procedure - Rev - A01Mitchellgrany80% (5)

- Sample - Template - Itp For Piping Fabrication and InstallationDocument2 pagesSample - Template - Itp For Piping Fabrication and Installationmohd as shahiddin jafriNo ratings yet

- Vacuum Box TestingDocument8 pagesVacuum Box TestingMajid Dawood Khan100% (2)

- BIX - RT ProcedureDocument36 pagesBIX - RT ProcedureEduard Abastillas100% (1)

- Chiller 252 TRDocument2 pagesChiller 252 TRhector diazNo ratings yet

- CamDocument52 pagesCamenchong091100% (1)

- PWHT Procedure for Boiler OverhaulDocument10 pagesPWHT Procedure for Boiler OverhaulDedy Trianda100% (1)

- Vacuum Box Test Procedure GudielinesDocument3 pagesVacuum Box Test Procedure Gudielinessbmmla100% (3)

- Shop Fabrication and Inspection Procedure for Gasoline and Engine Oil TankDocument7 pagesShop Fabrication and Inspection Procedure for Gasoline and Engine Oil TankGATOTNo ratings yet

- Vaccum Box Procedure API 650 OKDocument7 pagesVaccum Box Procedure API 650 OKTouil Houssem100% (1)

- UT Procedure GuideDocument15 pagesUT Procedure GuideAmir Reza RashidfarokhiNo ratings yet

- Pneumatic Leak Testing Procedure for Reinforcement PadsDocument4 pagesPneumatic Leak Testing Procedure for Reinforcement PadsHansel Francis100% (5)

- Injection Molding SOP for Mini-Jector #55.1 MachineDocument12 pagesInjection Molding SOP for Mini-Jector #55.1 MachineYusuf SethNo ratings yet

- VACCUM BOX Test ReportDocument1 pageVACCUM BOX Test ReportYu Haiyue100% (1)

- Job Procedure For PWHT of Storage Tanks: 10 of Ramadan City, Industrial Area A1, EgyptDocument5 pagesJob Procedure For PWHT of Storage Tanks: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaNo ratings yet

- Vacume Box Test ProcedureDocument5 pagesVacume Box Test ProcedureFarhan Sheikh100% (3)

- Earthing CalculationDocument4 pagesEarthing Calculationanandpurush100% (1)

- Radiographic Examination Procedure (RTDocument16 pagesRadiographic Examination Procedure (RTWisüttisäk Peäröön100% (2)

- RoundnessDocument35 pagesRoundnesssrinivasansscNo ratings yet

- 25.tank Water Fill TestDocument4 pages25.tank Water Fill TestShubham ShuklaNo ratings yet

- Oil Chalk Test/Penetrating Oil TestDocument6 pagesOil Chalk Test/Penetrating Oil TestWeld ManiacNo ratings yet

- Job Procedure For Vacuum Test of Tanks: 10 of Ramadan City, Industrial Area A1, EgyptDocument5 pagesJob Procedure For Vacuum Test of Tanks: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaNo ratings yet

- PNEUMATIC TESTDocument2 pagesPNEUMATIC TESTdyke_engg50% (2)

- STS Co. storage tank fabrication methodologyDocument15 pagesSTS Co. storage tank fabrication methodologypurshottam GHNo ratings yet

- Procedure For Vacuum Box TestingDocument3 pagesProcedure For Vacuum Box TestingZakirUllahNo ratings yet

- Inspection & Test Plan TankDocument3 pagesInspection & Test Plan TankJOSHUA SULLEGUE100% (1)

- Checklist Tank NewDocument11 pagesChecklist Tank NewamevaluacionesNo ratings yet

- Procedure For DPT PDFDocument4 pagesProcedure For DPT PDFSaut Maruli Tua Samosir50% (2)

- Api 653 Report-Hydrolic Test PDFDocument12 pagesApi 653 Report-Hydrolic Test PDFnaoufel1706No ratings yet

- Boiler Water ChemistryDocument63 pagesBoiler Water ChemistryDeepak JayNo ratings yet

- 24.tank Oil Chalk TestDocument3 pages24.tank Oil Chalk TestShubham ShuklaNo ratings yet

- Hydrostatic and Settlement Tests ProcedureDocument12 pagesHydrostatic and Settlement Tests Procedureツ ツ100% (1)

- RT ProcedureDocument22 pagesRT ProcedureRavindra S. JivaniNo ratings yet

- Third Party Inspection For Storage TankDocument8 pagesThird Party Inspection For Storage TankGeroldo 'Rollie' L. QuerijeroNo ratings yet

- QCP-0714-11, Rev. A, Field Welded API Std. 650 Tanks' Shop Pre-Fabrication QC Procedure.Document6 pagesQCP-0714-11, Rev. A, Field Welded API Std. 650 Tanks' Shop Pre-Fabrication QC Procedure.abdul aziz100% (1)

- Vacuum Boxes TestDocument3 pagesVacuum Boxes TestTomy GeorgeNo ratings yet

- BEMO Roof Brochure en 2019Document27 pagesBEMO Roof Brochure en 2019Anonymous wzuyBcNo ratings yet

- Vacuum Box Testing ProcedureDocument6 pagesVacuum Box Testing ProcedureKandula Raju100% (1)

- Vacuum Box Test Report of Tank T-8112 Bottom PlatesDocument8 pagesVacuum Box Test Report of Tank T-8112 Bottom PlatesShalom LivingstonNo ratings yet

- Tank Vacuum Leak Test ProcedureDocument6 pagesTank Vacuum Leak Test ProcedureTomy George100% (4)

- Kathrein 80010761Document2 pagesKathrein 80010761Sego Megono100% (1)

- 50037-QA-PLN-002 Rev.0Document13 pages50037-QA-PLN-002 Rev.0seehari100% (3)

- Vacuum Box Test PDFDocument3 pagesVacuum Box Test PDFWilson RodriguezNo ratings yet

- Documents - MX - Vacuum Box Testing PDFDocument8 pagesDocuments - MX - Vacuum Box Testing PDFMuhammad Nasir SiddiqueNo ratings yet

- Vaccum Box Test Procedure For All TanksDocument6 pagesVaccum Box Test Procedure For All Tanksויליאם סן מרמיגיוסNo ratings yet

- Pressure Vessel Dimension InspectionDocument3 pagesPressure Vessel Dimension InspectionAnas Sarkiah0% (1)

- Dye Penetrant Testing ProcedureDocument5 pagesDye Penetrant Testing ProcedureTabish Shaikh50% (2)

- Iot-Q-Bbb-Pr-005 Vacuum Box Test Procedure Rev - ADocument7 pagesIot-Q-Bbb-Pr-005 Vacuum Box Test Procedure Rev - AMikiRoniWijaya100% (4)

- PTDocument7 pagesPTMohdHuzairiRusliNo ratings yet

- Russindo Group Vacuum Box Test ProcedureDocument5 pagesRussindo Group Vacuum Box Test ProcedureIkhsan Dalimunthe100% (2)

- Vessel Cleaning ProcedureDocument6 pagesVessel Cleaning ProcedureZool HilmiNo ratings yet

- Peaking BandingDocument2 pagesPeaking Bandingsetak100% (4)

- Proc SopDocument90 pagesProc SopJohn Dolan100% (1)

- Procedure For Ferrit TestingDocument11 pagesProcedure For Ferrit TestingKarrar TalibNo ratings yet

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Document17 pagesWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizNo ratings yet

- Underground Tank Inspection ReportsDocument2 pagesUnderground Tank Inspection ReportsRavi Kumar VatturiNo ratings yet

- Bridge Crane Installation ProcedureDocument7 pagesBridge Crane Installation Procedurenike_y2kNo ratings yet

- Method Statement For Vacuum Box Test For DM and SW TANKDocument5 pagesMethod Statement For Vacuum Box Test For DM and SW TANKYurizal firmansyahNo ratings yet

- Spectrum OFDMFDocument1 pageSpectrum OFDMFvcazacuNo ratings yet

- Respect The Unstable PDFDocument14 pagesRespect The Unstable PDFMarcelo Quispe CcachucoNo ratings yet

- Uluru-KataTjuta Maps VisitoressentialsDocument4 pagesUluru-KataTjuta Maps VisitoressentialsbennysgigNo ratings yet

- Structures: Muhammad Zain, Muhammad Usman, Syed Hassan FarooqDocument11 pagesStructures: Muhammad Zain, Muhammad Usman, Syed Hassan FarooqDilum VRNo ratings yet

- IR Drop PDFDocument3 pagesIR Drop PDFarammartNo ratings yet

- Center of Mass and The Motion of A SystemDocument13 pagesCenter of Mass and The Motion of A SystemNitin SharmaNo ratings yet

- Thermal Physics Question BankDocument6 pagesThermal Physics Question BankpranavabaascaranNo ratings yet

- Fishers LDADocument47 pagesFishers LDABinduNo ratings yet

- Stage Separation Dynamic Analysis of Upper State PDFDocument18 pagesStage Separation Dynamic Analysis of Upper State PDFandradesosNo ratings yet

- Work Sheet IDocument5 pagesWork Sheet IgrmdrjNo ratings yet

- Application of The Giroud - Han Design Method For Geosynthetic Reinforced Unpaved Roads With Tencate Mirafi GeosyntheticsDocument7 pagesApplication of The Giroud - Han Design Method For Geosynthetic Reinforced Unpaved Roads With Tencate Mirafi GeosyntheticsFaten Abou ShakraNo ratings yet

- M.Tech M 2016Document133 pagesM.Tech M 2016Priya ApteNo ratings yet

- Providing Optimized Alignment & Automatic Interchange Design Software TutorialDocument11 pagesProviding Optimized Alignment & Automatic Interchange Design Software Tutorialadera1No ratings yet

- 9000 SPXDocument220 pages9000 SPXIsmael GraciaNo ratings yet

- RT60 Reverberation TimeDocument21 pagesRT60 Reverberation TimeDinushaNo ratings yet

- Mathematics Online WWW - Mathematicsonline.co - in Three Dimensional Coordinate Assignment 3Document5 pagesMathematics Online WWW - Mathematicsonline.co - in Three Dimensional Coordinate Assignment 3Karm VeerNo ratings yet

- Armor Rods: NomenclatureDocument8 pagesArmor Rods: NomenclatureArturo Tipacti QuijanoNo ratings yet

- Lecture TutorialDocument40 pagesLecture TutorialAhmed A. RadwanNo ratings yet

- TDS - Micro-Air 120Document3 pagesTDS - Micro-Air 120aahtagoNo ratings yet

- Cazoom Maths. Lines and Angles. Angles On Parallel Lines (A)Document2 pagesCazoom Maths. Lines and Angles. Angles On Parallel Lines (A)Apex GamingNo ratings yet

- Bullet Holes in PlasticDocument7 pagesBullet Holes in PlasticSonya PriceNo ratings yet