Professional Documents

Culture Documents

FPR Regulator

Uploaded by

Hamit MavriqiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FPR Regulator

Uploaded by

Hamit MavriqiCopyright:

Available Formats

How does an FPR work?

What is a fuel pressure regulator? A fuel pressure regulator (FPR) is a device which controls the pressure of fuel supplied to the fuel injectors on an engine.

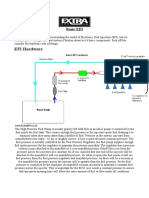

How does a Turbosmart FPR work? A Turbosmart FPR works by bleeding off a portion of the fuel flow to the injectors from the fuel pump to control the fuel pressure. Fuel is pumped from the fuel tank to the fuel rail by the fuel pump. The FPR is normally mounted after the fuel rail to ensure that the fuel rail has priority in fuel flow. The valve in the FPR controls the amount of fuel that is bled from the fuel rail by opening an outlet port to allow fuel to flow back into the fuel tank.

All injectors need a pressure difference between the inlet and the outlet of the injector to spray fuel into the combustion chamber. This is called the base pressure. The base pressure is adjusted on all Turbosmart FPRs via the adjustment screw to suit the injectors and fuel pump system you are using.

The adjustment screw pushes down on a spring which applies a force onto the valve. When the pressure inside the bottom chamber of the FPR exerts a high enough force on the valve to overcome the spring force and lift the valve off its seat, it allows fuel to flow through the outlet port effectively controlling the fuel pressure in the fuel rail.

Since the outlet of the injector is exposed to manifold vacuum/pressure which varies depending on throttle movement, but the flow of fuel from the fuel pump is constant, the valve needs a reference to continuously change the amount of fuel bled to maintain constant fuel pressure to the injectors. In addition to the spring force acting on the valve, a vacuum/boost signal also applies a force onto the valve so that the valve is always maintaining a constant pressure difference between the inlet and outlet of the injector.

The base pressure is set without any line connected to the vacuum/boost reference nipple. Once the base pressure has been set, the vacuum/boost line is then connected to the reference nipple.

Example: With a base pressure of 40PSI Idling at 20inHg, the nozzle is exposed to 20 inHg vacuum causing fuel to be sucked into the intake manifold. This combined with the 40 PSI base pressure would equated to a theoretical spray pressure of 50 PSI which is above the desired fuel pressure of 40 PSI. Since the top of the valve in the FPR is also exposed to 20 inHg, the valve is pulled up which opens the outlet port up increase the fuel being bled from the fuel rail which reduces the pressure by 10 PSI. This then gives you your desired fuel pressure of 40 PSI. At a boost pressure of 10 PSI, the nozzle is exposed to 10 PSI of pressure. This pressure is acting against the base fuel pressure which would mean that the spray pressure would be 30 PSI which is below the target fuel pressure. By also providing the top of valve with a reference boost signal of 10 PSI, the FPR now has a combined force to provide 50 PSI of fuel pressure which can overcome the force exerted on the nozzle to give you your 40 PSI target pressure.

Important features of Turbosmarts FPR range

1. Ratio This is the ratio between boost pressure and fuel pressure increase. A 1:1 ratio means that for every 1 PSI increase in boost pressure, Fuel pressure will also increase by 1 PSI to ensure that the pressure differential between the inlet and outlet of the injector is constant. All injectors are rated to certain base pressure. Injectors are solenoid valves which open and close when power is applied to them. The injector has a solenoid which provides enough force to pull open the valve in the injector to overcome the fuel pressure keeping the injector closed. If the fuel pressure is too high, the solenoid will not have enough energy to open the valve fully causing the engine to starve of fuel. It is essential to maintain a constant pressure differential between the inlet and outlet of the injector and hence why a 1:1 ratio FPR is ideal. All Turbosmart FPRs feature a 1:1 rising rate.

2. Flow capabilities Electric fuel pumps are designed to flow a constant amount of fuel regardless of engineRPM and/or boost pressure. At idle, the fuel regulator needs to flow the maximum amount of fuel as the fuel pump is at maximum flow, but the engine is using minimal fuel. If the FPR is not capable of flowing enough fuel, the fuel pressure will be above what is desired. A high flowing FPR is extremely critical on a high horsepower car running a mechanical fuel pump. Mechanical fuel pumps are driven directly by the engine. Fuel flow increases as the engine RPM increases. In a situation such as the end of a drag race, engine RPMis high but the throttle is closed and the engine is consuming minimal fuel. The FPR needs to be capable of diverting high amounts of fuel so that in situations like this, the fuel pressure differential between the inlet and outlet of the injector is optimal. Large pressure spikes from an FPR not flowing enough fuel can result in damaged injectors or mechanical failure to fuel rails and lines. All Turbosmart FPRs are designed for high flow and are capable of supporting a fuel system rated to the model of FPR. 3. Materials Todays fuels have a variety of chemicals to increase its octane rating. The higher the octane rating, the less susceptible it is to engine knock. Fuels such as alcohols and unleaded race fuels can corrode untreated metals and destroy diaphragms. All Turbosmart FPRs use anodized billet aluminium bodies for strength and corrosion resistance. The FPR800 uses a diaphragm that can withstand any type of pump fuel whereas the FPR1200, FPR2000 and FPR3000 have diaphragms which can handle any type of race fuel or alcohol. 4. Base Pressure All injectors have a recommend optimal working base pressure from the manufacturer and the FPR needs to be adjusted to provide this optimal base pressure. Turbosmart FPRs have adjustments screws that allow the user to set the base pressure between 30 70 PSI, allowing them to be matched to any type of fuel injector and fuel pump.

What to consider when choosing a Turbosmart FPR? Target Power level The target power level will determine the amount of fuel needed from the fuel pumps and the amount of fuel the FPR needs to control. The higher the target power level, the more fuel flow needed, the larger the FPR needs to be to flow enough fuel to keep pressures at the desired level. All Turbosmart FPRs are horsepower rated to the series number e.g. the FPR1200 is capable of controlling 1200 horsepower worth of fuel Fuel Type It is best to choose a FPR which is capable of handling the type of fuel being used on the engine. Street cars which use pump fuel can use the FPR800 whereas race cars using race fuel or alcohol will need to use the higher FPR series such as the FPR1200, FPR2000 and FPR3000.

You might also like

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- RA HPFP Tuning GuideDocument5 pagesRA HPFP Tuning GuidesxpNo ratings yet

- ProperlySelectingEFIComp PDFDocument5 pagesProperlySelectingEFIComp PDFEduardo VilchezNo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Fuel Injectors and AdaptorsDocument6 pagesFuel Injectors and AdaptorsPeter Piper100% (1)

- 5 Fuel PumpDocument3 pages5 Fuel PumprukmavaNo ratings yet

- Learn to Drive: Everything New Drivers Need to KnowFrom EverandLearn to Drive: Everything New Drivers Need to KnowRating: 4 out of 5 stars4/5 (1)

- Komat'Su - HPI Fuel SystemDocument76 pagesKomat'Su - HPI Fuel SystemKarthik Rao100% (2)

- Diesel Common Rail Injection Electronic Components ExplainedFrom EverandDiesel Common Rail Injection Electronic Components ExplainedRating: 3.5 out of 5 stars3.5/5 (7)

- Bosch CP3 OperationDocument6 pagesBosch CP3 OperationGianfranco Danna Gálvez100% (2)

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Rating: 1 out of 5 stars1/5 (3)

- Fuel PumpDocument2 pagesFuel PumpGeorgeNo ratings yet

- VW Transporter T4 Workshop Manual Diesel 2000-2004From EverandVW Transporter T4 Workshop Manual Diesel 2000-2004Rating: 5 out of 5 stars5/5 (5)

- Subaru WRX Performance GuideDocument202 pagesSubaru WRX Performance Guidegigabyte3235840No ratings yet

- Industrial Training Template BasicsDocument65 pagesIndustrial Training Template BasicsFaiz IbrahimNo ratings yet

- Ford Manual for Owners and Operators of Ford Cars and Trucks (1919)From EverandFord Manual for Owners and Operators of Ford Cars and Trucks (1919)No ratings yet

- Fuel Oil System GuideDocument28 pagesFuel Oil System Guidesandeep kumar vishwakarmaNo ratings yet

- Boiler Feed Water Pumps & Water Analysis (PB QBook)Document8 pagesBoiler Feed Water Pumps & Water Analysis (PB QBook)Ehsan Pappu100% (1)

- Basic Fuel System Analysis: Understanding Components, Pressure, and FlowDocument6 pagesBasic Fuel System Analysis: Understanding Components, Pressure, and FlowadzimskaloNo ratings yet

- Bosch Fuel - TechDocument3 pagesBosch Fuel - TechMoaed KanbarNo ratings yet

- JT8D Fuel SystemDocument8 pagesJT8D Fuel SystemTrifi AJe JaenuriNo ratings yet

- How To Read Compressor MapDocument1 pageHow To Read Compressor MapPepenauta InternautaNo ratings yet

- Optimize Fuel System PerformanceDocument14 pagesOptimize Fuel System Performanceservice_007100% (1)

- Fuel Charging and Controls - INGENIUM I4 2.0L PetrolDocument274 pagesFuel Charging and Controls - INGENIUM I4 2.0L Petrolkhaledserag23No ratings yet

- How HEUI Injectors WorkDocument3 pagesHow HEUI Injectors WorkSebutSajaRizkiNovNo ratings yet

- Basic EFI simplifiedDocument6 pagesBasic EFI simplifiedvictorjoseteixeiraNo ratings yet

- 1927 Bosch Diesel Fuel Injection Pump DesignDocument16 pages1927 Bosch Diesel Fuel Injection Pump Designdivyanshpancholi100% (2)

- Tech Information Basic Weber TuningDocument6 pagesTech Information Basic Weber TuningYacullsNo ratings yet

- 7.3 DIT Powerstroke Part 1 PDFDocument6 pages7.3 DIT Powerstroke Part 1 PDFFEF777100% (2)

- Fuel Oil System by P.KDocument28 pagesFuel Oil System by P.Kkr_abhijeet72356587100% (1)

- Mikuni HS40 Carburetor Tuning GuideDocument5 pagesMikuni HS40 Carburetor Tuning GuideS2gizzleNo ratings yet

- Detroit-Diesel-DD-Three-Filter-SystemDocument170 pagesDetroit-Diesel-DD-Three-Filter-Systemcristian picadoNo ratings yet

- LECTURSYSTEMDocument32 pagesLECTURSYSTEMabdul masudNo ratings yet

- Carbo RateDocument3 pagesCarbo RateJeevan Landge PatilNo ratings yet

- New Microsoft Office Word DocumentDocument11 pagesNew Microsoft Office Word DocumentJunaid YNo ratings yet

- 10 FuelDocument12 pages10 FuelBlueSkyMaster100% (2)

- lm2500 LubesupplyDocument3 pageslm2500 LubesupplyDenis Jimenez100% (2)

- Automobile EnggDocument43 pagesAutomobile EnggV V DEVADASNo ratings yet

- Fuel Metering SystemsDocument33 pagesFuel Metering SystemsSouvagya Raj Sahoo100% (1)

- Complex High PerformanceDocument2 pagesComplex High PerformanceDaniel WieseNo ratings yet

- Robert Bosch Type VE Diesel Injection PumpDocument5 pagesRobert Bosch Type VE Diesel Injection PumpShahrizan abdul rahman0% (1)

- FAF287 LowdownDocument3 pagesFAF287 LowdownKandy KnNo ratings yet

- Turbine Engine Fuel MeteringDocument28 pagesTurbine Engine Fuel MeteringJennifer LigayaNo ratings yet

- Details of FipDocument13 pagesDetails of FipSRIKANTH GDNo ratings yet

- Turbine Engine Fuel Injection Calibration Using Standard Pressure GaugesDocument4 pagesTurbine Engine Fuel Injection Calibration Using Standard Pressure GaugesAFM ChannelNo ratings yet

- Common Rail Fuel Injection SystemDocument56 pagesCommon Rail Fuel Injection SystemMarcos Maciel100% (1)

- Bosch Fuel System Common RailDocument4 pagesBosch Fuel System Common RailAlaa saidNo ratings yet

- What is a Fuel Injection Pump? Its Parts, Working, Types and SymptomsDocument7 pagesWhat is a Fuel Injection Pump? Its Parts, Working, Types and SymptomsGANAPATHY MNo ratings yet

- CenstarDocument12 pagesCenstarSUJAN RANASINGHENo ratings yet

- How To Read Pump CurveDocument4 pagesHow To Read Pump Curvebotaqi100% (6)

- ICE Turbocharger BasicsDocument18 pagesICE Turbocharger Basicssafwansd750% (2)

- v4 System DescriptionDocument10 pagesv4 System DescriptionkrenlanNo ratings yet

- Fuel rail components and operationDocument4 pagesFuel rail components and operationВячеслав ГлушакNo ratings yet

- Hydraulic Pump Functions and TypesDocument23 pagesHydraulic Pump Functions and TypesschaNo ratings yet

- Below Is An Overview of The Fuel System Intake OperationDocument8 pagesBelow Is An Overview of The Fuel System Intake OperationchigauNo ratings yet

- Vehicle Electrical Actuators GuideDocument40 pagesVehicle Electrical Actuators GuideBence M Zoltan100% (1)

- Intro. To TurboDocument8 pagesIntro. To TurboKevin GutierrezNo ratings yet

- EMU8086 SolutionsDocument10 pagesEMU8086 SolutionsNaga Venkat0% (1)

- Pawai Dam MVRWSS Project Progress in PannaDocument4 pagesPawai Dam MVRWSS Project Progress in PannaWater Supply Project PannaNo ratings yet

- Case Study AppleDocument5 pagesCase Study AppleKim Ericka Bautista100% (1)

- User Manual - English (Vodacom)Document2 pagesUser Manual - English (Vodacom)OratilweNo ratings yet

- Lite-Puter DX-610/DX-626 User ManualDocument12 pagesLite-Puter DX-610/DX-626 User Manualescuela_danza_2No ratings yet

- Subaru Automatic Transmissions 4EAT Module 302 Technicians Reference BookletDocument37 pagesSubaru Automatic Transmissions 4EAT Module 302 Technicians Reference BookletFábio Silva de Oliveira100% (1)

- Shoes Shop PresentationDocument19 pagesShoes Shop PresentationArvindra SinhaNo ratings yet

- Philippine Health Information Exchange Objectives and ComponentsDocument3 pagesPhilippine Health Information Exchange Objectives and ComponentsAnna Lou PatalinghugNo ratings yet

- Anson Ortigas FPS Sell-Out Report Week 2 JuneDocument30 pagesAnson Ortigas FPS Sell-Out Report Week 2 JuneRevssor PeraltaNo ratings yet

- CM20150930 35537 44540Document2 pagesCM20150930 35537 44540fangrui maiNo ratings yet

- Meter Comparison Table: Powerlogic Power Monitoring and Control SystemsDocument11 pagesMeter Comparison Table: Powerlogic Power Monitoring and Control SystemsRomi AntonNo ratings yet

- DIGITUS DA-10287 Bluetooth Speaker ManualDocument7 pagesDIGITUS DA-10287 Bluetooth Speaker Manualbuns301No ratings yet

- Standard Specification For Security AlarmsDocument52 pagesStandard Specification For Security AlarmsEren YedeNo ratings yet

- Meters EPM Modbus A2Document2,733 pagesMeters EPM Modbus A2Gerardo RamirezNo ratings yet

- KA7630/KA7631: Fixed Multi-Output RegulatorDocument6 pagesKA7630/KA7631: Fixed Multi-Output RegulatorTecnico GenioNo ratings yet

- 1992 Toyota Previa Electrical DiagramDocument175 pages1992 Toyota Previa Electrical DiagramTam DominhNo ratings yet

- MSX Computing - Dec 1985-Jan 1986Document84 pagesMSX Computing - Dec 1985-Jan 1986BulesteNo ratings yet

- Gold Medals List 2013Document10 pagesGold Medals List 2013Naveed Khan AbbuNo ratings yet

- Synology DS1019 Plus Data Sheet EnuDocument6 pagesSynology DS1019 Plus Data Sheet EnuSteve AttwoodNo ratings yet

- Business Plan Report-Auto-Acoustic IncDocument10 pagesBusiness Plan Report-Auto-Acoustic IncLongyin WangNo ratings yet

- Fisher 500BDocument8 pagesFisher 500BGam Ma ZacNo ratings yet

- Simranjeet's ResumeDocument1 pageSimranjeet's ResumeGurjeet kaur RanaNo ratings yet

- Bim Contract IssuesDocument9 pagesBim Contract IssuesEl ZharNo ratings yet

- BS 1501-2 (1988) PDFDocument30 pagesBS 1501-2 (1988) PDFAdesina AlabiNo ratings yet

- Chassis DTC Summaries: Quick Reference Diagnostic GuideDocument20 pagesChassis DTC Summaries: Quick Reference Diagnostic GuideAhmedAlbarragNo ratings yet

- Vehicle Tracking Using Android AppDocument2 pagesVehicle Tracking Using Android AppmonkeNo ratings yet

- Stable and Highly EfficientDocument10 pagesStable and Highly EfficientNexgen TechnologyNo ratings yet

- Subroutines: Nithin S. EEE DeptDocument33 pagesSubroutines: Nithin S. EEE DeptabcdefgNo ratings yet

- Natural gas installation applicationDocument1 pageNatural gas installation applicationAserNo ratings yet

- Taxonomy of Architectural StylesDocument4 pagesTaxonomy of Architectural StylesMason MountNo ratings yet

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Implementing an Integrated Management System (IMS): The strategic approachFrom EverandImplementing an Integrated Management System (IMS): The strategic approachRating: 5 out of 5 stars5/5 (2)

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyFrom EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNo ratings yet

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)

- ASE A1 Engine Repair Study Guide: Complete Review & Test Prep For The ASE A1 Engine Repair Exam: With Three Full-Length Practice Tests & AnswersFrom EverandASE A1 Engine Repair Study Guide: Complete Review & Test Prep For The ASE A1 Engine Repair Exam: With Three Full-Length Practice Tests & AnswersNo ratings yet

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Driver CPC – the Official DVSA Guide for Professional Goods Vehicle Drivers: DVSA Safe Driving for Life SeriesFrom EverandDriver CPC – the Official DVSA Guide for Professional Goods Vehicle Drivers: DVSA Safe Driving for Life SeriesNo ratings yet

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- How to Design and Install In-Car Entertainment SystemsFrom EverandHow to Design and Install In-Car Entertainment SystemsRating: 5 out of 5 stars5/5 (1)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeFrom EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeRating: 4 out of 5 stars4/5 (130)

- LS Swaps: How to Swap GM LS Engines into Almost AnythingFrom EverandLS Swaps: How to Swap GM LS Engines into Almost AnythingRating: 3.5 out of 5 stars3.5/5 (2)