Professional Documents

Culture Documents

Heat Transfer Modeling in Multi-Layer Cookware Using Finite Element Method

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heat Transfer Modeling in Multi-Layer Cookware Using Finite Element Method

Copyright:

Available Formats

97

International Journal of

Science and Engineering Investigations vol. 1, issue 1, February 2012

Heat Transfer Modeling in Multi-Layer Cookware Using Finite

Element Method

Mohammadreza Sedighi

1

, Behnam Nilforooshan Dardashti

2

1

Young Researchers Club, Islamic Azad University Bueenzahra Branch, Bueenzahra, Iran

2

Mechanics Department, Islamic Azad University Bueenzahra Branch, Bueenzahra, Iran

(

1

MR.Sedighi67@gmail.com,

2

B.Nilforooshan@gmail.com)

Abstract-Temperature and its distribution (TD) on the surface

that contacts food are important parameters in improving

cookware performance. Heat capacity of utensil material and

its inertness to the contents are also significant. Multi-layer-

plate (MLP) provides improved thermal and chemical

properties. In this study the main objectives are to find the best

structure (single or multi-layer) and materials to provide

maximum temperature degree and uniform TD up side surface

of pan. And also heat retaining of used metals with goal of

improving the thermal quality of pan to economize the energy.

To achieve this aim were employed Finite Element Method

(FEM) for analyzing transient thermal behavior of applied

materials. The analysis has been extended for different metals,

we achieved the best temperature profile and heat retaining in

Copper/ Stainless Steel MLP.

Keywords- Cookware, Energy optimization, Heat retaining,

Laminated plate, Temperature distribution.

I. INTRODUCTION

We can meet the wide variety of demands such as superior

mechanical and thermal properties by using multi materials

together [1], [2]. Choosing of multi-layer structure and

materials of layers can be effective on improving TD and heat

storing. It can optimize the energy consumption. The energy

obtains mainly from burning gas and electrical resistivity. The

heat is not uniformly spread over the pan in both methods.

Using MLP causes regular TD on the top while bottom heated

irregularly [3], [4], [11].

Kitchens are one of the places where deals with this

phenomenon daily in cookware application. This leads us to

two considerations: thermal diffusivity and reactivity. Thermal

diffusivity determines how fast the pan will heat up. We do

not have to concern ourselves with the thermal properties of

materials only, but we need to make sure that the materials we

use in our cookware do not harm us or adversely affects the

taste of our food [24]. For this reason, in addition to the high

thermal diffusivity, we would also like non-reactive materials.

copper and aluminum have high thermal diffusivity but both

of them reacts readily to foods (copper and aluminum can

threat healthy [21], [22]) while some materials like stainless

steel, the least reactive of all popular materials used in

cookware, also has the low thermal diffusivity. By combining

the non-reactive surface of some materials such as stainless

steel with the thermal properties of copper or aluminum,

achieves the best results [5]. Consequently, the pan should be

constructed of conductive metal in bottom layer such as

copper and aluminum that are great conductor of heat and

non-reactive metal therefore safe to use with any food product

in upside of pan which is exposed to food [6].

In the other hand cast iron has a large heat capacity as

compared with the other materials. When the cooking task

requires the ability to maintain consistent and ample amount

of heat, cast iron is desirable. Even after you remove your cast

iron from the heat source, the heavy metal of pan keeps the

food warm. Also It is easy to use and care for wide range of

cooking. These attributes make it such a good cookware [7].

We used Grey Cast Iron (GCI) because it has greater thermal

properties [8], [9].GCI's high thermal conductivity and are

often exploited to make cast iron cookware.

Reference [10] has optimized thickness and material of the

bottom layer containing different alloys of aluminum or

copper. It showed that the optimum thickness is 8 (mm) for

copper and 67 (mm) for aluminum. As demonstrated in [12]

for the stainless steel and titanium in second layer, the TD are

almost equivalently.

In this paper, at first we represented advantage of using

MLP to provide the more uniform TD than single layer by

comparison of the Cu and Cu/SSt pan. We used multi-layer

pan by bonding highly conductivity and non-reactive materials

consist of Al/Cr-Ni, Al/SSt, Cu/Cr-Ni, Cu/SSt and GCI as

single layer pan. We found the best metals in the mentioned

metals to provide the maximum temperature degree and

uniform TD on food preparation surface of pan and finally

best heat retaining for constructing pan product with optimum

performance.

In this study, we have employed FEM to calculate the

temperature profile all over the pan and we showed how much

wall of pan affects in heat transfer causes highly temperature

gradients.

International Journal of Science and Engineering Investigations, Volume 1, Issue 1, February 2012 98

www.IJSEI.com Paper ID: 10112-20

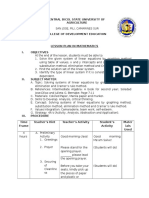

TABLE I. SYMBOLS AND THICKNESSES

Metals Symbols Thicknesses

Copper Cu 8 (mm)

Aluminum Al 6.5 (mm)

Stainless Steel SSt 2 (mm)

Chromium- Nickel Cr-Ni 2 (mm)

Grey Cast Iron

(single layer)

GCI 10 (mm)

II. MODELING

A. Boundary Condition and Geometry

As we want to model irregularly heating we constrained

annular part of the circular surface of bottom side pan, which

illustrated in Fig. 1 as r, by constant temperature about 773

(K). There is a geometrical symmetry so the system can be

modeled by rectangle plane with length of the pan radius and a

thin and long rectangle as wall of pan. Because of the

symmetry, the temperature gradients at the centre of plate

along the y-axis have zero value. Hence there is no heat flux at

the centre of plate along the y-axis. Side of pan has convection

heat transfer with air in ambient temperature. We have taken

thickness of layers according to Table I. r is 2 (cm). The

ambient temperature and the coefficient of heat transfer have

been assumed as 293 (K) and 17 (W/ (m.K)), respectively. In

addition, it is also assumed that the pan is filled up by water

with boiling temperature, and the coefficient of heat transfer

between the pan and the water is 50 (W/ (m.k)).

B. Meshing

The model was meshed with PlANE55.this element can be

used as a plane element or as an axis-symmetric ring element

with a 2-D thermal conduction capability and it capable to

modeling the axis-symmetric geometry. The element has four

nodes with a single degree of freedom, temperature, at each

node. The element is applicable to a 2D, steady-state or

transient thermal analysis.

Figure 1. 2D bi-layer model in numerical analysis and positions of different

selected nodes, named T1-T6

III. FINITE ELEMENT METHOD

In the finite element method, a given computational

domain is subdivided as a collection of a number of finite

elements, subdomains of variable size and shape, which are

interconnected in a discrete number of nodes. The solution of

the partial differential equation is approximated in each

element by a low-order polynomial in such a way that it is

defied uniquely in terms of the solution at the nodes. The

global solution can then be written as series of low-order

piecewise polynomials with the coefficients of series equal to

the approximate solution at the nodes [13].

With the advent of digital computers, discrete problems

can generally be solved readily even if the number of elements

is very large. As the capacity of all computers is finite,

continuous problems can only be solved exactly by

mathematical manipulation. The available mathematical

techniques for exact solutions usually limit the possibilities to

over-simplified situations [14].

Various discretization methods have been used in the past

for numerical solution of heat conduction problems. It must be

emphasized that particularly in the case of nonlinear heat

transfer problems the numerical solution must always be

validated [13].

Use to solve the transient heat conduction process is

governed by:

( ) ( ) ( )

x y

T T T

k k c

x x y y t

c c c c c

+ =

c c c c c

(1)

The finite element method can be applied as:

KT CT P + = (2)

The denotes the material density, c the specific heat of

material at constant pressure, and C the damping matrix of the

thermal system. In the finite element analysis, the numerical

integration is carried out through N time steps. Between two

adjacent time steps, the jth and (j-1)th, we can have the

following approximation:

j= (1, 2, , N)

1

1

(1 )

j j

j j

T T T

T T

dT

dt t

= +

=

A

(3)

The is the relaxation parameter. The finite element

equation (2) becomes:

1

(1 ) . .

j j

C C

K T K T F

x x

( (

+ = +

( (

A A

(4)

By solving (4), temperature fields T at different time steps

are found [15].

International Journal of Science and Engineering Investigations, Volume 1, Issue 1, February 2012 99

www.IJSEI.com Paper ID: 10112-20

There are many papers, used FEM to calculate thermal

buckling of laminated plate subjected to uniform or non-

uniform temperature [16]-[20]. As stated earlier we employed

finite element analysis of heat transfer to calculate the TD in

laminated plate which heated non-uniformly.

TABLE II. DENSITY AND THERMAL PROPERTIES OF METALS

Symbol

Density

(kg/m

3

)

K (W/m.K)

C (J/Kg.K)

T=200K T=400K T=600K T=800K

Cu

8933

413

356

393

397

379

417

366

433

Al

2700

237

798

240

949

231

1033

218

1146

Cr-Ni 8400

12

420

14

480

16

525

21

545

SSt 8055

15.1

480

17.3

512

20

559

22.8

585

293K 473K 573K

773K

GCI 7340

55

490

41

37

585

31

675

The properties of applied metals are according to [8], [23].

IV. FINITE ELEMENT ANALYSIS

We analyzed the model by using different materials in

transient behavior to reach steady state. In this part we want to

analyze TD and temperature degree on top surface of pan.

After that, in second step we changed the boundary conditions

and again we analyzed transient behavior to reach equilibrium

point for analyzing the heat retaining of used metals. We

employed finite element method with ANSYS program to find

both better structure and materials that provides more uniform

TD and heat retaining in the pan production. The time step is

determined automatically. The time step size is increased or

decreased during solution, depending on how the model

responds. It gets shorter for any significant amount of

deformation to occur.

V. RESULTS

A. Temperature Distribution of single layer in comparison

with bi-layer structure

Its obviously when the model reached to steady state, the

maximum temperature on upside surface of Cu pan is higher

than Cu/SSt, its771.618 (K) and 769.66 (K) respectively. But

the difference between maximum and minimum temperature

on food preparation surface of Cu and Cu/SSt pan in steady

state is 32 and 25 degrees respectively. It showed that TD in

Cu/SSt multi-layer pan is more uniform than Cu single layer

pan. In Fig. 2, 3 are illustrated the differences between

maximum and minimum temperature during analysis time. It

is observed that this difference for Cu in beginning of analysis

is about 80 degrees greater than Cu/SSt and it is decreased to 7

degrees in steady state. Fig. 2, 3 represent that MLP provides

more uniform TD upside surface of multi-layer pan than

single layer.

Figure 2. Time variation of differences between maximum and minimum

temperature on food preparation surface of Cu and Cu/SSt pan

Figure 3. Time variation of differences between maximum and minimum

temperature on food preparation surface of Cu and Cu/SSt pan

B. Temperature Distribution in Different Materials

We used combinations of metals in bi-layer structure

consist of Cu/SSt, Cu/Cr-Ni, Al/SSt and Al/Cr-Ni. It is

predictable that minimum temperature observed at edge of

wall. There is highly temperature gradient so it represented

high convection heat transfer side of pan. We have the regular

and uniform TD in all MLP as compared with single layer and

between these MLP, Cu/SSt combination has maximum

temperature profile. The minimum temperature in Cu/SSt is

greater than minimum temperature of other combinations and

its about451.1 (K) illustrated in Fig. 4.

0

50

100

150

200

250

300

350

400

450

0 100 200 300 400 500 600 700

Time(s)

T

m

a

x

-

T

m

i

n

Cu/SSt

Cu

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

80 130 180 230 280 330 380 430 480 530 580 630 680

Time(s)

T

m

a

x

-

T

m

i

n

Cu/SSt

Cu

International Journal of Science and Engineering Investigations, Volume 1, Issue 1, February 2012 100

www.IJSEI.com Paper ID: 10112-20

Figure 4. 3D-TD of Cu/SSt bi-layer pan at steady state

Fig. 4 illustrates uniform TD upside surface of Cu/SSt pan

because we used high conductive metal in bottom layer to

transfer heat quickly but in second layer is used a metal that

has too low conductivity to transfer heat quickly so the heat

has opportunity to spread over first layer which has high

conductive metal. Therefore uniform heat flux from this layer

is transferred to second layer relatively. In another word it is

like that we used a heat source which spread the heat

uniformly over the plate.

Different positions of pan at different time after analysis

start, reach to steady state so we chose 4node at various point

of pan called T1-T4 that illustrated in Fig.1.

As stated earlier we solved this model with another

combination as follow. The minimum temperature of Al/SSt,

Cu/Cr-Ni, and Al/Cr-Ni after 1500 second reached to steady

state are 447.266 (K), 431.441(K), and 428.232 (K)

respectively. In all them we observed regular TD on surface

which contact with foods while heated irregularly because of

using bi-layer plate. Transient thermal behavior of all bi-layer

pans to reach steady state illustrated in Fig. 5-8

You see some differences among Fig. 5, 8. The T2 node in

combination consists of Al after 30 second is higher than Cu

combination. It is predictable because thickness of Al is

lower than Cu thickness so the heat flux reaches to T2 point

sooner.

Figure 5. Time variation of temperature in Cu/SSt pan

Figure 6. Time variation of temperature in Cu/Cr-Ni pan

Figure 7. Time variation of temperature in Al/Cr-Ni pan

Figure 8. Time variation of temperature in Al/SSt pan

We compared transient response of T4 node with all

combinations. Temperature variations of T4 node in all

combinations during first 100 seconds are same

approximately. After this time we observed some differences

between bi-layer pan containing SSt and bi-layer pan

including Cr-Ni layer obviously. Insofar as after 500 seconds

it is apparent about 17 degree differences between them as

shown in Fig. 9.

293

343

393

443

493

543

593

643

693

743

793

0 100 200 300 400 500 600

Time(s)

T

e

m

p

e

r

a

t

u

r

e

(

K

)

T1

T2

T3

T4

293

343

393

443

493

543

593

643

693

743

793

0 100 200 300 400 500 600

Time(s)

T

e

m

p

e

r

a

t

u

r

e

(

K

)

T1

T2

T3

T4

293

343

393

443

493

543

593

643

693

743

793

0 100 200 300 400 500 600

Time(s)

T

e

m

p

e

r

a

t

u

r

e

(

K

)

T1

T2

T3

T4

293

343

393

443

493

543

593

643

693

743

793

0 100 200 300 400 500 600

Time(s)

T

e

m

p

e

r

a

t

u

r

e

(

K

)

T1

T2

T3

T4

International Journal of Science and Engineering Investigations, Volume 1, Issue 1, February 2012 101

www.IJSEI.com Paper ID: 10112-20

Figure 9.Temperature variation comparison of T4 node for all combination bi-

layer pans

Figure 10. Temperature variation of Thermal diffusivity in SSt and Cr-Ni

This difference is originated from SSt and Cr-Ni

properties. Thermal diffusivity of SSt is greater than Cr-Ni

and by increasing temperature, differences of thermal

diffusivity of SSt and Cr-Ni became greater that illustrated in

Fig 10.

Cast iron has played role in cookware.GCI has high heat

capacity and density so we compared the metals that are

analyzed earlier with GCI. We have done the above processes

for single layer GCI.

By comparison transient behavior of GCI and combinations,

we observed after about 90 second is provided uniform TD top

surface of the multi-layer pan relatively whereas GCI cannot

provide the uniform or even regular TD during the analysis

time to reach steady state. Fig. 12 illustrated that TD in single

layer is not uniform as stated earlier clearly, especially in low

conductivity metals such as GCI. By comparison of T1, T2

,T3 nodes of model in all materials, Fig. 5-8, 11, it is showed

that which one can provide more uniform TD. As a result

Cu/SSt combination provided most uniform TD and highest

temperature degree on surface which contact with foods

between studied cases. After it the combinations consist of Al

and finally GCI pan.

Figure 11. Time variation of temperature in GCI pan

Figure 12. TD of GCI single layer pan at steady state

C. Heat Retaining

After that the model reached to steady state we changed the

boundary conditions of pan to analyzing the heat retaining of

the model. Hence we modeled the heated pan to transfer the

heat just with air at ambient temperature for cooling. The

results of this analysis are illustrated in Fig. 13-17 for all used

metals. We compared the T5 node of model with all applied

metals as shown in Fig. 18. It represents the heat storing

differences of studied cases clearly. It shows that the pans

consist of Cu can retain the heat better than others even GCI.

But the cookware containing Al cannot retain the heat well in

compare with Cu and GCI. The GCI because of the high

specific heat and density and low conduction coefficient have

low thermal response so it has good heat retaining. You see

that temperature of T4 node first increase and then it decrease

because T4 node has minimum temperature in compared with

all over the pan so there is a heat flux from high to low

temperature degree. In the other hand conduction coefficient

of metals is very greater than convection coefficient of air.

293

313

333

353

373

393

413

433

453

473

0 100 200 300 400 500

Time(s)

T

e

m

p

e

r

a

t

u

r

e

(

K

)

Al/CrNi

Cu/CrNi

Al/SSt

Cu/SSt

3.00E-06

3.20E-06

3.40E-06

3.60E-06

3.80E-06

4.00E-06

4.20E-06

4.40E-06

300 320 340 360 380 400

Temperature(K)

T

h

e

r

m

a

l

d

i

f

f

u

s

i

v

i

t

y

St Cr-Ni

293

343

393

443

493

543

593

643

693

743

793

0 200 400 600 800

Time(s)

T

e

m

p

e

r

a

t

u

r

e

(

K

)

T1

T2

T3

T4

International Journal of Science and Engineering Investigations, Volume 1, Issue 1, February 2012 102

www.IJSEI.com Paper ID: 10112-20

Figure 13. Time variations of temperature for cooling the Cu/SSt pan

Figure 14. Time variations of temperature for cooling the Cu/Cr-Ni pan

Figure 15. Time variations of temperature for cooling the Al/SSt pan

Figure 16. Time variations of temperature for cooling the Al/Cr-Ni pan

Figure 17. Time variations of temperature for cooling the GCI pan

Figure 18. Temperature variation comparison of T5 node for all metals in

cooling step

VI. CONCLUSION

This paper describes the numerical, finite element method,

analysis of transient thermal behaviors of the single metal and

MLP heated irregularly to improving the thermal behavior of

cookware. First we showed that multi-layer structure provides

more uniform TD upside surface of pan. By combining metals

of higher thermal conductivity with metals of lesser

conductivity but higher inertness achieved the best in cooking

therefore the thermal quality advantage of laminated plate in

the cookware deduced as reliable results. As can be seen from

results, the Cu/SSt in MLP provides highest temperature

degree and most uniform TD upside surface of pan that

exposed to food in addition it can retain the heat well in

compared with others.

There are some Suggestions for optimizing the cookware.

From this analysis the result suggests that find the optimum

thickness of layers and various alloys of appropriate metals.

After thickness and material of pan the other

considerations are the shape and sizes of the pan that causes

maximum heat transfer to food and provides the desirable TD.

Another suggestion to optimize cookware and cooking is,

compared that which type of heat source consist of burning

gas or electrical resistivity, will transfer more energy to

cookware and improve the heat source to spread the heat

uniformly. Finally thermal stress and thermal expansion in

MLP should be considered for MLP manufacturing.

290

340

390

440

490

540

590

640

690

740

790

0 500 1000 1500 2000 2500 3000

Time(s)

T

e

m

p

e

r

a

t

u

r

e

(

K

)

T1

T3

T4

T5

T6

290

340

390

440

490

540

590

640

690

740

790

0 500 1000 1500 2000 2500 3000

Time(s)

T

e

m

p

e

r

a

t

u

r

e

(

K

)

T1

T3

T4

T5

T6

290

340

390

440

490

540

590

640

690

740

790

0 500 1000 1500 2000 2500 3000

Time(s)

T

e

m

p

e

r

a

t

u

r

e

(

K

)

T1

T3

T4

T5

T6

290

340

390

440

490

540

590

640

690

740

790

0 500 1000 1500 2000 2500 3000

Time(s)

T

e

m

p

e

r

a

t

u

r

e

(

K

)

T1

T3

T4

T5

T6

290

340

390

440

490

540

590

640

690

740

790

0 500 1000 1500 2000 2500 3000

Time(s)

T

e

m

p

e

r

a

t

u

r

e

(

K

)

T1

T3

T4

T5

T6

290

340

390

440

490

540

590

640

690

740

790

0 500 1000 1500 2000 2500 3000 3500 4000

Time(s)

T

e

m

p

e

r

a

t

u

r

e

(

K

)

Cu-SSt

Al-SSt

Al-CrNi

Cu-CrNi

GCI

International Journal of Science and Engineering Investigations, Volume 1, Issue 1, February 2012 103

www.IJSEI.com Paper ID: 10112-20

REFERENCES

[1] K Y Rhee, W Y Han, H J Park, et al. Fabrication of Aluminum/Copper

Clad Composite Using Hot Hydrostatic Extrusion Process and Its

Material Characteristics [J]. Materials Science and Engineering, 2004,

384: 70-76

[2] J E Lee, D H Bae, W S Chung. Effects of Annealing on the Mechanical

and Interface Properties of Stainless Steel/Aluminum/Copper Clad-metal

Sheets[J]. Journal of Materials Processing Technology, 2007, 187-188:

546-549

[3] Sarkar A, Erdogdu F, Singh PR. Measurement of spatial variations of

heat transfer coefficient on flat surfaces for food processing applications.

In: Conference of food engineering. American Institute of Chemical

Engineers, New York, USA, 6 November 2001.

[4] Pan Z. Temperature distribution and heat transfer coefficient of a clam-

shell grill. In: Conference of food engineering. American Institute of

Chemical Engineers, New York, USA, 6 November 2001.

[5] Barham, Peter,The Science of Cooking2001 (Book Style), VIII, 244 p. 27

illus. ISBN 3-540-67466-7 Springer-Verlag Berlin Heidelberg New

York-5, pp. 58-62.

[6] Peter Prip, 39 Sefto Dr., Cranston, RI(US) 02905, Grill Top Cooking

Tool, United States Patent, Patent No: US6,644,176 B2, Nov 11, 2003

[7] By Tracy Barr,Cast Iron Cooking For Dummies, Publisher: Wiley, John

& Sons, Incorporated, Format: NOOK Book (eBook) , 360pp Pub. Date:

April 2011- ISBN-13: 9781118053188, ch1

[8] Rena L. Hecht, et al. Thermal Transport Properties of Grey Cast Irons,

SAE 962126.

[9] W. L. Guesser, Thermal Conductivity of Gray Iron and Compacted

Graphite Iron Used for Cylinder Heads, Revista Materia, v. 10, n. 2, pp.

265-272, ISSN 1517-7076, Junho de 2005.

[10] TahirAyata, et al. Predictions of temperature distributions on layered

metal plates using artificial neural networks, Energy Conversion and

Management 47 (2006) 2361-2370, Elsevier, 28November 2005.

[11] Anthony J. Abrami, poughkeepsie, Temperature Controlled Multi-Layer

Module, United States Patent, Patent No: 5,539,186, Jul. 23, 1996

[12] B. Nilforooshan Dardashti, M. R Sedighi, Numerical Solution of Heat

Transfer In Single and Multi-Metal Pan, Applied Mechanics and

Materials Vols. 148-149 (2012) pp 227-231, Trans Tech Publications.

[13] Philip Richardson, Thermal technologies in food processing, first

published 2001, woodhead Publishing and CRC Press, pp. 97-101

[14] O. C.Zienkiewicz, CBE, FRS, The Finite Element Method: Its Basis and

Fundamentals, (book style) CIMNE, ISBN 0 7506 6320 0, sixth edition

2005, Elsevier Butterworth- Heinemann, pp. 12

[15] Qing Li, Grant P. Steven, Thermo elastic Topology Optimization For

Problems With Varying Temperature Fields, Journal of Thermal

Stresses, 24:347-366, 2001 Taylor & Francis.

[16] Chen Lien-Wen, Chen Lei-Yi,Thermal buckling analysis of laminated

cylindrical plates by the finite element method. ComputStruct

1990;34(1):718

[17] Noor AK, Peters JM, Finite element buckling and postbuckling solutions

for multilayered composite panels, Finite Element Analysis and Design,

1994; 15(4):343367.

[18] Chandrashekhara K, Thermal buckling of laminated plates using a shear

exible nite element. Finite Element Analysis and Design,

1992;12(1):5161

[19] Kari R. Thangaratnam, Thermal buckling of composite laminated plates,

Computers & Structure, v 53 (1994), pp 1193-1204, Elsevier, Available

online 12 February 2003.

[20] S.Maloy K. Singha, Thermal postbuckling analysis of laminated

composite plates, Composite Structure 54 (2001) 453-458, 2001 Elsevier

Science Ltd.

[21] Arezoo Campbell , The role of aluminum and copper on

neuroinflammation and Alzheimer's disease, Journal of Alzheimer's

Disease, IOS Press, Volume 10, Number 2-3/2006, pp. 165-172

[22] Poonam Raj, et al, Leaching of aluminum from cookwares- a review,

Environmental Geochemistry and Health (1997), 19, 1-18.

[23] Incropera, Frank P, Introduction to heat transfer, (Book style) Publisher:

Wiley & Sons, Inc. 4th ed,

[24] http://www.cookingforengineers.com, Equipment and Gear; Commons

Materials of Cookware, Michael Chu, 2005

Behnam Nilforooshan Dardashti was born in

Tehran, Iran, in 1974. He got M.Sc. degree in Nuclear

Engineering, 1997-2002, and B.Sc. in Solid State

Physics, 1991-1997.

He is currently Instructor-Member of Scientific Board

Islamic Azad University Bueen Zahra branch, Qazvin, Iran. He

published several books and articles such as Critical Heat Flux

Prediction by using Radial Basis Function and Multilayer Perceptron

Neural Networks: A Comparison Study, Nuclear Engineering and

Design, 237, 2007, 377- 38, general Physics (Mechanics and Heat)

(Azarbad, Tehran, 2008, 2

nd

edition, to be published), Prediction of

Film-Boiling Heat Transfer Coefficient Using Modular Neural

Network", Nuclear Energy for New Europe, 2006, NENE-620etc. His

areas of interest include heat transfer, Fluid mechanics, Muon

catalyzed fusion.

Mohammadreza Sedighi was born in Tehran, Iran, in

1988. He is studying the last term of Mechanical

Engineering Fluid &Thermal Approach in IAU Karaj

branch, Iran.

He published Numerical Solution of Heat Transfer In

Single and Multi-Metal Pan, Applied Mechanics and Materials,

2011. His research interests include heat transfer impinging jets,

Computational Simulation and CFD applications in heat transfer and

fluid dynamics science.

Mr. Sedighi joined Young Researchers Club since 2008 up to now.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 1.6.1 Review - Expressions, Equations, and Inequalities (Review)Document30 pages1.6.1 Review - Expressions, Equations, and Inequalities (Review)Rolyn Grace Domagoso VergaraNo ratings yet

- System of Linear EquationsDocument13 pagesSystem of Linear EquationsKomal ShujaatNo ratings yet

- Metabolic Response To Repetitive Lifting Tasks: Predetermined vs. Self-Selected PaceDocument4 pagesMetabolic Response To Repetitive Lifting Tasks: Predetermined vs. Self-Selected PaceInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Vapour-Phase Dehydrogenation of Ethanol Using Heterogeneous Modified Kaolinite CatalystDocument3 pagesVapour-Phase Dehydrogenation of Ethanol Using Heterogeneous Modified Kaolinite CatalystInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Evaluation Methods of Limiting Switching Overvoltage During Line EnergizationDocument6 pagesEvaluation Methods of Limiting Switching Overvoltage During Line EnergizationInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Performance Evaluation of Petroleum Refinery Wastewater Treatment PlantDocument6 pagesPerformance Evaluation of Petroleum Refinery Wastewater Treatment PlantInternational Journal of Science and Engineering InvestigationsNo ratings yet

- The Modeling of Electric Arc in High Voltage Circuit Breakers With Use of Schavemaker Model and Negative FeedbackDocument4 pagesThe Modeling of Electric Arc in High Voltage Circuit Breakers With Use of Schavemaker Model and Negative FeedbackInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Temporal Variation of Soil Surface Temperature in Dalugha (Cyrtosperma Merkusii (Hassk.) Schott) Swamp HabitatDocument4 pagesTemporal Variation of Soil Surface Temperature in Dalugha (Cyrtosperma Merkusii (Hassk.) Schott) Swamp HabitatInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Biogas Production From Municipal Sewage Sludge Using Ultrasound Speeding Digestion ProcessDocument10 pagesBiogas Production From Municipal Sewage Sludge Using Ultrasound Speeding Digestion ProcessInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Biodiesel Production in Nigeria Using Cocoa Pod Ash As A Catalyst BaseDocument4 pagesBiodiesel Production in Nigeria Using Cocoa Pod Ash As A Catalyst BaseInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Ad-Hoc Optical Network ProtocolDocument4 pagesAd-Hoc Optical Network ProtocolInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Science and Engineering InvestigationsDocument4 pagesScience and Engineering InvestigationsInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Beneficiation and Characterization of A Benetonite From Niger Delta Region of NigeriaDocument5 pagesBeneficiation and Characterization of A Benetonite From Niger Delta Region of NigeriaInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Linear CongruencesDocument3 pagesLinear CongruencesJohn Albert ReyesNo ratings yet

- Aprendendo AL Com ISETLDocument401 pagesAprendendo AL Com ISETLjeancamposNo ratings yet

- 7th-Online-Class-Solving Problems Involving System of Linear Equation in Two VariablesDocument31 pages7th-Online-Class-Solving Problems Involving System of Linear Equation in Two VariablesMardy May-asNo ratings yet

- 5@ Properties of Rational NUMBERSDocument18 pages5@ Properties of Rational NUMBERSsvenkatk737No ratings yet

- AdvancedNumericalDifferentialEquationSolvingInMathematica PDFDocument372 pagesAdvancedNumericalDifferentialEquationSolvingInMathematica PDFJMATALLANAARENASNo ratings yet

- Steps To Solve A Linear Programming Problem - SuperprofDocument11 pagesSteps To Solve A Linear Programming Problem - SuperprofClement SundayNo ratings yet

- Ch-2 Solution of Non Linear EquationsDocument14 pagesCh-2 Solution of Non Linear EquationsAbel TayeNo ratings yet

- College Readiness StandardsDocument116 pagesCollege Readiness Standardsroyal5designNo ratings yet

- SeminarDocument22 pagesSeminarseid negashNo ratings yet

- C3 Course Work NotesDocument20 pagesC3 Course Work NotesRedouane KhechaNo ratings yet

- Quantitative Techniques and StatsDocument330 pagesQuantitative Techniques and Statsdiana nyamisaNo ratings yet

- Dr. Ahsanullah Baloch ProfessorDocument22 pagesDr. Ahsanullah Baloch ProfessorKashif ZiaNo ratings yet

- Math Quest Math Methods VCE 12 (2016 Edition)Document542 pagesMath Quest Math Methods VCE 12 (2016 Edition)NhiNo ratings yet

- PolymathDocument28 pagesPolymathAlan Cereceda EscalonaNo ratings yet

- Algebra - A Complete IntroductionDocument491 pagesAlgebra - A Complete IntroductionRichard FeynmanNo ratings yet

- Chapter 2 Lecture Notes - DivisibilityDocument70 pagesChapter 2 Lecture Notes - DivisibilityShatishwaran NaderajanNo ratings yet

- Bernoulli Differential EquationsDocument5 pagesBernoulli Differential EquationschrischovNo ratings yet

- 08 Chapter08 126-138Document13 pages08 Chapter08 126-138api-258749062No ratings yet

- 03 - Pair of Linear Equation in Two VariablesDocument13 pages03 - Pair of Linear Equation in Two VariablesSamveg ClassesNo ratings yet

- Word ProblemsDocument13 pagesWord Problemsbilal_kaimkhaniNo ratings yet

- Numerical Investigations of The Unsteady Flow in The Stuttgart Swirl Generator With OpenfoamDocument75 pagesNumerical Investigations of The Unsteady Flow in The Stuttgart Swirl Generator With OpenfoamsagarsrinivasNo ratings yet

- Chapter 3-2Document44 pagesChapter 3-2rawadNo ratings yet

- Simultaneous EquationsDocument14 pagesSimultaneous Equationsapi-2539015650% (1)

- Week01 - Introduction To NumericalDocument48 pagesWeek01 - Introduction To NumericalInunHazwaniKhairuddinNo ratings yet

- Solving Sle by Graphing MethodDocument21 pagesSolving Sle by Graphing Methodapi-313517608No ratings yet

- Algebra 2Document7 pagesAlgebra 2api-262893996No ratings yet

- Maple For Math Majors: Solve FsolveDocument21 pagesMaple For Math Majors: Solve FsolveAleksandar MicicNo ratings yet

- Module 6Document24 pagesModule 6Louie BarrientosNo ratings yet