Professional Documents

Culture Documents

Hoist Design

Uploaded by

Ezhil KumarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hoist Design

Uploaded by

Ezhil KumarCopyright:

Available Formats

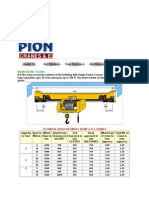

THE DESIGN We are concerned with the design of the hoisting arrangement of 2 tonne capacity of EOT crane ,which

will lift the load up to a distance of 8 meters. 1.DESIGN OF HOOK

HOOK

hook-cross-section

LINK

SHEAVE

Selection of section : The section is trapezoidal Selection of material : Mild steel Load to lift : 2 tonne Considering 50 % over loading. So the design load = 2 tonne+50% of 2 tonne = 3tonne Taking the help of (IS 3815-1969) for selection of material for 8 dimensions of crane hook.In IS 3815-1969 the nearest selection for 3.3 tonne is 3.2 tonne. For load 3.2, proof load (P) is 6.4 tonne. So C = 26.73P = 26.73 x 6.4 = 67.62 68 mm A = 2.75 C = 2.75 x 68 187 mm B = 1.31 C = 1.31 x 68 89mm D = 1.44 x C = 1.44 x 68 98mm E = 1.25C = 1.25 x 68 85mm F = C = 68mm G = 35mm G1 = M33, Pitch = 6mm (Coarse series) H = 0.93 x C = 0.93 x 68 63mm J = 0.75 x C = 0.75 x 68 51mm K = 0.92 x C = 63mm L = 0.7 x C = 0.7 x 68 48mm M = 0.6 x C = 0.6 x 68 41mm N = 1.2 x C = 82mm P = 0.5 x C = 34mm 34mm R = 0.5 x C = 0.5 x 68 U = 0.33 x C = 0.3 x 6820 mm Checking for strength Area of the section = x 63 x (41+8) = 1543.5 mm2 Centroid from a = (.05 x 8 x 65) 63/3+(.5 x 41 x 63) x (2 x 63)/3 x 68 x (41+8) = 38.571mm = 38.6 mm= h2 So centroid from b = 63-38.6=24.4mm =h1 0 = 34 +24.4 = 58.4mm r0 = A/(dA/u) dA/u = [b2+r2/h (b1-b2)] ln r2/r1 (b1-b2) =28.65mm r0 = A/(dA/u) = 1543.5 = 53.9 mm. 53.87 28.65 0-r0 = 58.4 53.9 = 4.5mm e=

Moment 0M = -P x = -3 x 58.4 = 175.2 (tonne x mm) Stress due to bending is given by b = M X 4 Ae r0-y For point a Y = -(e+h2) = -(4.5+38.6) = 43.1 mm For point b Y = r0-r1 = 53.9 3.4 = 19.9 mm Stress due to direct loading = P/A = 3/1543.5 = 1.9436 x 10-3 Tonne/mm3 Stress due to curvature of a ba = (-175.2) x -43.1 1543.5 x 4.5 {53.99 (-43.1)} = 0.0112 So total tress at a = 0.0112 + 1.9436 x 10-3 = 9.2642 x 10-3 Tonne/mm2 -90.85 Mp = 9.2642 kg/mm2 Stress due to curvature at b bb = -(-175.2) x . 19.99 . 1543.5x 4.5 (53.9 19.9) = 0.014763 So total stress at b bb + 1.9436 x10-3 = =0.014763 + 1.9436 x 10-3 =0.0167 tonne/mm2 163.84 MPa = 16.7 Kg/mm2 Let the material be class 4 carbon steel ( 55C 8) Ultimate tensil strength I 710MPa Design strength = Ultimate tensil strength Factor of safety = 710/4 = 177.5 MPa 163.84 > 177.5 So design is safe

Determination of length of threaded portion Pitch = 6mm Nominal dia of thread = 33 mm (G1) = d Considering the screw and thread are of single safest & square mean diameter of screw = dm = d- (p/2) = 33 (6/2) = 30 x 30) dm = 6/( = 1/ tan = tan-1 tan x 30)} = 3.640 { 6/( Let the co-efficient of fraction be 0.15 = 0.15 = tan So = 8.530 Torque required to resist the load )+ = W x dm* tan ( T 2 Where w is the weight of load is 3 tonne and the load of the hook itself. The maximum weight of the hook is 50kg (from the use of the soft ware Pro-Engineer) So T = 3050x 30 x tan (3.61+ 8.53) 2 =9866.42 Kgmm Stress induced in the screw Direct tensible stress (allowable or design) d02=4w/ d0 = core diameter of the screw. dc = d-p = 33-6 = 27 mm 1 = 4x 3050 272 = 52.24MR 5.326 kg/mm2 Torssional shear stress = 16T = 169866.42 de3 x 273 = 2.5529 Kg/mm2 = 25MP Maximum shear stress in the screw 2) + 4 ( 2 max = = (52.242 + 4 x 252) max = 36.15Mpa= Height of the nut a)Considering bearing action between the thread in engagement. Let n is no of thread in engagement with screw. Considering bearing action between nut & screw. Let the permissible bearing pressure =pi= 6 MR. We know

Pi = 4W (d2-dc2) x n So 6 = 43050 x 9.8 (332-272) x n N = 4 x 3050 x 9.8 (332-272) x 6 1.27 x 9.8 12.5 So the height of the nut is = 2 x 12.5 = 25mm. b) Considering shear failure of thread across root Shear stress induced =.W. dc(0.5xP) xn = . 3050 x 9.8 . x 27 x (0.5 x 6) x n = 117.46 n = 0.5 x 177.5 = 117.46 nn = 117.46 177.5 x0.5 = 1.32 = 2 So height is n x p = 2 x 6 =12mm Tacking the highest value 25mm Design of pin which will carry the dead load & the load of hook. We have to determine the dimension of t. n = M x Y I = M x (24) I2 Where I is moment of inertial about bh3 t x 243 x 2 12 12 Maximum bending moment for = M = x W x L Let L = 70 mm So M = x 3050 x 70 = 2 x 26687.5 Kgmm. = 2 x 261.715 x 103 N-mm = 2x 261.715 x 103 x 24 1 t x 243 2 177.5 = 1363 x 2 t t = 1363 x 2 = 15.2 MM 7.8 x 2 177.5 16 mm

Taking 20 m for additional safety Diameter of the projected portion The projected position is undergo only shearing failure. = 0.5 x design tensive stress. Design shear stress Force action on each side i.e. projected portion is 14.95 x 1033050/2 =1525 kg 15 KN So the minimum value of the height of the projected portion is 15mm, taking n= 40mm for screwing arrangement. = 15 x 103 /4 x dk2 = 177.5 x 0.5 = 15 x 103 /4) dk2 ( = dk2 = 15 x 103 x 4 177.5 x 0.5 x = dk2 = 15 x 103 x 4 177.5 x 0.5 x = 215.19 = 14.66 15mm Taking 20 mm for additional safety purpose. So that it can be turned to thread in size m20. Height of the projected portion P * x * dk = w/2 Where p = bearing pressure or crushing stress. Let p = 210 MPx Allow crushing stress =210/4 = 210/4 x x x 20 = 3050 x 9.8 2 x = 3050 x 9.8 x 5 2 x 20 x 210 = 3.56 mm x 4 = 14.024 =15 mm So the minimum value of the height of the projected portion is 15 mm, taking x = 40 mm for screwing arrangement. Design of link and the cover plate

coverplate

Thickness of link and cover plate should not be minimum. Let the material be (55C8). a)Hole fopr placing the pin which will carry the hook will be dk i.e. 20 mm. zchecking for the failure of link & cover plate combindely(as they are of same material and undergone same condition of failure). Mode of failure Tearing of cover plate & link at the edge. Crushing of cover plate and link. Breaking at the lowest cross section. i).Considering tearing of cover plate & link at the edge Experiments from the riveted joints have shown that if the distance between the centre of rivet and the edge is 1.5 times the diameter of the rivet.The element will not undergo the failure of tearing at the edge. The same condition is also applicable in our case. But for more safety reasons taking the distance between the centre of the projected element and the edge of the cover plate & linkis 2 times the dia of the projected element. So Z = 2 x dk = 2 x 20 = 40 mm Considering tensile failure at the lower cross section So d = w/2 A 177.5 = 3050 x 9.8/2 2 x x x 30 x = 3050 x 9.8/2 2 x 30 x 177.5

= 28/2 mm 1.4 mm Considering crushing failure Force = crushing(d) x projected area 3050 x 9.8 = crushing(d) x (20 x x) FOS = 3050 x 9.8 x 4 = 14.24 mm 15 mm 2 x 210 x 20 So taking maximum of x i.e 15 mm, So x = 15 mm

cover-plate-auto-cad

AutoCAD drawing Of Cover plate

auto_link Auto CAD

AutoCAD Drawing Of Link Design of shaft carrying the pulley

shaft to carry pully

Pulley

The weight of each cover plate is 2.5 kg. Weights of each link weigh 2 kg. So weight of 2 covers plate & 2 link Is 2 x 2.5 + 2 x 2 = 9 kg. So the total weight which the shafts carry is 3050 + 9 = 3059 3060 Each Side subjected to a load of 3060/2 = 1530 kg. The shaft is only subjected to Crushing failure (at the cover plate and link). Shear failure. Crushing failure (at the pulley)

Considering shear failure = f/a = allowable shear stress = 0.5 x 177.5 = 0 .5 x 177.5 = 22.2 MR FOS 4 Stress induced = 1530 x 9.8 = 150042 /4 x 302 /4 x 302 = 21.22 MPa As induced stress is less than that allowable stress, the design is safe Considering crushing failure at the cover plate Crushing stress = Force/Protected area Allowable stress = 240/4 = 60MPa Induced Crushing stress = Force Projected area = 3060 x 9.8 70 x 40 As allowable induced stress 60.86 KN. The selection is feasible. Design of Sheave

sheave

a = 40mm b = 30mm c = 7mm d = 18mm e = 1mm l = 10mm r = 12mm

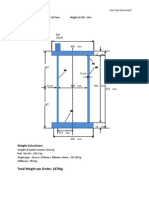

r4 = 8mm h = 25mm r1 = 4mm r2 = 3mm r3 = 12mm Material is caste iron Let dia of the sheave = 20 x d = 20 x 14 = 240mm The reference is made from Rudenko,N.Materials Handling Equipment ,Mir Publishers, Moscow(1969). P .86,Table 16. Drum design Drum grove size Referring to Redenko,N Materials Handing Equipment,Mir publishers,Moscow (1969),P.No.90 table 17. Considering standard groove of drum, for, diameter of wire 15 mm as it is nearest to 14mm. Drum diameter = sheeve diameter = 240 mm. r 1 = 0.53 x d (d 15) = 9mm s1 = 1.15d = 17mm C1 = 0.25 d = 5mm No. of turn on each side of drum Z = (hi/d) + 2 = Where H = Lifting Height. I = Ratio of the pulley system. D = Drum diameter 45 x 14 = 630 So Z = ( 8.00 x 2) + 2 x63 Z = 10 Full lenth of drum for one rope. L = (2HI + 7)Si (I = 2 assumed) D =(2 x 800 x 2 + 7)1.5 =34.75 35 cm The drum is made up of IS grade = SG 80/2 With stress = 480Mpa W = 0.02 x 630 = 10 = 22.6 23 mm Outside dia of the drum Do = D + 6d = 630 + 6 x 14 = 714mm

Inside dia of the drum = Di = D 2W = 630 2 x 25 = 584 mm Checking of strength Bending Stress in drum bend = 8WLD (D4 Di4) = 8 x 6200 x 9.8 x 35 x 630 x (6304 5844) = 0.0828MP Maximun Torque Tmax = W (D + d) 2 = 6200 x 9.8 (630 + 14) 2 = 19.564 x 106 Maximum Shear Stress = 16 Tmax D (D4 Di4) = 16 x 19.56 x 106 x 630 x (6304 5844) 1.523 MPx Direct Compressive Stress = W = c wSi = 6200 x 9.8 23 x 17 = 155.4MPx Maximum Stress in the Drum max2 = bend2 + c2 + 4 = (0.08282 +155.42 = 4 x 1.5232)1/2 < 480 MPx, S the Design is safe. Fastening Of Rope With The Drum For 14 mm dia Locating Dimension Pitch of screw = 53 mm T = 43 mm Screw size Lo = 18 mm L = 50 mm Plate C = 7 mm No. of fastenings = 1

Selection of Motor W = 3100 kg x 9.8 m/s2 V = 0.2m/sec So power required = 3100 x 9.8 x 0.2 = 6080.123Nm/sec = 6.08 Kwatt Taking 11 Kwatt 3 phase induction motor (flange type) of 11 KW (nearest to 6.08KW) Frame No. 132 M Flange designation F265B The speed is 1000 RPM By using gear box the speed can be reduced to 300 RPM GearBox Calculation Gearbox ratio = (Input RPM x x rope drum dia) (speed x no. of falls /2) = ( 980 x x .714) = 183.54 (3.00 x 4 ) Brake calculation Required Brake Torque = 1.5 x 716.2 x mech H.P. Motor RPM = 1.5 x 716.2 x 50.12 300 = 53.84 Nm Design of wormset Power = P = 6.08 Kwatt RPM of Worm = Nw = V x 60 d = 0.2 x 60 x 0.63 RPM of Worm Gear NG = 300 RPM So R = NG Nw = 300 6 Let = 14.5o Let the centre distance = C = 300 mm =0.3m Pitch circle diameter of the worm Dw = C.8750 = 3Pc 3.48 Dw = 3.8750 = 0.10020m 3.48 100mm Dw = 3Pc = 3Pa = 3 x x ma

So ma = Dw/3 = 100.2/3 = 10.63 mm 11mm Pitch circle dia of the gear Dg = 2C Dw = 2x 300 100 = 500 mm Velocity ratio = Ng/Nw = 50 Ng/Nw = Dg /(ma x Nw) 50 = Dg/(11 x Nw) Dg = 50 x 11 x Nw

Taking Ng = 1 , because Dw is closer to the calculated. So, Dg = 550 Dw = 2C Dg = 2 x 300 -500 = 50mm Face width of the gear b = 0.73 x Dw = 0.73 x 50 = 36.5 = 40 mm Static strength of Bronze d = 90MPa In worm drive irrespective of materials of worm and worm ger,the gear is weak. So design should be based on gear. Tangential load on the gear : Ft = mn y b = (d x Cv) mn y b Velocity factor Cv = 6 . 6 + Vg Vg = x Dg x Ng 60 = 8.69 Cv = 6 = 0.41 6 + 8.69 Form factor Y = 0.124 0.684 Ng = 0.11132 Tan = m x Nw Dw

= 11 x 1 50 = tan-1 (.22) = 12.4o Nominal Module = m (ma) x cos = 11 x cos 12.4 = 10.743 mm Ft = 90 x .41 x x 1o.743 x .11132 x 40 = 5545.47 N = 5.55 KN Power Capacity = P1 = Ft x Vg = 5.55 x 103 x 8.69 = 48.19 K watt Which is greater than capacity so the design is safe. Powe capacity of drive from wear point of view P2 = Dg x b x W x Vg = 550 x 40 x W x 8.64 W = .550 = Material combination factor. For worm and worm gear made up of hardened steel and phosphor bronze So, P2 = (550 / 1000) x 40 x .55 x 8.64 = 104.4 Kwatt Power capacityof the drive, from the heat dissipation point of view is given by : P3 = 3650 x C17 R+5 = 3650 x 300 17 50 + 5 = 361.99K watt So The safe power capacity is minimum i.e P1 = 48.19 Kw CONCLUSION : The design of the hoist of EOT crane is done Numerically .We can implement the design practically in industries for various lifting jobs. (For More Information Regarding This Topic Please Give Your Email id )

You might also like

- Gates, Hoisting ArrangementsDocument19 pagesGates, Hoisting Arrangementsteklador123456No ratings yet

- SHEAR (Vertical Reaction) : SolutionDocument4 pagesSHEAR (Vertical Reaction) : SolutionxtianNo ratings yet

- Overhead Crane Governing Bodies and Specs PDFDocument1 pageOverhead Crane Governing Bodies and Specs PDFscofiel1No ratings yet

- Steel Structure ST 37Document11 pagesSteel Structure ST 37aliNo ratings yet

- FinalDocument49 pagesFinalanon_118283479100% (1)

- Sectional MoiDocument7 pagesSectional MoiAnonymous sfkedkymNo ratings yet

- 2400 Tema DCDocument7 pages2400 Tema DCMasoodMiyanNo ratings yet

- Rope Drum Hoist For Overshot Gate PDFDocument12 pagesRope Drum Hoist For Overshot Gate PDFariza15100% (1)

- Trolley Winch DesignDocument16 pagesTrolley Winch DesignUtaya Kumar VeelmuruganNo ratings yet

- Water Control Gates TrainingDocument132 pagesWater Control Gates TrainingsaishankarlNo ratings yet

- Cap Screws: Sae J429 Grade IdentificationDocument6 pagesCap Screws: Sae J429 Grade IdentificationHomer SilvaNo ratings yet

- AISC 13th Slip Critical Bolt Capacity ASDDocument1 pageAISC 13th Slip Critical Bolt Capacity ASDdantevariasNo ratings yet

- Design of Rope Drum and Chain HoistsDocument19 pagesDesign of Rope Drum and Chain Hoistssuresh_501100% (1)

- Pipe Support - Type 3Document17 pagesPipe Support - Type 3Angelique SutantoNo ratings yet

- MonorailDocument13 pagesMonorailleodegarioporralNo ratings yet

- Design of Plate GirdersDocument30 pagesDesign of Plate GirdersTHULASI MNo ratings yet

- Trailer Overall Dimensions:: Page 1 of 11Document11 pagesTrailer Overall Dimensions:: Page 1 of 11Prem KumarNo ratings yet

- Static Resistance Bolted Circular Flange JointsDocument9 pagesStatic Resistance Bolted Circular Flange JointsBálint Vaszilievits-SömjénNo ratings yet

- Radial Gates Drawing Design - 2pgsDocument2 pagesRadial Gates Drawing Design - 2pgsPaolo AfidchaoNo ratings yet

- Trashrack DesignDocument12 pagesTrashrack DesignAnonymous b9DIaPTq6BNo ratings yet

- Calculation and Analyzing of Braces ConnectionsDocument71 pagesCalculation and Analyzing of Braces Connectionsjuliefe robles100% (1)

- Sumitomo Corporation: Checked by of Area: Turbine Build. Rev Dept StructuralDocument18 pagesSumitomo Corporation: Checked by of Area: Turbine Build. Rev Dept Structuralabhi aroteNo ratings yet

- Hilti Anchor DesignDocument7 pagesHilti Anchor DesignKenny100% (1)

- Prying ActionDocument8 pagesPrying ActionjoseherreramogollonNo ratings yet

- Steel JoistDocument20 pagesSteel JoistMahfuzur RahmanNo ratings yet

- Comparative Study of Steel Structures Design Using IS 800 PDFDocument8 pagesComparative Study of Steel Structures Design Using IS 800 PDFshivarajNo ratings yet

- Gantry Crane Load r2Document12 pagesGantry Crane Load r2Bang OchimNo ratings yet

- Hoist DesignDocument16 pagesHoist DesignluisparedesNo ratings yet

- V-340 OutDocument14 pagesV-340 OutSachin5586No ratings yet

- Vertical Brace ConnectionsDocument13 pagesVertical Brace ConnectionsAnkit GuptaNo ratings yet

- Brace Compression and Tension Capacity Design Charts As Per CSA S16 09 Rev1.5Document44 pagesBrace Compression and Tension Capacity Design Charts As Per CSA S16 09 Rev1.5Antonio LópezNo ratings yet

- Mi 1Document9 pagesMi 1XNo ratings yet

- Saddle Supports PDFDocument5 pagesSaddle Supports PDFsizmaruNo ratings yet

- Gantry Crane Beam Design Calculation PDFDocument2 pagesGantry Crane Beam Design Calculation PDFSOUFIANE ADIBNo ratings yet

- Tank 14m x12 M HeightDocument60 pagesTank 14m x12 M Heighthgag selim100% (1)

- Crane Design DataDocument4 pagesCrane Design DatapradeepqNo ratings yet

- Duct Design With StiffenersDocument67 pagesDuct Design With StiffenersRico CaraNo ratings yet

- Unsymmetric BeamsDocument51 pagesUnsymmetric Beamsfoufou2003100% (1)

- 4.3 Design Values of Bending Moments and Shear ForcesDocument7 pages4.3 Design Values of Bending Moments and Shear Forcesmn4webNo ratings yet

- The Flow Chart Below Can Be Used As A Guide To Design A Steel Beam MemberDocument27 pagesThe Flow Chart Below Can Be Used As A Guide To Design A Steel Beam MembernasyahrahNo ratings yet

- 9178 3Document72 pages9178 3govimanoNo ratings yet

- Lecture 8 Shaft DesignDocument65 pagesLecture 8 Shaft DesignYasir A. Al-Shataif100% (1)

- Crane Rail Selection: Calculation of Required Rail Head WidthDocument1 pageCrane Rail Selection: Calculation of Required Rail Head WidthMAHMOUD YOUNISNo ratings yet

- Anchor Chair Design CheckDocument5 pagesAnchor Chair Design CheckHomer SilvaNo ratings yet

- Design and Development of Overhead Monor PDFDocument5 pagesDesign and Development of Overhead Monor PDFFiroz PawaskarNo ratings yet

- WRC 297 RWE NODE 6340 25febDocument4 pagesWRC 297 RWE NODE 6340 25febnamasralNo ratings yet

- WF Monorail Beam MetricDocument21 pagesWF Monorail Beam MetricManish DuggadNo ratings yet

- Comparison Between Static and Dynamic Analysis of Elevated Water TankDocument10 pagesComparison Between Static and Dynamic Analysis of Elevated Water TankA RafiNo ratings yet

- Machine Design Project ReportDocument11 pagesMachine Design Project ReportMuhammad Abdullah100% (1)

- Calculation Note For Compressor Shelter - Rev ADocument54 pagesCalculation Note For Compressor Shelter - Rev AmaniaxpdfNo ratings yet

- Idea - Wheel CalculationDocument35 pagesIdea - Wheel Calculationbambang satryojatiNo ratings yet

- Columns DesignDocument60 pagesColumns DesignifsrebraNo ratings yet

- Handbook Os Structural StabilityDocument106 pagesHandbook Os Structural StabilityGuilherme Monteiro de CarvalhoNo ratings yet

- Hilti Bolt Design For CanadaDocument120 pagesHilti Bolt Design For Canadadeepteck00No ratings yet

- Analysis of Main Beam of Bridge Crane Based On ANSYSDocument5 pagesAnalysis of Main Beam of Bridge Crane Based On ANSYSInternational Journal of Research in Engineering and ScienceNo ratings yet

- Mathcad - 06-Loads On StaircaseDocument2 pagesMathcad - 06-Loads On Staircasedinu69inNo ratings yet

- Limit States Design of Crane Runway GirdersDocument7 pagesLimit States Design of Crane Runway GirdersRatna YanuarNo ratings yet

- Buried Pipe Thickness Calculations-GuidelinesDocument4 pagesBuried Pipe Thickness Calculations-Guidelines9703422499No ratings yet

- Hoist Design Procedure For EOT CraneDocument14 pagesHoist Design Procedure For EOT CraneKeerthi KumarNo ratings yet

- Workbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsDocument26 pagesWorkbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsShubham mishraNo ratings yet

- Mathur - How To Time EventsDocument370 pagesMathur - How To Time EventsVIJAY90% (29)

- Polyhydron Check ValveDocument2 pagesPolyhydron Check ValveEzhil KumarNo ratings yet

- Mathur - How To Time EventsDocument370 pagesMathur - How To Time EventsVIJAY90% (29)

- E-Auction Notice For Auction Sale of Immovable Properties With T&C For WebsiteDocument15 pagesE-Auction Notice For Auction Sale of Immovable Properties With T&C For WebsiteEzhil KumarNo ratings yet

- EIC E 1001 0 DSG 01 Series Direction Control Valve PDFDocument12 pagesEIC E 1001 0 DSG 01 Series Direction Control Valve PDFmaherNo ratings yet

- The Disinformation PlaybookDocument7 pagesThe Disinformation PlaybookEzhil KumarNo ratings yet

- Springer Text Books: S.No. Book Title Author Edition OpenurlDocument21 pagesSpringer Text Books: S.No. Book Title Author Edition OpenurlGustavo ReyesNo ratings yet

- 2-Latest EIC-E-1002-0 (DSG-03 Series Solenoid Operated Directional Valves)Document12 pages2-Latest EIC-E-1002-0 (DSG-03 Series Solenoid Operated Directional Valves)Sujeet KumarNo ratings yet

- TC 513Document25 pagesTC 513MuthuRaj TcsNo ratings yet

- Alkon Cast 204 MsdsDocument7 pagesAlkon Cast 204 MsdsEzhil KumarNo ratings yet

- TC 513Document25 pagesTC 513MuthuRaj TcsNo ratings yet

- Alkon Cast 204 MsdsDocument7 pagesAlkon Cast 204 MsdsEzhil KumarNo ratings yet

- 003 Heating ProcedureDocument1 page003 Heating ProcedureEzhil KumarNo ratings yet

- TallyDocument172 pagesTallyEzhil Kumar100% (1)

- Plate GirderDocument11 pagesPlate GirderEzhil Kumar50% (2)

- Chapter15 Plate GirdersDocument17 pagesChapter15 Plate GirdersnvnrevNo ratings yet

- Fuels and CombustionDocument26 pagesFuels and CombustionEjaz AhmedNo ratings yet

- Insulation Castables Application Procedure - Rev-2Document10 pagesInsulation Castables Application Procedure - Rev-2Ezhil KumarNo ratings yet

- Method For Melting of AluminiumDocument11 pagesMethod For Melting of AluminiumEzhil KumarNo ratings yet

- Limit State DesignDocument12 pagesLimit State DesignEzhil KumarNo ratings yet

- GSM 822 WDocument251 pagesGSM 822 WSamir SirohiNo ratings yet

- M 2 MDocument3 pagesM 2 MEzhil KumarNo ratings yet

- EOT CraneDocument84 pagesEOT CraneSambhav Poddar80% (5)

- DG Test CaseDocument3 pagesDG Test CaseEzhil KumarNo ratings yet

- Crane TipsDocument10 pagesCrane TipskhayagskiNo ratings yet

- Laser 1Document22 pagesLaser 1Mantu KumarNo ratings yet

- Research in NursingDocument54 pagesResearch in Nursingrockycamaligan2356No ratings yet

- Soal Ujian Tengah Semester Genap Sma Islam Diponegoro Surakarta TAHUN PELAJARAN 2020/2021Document5 pagesSoal Ujian Tengah Semester Genap Sma Islam Diponegoro Surakarta TAHUN PELAJARAN 2020/2021Dian OctavianiNo ratings yet

- Lesson 6 S and V AgreementDocument6 pagesLesson 6 S and V AgreementLinh Ngọc NguyễnNo ratings yet

- Data Sheet Physics 1 Module 10BDocument2 pagesData Sheet Physics 1 Module 10BBryanHarold BrooNo ratings yet

- Module 7 - Prob D-E Valuation and Concepts AnswersDocument3 pagesModule 7 - Prob D-E Valuation and Concepts Answersvenice cambryNo ratings yet

- Human Right and Humanitarian. by Solicitor KaturaDocument12 pagesHuman Right and Humanitarian. by Solicitor KaturaFlavian PangahNo ratings yet

- Chapter 6 Coming of SpainDocument4 pagesChapter 6 Coming of SpainJayvee MacapagalNo ratings yet

- Hyrons College Philippines Inc. Sto. Niño, Tukuran, Zamboanga Del Sur SEC. No.: CN200931518 Tel. No.: 945 - 0158Document5 pagesHyrons College Philippines Inc. Sto. Niño, Tukuran, Zamboanga Del Sur SEC. No.: CN200931518 Tel. No.: 945 - 0158Mashelet Villezas ValleNo ratings yet

- High Court Judgment On Ex Party DecreeDocument2 pagesHigh Court Judgment On Ex Party Decreeprashant pathakNo ratings yet

- 002 Constraints and Generalized Coordinates PDFDocument27 pages002 Constraints and Generalized Coordinates PDFNiveCeciliaNo ratings yet

- Rules of SyllogismDocument6 pagesRules of Syllogismassume5No ratings yet

- ADDICTED (The Novel) Book 1 - The Original English TranslationDocument1,788 pagesADDICTED (The Novel) Book 1 - The Original English TranslationMónica M. Giraldo100% (7)

- Vice President Marketing Communications in Washington DC Resume Mary GotschallDocument3 pagesVice President Marketing Communications in Washington DC Resume Mary GotschallMaryGotschallNo ratings yet

- Anesthesia Considerations in Microlaryngoscopy or Direct LaryngosDocument6 pagesAnesthesia Considerations in Microlaryngoscopy or Direct LaryngosRubén Darío HerediaNo ratings yet

- Reaction PaperDocument3 pagesReaction PaperPatrick Ramos80% (15)

- Qsen CurriculumDocument5 pagesQsen Curriculumapi-280981631No ratings yet

- Operate A Word Processing Application BasicDocument46 pagesOperate A Word Processing Application Basicapi-24787158267% (3)

- Equilibrium of Firm Under Perfect Competition: Presented by Piyush Kumar 2010EEE023Document18 pagesEquilibrium of Firm Under Perfect Competition: Presented by Piyush Kumar 2010EEE023a0mittal7No ratings yet

- HotsDocument74 pagesHotsgecko195No ratings yet

- Program PlanningDocument24 pagesProgram Planningkylexian1No ratings yet

- Investigative Project Group 8Document7 pagesInvestigative Project Group 8Riordan MoraldeNo ratings yet

- The American New CriticsDocument5 pagesThe American New CriticsSattigul KharakozhaNo ratings yet

- Antenna Wave Propagation Lab Manual CSTDocument13 pagesAntenna Wave Propagation Lab Manual CSTPrince Syed100% (3)

- A Social Movement, Based On Evidence, To Reduce Inequalities in Health Michael Marmot, Jessica Allen, Peter GoldblattDocument5 pagesA Social Movement, Based On Evidence, To Reduce Inequalities in Health Michael Marmot, Jessica Allen, Peter GoldblattAmory JimenezNo ratings yet

- Eyewitness Bloody Sunday PDFDocument2 pagesEyewitness Bloody Sunday PDFKatie0% (1)

- The Interplay of Religion and PoliticsDocument10 pagesThe Interplay of Religion and PoliticsThompson mercyNo ratings yet

- Review of Related LiteratureDocument5 pagesReview of Related LiteratureRJ PareniaNo ratings yet

- Introduction, Case StudyDocument56 pagesIntroduction, Case StudyLeanna Cantanero67% (3)

- Diexis in Red by Taylor SwiftDocument11 pagesDiexis in Red by Taylor SwiftNirmana ArtstikaNo ratings yet