Professional Documents

Culture Documents

Geotech Report - USQ - BL4&5 - 5.31.11

Uploaded by

Thuy Tran0 ratings0% found this document useful (0 votes)

51 views87 pagesCopyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

51 views87 pagesGeotech Report - USQ - BL4&5 - 5.31.11

Uploaded by

Thuy TranCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 87

Geotechnical Engineering Report

U Square Development Blocks 4 and 5

Calhoun Street

Cincinnati, Ohio

May 31, 2011

Terracon Project Number: N1115051

Prepared for:

Al Neyer, LLC

Cincinnati, Ohio

Prepared by:

Cincinnati, Ohio

TABLE OF CONTENTS

EXECUTIVE SUMMARY ............................................................................................................................... I

1.0 INTRODUCTION .............................................................................................................................. 1

2.0 PROJECT INFORMATION .............................................................................................................. 2

2.1 Project Description .............................................................................................................. 2

2.2 Site Location and Description ............................................................................................. 3

3.0 SUBSURFACE CONDITIONS ........................................................................................................ 4

3.1 Site Background .................................................................................................................. 4

3.2 Typical Profile ...................................................................................................................... 4

3.3 Groundwater ....................................................................................................................... 5

4.0 RECOMMENDATIONS FOR DESIGN AND CONSTRUCTION ..................................................... 6

4.1 Geotechnical Considerations .............................................................................................. 6

4.2 Earthwork ............................................................................................................................ 9

4.2.1 Site Preparation ...................................................................................................... 9

4.2.2 Material Types......................................................................................................... 9

4.2.3 Compaction Requirements ................................................................................... 11

4.2.4 Utility Trench Backfill ............................................................................................. 11

4.2.5 Grading and Drainage ........................................................................................... 12

4.2.6 Construction Considerations ................................................................................. 12

4.3 Foundations ...................................................................................................................... 13

4.3.1 Drilled Shafts Design Recommendations ............................................................. 13

4.3.2 Spread Footing Design Recommendations .......................................................... 14

4.3.3 Spread Footing Construction Considerations ....................................................... 15

4.4 Seismic Considerations .................................................................................................... 16

4.5 Floor Slab .......................................................................................................................... 16

4.5.1 Design Recommendations .................................................................................... 16

4.5.2 Construction Considerations ................................................................................. 17

4.6 Lateral Earth Pressures .................................................................................................... 18

4.6.1 Design Recommendations .................................................................................... 18

4.6.2 Construction Considerations ................................................................................. 19

4.7 Pavements ........................................................................................................................ 19

4.7.1 Subgrade Preparation ........................................................................................... 19

4.7.2 Design Considerations .......................................................................................... 20

4.7.3 Pavement Drainage .............................................................................................. 21

4.7.4 Pavement Maintenance ........................................................................................ 21

5.0 GENERAL COMMENTS................................................................................................................ 21

APPENDIX A FIELD EXPLORATION

Exhibit A-1 Site Location Map

Exhibit A-2 Test Boring and Test Pit Location Plan

Exhibit A-3 1966 Hamilton County Topographic Survey

Exhibit A-4 1912 Hamilton County Topographic Survey

Exhibit A-5 Historic Basement Information

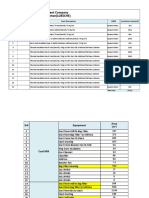

Exhibits A-6A, A-6B Summary of Geotechnical Data

TABLE OF CONTENTS (CONTINUED)

Exhibit A-7 Top of Unweathered Gray Shale and Limestone Bedrock

Contours

Exhibit A-8 Field Exploration Description

Borings B4G-1 to B4G-5 Block 4 Garage Test Boring Logs

Borings B4B-1 to B4B-6 Block 4 Retail, Office and Hotel Boring Logs

Borings B5G-1 to B5G-5 Block 5 Garage Test Boring Logs

Borings B5B-1 to B5B-8 Block 4 Retail, Housing Boring Logs

Test Pits TP-1 to TP-10 Test Pit Logs

APPENDIX B LABORATORY TESTING

Exhibit B-1 Laboratory Testing

Exhibits B-2 to B-8 Unconfined Compression Test Data

APPENDIX C SUPPORTING DOCUMENTS

Exhibit C-1 General Notes

Exhibit C-2 Unified Soil Classification System

Exhibit C-3 Description of Rock Properties

Geotechnical Engineering Report

Proposed U Square Development-Blocks 4 & 5 Calhoun St., Cincinnati, Ohio

May 31, 2011 HCN/Terracon Project No. N1115051

Responsive Resourceful Reliable i

EXECUTIVE SUMMARY

A geotechnical study has been performed for Blocks 4 and 5 of the proposed U Square

development on Calhoun Street in Cincinnati, Ohio. A total of 24 new test borings were drilled

across the proposed structure footprints to depths ranging from approximately 5 to 50 feet

below existing ground surface. In addition, 10 test pits were performed across the project site to

depths ranging from about 2.5 to 8 feet below surface grades. Also, information developed from

previous geotechnical studies across this site has been reviewed and included as deemed

appropriate. Based on the information obtained from our subsurface explorations, the following

geotechnical considerations were identified:

The project site has variable depths of existing uncontrolled fill ranging from about 0.5 feet to

20 feet, being typically less than 10 feet. The existing fill was observed to contain various

proportions of construction debris including bricks, large limestone floaters, wood, asphalt and

concrete fragments. Remnants (including foundation and floor slab) of previously existing

structures were encountered in some of the test pits. The existing uncontrolled fill is unsuitable

for direct foundation, floor slab or pavement support. Selective reuse of existing uncontrolled

fill is anticipated and will require culling of construction debris and other deleterious material.

Additional test pits are recommended during construction to further evaluate existing

uncontrolled fill and delineate/remove remnants of previous structures.

The garage structure foundations should bear within unweathered gray shale and limestone

bedrock. To this end, drilled shafts will be required within portions of the footprint and spread

footings can be considered in areas where bedrock is at shallow depths below existing grades.

However, in light of the observed near-surface bedrock characteristics and presence of

backfilled basements, we recommend that all of the garage structure columns be supported on

drilled shafts to control foundation excavation and overexcavation. The lightly loaded knee

walls, retail area first floor walls and detention area grade separation walls can be supported on

spread footings bearing within very stiff natural overburden soils, brown weathered shale or

interbedded gray shale and limestone bedrock. However, it would be advantageous to use

grade beams connected to the drilled shafts for foundation support to control overexcavation.

Due to variable subsurface conditions (including varying depth to bedrock, uncontrolled fill

depths, overburden soil thickness) and for the estimated column loads, it is recommended

that the Retail/Office, Hotel and Retail/Housing structure columns be supported on drilled

shafts bearing within interbedded gray shale and limestone bedrock to keep total and

differential settlements within tolerable levels. The lightly loaded first floor walls of these

structures can be supported on spread footings bearing within very stiff natural overburden

soils, brown weathered shale or interbedded gray shale and limestone bedrock. It would be

advantageous to use grade beams connected to the drilled shafts for foundation support to

control overexcavation.

Per 2007 Ohio Building Code, a seismic Site Class C is recommended for seismic design.

Geotechnical Engineering Report

Proposed U Square Development-Blocks 4 & 5 Calhoun St., Cincinnati, Ohio

May 31, 2011 HCN/Terracon Project No. N1115051

Responsive Resourceful Reliable ii

The floor slabs for the structures can be designed as slabs-on-grade bearing on natural

overburden soils, engineered fill or bedrock. In areas of existing uncontrolled fill, the positive

approach is to completely undercut the uncontrolled fill and replace as/with engineered fill. This

is recommended for floor slabs with stringent performance requirements. A reduced risk

approach is to undercut the uncontrolled fill such that the floor slab subgrade consists of a

minimum 3 feet of new engineered fill reinforced with 2 layers of geogrid reinforcement.

In pavement areas located over existing uncontrolled fill, it is recommended that the

uncontrolled fill be undercut such that the subgrade consists of a minimum 3 feet of new

engineered fill (a reduced risk approach). Consideration could be given to reinforcing the

engineered fill with 2 layers of geogrid to improve its performance in accommodating

differential settlements. The positive approach is to completely undercut the uncontrolled fill

and replace as/with engineered fill.

Excavations for new foundations, and utilities, undercuts, and site grading will likely

encounter remnants of previously existing structures. Removal of old foundations and floor

slabs should be anticipated. In new floor slab and pavement areas, consideration could be

given to removing the foundations a minimum 2 feet below design subgrade and leaving the

lower portion in place.

Close monitoring of the construction operations discussed herein will be critical in achieving the

design subgrade support. Due to the presence of variable subsurface conditions including

backfilled basements and remnant foundations, full-time monitoring by geotechnical personnel is

recommended during site preparation, earthwork and foundation installation. We recommend that

HCN be retained to perform construction testing and monitoring for this project.

This summary should be used in conjunction with the entire report for design purposes. It

should be recognized that details were not included or fully developed in this section, and the

report must be read in its entirety for a comprehensive understanding of the items contained

herein. The section titled GENERAL COMMENTS should be read for an understanding of the

report limitations.

Responsive Resourceful Reliable

1

GEOTECHNICAL ENGINEERING REPORT

U SQUARE DEVELOPMENT BLOCKS 4 AND 5

CALHOUN STREET, CINCINNATI, OHIO

HCN/Terracon Project No. N1115051

May 31, 2011

1.0 INTRODUCTION

A geotechnical engineering report has been completed for Blocks 4 and 5 of the proposed U

Square development on Calhoun Street in Cincinnati, Ohio. A total of twenty four (24) new test

borings were performed to supplement data obtained from previous geotechnical studies across

the project site. This included: five (5) test borings, designated B4G-1 through B4G-5, across the

Block 4 garage footprint drilled to approximate depths of 30 to 45 feet below existing ground

surface; five (5) test borings, designated B5G-1 through B5G-5, across the Block 5 garage

footprint drilled to approximate depths of 30 to 50 feet below existing ground surface; six (6) test

borings, designated B4B-1 through B4B-6, across the Block 4 Retail/Office and Hotel footprints

drilled to approximate depths of 6 to 21.5 feet below existing ground surface; and eight (8) test

borings, designated B5B-1 through B5B-8, across the Block 5 Retail/Housing footprint drilled to

approximate depths of 5 to 21 feet below existing ground surface. In addition to the test borings,

ten (10) test pits designated TP-1 through TP-10 were performed across the project site to

primarily evaluate the existing fill and identify remnants of previously existing structures. Logs of

the test borings and test pits along with a Site Location Map and Test Boring and Test Pit Location

Plan are included in Appendix A of this report.

The purpose of these services is to provide information and geotechnical engineering

recommendations relative to:

subsurface soil conditions seismic considerations

short-term groundwater conditions floor slab design and construction

earthwork

foundation design and construction

grade separation walls

pavement design and construction

Geotechnical Engineering Report

Proposed U Square Development-Blocks 4 & 5 Calhoun St., Cincinnati, Ohio

May 31, 2011 HCN/Terracon Project No. N1115051

Responsive Resourceful Reliable 2

2.0 PROJECT INFORMATION

2.1 Project Description

ITEM DESCRIPTION

Site layout As shown in Exhibit A-2, Appendix A.

Buildings

Blocks 4 and 5 Garages: 6-level parking structure with

rectangular footprint having maximum plan dimensions of

approximately 178 feet x 127 feet. Retail area (approximately 78

feet x 60 feet) located within northwest corner of garage footprint.

Storm water detention area (approximately 65 feet x 30 feet)

located immediately south of/adjoining retail area.

Block 4 Retail/Office: 3-story, L-shaped footprint with maximum

plan dimensions of approximately 227 feet (along Calhoun

Street) x 111 feet. No basement.

Block 4 Select Service Hotel: In concept stage at the time of this

report; specific details not available. Maximum plan dimensions

anticipated to be about 220 feet (along McMillan Street) x 65

feet.

Block 5 Retail/Housing: 5-story, near-rectangular footprint with

maximum plan dimensions of approximately 395 feet (along

Calhoun Street) x 170 feet. No basement.

Building construction

Blocks 4 and 5 Garages: concrete frame structure with knee

walls, retail store front walls and detention structure walls on first

level.

Block 4 Retail/Office: steel-framed structure with lightly loaded

first floor walls.

Block 4 Select Service Hotel: In concept stage; details not

available.

Block 5 Retail/Housing: Concrete frame and roof platform for first

floor supporting 4 stories of wood-framed residential structure.

First floor walls are lightly loaded.

Finished floor elevations

Blocks 4 and 5 Garages: El. 864 feet toward south end (along

McMillan Street) to El. 858 feet toward north end (along

Calhoun Street). Between 856 feet and 858 feet in storm

water detention area.

Block 4 Retail/Office: El. 858 feet

Block 4 Select Service Hotel: In concept stage; assumed to be

between El. 862 and 864 feet

Block 5 Retail/Housing: Varies between El. 863 feet toward

south (along McMillan Street) to El. 860 feet toward north

(along Calhoun Street).

Maximum loads

Blocks 4 and 5 Garages:

Columns: 810 kips to 2,160 kips

First Floor Walls: 2 to 3 kips per lineal foot (assumed)

Geotechnical Engineering Report

Proposed U Square Development-Blocks 4 & 5 Calhoun St., Cincinnati, Ohio

May 31, 2011 HCN/Terracon Project No. N1115051

Responsive Resourceful Reliable 3

ITEM DESCRIPTION

Slab-on-grade: 150 psf (assumed)

Block 4 Retail/Office:

Columns: 190 kips to 290 kips

First Floor Walls: 2 to 3 kips per lineal foot (assumed)

Slab-on-grade: 150 psf (assumed)

Block 4 Select Service Hotel:

In concept; loads not available at time of report.

Block 5 Retail/Housing:

Columns: 225 kips to 350 kips

First Floor Walls: 2 to 3 kips per lineal foot (assumed)

Slab-on-grade: 150 psf (assumed)

Assumed loads should be confirmed by structural engineer

Maximum allowable settlement

Columns: 1 inch (assumed)

Walls: inch over 40 feet (assumed)

Tolerable settlements should be confirmed by structural engineer

Grading

Fill: Minimal (on the order of 1 to 2 feet) for general site grading;

up to about 7 feet for first floor garage ramp

Cut: up to about 8 feet

Cut and fill slopes None anticipated.

Below Grade Areas In elevator pit and garage storm water detention footprints.

Retaining walls

Short (less than 6 feet) below grade walls in elevator pit and

garage storm water detention areas; above grade ramp walls in

garage footprint and short grade separation walls in loading dock

areas.

2.2 Site Location and Description

ITEM DESCRIPTION

Location

The site is located on Calhoun Street (between Calhoun and

McMillan Streets) south of the University of Cincinnati west

campus in Cincinnati, Ohio (see Exhibit A-1, Appendix A).

Existing improvements

Site is currently an open area with surface parking lots

toward the central and southeast portions. The site was

previously occupied by several structures (see Exhibits A-3

and A-5, Appendix A) that have been demolished. Specific

details are not available for these structures. Remnants of

these structures are not currently visible at the surface.

Current ground cover

Primarily lawn covered with widely scattered trees along the

perimeter. An asphalt concrete pavement surface parking

lot is located toward the central portion of the site and a

fenced-in gravel lot is located toward the southeast corner of

the site.

Geotechnical Engineering Report

Proposed U Square Development-Blocks 4 & 5 Calhoun St., Cincinnati, Ohio

May 31, 2011 HCN/Terracon Project No. N1115051

Responsive Resourceful Reliable 4

ITEM DESCRIPTION

Existing topography

Relatively level to gently sloping downward from south

(along McMillan Street) to north (along Calhoun Street);

grades range between elevation 861 and 864 feet along

McMillan Street and between elevation 855 and 860 feet

along Calhoun Street

3.0 SUBSURFACE CONDITIONS

3.1 Site Background

The project site is currently open and includes surface parking lots. The 1966 Topographic

Survey (Exhibit A-3) indicates footprints of numerous structures within Blocks 4 and 5. The

structures have since been demolished. Specific details (including basements) for each of the

previously existing structures are not available. ATC Associates, Inc. reviewed/researched

available information (obtained primarily for environmental studies) and developed limited

historic basement data for Blocks 4 and 5 (Basement Data Review/Research Report, Calhoun

Street Development- Blocks 4 and 5. Prepared for Towne Development Group, Ltd. by ATC

Associates, Inc., Cincinnati, Ohio; August 19, 2008). Our interpretation of approximate

basement elevation (based on provided basement and current topographic survey information)

is shown on Exhibit A-5. It should be noted that these elevations are very approximate and field

variations should be expected. Details regarding foundation/basement walls that have either

been removed or left in-place, basement backfill material and placement methods are not

available.

The 1966 and 1912 Topographic Surveys (Exhibits A-3 and A-4, respectively) indicate grades

that are generally comparable to existing grades (Exhibit A-2) thereby suggesting minor site

grade alterations between the referenced periods.

3.2 Typical Profile

Based on the results of the test borings and test pits, subsurface conditions on the project site can

be generalized as follows:

Stratum

Approximate Depth to

Bottom of Stratum (feet)

Material Encountered Consistency/Density

Surficial

Material

0.2 to 0.5

Asphalt Pavement, Granular

Base, Topsoil, Floor Tile

N/A

Geotechnical Engineering Report

Proposed U Square Development-Blocks 4 & 5 Calhoun St., Cincinnati, Ohio

May 31, 2011 HCN/Terracon Project No. N1115051

Responsive Resourceful Reliable 5

Stratum

Approximate Depth to

Bottom of Stratum (feet)

Material Encountered Consistency/Density

Existing Fill

1

0.5 to 20, typically less than

10 feet

Lean Clay, Sand, Gravel,

with various proportions of

cinders, brick, concrete,

wood, limestone floaters,

construction debris

N/A

Natural

Cohesive

Soils

2.5 to 35

Lean Clay with various

proportions of sand,

limestone fragments

Medium Stiff to Hard

Weathered

Bedrock

2

2 to 20, does not occur at

all borings

Severe to moderately severe

weathered shale with various

proportions of limestone

Very soft to Soft (in terms

of rock hardness)

Unweathered

Bedrock

3

Borings terminated in this

stratum

Interbedded gray shale and

limestone (approximately

80% shale and 20%

limestone)

Very Soft to Moderately

Hard (in terms of rock

hardness)

1. We have not been provided any records confirming placement of existing fill as engineered fill.

Furthermore, the test pits revealed various proportions of construction debris. Some of the test pits

encountered floor tile, concrete slabs and foundation walls of previous structures. It is our opinion that

the fill is uncontrolled.

2. The weathered shale bedrock was encountered only at a few borings. The thickness of this stratum

was up to about 5 feet.

3. Published geologic literature cites that the bedrock belongs to the Maysville Formation, Corryville

and Mt. Auburn Members.

Conditions encountered at each test boring and test pit location are indicated on the individual

boring and test pit logs in Appendix A of this report. Stratification boundaries on the boring and test

pit logs represent the approximate location of changes in soil and bedrock types; in-situ, the

transition between materials may be gradual. The conditions encountered in test borings and test

pits for this study and relevant test borings of previous geotechnical studies in the project area are

graphically illustrated on the Summary of Geotechnical Data drawings (Exhibits A-6A and A-6B) in

Appendix A. The approximate top-of-gray shale and limestone bedrock contours are shown on

Exhibit A-7. These contours were developed using available test boring and test pit information

and are intended only to illustrate general trends; field variations from those shown on Exhibit A-7

should be expected. Excavations for the basements of previously existing structures could alter

the top of bedrock. Some the test borings and test pits encountered existing fill directly on top of

bedrock suggesting that previous site grading activities could have altered the bedrock surface.

3.3 Groundwater

The boreholes were observed while drilling and immediately after completion for the presence and

level of groundwater. Groundwater conditions were also observed during the excavation of test

pits. The water levels observed in the boreholes and test pits are noted on the boring and test pit

logs in Appendix A. During drilling, water was encountered only at borings B4G-5 and B5G-5 at

Geotechnical Engineering Report

Proposed U Square Development-Blocks 4 & 5 Calhoun St., Cincinnati, Ohio

May 31, 2011 HCN/Terracon Project No. N1115051

Responsive Resourceful Reliable 6

approximate depths of 4.5 feet and 18.5 feet below surface grades, respectively. Upon completion

of drilling, water was encountered only at the garage borings (B4G-1 through B4G-5 and B5G-1

through B5G-5) where rock coring was performed. However, water was added to these borings to

facilitate rock coring; hence the at-completion water levels in these borings are not reliable. The

test pits, except TP-5, did not encounter water during the excavation program. At TP-5, significant

water was encountered in the excavation below about 4 feet. The excavated material in this test

pit was primarily sand in the upper 4 feet underlain by gravel to the maximum explored depth of 8

feet (test pit was terminated because of significant caving). PVC pipe fragments were observed in

the lower gravel fill.

The short-term groundwater conditions summarized above does not necessarily represent stable

groundwater levels at the site. Due to the low permeability of the soils encountered in the borings,

a relatively long period of time may be necessary for a groundwater level to develop and stabilize in

a borehole in these materials. Long-term observations in piezometers or observation wells sealed

from the influence of surface water are often required to define groundwater levels in materials of

this type. From experience in the area, perched water conditions could be present within the

uncontrolled fill. Also, seepage is commonly observed along the uncontrolled fill/natural

overburden soil, natural overburden soil/bedrock interface and within bedrock along bedding

planes, cracks and fissures.

Groundwater level fluctuations occur due to seasonal variations in the amount of rainfall, runoff

and other factors not evident at the time the borings and test pits were performed. Therefore,

groundwater levels during construction or at other times in the life of the structure may be higher

or lower than the levels indicated on the boring and test pit logs. The possibility of groundwater

level fluctuations should be considered when developing the design and construction plans for

the project.

4.0 RECOMMENDATIONS FOR DESIGN AND CONSTRUCTION

4.1 Geotechnical Considerations

The field exploration program revealed a subsurface profile consisting of variable depths of existing

fill underlain by natural cohesive overburden soils and shale bedrock. The depth of existing fill

ranged from about 0.5 feet to 20 feet, being typically less than 10 feet. The existing fill was

observed to contain various proportions of construction debris including bricks, large limestone

floaters, wood, asphalt and concrete fragments. Remnants (including foundation and floor slab) of

previously existing structures were encountered in some of the test pits. We have interpreted the

existing fill to be uncontrolled and consider it to be unsuitable for foundation, floor slab or pavement

support.

Geotechnical Engineering Report

Proposed U Square Development-Blocks 4 & 5 Calhoun St., Cincinnati, Ohio

May 31, 2011 HCN/Terracon Project No. N1115051

Responsive Resourceful Reliable 7

Selective reuse of existing uncontrolled fill is anticipated and will require culling of construction

debris and other deleterious material. Additional test pits are recommended during construction to

further evaluate the uncontrolled fill and delineate/remove remnants of previous structures.

Based on the estimated garage column loads, we recommend that the garage structure column

foundations bear within competent unweathered gray shale and limestone bedrock. To this end,

drilled shafts will be required within portions of the footprint and spread footings can be considered

in areas where bedrock is at shallow depths (less than about 6 feet) below design subgrades.

However, in shallow bedrock areas, the bedrock near its interface with the overburden soils was

generally observed to be very soft and include weathered zones. Hence, overexcavation of

bedrock (possibly on the order of 3 to 4 feet) will likely be required to expose suitable bearing

material. Additionally, natural erosion and weathering of bedrock and the presence of backfilled

basements can alter the surface of unweathered bedrock and depth of foundation

excavation/overexcavation. Therefore, we recommend that all of the garage structure columns be

supported on drilled shafts to control foundation overexcavation and provide a more uniform

support.

The lightly loaded first floor garage walls and detention area grade separation walls can be

supported on spread footings bearing within very stiff natural overburden soils, brown weathered

shale or interbedded gray shale and limestone bedrock. However, it would be advantageous to

use grade beams connected to drilled shafts for foundation support of the walls to control

overexcavation and differential settlements.

We recommend that foundations for the columns of the Block 4 Retail/Office and Block 5

Retail/Housing structures be supported on layered bedrock (either brown weathered shale or gray

shale bedrock) to keep total and differential settlements within tolerable levels. To this end, rock-

bearing spread footings could be considered for foundation support in many areas with drilled

shafts being required in isolated areas. The lightly loaded first floor walls could be supported on

spread footings bearing within very stiff natural overburden soils, weathered brown shale bedrock

and unweathered gray shale bedrock. However, as discussed before, the top-of-bedrock across

the project site has very likely been altered by previously excavated basements and various depths

of excavation/overexcavation should be anticipated to reach suitable bearing material. From a

constructability standpoint it would be advantageous to use drilled shafts and grade beams (our

recommendation) to control the excavation depths and provide a more uniform foundation support.

The subgrade for the floor slab of the various structures is anticipated to consist of a

combination of existing uncontrolled fill, natural overburden soils, shale bedrock, and new

engineered fill. The existing uncontrolled fill is unsuitable for direct floor slab support. A

complete undercut of the uncontrolled fill and replacement with engineered fill is recommended

for floor slabs with stringent performance requirements. Consideration could be given to leaving

the lower portion of the uncontrolled fill in place below floor slabs depending on performance

requirements (at higher risk). With the partial undercut approach, the existing uncontrolled fill

Geotechnical Engineering Report

Proposed U Square Development-Blocks 4 & 5 Calhoun St., Cincinnati, Ohio

May 31, 2011 HCN/Terracon Project No. N1115051

Responsive Resourceful Reliable 8

should be undercut such that the floor slab subgrade consists of a minimum 3 feet of

engineered fill (the undercut can be terminated if competent natural soils or bedrock is

encountered at shallow depth). It is recommended that the engineered fill zone be reinforced

with two layers of geogrid (Tensar TX5 or approved equivalent) to improve the performance of

the engineered fill mattress in handling differential settlements. These geogrid layers should be

placed in the lower and mid-levels of the new fill zone and be separated by at least 8-inches

(vertically). It is important to recognize that the partial undercut only helps reduce the risk of

intolerable settlements, not eliminate it.

In pavement areas located over existing uncontrolled fill, it is recommended that the

uncontrolled fill be undercut such that the subgrade consists of a minimum 3 feet of engineered

fill (a reduced risk approach; the undercut can be terminated if competent natural soils or

bedrock is encountered at shallow depth). Consideration could be given to reinforcing the

engineered fill with 2 layers of geogrid (Tensar TX5 or approved equivalent) to improve its

performance in accommodating differential settlements. The geogrid placement should be as

described above. The positive approach is to completely undercut the uncontrolled fill and

replace as/with engineered fill.

Existing foundation walls were encountered in test pits TP-6 and TP-8. As discussed before,

the site was previously occupied by numerous structures that have been demolished and

specific information regarding their foundations and demolition is not available. Based on

conditions encountered at the test borings and test pits and our general understanding of the

use/type of structures, we anticipate spread footings were primarily used for foundation support.

The presence of previously existing structure foundations and floor slabs should be expected. A

complete removal of old foundations (in case of spread footings) and floor slabs will be required

in new foundation footprint areas. Offsetting of new foundations to avoid old foundations may

be required in areas where deep foundations were previously used. In new floor slab and

pavement areas, consideration could be given to demolishing/terminating the old foundation

walls/foundations a minimum 3 feet below design subgrade and leaving the lower portion in

place.

Support of floor slabs and pavements above existing fill soils is discussed in the following

paragraphs. However, even with the recommended construction testing, there is a risk for the

owner that unsuitable material within or buried by the fill will not be discovered. This risk cannot

be eliminated without removing all of the fill, but can be minimized by thorough exploration and

testing. The amount and depth of exploration should be field determined at the time of

observation.

Geotechnical Engineering Report

Proposed U Square Development-Blocks 4 & 5 Calhoun St., Cincinnati, Ohio

May 31, 2011 HCN/Terracon Project No. N1115051

Responsive Resourceful Reliable 9

4.2 Earthwork

4.2.1 Site Preparation

Site preparation should include stripping of topsoil, asphalt pavement and granular base and

removal of trees (including grubbing of roots). The stripped topsoil is not suitable for reuse as

engineered fill; however it can be stockpiled for use in future landscape areas. The stripped

asphalt (after processing) and granular base can be considered for reuse in new pavement

areas. Existing utilities within new structure footprints should preferably be relocated to the

outside. Abandoned utilities should either be completely removed (preferred) or grouted full

under pressure when left in place. After rough grading the site, it is recommended that a test pit

program be undertaken to explore backfilled basements, old foundations and further evaluate

the uncontrolled fill. Additional exploration is recommended in the vicinity of test pit TP-5 where

saturated gravel backfill was encountered to a depth of about 8 feet (test pit was terminated due

to caving conditions).

Foundations of previously existing structures should be removed completely or minimum 2 feet

below design subgrade. The uncontrolled fill should be undercut (and foundations

demolished/removed) as discussed and the bottom of the undercut (exposed soil areas only)

should be proof rolled with several passes of a loaded tandem-axle dump truck (weighing at

least 20 tons). Additionally, the use of a vibratory roller is recommended over exposed

uncontrolled fill areas to compact underlying construction debris left in-place. The proofrolling

should be performed under the observation of geotechnical personnel to delineate soft or

yielding areas. These areas will either need to be removed or stabilized in place to develop a

stable subgrade for engineered fill placement. The appropriate remedial measure(s) will

depend on encountered conditions and be field determined. Engineered fill can be placed on

the approved undercut subgrade to establish design subgrades.

All soil subgrade areas (including those areas to receive engineered fill to establish design

subgrades) should be proofrolled as discussed above. Soft, yielding areas should be delineated

and appropriate remedial measures should be employed to develop stable subgrades. See

Sections 4.1, 4.5.1, and 4.7.1 for discussion on undercuts and reinforcement of replacement fill

with geogrid.

All excavations at the site should be in accordance with current OSHA Excavation Regulations.

4.2.2 Material Types

Engineered fill should meet the following material property requirements:

Fill Type

1

USCS Classification Acceptable Location for Placement

Lean clay

CL

(LL<40)

All locations and elevations

Geotechnical Engineering Report

Proposed U Square Development-Blocks 4 & 5 Calhoun St., Cincinnati, Ohio

May 31, 2011 HCN/Terracon Project No. N1115051

Responsive Resourceful Reliable 10

Fill Type

1

USCS Classification Acceptable Location for Placement

Lean to fat clay

CL/CH

(40<LL<50)

> 3 ft. below finished grade in structural areas

Fat clay

2

CH

(LL >50)

In non-structural areas

Well graded

granular

GW

3

All locations and elevations

On-site soils and

bedrock

4

Varies

The existing uncontrolled fill soils primarily consist of

lean clays with various proportions of construction

debris. The uncontrolled fill will need to be

processed (including removal of construction debris

and other deleterious materials) to make it suitable

for use as engineered fill. The natural overburden

soils generally appear suitable for reuse as

engineered fill. Appropriate moisture conditioning

may be needed for all on site soils.

Bedrock will first need to be processed to make it

suitable for reuse as engineered fill. Preferable to

limit use to pavement and non-structural areas.

1. New engineered fill should consist of approved materials that are free of organic matter and

construction debris. Frozen material should not be used, and fill should not be placed on a frozen

subgrade. A sample of each material type should be submitted to the geotechnical engineer for

evaluation.

2. Delineation of fat clays should be performed in the field by a qualified geotechnical engineer or

their representative. Generally it is preferred not to use high plasticity clay within structural areas.

3. Similar to ODOT No. 304 stone or crushed limestone aggregate or granular material such as sand,

gravel or crushed stone containing no more than 18% low plasticity fines.

4. The brown weathered shale bedrock will need to be processed (primarily anticipated to consist of

removal/breakdown of large limestone floaters) to make it suitable for reuse as engineered fill. A

significant amount of processing (including slaking of the shale and breaking down of limestone)

will be necessary to make the gray shale and limestone bedrock suitable for use in engineered fill.

Consideration could be given to using the brown weathered shale bedrock after processing.

Maximum allowable solid fragment sizes should not exceed about 4-inches in any dimension. We

recommend that the gray shale and limestone bedrock be wasted off site. Recommendations for

processing the gray shale bedrock can be provided upon request.

Geotechnical Engineering Report

Proposed U Square Development-Blocks 4 & 5 Calhoun St., Cincinnati, Ohio

May 31, 2011 HCN/Terracon Project No. N1115051

Responsive Resourceful Reliable 11

4.2.3 Compaction Requirements

ITEM DESCRIPTION

Fill Lift Thickness (Structural Areas)

8-inches or less in loose thickness when heavy, self-

propelled equipment is used

6-inches or less in small, confined spaces and where

hand compaction equipment is used

Compaction Requirements

1

(Structural Areas)

Minimum 98% of the materials Standard Proctor

maximum dry density (ASTM D 698)

Compaction Requirements

1

(Non-Structural/Landscape Areas)

Minimum 95% of the materials Standard Proctor

maximum dry density (ASTM D 698) provided long-term

plans do not include a structure

Moisture Content - Cohesive Soil

(Low Plasticity)

Within 3% of optimum moisture content (OMC) as

determined by the Standard Proctor test at the time of

placement and compaction

Moisture Content - Granular Material

2

Within workable moisture levels

1. Should the results of the in-place density tests indicate the specified moisture or compaction limits

have not been met, the area represented by the test should be reworked and retested as required

until the specified moisture and compaction requirements are achieved.

2. Specifically, moisture levels should be maintained low enough to allow for satisfactory compaction

to be achieved without the cohesionless fill material pumping when proofrolled.

All materials to be used as engineered fill should be tested in the laboratory to determine their suitability

and compaction characteristics.

4.2.4 Utility Trench Backfill

All trench excavations should be made with sufficient working space to permit construction

including backfill placement and compaction. If utility trenches are backfilled with relatively clean

granular material, they should be capped with at least 18 inches of cohesive fill in non-pavement

exterior areas to reduce the infiltration and conveyance of surface water through the trench backfill.

Utility trenches are a common source of water infiltration and migration. All utility trenches that

penetrate beneath the buildings should be effectively sealed to restrict water intrusion and flow

through the trenches that could migrate below the building. We recommend constructing an

effective clay trench plug that extends at least 5 feet out from the face of the building exterior.

The plug material should consist of clay compacted at a water content at or above the soils

optimum water content. The clay fill should be placed to completely surround the utility line and be

compacted in accordance with recommendations in this report.

Geotechnical Engineering Report

Proposed U Square Development-Blocks 4 & 5 Calhoun St., Cincinnati, Ohio

May 31, 2011 HCN/Terracon Project No. N1115051

Responsive Resourceful Reliable 12

4.2.5 Grading and Drainage

Final surrounding grades should be sloped away from the structure on all sides to promote

positive drainage and prevent ponding of water. Gutters and downspouts that drain water a

minimum of 10 feet beyond the footprint of the proposed structures are recommended. This can

be accomplished through the use of splash-blocks, downspout extensions, and flexible pipes

that are designed to attach to the end of the downspout. Flexible pipe should only be used if it

is daylighted in such a manner that it gravity-drains collected water. Splash-blocks should also

be considered below hose bibs and water spigots.

4.2.6 Construction Considerations

Although the exposed subgrade is anticipated to be relatively stable upon initial exposure, unstable

subgrade conditions could develop during general construction operations, particularly if the soils

are wetted and/or subjected to repetitive construction traffic. The use of light construction

equipment would aid in reducing subgrade disturbance.

Shale bedrock (primarily gray) is anticipated to be exposed across portions of the subgrades.

The shale bedrock slakes (becomes soil like) upon exposure to water and may require

undercutting to stable bedrock. Consideration could be given to placing a lean concrete mud

mat on the approved bedrock subgrade to minimize exposure to weather and control

undercutting.

Upon completion of filling and grading, care should be taken to maintain the subgrade moisture

content prior to construction of floor slabs and pavements. Construction traffic over the

completed subgrade should be avoided to the extent practical. The site should also be graded

to prevent ponding of surface water on the prepared subgrades or in excavations. If the

subgrade should become frozen, desiccated, saturated, or disturbed, the affected material

should be removed or these materials should be scarified, moisture conditioned, and

recompacted prior to floor slab and pavement construction.

Trees or other vegetation whose root systems have the ability to remove excessive moisture

from the subgrade and foundation soils should not be planted next to the structure. Trees and

shrubbery should be kept away from the exterior edges of the foundation element a distance at

least equal to 1.5 times their expected mature height.

As a minimum, all temporary excavations should be sloped or braced as required by current

OSHA regulations to provide stable and safe working conditions. Temporary excavations will be

required during grading operations. The grading contractor, by his contract, is usually

responsible for designing and constructing stable, temporary excavations and should shore,

slope or bench the sides of the excavations as required, to maintain stability of both the

excavation sides and bottom. All excavations should comply with applicable local, state and

federal safety regulations, including the current Occupational Health and Safety Administration

(OSHA) Excavation and Trench Safety Standards.

Geotechnical Engineering Report

Proposed U Square Development-Blocks 4 & 5 Calhoun St., Cincinnati, Ohio

May 31, 2011 HCN/Terracon Project No. N1115051

Responsive Resourceful Reliable 13

The geotechnical engineer should be retained during the construction phase of the project to

observe earthwork and to perform necessary tests and observations during subgrade

preparation; proof-rolling; placement and compaction of engineered fills; backfilling of

excavations into the completed subgrade, and just prior to construction of building floor slabs

and pavements.

4.3 Foundations

4.3.1 Drilled Shafts Design Recommendations

Straight-sided drilled shafts bearing a minimum of 3 feet or 1-pier diameter (which ever is

greater) into the gray unweathered shale and limestone bedrock can be proportioned using an

allowable end bearing capacity is 50,000 psf over the cross-sectional area of the shaft bottom.

Additionally, if the drilled shafts are extended deeper than the minimum socket requirement into

the gray unweathered shale and limestone bedrock, an allowable side resistance of 2,500 psf

can be used for the shaft portion below the minimum socket length. A minimum drilled shaft

length of 10 feet or 3-shaft diameters (whichever is greater) is recommended in order to take

advantage of the depth factor associated with deep foundations.

It is recommended that the following criteria be used in the design and construction of the drilled

shaft foundation system.

1. The shaft diameter should be no less than 30-inches for inspection purposes. The use

of 24-inch diameter shafts will require specific evaluation.

2. The actual bottom elevation of each shaft will be determined in the field during

construction, through inspection by a representative (geotechnical technician) of the

geotechnical engineer.

3. The specifications should be clear that the bottom of drilled shaft elevations shown on

the plans is for estimating purposes only. The actual determination will be made (by the

geotechnical engineer or his representative) from examination of the material brought to

the surface by the auger during shaft construction.

4. The specifications should require that no concrete be placed until the dimensions,

bottom elevation and excavation of each shaft has been approved by the inspector. It is

possible that groundwater will enter some of the shaft. It is recommended that the

specifications state that the depth of water and loose materials at the bottom of the shaft

at the time of concreting shall not be greater than 2 inches.

5. Temporary casing should be available on-site and shall be placed wherever required to

stabilize loose or caving materials, or to seal off any water bearing zones.

Geotechnical Engineering Report

Proposed U Square Development-Blocks 4 & 5 Calhoun St., Cincinnati, Ohio

May 31, 2011 HCN/Terracon Project No. N1115051

Responsive Resourceful Reliable 14

6. It is recommended that the specifications state that all structural steel and shaft concrete

be placed the same day as the shaft is drilled. No completed shaft excavation should be

allowed to remain open overnight. It is suitable, however, for the contractor to excavate

a portion of the drilled shaft, and complete the shaft excavation the next day. The

bedrock socket portion of the drilled shaft should be excavated and concreted the same

day

7. When a shaft excavation is allowed to remain open overnight, a portion of the excavation

typically fills with water, which then needs to be pumped out. Also, the bottom of the

excavation then needs to be mucked of soft material.

Old foundations, floor slabs, construction debris and other obstructions associated with

remnants of previous structures may be encountered during the installation of drilled shafts.

4.3.2 Spread Footing Design Recommendations

DESCRIPTION Column Wall

Net allowable bearing pressure

1

Very stiff natural soils :

3,000 psf

Gray shale bedrock :

25,000 psf

Very stiff natural soils :

2,500 psf

Gray shale bedrock :

20,000 psf

Minimum dimensions 24 inches 18 inches

Minimum embedment below finished

grade for frost protection

2

30 inches 30 inches

Estimated total settlement

3

Up to 1-inch Up to 0.75-inch

Estimated differential settlement Up to 0.75-inch Up to 0.50-inch

Allowable passive pressure

4

Natural very stiff soil : 500 psf

Gray shale bedrock : 1,500 psf

Ultimate coefficient of sliding friction

4

Soil : 0.30

Gray shale bedrock : 0.40

1. The recommended net allowable bearing pressure is the pressure in excess of the minimum

surrounding overburden pressure at the footing base elevation. Assumes any unsuitable fill or soft

soils and shale bedrock, where present, will be undercut and the footing will be lowered to at least

very stiff natural cohesive soils, medium hard gray shale bedrock or the overexcavations will be

backfilled with lean concrete (minimum 28-day compressive strength of 1,500 psi for garage

columns and 1,000 psi in other areas) .

2. To reduce the effects of seasonal moisture variations in the subgrade soils. Perimeter footings and

footings beneath unheated areas.

Geotechnical Engineering Report

Proposed U Square Development-Blocks 4 & 5 Calhoun St., Cincinnati, Ohio

May 31, 2011 HCN/Terracon Project No. N1115051

Responsive Resourceful Reliable 15

DESCRIPTION Column Wall

3. The foundation settlement will depend upon the variations within the subsurface soil and bedrock

profile, the structural loading conditions, the embedment depth of the footings, the thickness of

compacted fill, and the quality of the earthwork operations.

4. The sides of the excavation for the spread footing foundation must be nearly vertical and the

concrete should be placed neat against these vertical faces for the passive earth pressure values

to be valid. If the loaded side is sloped or benched, and then backfilled, the allowable passive

pressure will be significantly reduced. Passive resistance in the upper 2.5 feet of the soil profile and

in uncontrolled fill should be neglected. If passive resistance is used to resist lateral loads, the base

friction should be neglected. The recommended ultimate coefficient of sliding friction values require

that mass concrete be placed directly on undisturbed, approved bearing material. A minimum factor

of safety of 1.5 is recommended.

4.3.3 Spread Footing Construction Considerations

The base of all footing excavations should be free of water and loose soil and rock prior to

placing concrete. Concrete should be placed soon after excavating to reduce bearing soil and

bedrock disturbance. Should the soils or bedrock at bearing level become excessively dry,

disturbed or saturated, or frozen, the affected soil, bedrock should be removed prior to placing

concrete. Place a lean concrete mud-mat over the bearing soils or bedrock if the excavations

must remain open over night or for an extended period of time. It is recommended that the

geotechnical engineer be retained to observe, test and approve the footing bearing materials.

If unsuitable bearing soils or bedrock are encountered in footing excavations, the excavations

should be extended deeper to suitable soils or bedrock and the footings could either bear

directly on these materials at the lower elevation or on lean concrete backfill (minimum 28-day

compressive strength of 1,500 psi for garage columns and 1,000 psi in other areas) placed in

the excavation. The overexcavation and backfill procedure is described in the figure below.

Geotechnical Engineering Report

Proposed U Square Development-Blocks 4 & 5 Calhoun St., Cincinnati, Ohio

May 31, 2011 HCN/Terracon Project No. N1115051

Responsive Resourceful Reliable 16

4.4 Seismic Considerations

Code Used Site Classification

2007 Ohio Building Code

1

C

2

1. In general accordance with the 2007 Ohio Building Code (OBC), Seismic Site Class is based on the

characteristics of the upper 100 feet of the subsurface profile.

2. The OBC requires a site soil/bedrock profile determination extending to a depth of 100 feet for

seismic site classification. The current study does not include the 100 foot soil/bedrock profile

determination. Borings extended to a maximum depth of 50 feet and were terminated in bedrock.

HCN has previously preformed downhole shear wave velocity testing in the immediate vicinity of the

project site. The data developed from previous shear wave velocity tests, our understanding of the

geology of the area and conditions encountered at this site was used to determine the seismic site

class.

As required in the OBC, evaluation of slope instability, liquefaction and surface rupture due to

failure or lateral spreading should be evaluated on sites categorized as Seismic Design

Category C. Due to the predominantly cohesive nature of the overburden soils, liquefaction of

the soils is not considered a significant concern. The proposed project site is relatively level to

gently sloping; therefore, slope stability should not be an issue. The overburden soils are not

considered susceptible to surface rupture due to faulting or lateral spreading.

4.5 Floor Slab

4.5.1 Design Recommendations

ITEM DESCRIPTION

Floor slab support

Presence of existing fill soils,

special subgrade preparation is required

1

Modulus of subgrade reaction

100 pounds per square inch per in (psi/in) for point loading

conditions

Aggregate base course/capillary

break

2

4 inches of free draining granular material

1. Floor slabs should be structurally independent of any building foundations or walls to reduce the

possibility of floor slab cracking caused by differential movements between the slab and

foundation.

Due to the presence of uncontrolled fill soils at floor slab subgrade level, we recommend

undercutting and replacement of existing fill soils with new engineered fill such that the floor slab is

supported on at least 3 ft. of new engineered fill with consideration of additional fill reinforcement

using geogrid (see Section 4.1 Geotechnical Considerations). This fill should meet the

requirements and placed as recommended in Section 4.2 Earthwork of the report.

We recommend floor subgrades be maintained in a relatively moist condition until floor slabs are

constructed. If the subgrade should become desiccated prior to construction of floor slabs, the

affected material should be removed or the materials scarified, moistened, and recompacted.

Geotechnical Engineering Report

Proposed U Square Development-Blocks 4 & 5 Calhoun St., Cincinnati, Ohio

May 31, 2011 HCN/Terracon Project No. N1115051

Responsive Resourceful Reliable 17

Upon completion of grading operations in the building areas, care should be taken to maintain the

recommended subgrade moisture content and density prior to construction of the building floor

slabs.

2. Free-draining granular material should have less than 5 percent fines (material passing the #200

sieve). Other design considerations such as cold temperatures and condensation development

could warrant more extensive design provisions.

The floor slab subgrade is anticipated to primarily consist of a combination of engineered fill and

gray shale and limestone bedrock with natural overburden soils and brown weathered shale in

some areas. Due to the variety of subgrade materials (and in areas where the existing

uncontrolled fill is left in place), it is recommended that the stiffness of the slab be increased

(either by increasing thickness, including reinforcing steel or both) to improve its performance.

Also, control joints are recommended in subgrade transition areas. Saw-cut control joints

should be placed in the slab to help control the location and extent of cracking. For additional

recommendations refer to the ACI Design Manual. Joints or any cracks that develop should be

sealed with a water-proof, non-extruding compressible compound specifically recommended for

heavy duty concrete pavement and wet environments.

The use of a vapor retarder should be considered beneath concrete slabs on grade that will be

covered with wood, tile, carpet or other moisture sensitive or impervious coverings, or when the

slab will support equipment sensitive to moisture. When conditions warrant the use of a vapor

retarder, the slab designer should refer to ACI 302 and/or ACI 360 for procedures and cautions

regarding the use and placement of a vapor retarder.

Where floor slabs are tied to perimeter walls or turn-down slabs to meet structural or other

construction objectives, our experience indicates that any differential movement between the

walls and slabs will likely be observed in adjacent slab expansion joints or floor slab cracks that

occur beyond the length of the structural dowels. The structural engineer should account for

this potential differential settlement through use of sufficient control joints, appropriate

reinforcing or other means.

4.5.2 Construction Considerations

On most project sites, the site grading is generally accomplished early in the construction phase.

However as construction proceeds, the subgrade may be disturbed due to utility excavations,

construction traffic, desiccation, rainfall, etc. As a result, the floor slab subgrade may not be

suitable for placement of aggregate base and concrete and corrective action will be required. The

gray shale bedrock slakes when exposed to water and will require undercutting to expose stable

bedrock. Consideration could be given to placing a lean concrete mud mat on the approved

subgrade for protection and to serve as a suitable working platform.

Grading to establish slab-on-grade subgrade is anticipated to expose bedrock/soil interface in

some areas. From experience, seepage commonly occurs along the bedrock/soil interface. Free

Geotechnical Engineering Report

Proposed U Square Development-Blocks 4 & 5 Calhoun St., Cincinnati, Ohio

May 31, 2011 HCN/Terracon Project No. N1115051

Responsive Resourceful Reliable 18

draining granular base is recommended below the floor slab (see Section 4.5.1 Design

Recommendations) to collect and discharge this seepage.

We recommend the area underlying the floor slab be rough graded and then thoroughly

proofrolled (soil areas) with a loaded tandem-axle dump truck (minimum 20-ton) prior to final

grading and placement of aggregate base. Particular attention should be paid to high traffic areas

that were rutted and disturbed earlier and to areas where backfilled trenches are located. Areas

where unsuitable conditions are located should be repaired by removing and replacing the

affected material with properly compacted fill. All floor slab subgrade areas should be moisture

conditioned and properly compacted to the recommendations in this report immediately prior to

placement of the aggregate base and concrete.

4.6 Lateral Earth Pressures

Permanent subsurface walls up to about 6 feet tall are anticipated within the storm water

detention areas (inside the garages) and elevator pit areas of the buildings. Grade separation

walls are also anticipated in loading dock areas (up to about 5 feet tall) and first floor garage

ramps. These walls are anticipated to be restrained against rotation at their top (braced by the

floor slab) and expected to behave in a relatively rigid manner. Therefore, it is recommended that

these walls be designed for near at-rest lateral earth pressures. The design recommendations

for the walls are summarized below. The recommended design lateral earth pressures do not

include a factor of safety and do not provide for possible hydrostatic pressure on the walls.

4.6.1 Design Recommendations

Backslope Level

Lateral Pressures

1

30H psf rectangular distribution plus 1/2 of any surcharge located

above the grade separation wall.

Backfill

2

Minimum 2-feet wide (from the backface of the wall) free-

draining granular material

Foundation See Section 4.3 Foundations

1 The earth pressure recommendation is based upon the requirement that free-draining granular backfill

zone be provided (as recommended above) along with drainage provisions. It is assumed that

adequate drainage measures (including foundation drains) will be incorporated so that hydrostatic

pressures will not be allowed to develop behind the wall.

2 Free-draining granular material should have less than 7 percent fines (material passing the #200

sieve), such as ODOT No. 57 or No. 67 crushed stone.

Consideration could be given to supporting the subsurface and grade separation walls on spread

footings bearing within very stiff natural overburden soils or bedrock. Alternately, these walls can

be supported on grade beams connected to drilled shafts. The design and construction of spread

footings should be in accordance with recommendations in Section 4.3 Foundations. The

feasibility of supporting short grade separation walls with spread footings bearing on partially

Geotechnical Engineering Report

Proposed U Square Development-Blocks 4 & 5 Calhoun St., Cincinnati, Ohio

May 31, 2011 HCN/Terracon Project No. N1115051

Responsive Resourceful Reliable 19

improved (with undercut and replacement) existing uncontrolled fill soils will require specific

evaluation.

4.6.2 Construction Considerations

The placement of retaining wall backfill should be consistent with recommendations in section

4.2.3 Compaction Requirements. It is recommended that light-duty, hand compaction

equipment be used within 5-feet of the wall backface to minimize compaction stresses on the

wall.

Consideration could be given to including a nonwoven geotextile fabric to separate the granular

wall backfill from the surrounding soil. Mirafi 140N, Carthage Mills FX-40HS or approved

equivalent geotextile fabric is recommended.

To avoid surface water from directly penetrating the wall backfill, a layer of cohesive soil or a

concrete floor slab or pavement should cap the surface of the backfill and slope away from the

wall. If cohesive soils are used, normally a 12 to 18-inch thick layer of cohesive material is

utilized for this purpose.

To control hydrostatic pressures behind the wall, we recommend that a drain be installed (behind

the wall at foundation level) with a collection pipe leading to a reliable discharge. If this is not

possible, then hydrostatic pressures will need to be included. Recommendations for specific cases

can be provided, upon request, as an addendum to this report.

4.7 Pavements

4.7.1 Subgrade Preparation

The subgrade for pavements should be prepared in accordance with recommendations in Section

4.2 Earthwork of this report. Existing uncontrolled fill soils at the pavement subgrade level should

be undercut and replaced with new engineered fill such that the subgrade consists of minimum 3

feet of engineered fill reinforced with geogrid as described in Section 4.1 Geotechnical

Considerations.

On most project sites, the site grading is accomplished relatively early in the construction phase.

Fills are placed and compacted in a uniform manner. However, as construction proceeds,

excavations are made into these areas, rainfall and surface water saturates some areas, heavy

traffic from concrete trucks and other delivery vehicles disturbs the subgrade and many surface

irregularities are filled in with loose soils to improve trafficability temporarily. As a result, the

pavement subgrades, initially prepared early in the project, should be carefully evaluated as the

time for pavement construction approaches.

We recommend the moisture content and density of the top 9 inches of the subgrade (in soil

areas) be evaluated and the pavement subgrade (soil areas) be proof-rolled within two days prior

Geotechnical Engineering Report

Proposed U Square Development-Blocks 4 & 5 Calhoun St., Cincinnati, Ohio

May 31, 2011 HCN/Terracon Project No. N1115051

Responsive Resourceful Reliable 20

to commencement of actual paving operations. Soil subgrade areas not in compliance with the

required ranges of moisture or density should be moisture conditioned and recompacted.

Particular attention should be paid to high traffic areas that were rutted and disturbed earlier and

to areas where backfilled trenches are located. Subgrade areas with gray shale bedrock should

be evaluated immediately prior to placing the aggregate base. All subgrade areas where

unsuitable conditions are located should be repaired by removing and replacing the materials with

properly compacted fills.

If a significant precipitation event occurs after the evaluation or if the surface becomes disturbed,

the subgrade should be reviewed by qualified personnel immediately prior to paving. The

subgrade should be in its finished form at the time of the final review.

4.7.2 Design Considerations

Traffic patterns and anticipated loading conditions were not available at the time that this report

was prepared. However, we anticipate that traffic loads will be produced primarily by automobile

traffic and occasional delivery and trash removal trucks. The thickness of pavements should be

determined using expected traffic volumes, vehicle types, and vehicle loads and should be in

accordance with local, city or county ordinances.

Pavement thickness can be determined using AASHTO, Asphalt Institute and/or other methods if

specific wheel loads, axle configurations, frequencies, and desired pavement life are available.

HCN can provide thickness recommendations for flexible and rigid pavements subjected to

anticipated traffic loads (if this information is provided) as an extension to our current scope of

work.

An estimated CBR value of 3 is recommended for proportioning flexible pavement sections.

This assumes that the subgrade is prepared in accordance with Section 4.7.1 Subgrade

Preparation. Laboratory and/or field CBR testing is recommended to be performed during

construction to confirm the design value. A modulus of subgrade reaction value of 100 pounds

per cubic inch is recommended for design of rigid Portland cement concrete (PCC) pavement

sections. PCC pavement sections are recommended in loading dock and dumpster areas.

Pavement performance is affected by its surroundings. In addition to providing preventive

maintenance, the civil engineer should consider the following recommendations in the design

and layout of pavements:

Final grade adjacent to parking lots and drives should slope down from pavement edges at

a minimum 2%;

The subgrade and the pavement surface should have a minimum inch per foot slope to

promote proper surface drainage;

Install pavement drainage surrounding areas anticipated for frequent wetting (e.g., landscape

islands);

Install joint sealant and seal cracks immediately;

Geotechnical Engineering Report

Proposed U Square Development-Blocks 4 & 5 Calhoun St., Cincinnati, Ohio

May 31, 2011 HCN/Terracon Project No. N1115051

Responsive Resourceful Reliable 21

Seal all landscaped areas in, or adjacent to pavements to reduce moisture migration to

subgrade soils;

Place compacted, low permeability backfill against the exterior side of curb and gutter; and,

Place curb, gutter and/or sidewalk directly on clay subgrade soils rather than on unbound

granular base course materials.

4.7.3 Pavement Drainage

Pavements should be sloped to provide rapid drainage of surface water. Water allowed to pond

on or adjacent to the pavements could saturate the subgrade and contribute to premature

pavement deterioration. In addition, the pavement subgrade should be graded to provide positive

drainage within the granular base section. Appropriate sub-drainage or connection to a suitable

daylight outlet should be provided to remove water from the granular base.

4.7.4 Pavement Maintenance

Periodic maintenance of pavement sections should be anticipated. Therefore preventive

maintenance should be planned and provided for through an on-going pavement management

program. Preventive maintenance activities are intended to slow the rate of pavement

deterioration, and to preserve the pavement investment. Preventive maintenance consists of both

localized maintenance (e.g., crack and joint sealing and patching) and global maintenance (e.g.,

surface sealing). Preventive maintenance is usually the first priority when implementing a planned

pavement maintenance program and provides the highest return on investment for pavements.

Prior to implementing any maintenance, additional engineering observation is recommended to

determine the type and extent of preventive maintenance. Even with periodic maintenance, some

movements and related cracking may still occur and repairs may be required.

5.0 GENERAL COMMENTS

Terracon should be retained to review the final design plans and specifications so comments

can be made regarding interpretation and implementation of our geotechnical recommendations

in the design and specifications. Terracon also should be retained to provide observation and

testing services during grading, excavation, foundation construction, floor slab and pavement

subgrade preparation, wall backfill placement and other earth-related construction phases of the

project.

The analysis and recommendations presented in this report are based upon the data obtained

from the borings performed at the indicated locations and from other information discussed in

this report. This report does not reflect variations that may occur between borings, across the

site, or due to the modifying effects of weather. The nature and extent of such variations may

not become evident until during or after construction. If variations appear, we should be

immediately notified so that further evaluation and supplemental recommendations can be

provided.

Geotechnical Engineering Report

Proposed U Square Development-Blocks 4 & 5 Calhoun St., Cincinnati, Ohio

May 31, 2011 HCN/Terracon Project No. N1115051

Responsive Resourceful Reliable 22

The scope of services for this project does not include either specifically or by implication any

environmental or biological (e.g., mold, fungi, bacteria) assessment of the site or identification or

prevention of pollutants, hazardous materials or conditions. If the owner is concerned about the

potential for such contamination or pollution, other studies should be undertaken. While

environmental-related services are not part of this scope, please note the detected

This report has been prepared for the exclusive use of our client for specific application to the

project discussed and has been prepared in accordance with generally accepted geotechnical

engineering practices. No warranties, either express or implied, are intended or made. Site

safety, excavation support, and dewatering requirements are the responsibility of others. In the

event that changes in the nature, design, or location of the project as outlined in this report are

planned, the conclusions and recommendations contained in this report shall not be considered

valid unless Terracon reviews the changes and either verifies or modifies the conclusions of this

report in writing.

APPENDIX A

FIELD EXPLORATION

CALHOUN STREET

McMILLAN STREET

McMILLAN STREET

H

A

R

T

S

H

O

R

N

W

. C

L

I F

T

O

N

CALHOUN STREET

1

-

2

-

4

-

859' 861' 860' 861'

861'

860' 859' 860'

859'

863' 863' 863'

862'

862' 861' 861'

860'

861'

861'

861'

861'

RETAIL

4,910 SF

STORMWATER

DETENTION

864'

864'

865'

861'

860'

859'

858'

857'

856'

857' 858' 859'

862'

861'

860'

859'

858'

1 A100

FLOOR PLAN

GROUND LEVEL

TEMPORARY

BENCHMARK

TEMPORARY

BENCHMARK

TEMPORARY

BENCHMARK

DESIGNED BY:

SCALE:

APPVD. BY:

DRAWN BY:

DATE:

SHEET NO.:

JOB NO.

B

Y

D

E

S

C

R

I

P

T

I

O

N

D

A

T

E

R

E

V

.

ACAD NO.

T

E

S

T

B

O

R

I

N

G

A

N

D

T

E

S

T

P

I

T

L

O

C

A

T

I

O

N

P

L

A