Professional Documents

Culture Documents

Tile Fixing Specification

Uploaded by

Komal PanchalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tile Fixing Specification

Uploaded by

Komal PanchalCopyright:

Available Formats

Tile Fixing Specification Tiling Specification

Specification No.1- Cement: Sand Screeds with Undertile Heating. Specification No.2- Existing Timber Floors with Undertile Heating. Specification No.3- Overlaid Plywood Floors with Undertile Heating.

Specification No.1 - Cement: Sand Screeds with Undertile Heating.

Preparation of the Base Before starting to tile the floor, ensure that backgrounds/bases are: - Sufficiently flat to permit the specified flatness of finished tiling. - Suitable for tiling in the service conditions to which they will be exposed. - Sufficiently strong and rigid to support the tile finish. If any of the above requirements are not met, the Site Supervisor must be informed and corrective measures agreed. NEW CEMENT: SAND SCREEDS: Before commencing tiling, screeds will have been allowed to dry out by exposure to air for at least 3 weeks. EXISTING BACKGROUNDS/BASES GENERALLY: Any efflorescence, laitance, dirt and other loose material will be removed by mechanical abrasion. - Any deposits of oil, grease and other materials incompatible with the bedding will be removed by mechanical abrasion. - The background/base will be allowed to dry before fixing tiles. EXISTING CONCRETE/SCREED BASES: All loose or hollow portions must be cut out and made good with ULTRA ProFlex SP Tile Adhesive. - Any soft or unsound adhesive residues must be removed without damaging the base. It will be ensured that any remaining adhesive residue is sound and firmly bonded to the base. Floors that are not deemed to be sufficiently level to receive a tile finish may be levelled using ULTRA LEVELLING COMPOUND, which should be allowed to dry. Fixing Insulation Board and Heating Cables. The Fastwarm insulation board may be fixed to the screed using ULTRA ProFlex SP Tile Adhesive. Once the adhesive has dried, the Cablewarm underfloor heating should be fixed to the Fastwarm insulation board as per the manufacturers recommendations. The heating cables should be screeded over using ULTRA ProFlex SP Tile Adhesive to provide a level surface. The adhesive should be allowed to dry. Adhesive New tiles may be fixed in a 3-25mm solid bed (i.e. ensuring no voids are left beneath the tiles) of ULTRA ProFlex SP Tile Adhesive. ADHESIVE BEDDING: THICK-BED/SOLID-BED (FLOORS): Use a suitable Thick Bed Solid Bed Trowel. - The adhesive will be applied to the dry base in areas up to 1m. For porous bases, a skim coat of adhesive will first be applied before combing the remaining adhesive while the skim coat is still wet. - Any depressions (ribbed, keyed profiles, etc.) to the backs of tiles will be filled with adhesive. - Tiles will be firmly pressed into position with a twisting/sliding action ensuring that as far as possible no voids are left beneath the tiles. Grouting Once the adhesive has set and dried, joints between the tiles may be filled with ULTRA Flexible Floor Grout. Movement Joints Movement joints in the floor tiling should be incorporated as outlined in British Standard BS 5385: Part 3:1989:Clauses 19 and 23.6. Briefly, this document requires that joints be located

a. Over existing and/or structural movement joints. b. Around the perimeter of the floor and where tiling abuts columns, curbs, steps and plant fixed to the base. c. In large floor areas tiles should be divided into bays at 8-10m intervals. Movement joints will be required in this installation. These joints should be a minimum of 6mm in cross section. Perimeter movement joints may be filled with a suitable sealant. On suspended floors the bay size should be reduced and additional joints provided over supporting walls or beams. General On completion of tiling ensure that 14 days elapse before the floor is brought slowly to its operating temperature ideally at a maximum rate of 5C per day.

Specification No.2- Existing Timber Floors with Undertile Heating.

Preparation of the Base Before starting floor tiling ensure that backgrounds/bases are: - Sufficiently flat to permit the specified flatness of finished tiling. - Suitable for tiling in the service conditions to which they will be exposed. - Sufficiently strong and rigid to support the tile finish. New timber bases should be designed not merely to carry the additional dead load but also to provide a stiff floor. Noggings should be fixed between joists. The limit of deflection permitted in BS5268 may be too great to avoid damage to a rigid finish and its bed. Existing timber bases should be carefully examined to ensure that they can carry the additional dead load without excessive deflection. Consideration should be given to removing existing boards and then stiffening the floor with noggings and proceeding as for new timber bases. Alternatively, the required rigidity may be achieved by fixing exterior grade plywood over existing boards. It should also be established that ventilation is adequate and that effective damp-proof courses are correctly located. Timber floors of faulty construction have often behaved unsatisfactorily for a period of years as a result of surface evaporation of moisture. If this is hindered by the laying of a nearly impervious covering the moisture content may rise to a dangerously high level, thus creating conditions favourable to fungal attack, e.g. dry rot. The design should take into account the initial drying shrinkage of the timber and subsequent movements due to seasonal moisture changes in mind the type of heating. New timber bases should have noggins between the joists at 300mm centres. The surface provided for tiling should ideally be exterior-grade plywood of a minimum thickness of 18mm screwed to both joists and noggings at intervals of a maximum of 300mm. The lower face and edges of plywood should be sealed with UNIVERSAL BONDING AGENT against the ingress of moisture before being screwed down. All junctions between boards should be supported by noggings or joists. EXISTING BACKGROUNDS/BASES GENERALLY: Any efflorescence, laitance, dirt and other loose material will be removed by mechanical abrasion. - Any deposits of oil, grease and other materials incompatible with the bedding will be removed by mechanical abrasion. - The background/base will be allowed to dry before fixing tiles. Prior to applying the Fastwarm insulation board, one proprietary system, designed for neutralising shear stresses that occur through movement of the timber substrate involves the use of Schlter Ditra Matting polyethylene membrane with anchoring fleece laminated on the underside. Advice on the correct bonding method for this product to timber should be sought from the manufacturer (Tel: 01530 813 396). Screed over the Ditra matting using ULTRA ProFlex SP Tile Adhesive to provide a level surface to receive the insulation board. Allow adhesive to dry. Fixing Insulation Board and Heating Cables. The Fastwarm insulation board may be fixed to the base using ULTRA ProFlex SP Tile Adhesive. Once the adhesive has dried, the Cablewarm underfloor heating should be fixed to the Fastwarm insulation board as per the manufacturers recommendations.

The heating cables should be screeded over using ULTRA ProFlex SP Tile Adhesive to provide a level surface. The adhesive should be allowed to dry. Adhesive New tiles may be fixed in a 3-25mm solid bed (i.e. ensuring no voids are left beneath the tiles) of ULTRA ProFlex SP Tile Adhesive. ADHESIVE BEDDING: THICK-BED/SOLID-BED (FLOORS): Use a suitable Thick Bed Solid Bed Trowel. - The adhesive will be applied to the dry base in areas up to 1m. For porous bases, a skim coat of adhesive will first be applied before combing the remaining adhesive while the skim coat is still wet. - Any depressions (ribbed, keyed profiles, etc.) to the backs of tiles will be filled with adhesive. - Tiles will be firmly pressed into position with a twisting/sliding action ensuring that as far as possible no voids are left beneath the tiles. Grouting Once the adhesive has set and dried, joints between the tiles may be filled with ULTRA Flexible Floor Grout. Movement Joints Movement joints in the floor tiling should be incorporated as outlined in British Standard BS 5385: Part 3:1989:Clauses 19 and 23.6. Briefly, this document requires that joints be located a. Over existing and/or structural movement joints. b. Around the perimeter of the floor and where tiling abuts columns, curbs, steps and plant fixed to the base. c. In large floor areas tiles should be divided into bays at 8-10m intervals. Movement joints will be required in this installation. These joints should be a minimum of 6mm in cross section. Perimeter movement joints may be filled with a suitable sealant. On suspended floors the bay size should be reduced and additional joints provided over supporting walls or beams. General On completion of tiling ensure that 14 days elapse before the floor is brought slowly to its operating temperature ideally at a maximum rate of 5C per day.

Specification No. 3- Overlaid Plywood Floors with Undertile Heating.

Preparation of the Base Before starting work ensure that backgrounds/bases are: - Sufficiently flat to permit the specified flatness of finished tiling. - Suitable for tiling in the service conditions to which they will be exposed. - Sufficiently strong and rigid to support the tile finish. If any of the above requirements are not met, the Site Supervisor must be informed and corrective measures agreed. New timber bases should be designed not merely to carry the additional dead load but also to provide a stiff floor. Noggings should be fixed between joists. The limit of deflection permitted in BS5268 may be too great to avoid damage to a rigid finish and its bed. Existing timber bases should be carefully examined to ensure that they can carry the additional dead load without excessive deflection. Consideration should be given to removing existing boards and then stiffening the floor with noggings and proceeding as for new timber bases. Alternatively, the required rigidity may be achieved by fixing exterior grade plywood over existing boards. It should also be established that ventilation is adequate and that effective damp-proof courses are correctly located. Timber floors of faulty construction have often behaved unsatisfactorily for a period of years as a result of surface evaporation of moisture. If this is hindered by the laying of a nearly impervious covering the moisture content may rise to a dangerously high level, thus creating conditions favourable to fungal attack, e.g. dry rot. The design should take into account the initial drying shrinkage of the timber and subsequent movements due to seasonal moisture changes in mind the type of heating. Plywood overlay

PLYWOOD OVERLAY: To BS 6566 or equivalent approved national standard. Surface grade: II or BB. Board type: WBP or Marine-grade. Durability class: H, untreated. Thickness: 15mm minimum. - It will be ensured that existing floorboards are dry, securely fixed and acceptably level. Gross irregularities will be filled or removed and any protruding fastenings will be punched in. - Prior to fixing, the underside and all edges of the plywood will be sealed with UNIVERSAL BONDING AGENT. - Sheets will be laid with cross joints staggered and a 0.5 to 1mm gap between boards and fixed with countersunk screws at 300mm centres with screw heads set flush with the surface. EXISTING BACKGROUNDS/BASES GENERALLY: Any efflorescence, laitance, dirt and other loose material will be removed by mechanical abrasion. - Any deposits of oil, grease and other materials incompatible with the bedding will be removed by mechanical abrasion. - The background/base will be allowed to dry before fixing tiles. Primer Prime surface of plywood with 2 coats of neat UNIVERSAL BONDING AGENT and allow to dry. Fixing Insulation Board and Heating Cables. The Fastwarm insulation board may be fixed to the base using ULTRA ProFlex SP Tile Adhesive. Once the adhesive has dried, the CablewarmT underfloor heating should be fixed to the Fastwarm insulation board as per the manufacturers recommendations. The heating cables should be screeded over using ULTRA ProFlex SP Tile Adhesive to provide a level surface. The adhesive should be allowed to dry. Adhesive New tiles may be fixed in a solid bed (i.e. ensuring no voids are left beneath the tiles) of ULTRA ProFlex SP Tile Adhesive or a 3-6mm solid bed of Setfast Plus. ADHESIVE BEDDING: THICK-BED/SOLID-BED (FLOORS): Use a suitable Thick Bed Solid Bed Trowel. - The adhesive will be applied to the dry base in areas up to 1m. For porous bases, a skim coat of adhesive will first be applied before combing the remaining adhesive while the skim coat is still wet. - Any depressions (ribbed, keyed profiles, etc.) to the backs of tiles will be filled with adhesive. - Tiles will be firmly pressed into position with a twisting/sliding action ensuring that as far as possible no voids are left beneath the tiles. Grouting Once the adhesive has set and dried, joints between the tiles may be filled with ULTRA Flexible Floor Grout . Movement Joints Movement joints in the floor tiling should be incorporated as outlined in British Standard BS 5385: Part 3:1989: Clauses 19 and 23.6. Briefly, this document requires that joints be located a. Over existing and/or structural movement joints. b. Around the perimeter of the floor and where tiling abuts columns, curbs, steps and plant fixed to the base. c. In large floor areas tiles should be divided into bays at 8-10m intervals. Movement joints will be required in this installation. These joints should be a minimum of 6mm in cross section. Perimeter movement joints may be filled with a suitable sealant. On suspended floors the bay size should be reduced and additional joints provided over supporting walls or beams. General On completion of tiling ensure that 14 days elapse before the floor is brought slowly to its operating temperature ideally at a maximum rate of 5C per day. Please note that any change of material, substrate or service conditions will alter this specification and further advice should be sought.

The contents of this specification are based upon the recommendations given in British Standard BS 5385, the Code of Practice for wall and floor tile fixing.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

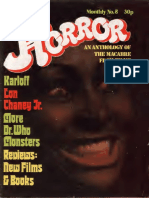

- World of Horror 008 (1972)Document27 pagesWorld of Horror 008 (1972)MindSpaceApocalypse100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Installation Method Statement for ITC One Colombo One FaçadeDocument37 pagesInstallation Method Statement for ITC One Colombo One FaçadeRavi Shankar Kolluru100% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Regis Windows Book 1Document11 pagesRegis Windows Book 1shstudioNo ratings yet

- Wagner Otto-Modern Arch 198Document202 pagesWagner Otto-Modern Arch 198Marta Donoso Llanos100% (2)

- 13 Theory and Design in The First Machine Age 2nd Ed-Banham ReynerDocument344 pages13 Theory and Design in The First Machine Age 2nd Ed-Banham ReynercrystalNo ratings yet

- Activity No. 3 Itak Sa Puso (Karen) PDFDocument4 pagesActivity No. 3 Itak Sa Puso (Karen) PDFKaren Guevarra100% (3)

- How Visual Illusions Work - WSJDocument2 pagesHow Visual Illusions Work - WSJCathy ApanNo ratings yet

- Resume Iryne RohDocument2 pagesResume Iryne RohIryne RohNo ratings yet

- CPAR MODULE 3 (Report)Document50 pagesCPAR MODULE 3 (Report)Gladys GaleraNo ratings yet

- Technical LetteringDocument3 pagesTechnical LetteringAdair LopezNo ratings yet

- William Morris - Hoa IiiDocument14 pagesWilliam Morris - Hoa Iiipushpa ganesanNo ratings yet

- Mesa Verde Cliff Dwellings 154Document2 pagesMesa Verde Cliff Dwellings 154api-443393016No ratings yet

- 5 SimplyPrintDocument3 pages5 SimplyPrintCatchmeUkznNo ratings yet

- Alfred TennysonDocument12 pagesAlfred TennysonAnonymous IogovJWNo ratings yet

- Concise for English Exam DocumentDocument4 pagesConcise for English Exam DocumentPutri_MawilianaNo ratings yet

- Architect Charles GarnierDocument20 pagesArchitect Charles Garniertanie100% (1)

- Hempedur 85671Document2 pagesHempedur 85671Shanoor ASNo ratings yet

- The Fire Station ProjectDocument147 pagesThe Fire Station Projectthrowmeaway34No ratings yet

- 4b-Engineering Applications of BotanyDocument60 pages4b-Engineering Applications of BotanyAshok NeneNo ratings yet

- Rosalia LombardoDocument2 pagesRosalia LombardoJuly CapilloNo ratings yet

- My Last DuchessDocument13 pagesMy Last DuchessixmawelNo ratings yet

- Commonalities in Park Chan Wook FilmsDocument4 pagesCommonalities in Park Chan Wook FilmsGermán MendozaNo ratings yet

- Powderhorn Art Fair 2010Document12 pagesPowderhorn Art Fair 2010Powderhorn Art FairNo ratings yet

- Dreams Really Do Come TrueDocument30 pagesDreams Really Do Come Trueantou74No ratings yet

- Luxury Lifestyle Awaits at Ushodaya ResidencyDocument16 pagesLuxury Lifestyle Awaits at Ushodaya ResidencyKiran Kumar VarriNo ratings yet

- Photoshop PDFDocument26 pagesPhotoshop PDFblob232No ratings yet

- Humanities and Social Science Unit PlannerDocument12 pagesHumanities and Social Science Unit Plannerapi-296998500No ratings yet

- Igor Vasiliadis PresentationDocument21 pagesIgor Vasiliadis Presentationapi-98123473No ratings yet

- Merritt Morning Market 3625 - October 27Document2 pagesMerritt Morning Market 3625 - October 27Kim LeclairNo ratings yet

- Impressionism movement overviewDocument13 pagesImpressionism movement overviewhNo ratings yet