Professional Documents

Culture Documents

TMM - XRF - Determination of Silicon Dioxide in Silica Sand by X-Ray Fluorescense Spectrometry

Uploaded by

Akma KamarudinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TMM - XRF - Determination of Silicon Dioxide in Silica Sand by X-Ray Fluorescense Spectrometry

Uploaded by

Akma KamarudinCopyright:

Available Formats

Determination of Silicon Dioxide (SiO2) in Silica Sand by X-Ray Fluorescence Spectrometry (XRFS)

1.0

Principle

The sample is fused using a mixture of lithium tetraborate and lithium metaborate flux. The fusion melt is cooled and undergo crystallization forming a clear fused bead. The fused bead is then irradiated by a high energy X-ray beam to produce a secondary X-ray. The characteristic beam is then dispersed by mean of crystal, and the produce intensities are measured by suitable detector at selected wavelength. Concentration of the elements are determined by relating the measured radiation of unknown sample to analytical curve prepared from reference materials of known concentration.

2.0

Scope

2.1.

This procedure covers the method for determination of silicon dioxide in silica sand.

3.0

Apparatus Analytical Balance with a readability of 0.1 mg. Plate Grinder or Pulverizer, with one static and one rotating disk for further grinding. Rotary Disk Mill or Shatter Box, with hardened grinding containers and timer control for final grinding. 3.4. 3.5. Fusion Equipment. Furnace or Gas burners, with a timer, capable of heating the sample and flux to at least 1000 C and homogenizing the melt. 3.6. 3.7. Platinum/Gold Crucible, 95 % platinum/5 % gold alloy, 30 to 35 ml capacity. Platinum/ Gold Casting Dish, 95 % platinum/5 % gold alloy, 30 to 35-ml capacity, with a flat bottom 30 to 35 mm in diameter. 3.8. 3.9. Glass rod. Wavelength Dispersive X-Ray Fluorescence Spectrometer (WDXRFS).

o

3.1. 3.2. 3.3.

Test Method Reference:

TMM/XRF/SILICA

Determination of Silicon Dioxide (SiO2) in Silica Sand by X-Ray Fluorescence Spectrometry (XRFS)

4.0

Reagents 4.1. Claisse Lithium Borate Pre-Fused Flux (49.75% Lithium Tetraborate : 49.75% Lithium Metaborate : 0.5% Lithium Bromite) 4.2. Detector Gas , consisting of a mixture of 90 % argon and 10 % methane for use with gas flow proportional counters only. 4.3. Reference Materials- Certified reference materials are available from the National

Institute for Standards and Technology (NIST) and other international certification agencies.

5.0

Preparation of Fusion Glass Bead

5.1

Weigh to the nearest 0.0001 g, 0.6000g of the finely ground sample into a crucible platinum containing 6.0000g of Claisse Lithium Borate pre-fused flux. (Note 9.1, Note 9.2)

5.2

Mix flux and sample properly using a glass rod, and wipe the glass rod to ensure most of the sample and fluxs is transfer back to the platinum crucible.

5.3

Place the crucible on the Claisse M4 fusion machine.

5.4

Choose the fusion silicate ingredient / method and set up the fusion parameter according to the sample decomposition requirement. (Appendix A)

5.5

Fuse the sample and flux mixture according to fusion ingredient until a complete decomposition of the sample.

5.6

After a complete dissolution transfer the hot melt to a platinum dish / mould and let the melt to cool and undergo crystallization.

5.7

Keeps the bead in air tight sample cup inside a desiccators ensuring that a minimal exposure with low relative humidity less than 15 for longer live spend of the bead.

Test Method Reference:

TMM/XRF/SILICA

Determination of Silicon Dioxide (SiO2) in Silica Sand by X-Ray Fluorescence Spectrometry (XRFS)

6.0

Calibration

6.1.

Fuse a series of calibration standard that comprise of Certified Reference Material (CRM) and In-House Reference Material (HRM) using above procedure (As in Para. 5.0) (Refer Appendix B). Set up the instrument according to the Manufacturers Instruction Manual.

6.2.

6.3.

Define the measurement parameters of the instrument to ensure repeatable analyses. (Refer Appendix C)

6.4.

Place the fuse glass bead onto an aluminium sample cup.

6.5.

Calibrate the instrument using the prepared fused glass bead of Certified Reference Material (CRM) and In-House Reference Material (HRM). Establish the calibration curve by a linear least square curve fit of the x-ray intensity measurement versus the corresponding weight percent concentration of element in the reference materials.

7.0

Calculation

)]

Ci Di Lij Cj Ei Ri

ij

= =

Concentration on element of interest / Mass Fraction (%) y-axis intercept Line Overlap Correction Corrected coefficient / factor of concentration on element of interest Inverse of sensitivity during calibration Nett Count Rate Matrix Influences Coefficient (Alpha Coefficient)

=

= = =

Test Method Reference:

TMM/XRF/SILICA

Determination of Silicon Dioxide (SiO2) in Silica Sand by X-Ray Fluorescence Spectrometry (XRFS)

8.0

Measurement

8.1.

Verification of Calibration (Drift Correction)

8.1.1.

Verify the calibration by measuring the verification glass (Herasil). The result of the verification glass should be in the range of 2. (Refer Table 1.1)

8.1.2.

If the result is not within the acceptable value (X - 2 / X + 2), measure drift monitor (Ausmon) to correct the calibration drift.

8.1.3.

After the drift monitor measurement is completed, re-measure the verification glass (Herasil) and compare the concentration obtained with the established concentration.

8.2.

Sample Measurement

Single Sample Measurement

8.2.1.

Sample is prepared in duplicate with the presence of In-House Reference Material (GS/SND 2009).

8.2.2.

The measurement of the sample duplicates are performed together with a InHouse Reference Material (GS/SND 2009) and Certified Reference Material (SGT8).

Sample Measurement in Batch

8.2.3.

Sample is prepared in duplicate with the presence of In-House Reference Material (GS/SND 2009).

8.2.4.

Each sample duplicates are measure in the presence of a In-House Reference Material (GS/SND 2009) Measurement of the Certified Reference Material (SGT8) is conducted at the end of the sample batch.

Test Method Reference:

TMM/XRF/SILICA

Determination of Silicon Dioxide (SiO2) in Silica Sand by X-Ray Fluorescence Spectrometry (XRFS)

9.0

Notes 9.1. The balance in use must be verified using internal calibration mode. Otherwise the calibration could be verified using an E2 type standard weight.

9.2.

Each batch of the fusion flux is checked for its spectrometric different. A conversion factor is determined by analyzing a series of In-House Reference Material (HRM-SND 2009) that is prepared using proposed procedure .

9.3.

Drift correction allows to apply a calibration perform on a given date to data measured subsequently. A drift check is conducted by measuring a verification glass called Herasil. If the intensity of the verification glass (Herasil) falls out of the proposed 2 value, a drift correction need to be performed by measuring a drift monitor (Ausmon).

Table 1.1 Verification Value of Herasil

SiO2 X + 2 Mean, X X - 2 709.70 709.60 709.50

Table 1.2 Verification Value of Ausmon

SiO2 X + 2 Mean, X X - 2 267.30 267.25 267.20

Test Method Reference:

TMM/XRF/SILICA

Determination of Silicon Dioxide (SiO2) in Silica Sand by X-Ray Fluorescence Spectrometry (XRFS)

9.4.

The Certified

Reference

Material

(SGT8)

and

In-House

Reference

Material

(GS/SND 2009) are to ensure that the sample preparation is conducted in a proper procedure. Any systematic error that is contributed during sample preparation is corrected by the In-House Reference Material (GS/SND 2009) (Refer Appendix D).

Table 1.3 Certified Value of the SGT8

SiO2 (%) X + 3 X + 2 Mean, X X - 2 X - 3 95.96 95.85 95.63 95.41 95.30

Table 1.4 Consensus Value of the SND 2009

SiO2 (%) X + 3 X + 2 Mean, X X - 2 X - 3 93.80 93.65 93.35 93.05 92.90

Test Method Reference:

TMM/XRF/SILICA

Determination of Silicon Dioxide (SiO2) in Silica Sand by X-Ray Fluorescence Spectrometry (XRFS)

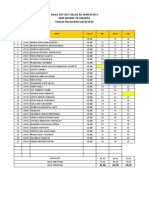

Appendix A Fusion Parameter for the Preparation of Fused Glass Bead for the Determination of Silicon Dioxide (SiO2) in Silica Sand (Using Claisse M4 Fusion Machine)

Test Method Reference:

TMM/XRF/SILICA

Determination of Silicon Dioxide (SiO2) in Silica Sand by X-Ray Fluorescence Spectrometry (XRFS)

Appendix B List of Calibration Standard for the Determination of Silicon Dixoide (SiO 2) in Silica Sand

No 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

Standards NIST SRM 165a GS/SND 99 SGT9 GS/SND 2002 NBS 267 SGT 8 NBS 102 GS/SND 2009 NIST SARM 1413 XRF- 4002 BCS 375/1 NIST SRM 70a GBW 03103 IPT 72 IPT 53 XRF-SOL 5a SY-3 NIST SRM 98b NIST SRM 97b JB-2 BCS CRM 348 NIST SRM 688 KK-1 JMG-Clay 2107 JMG-Clay 2207 NBS 697

Material Sand Silica Sand Glass Sand Silica Sand Glass Sand Glass Sand Glass Sand Silica Sand High Aluminium Sand Ryolite Feldspar Feldspar Kaolin Feldpar Feldpar Soil Syenite Plastic Clay Flint Clay Basalt Ball Clay Basalt Kaolin Clay Clay Bauxite

Test Method Reference:

TMM/XRF/SILICA

Determination of Silicon Dioxide (SiO2) in Silica Sand by X-Ray Fluorescence Spectrometry (XRFS)

Appendix C Measurement Parameter for the Determination of Silicon Dixoide(SiO 2) in Silica Sand Parameter Element Line Crystal Collimator Detector Voltage (kV) Ampere (mA) 2Th (Peak) Value Si K XS-55 0.23 Flow Counter 30 60 15.040

Test Method Reference:

TMM/XRF/SILICA

Determination of Silicon Dioxide (SiO2) in Silica Sand by X-Ray Fluorescence Spectrometry (XRFS)

Appendix D Consensus Value of In-House Reference Material (HRM) GS/SND 2009

Test Method Reference:

TMM/XRF/SILICA

10

You might also like

- Proximate Analysis of Coal and Coke: Standard Practice ForDocument2 pagesProximate Analysis of Coal and Coke: Standard Practice ForJesha LibreaNo ratings yet

- Lund, 2013. Mineralogical, Chemical and Textural Characterisation of The Malmberget Iron Ore Deposit For A Geometallurgical ModelDocument190 pagesLund, 2013. Mineralogical, Chemical and Textural Characterisation of The Malmberget Iron Ore Deposit For A Geometallurgical ModelLucas Pereira100% (1)

- On Paratacamite and Some Related Copper ChloridesDocument12 pagesOn Paratacamite and Some Related Copper ChloridesHJKB1975No ratings yet

- GBT 2566-2010 - en PhotopermiabilityDocument11 pagesGBT 2566-2010 - en PhotopermiabilityYudan TonoNo ratings yet

- Role of Silica and Alumina Content in The Flotation of Iron OresDocument9 pagesRole of Silica and Alumina Content in The Flotation of Iron OresBismark SarpongNo ratings yet

- Gold AnalysisDocument4 pagesGold AnalysisAkshay AKNo ratings yet

- Ceramics InternationalDocument23 pagesCeramics InternationalLeonardo JaimesNo ratings yet

- RDF KoreanDocument7 pagesRDF KoreanNghi VoNo ratings yet

- SOP 006 Knelson EGRG Procedure Rev 3 PDFDocument8 pagesSOP 006 Knelson EGRG Procedure Rev 3 PDFjose hernandezNo ratings yet

- Stanley M. Wallas Chem Proc EquipmentDocument774 pagesStanley M. Wallas Chem Proc Equipmentjesús Iván Santamaria najarNo ratings yet

- D 8010 - 16 PDFDocument3 pagesD 8010 - 16 PDFothman ok100% (1)

- Nickel Mond ProcessDocument1 pageNickel Mond ProcessDapoer OmaOpaNo ratings yet

- D 6385 - 99Document2 pagesD 6385 - 99LoanNo ratings yet

- Astm D 1762 - 84 R01Document2 pagesAstm D 1762 - 84 R01AnselmoNo ratings yet

- Astm D-2361Document4 pagesAstm D-2361Claudia Da Rolt0% (1)

- ISO 5071 1 2013 褐煤挥发份Document19 pagesISO 5071 1 2013 褐煤挥发份Winnjone YinNo ratings yet

- Kinetic Leaching CopperDocument15 pagesKinetic Leaching CopperSteven DziobaNo ratings yet

- Flotation Copper PDFDocument21 pagesFlotation Copper PDFaliNo ratings yet

- Acid Digestion ProcedureDocument2 pagesAcid Digestion ProcedureSolehah OmarNo ratings yet

- Satmagan Description and II Info Oct 2005Document7 pagesSatmagan Description and II Info Oct 2005Ingridh D Quispe ChuanNo ratings yet

- Physicochemical Problems of Mineral Processing: ISSN 1643-1049 Index No. 32213XDocument329 pagesPhysicochemical Problems of Mineral Processing: ISSN 1643-1049 Index No. 32213XAnonymous OnoowoNo ratings yet

- Ball To Powder RatioDocument9 pagesBall To Powder RatioNatalia Eki MulyaniNo ratings yet

- A Novel Technique For Silver Extraction From Silver Sulphide OreDocument5 pagesA Novel Technique For Silver Extraction From Silver Sulphide OreWawan HermawanNo ratings yet

- Sma Negeri 78 Jakarta Hasil Try Out Kelas Xii Semester 5Document11 pagesSma Negeri 78 Jakarta Hasil Try Out Kelas Xii Semester 5EdwardoNo ratings yet

- As 1038.10.3-1998 Coal and Coke - Analysis and Testing Determination of Trace Elements - Coal and Coke - DeteDocument6 pagesAs 1038.10.3-1998 Coal and Coke - Analysis and Testing Determination of Trace Elements - Coal and Coke - DeteSAI Global - APACNo ratings yet

- Leaching of Copper OxideDocument6 pagesLeaching of Copper OxideWinmtyNo ratings yet

- Astm D 2014 - 97 (2010)Document5 pagesAstm D 2014 - 97 (2010)alexander guerraNo ratings yet

- 146 Glue Analysis and Behavior in Copper ElectrolyteDocument11 pages146 Glue Analysis and Behavior in Copper ElectrolyteEugenia Araneda Hernandez100% (1)

- Determination of The Lime Requirement PDFDocument4 pagesDetermination of The Lime Requirement PDFJHP100% (3)

- Flow SheetDocument48 pagesFlow SheetRAVI1972No ratings yet

- 1 Synthesis and Characterization of 13X Zeolite From Low-GradeDocument5 pages1 Synthesis and Characterization of 13X Zeolite From Low-GradeAmir SetiadiNo ratings yet

- K en FertilizanteDocument2 pagesK en FertilizanteMarianita GonzalezNo ratings yet

- Quality Improvement in The Production Process of Grinding BallsDocument5 pagesQuality Improvement in The Production Process of Grinding BallsYaser Mohamed AbasNo ratings yet

- A New Look at Mineral Maps and The Potential Relationships of PDFDocument4 pagesA New Look at Mineral Maps and The Potential Relationships of PDFDaniel Valdes JamettNo ratings yet

- GOLD AND COPPER ELECTROWINNING FROM A GOLD PLANT WASTE SOLUTION by A.J.B. Dutra (EDocFind - Com) PDFDocument10 pagesGOLD AND COPPER ELECTROWINNING FROM A GOLD PLANT WASTE SOLUTION by A.J.B. Dutra (EDocFind - Com) PDFFerudun AkyolNo ratings yet

- Contoh MetlitDocument5 pagesContoh MetlitMuhammad Idrus Abdul BasirNo ratings yet

- PPoMP 2014 50 1 PDFDocument402 pagesPPoMP 2014 50 1 PDFAnonymous OnoowoNo ratings yet

- Modern Practice of Lab Flotation Testing For Flowsheet Development, A Review, by NOL, EW, DB, (Elsevier 2014), Minerals EngineeringDocument11 pagesModern Practice of Lab Flotation Testing For Flowsheet Development, A Review, by NOL, EW, DB, (Elsevier 2014), Minerals EngineeringMARCELO HINOJOSA HERNANDEZ100% (1)

- Tutorial 1 Hmete 510Document3 pagesTutorial 1 Hmete 510TINOTENDASHE MAKONESENo ratings yet

- RWPR 900 Pellet Mill BrochureDocument4 pagesRWPR 900 Pellet Mill Brochuregrupa2904No ratings yet

- Suitability of Using Silica Sand From Katsina As An Essencial Raw Material in The Production of Soda-Lime Silica GlassDocument48 pagesSuitability of Using Silica Sand From Katsina As An Essencial Raw Material in The Production of Soda-Lime Silica GlassAhmad A Liadi100% (1)

- Determination of Copper by AASDocument18 pagesDetermination of Copper by AASWan ShamNo ratings yet

- Microscopic Analysis of DR Grade Pellet From ParadeepDocument6 pagesMicroscopic Analysis of DR Grade Pellet From Paradeepsharma karamjithNo ratings yet

- Hatch and Northern Graphite PaperDocument6 pagesHatch and Northern Graphite PaperNarayana Murthy GadiNo ratings yet

- A Study On The Characterization of Red Mud: January 2014Document5 pagesA Study On The Characterization of Red Mud: January 2014Ken FabeNo ratings yet

- Sgs Min Tp2002 04 Bench and Pilot Plant Programs For Flotation Circuit DesignDocument10 pagesSgs Min Tp2002 04 Bench and Pilot Plant Programs For Flotation Circuit DesignevalenciaNo ratings yet

- 0322 PANalyticalDocument48 pages0322 PANalyticalcemsavant100% (1)

- Recent Advances in Sample Preparation Methods Analysis of Geological Samples - 2019Document16 pagesRecent Advances in Sample Preparation Methods Analysis of Geological Samples - 2019Marcial PerezNo ratings yet

- Tanzania Audits Final Report (Workstations GEITA) PDFDocument22 pagesTanzania Audits Final Report (Workstations GEITA) PDFRegina Efraim100% (1)

- E 925 - 83 R94 - Rtkyns04m1i5neux PDFDocument6 pagesE 925 - 83 R94 - Rtkyns04m1i5neux PDFpechugonisNo ratings yet

- Life Cycle Assessment Pabrik Semen PT Holcim Indonesia Tbk. Pabrik Cilacap: Komparasi Antara Bahan Bakar Batubara Dengan BiomassaDocument8 pagesLife Cycle Assessment Pabrik Semen PT Holcim Indonesia Tbk. Pabrik Cilacap: Komparasi Antara Bahan Bakar Batubara Dengan BiomassahafizahazmianisaNo ratings yet

- Chap 11Document3 pagesChap 11Flia Diaz ZunigaNo ratings yet

- Standard Operating Procedure For Ball Mills and Sieve ColumnsDocument3 pagesStandard Operating Procedure For Ball Mills and Sieve ColumnsZack EmeryNo ratings yet

- Silica Fume - Specification: Indian StandardDocument10 pagesSilica Fume - Specification: Indian StandardVenkat BalajiNo ratings yet

- Rilem TestDocument6 pagesRilem TestMOSTEFA FouziaNo ratings yet

- Conditions of Sample Preparation For Quantitative X-Ray Diffraction of Cement ClinkerDocument6 pagesConditions of Sample Preparation For Quantitative X-Ray Diffraction of Cement ClinkeryinglvNo ratings yet

- C 146Document12 pagesC 146donaldoguerrero67% (3)

- Technical Guide: UV/Vis Spectrophotometer Calibration ProceduresDocument7 pagesTechnical Guide: UV/Vis Spectrophotometer Calibration Procedureslong100% (1)

- Tutorial PTP 200407Document42 pagesTutorial PTP 200407Akma KamarudinNo ratings yet

- 7473-Mercury in Solids and Solutions by Thermal Decomposition, Amalgamation, and Atomic Absorption SpectrophotometryDocument17 pages7473-Mercury in Solids and Solutions by Thermal Decomposition, Amalgamation, and Atomic Absorption SpectrophotometrydrakenhavenNo ratings yet

- Hig 79 9 PDFDocument63 pagesHig 79 9 PDFAkma DinNo ratings yet

- Alteration and Fluid Inclusion (Arif M)Document52 pagesAlteration and Fluid Inclusion (Arif M)Akma Kamarudin100% (1)

- Mining BooksDocument5 pagesMining BooksAkma Kamarudin100% (1)

- Structural Imperfections (Defects) in Crystalline Solids: These Lecture Notes Are Taken From METU CE241 ClassDocument23 pagesStructural Imperfections (Defects) in Crystalline Solids: These Lecture Notes Are Taken From METU CE241 Classvamps sierNo ratings yet

- OptiFDTD Tutorials PDFDocument36 pagesOptiFDTD Tutorials PDFKhải NguyễnNo ratings yet

- Thermalrock S Data Sheet - inDocument2 pagesThermalrock S Data Sheet - inlac ngoNo ratings yet

- SSPC Pa 2Document16 pagesSSPC Pa 2Rony Ruiz100% (5)

- A Hydraulic Cylinder Subjected To Euler's LoadDocument17 pagesA Hydraulic Cylinder Subjected To Euler's LoadOlaf HaflpafNo ratings yet

- Conics 2Document8 pagesConics 2Boy ShahNo ratings yet

- 1.'motivation For SoC Design - by Raveendra SomanaDocument13 pages1.'motivation For SoC Design - by Raveendra SomanaSantosh Shivapuji100% (1)

- Murray Leinster - Sidewise in TimeDocument25 pagesMurray Leinster - Sidewise in Timemiquester50% (2)

- The Key To Super Consciousness Chapter 1Document6 pagesThe Key To Super Consciousness Chapter 1Will FortuneNo ratings yet

- Bio Analytical SopDocument17 pagesBio Analytical SopalexpharmNo ratings yet

- Mollier Diagram BeginDocument3 pagesMollier Diagram BeginKalu BhaiNo ratings yet

- (M1 Technical) Cpe0011lDocument12 pages(M1 Technical) Cpe0011lJoel CatapangNo ratings yet

- Csi ReferDocument502 pagesCsi Referrenzo wilber bernedo beltranNo ratings yet

- Aaronia AARTOS DDS FAQ PDFDocument10 pagesAaronia AARTOS DDS FAQ PDFUmar FarooqNo ratings yet

- Exam Style Answers 18 Asal Physics CBDocument2 pagesExam Style Answers 18 Asal Physics CBAnshul ShahNo ratings yet

- Effect of Sawdust Filler With Kevlarbasalt Fiber On The MechanicalDocument6 pagesEffect of Sawdust Filler With Kevlarbasalt Fiber On The MechanicalKarim WagdyNo ratings yet

- 1PH7 MotorDocument244 pages1PH7 MotorgetNo ratings yet

- Buried Pipe NDTDocument224 pagesBuried Pipe NDTDemian PereiraNo ratings yet

- S Puiching10 F3Document8 pagesS Puiching10 F3Carlos TorresNo ratings yet

- Application of Mecanum WheelsDocument12 pagesApplication of Mecanum WheelsMithun JohnNo ratings yet

- Marine Hydrodynamics - J. N. Newman PDFDocument450 pagesMarine Hydrodynamics - J. N. Newman PDFfarazali2919100% (4)

- TIME TABLE - M.E/M.Tech. - APRIL/MAY-2010 Regulations: 2005Document12 pagesTIME TABLE - M.E/M.Tech. - APRIL/MAY-2010 Regulations: 2005Sathis KumarNo ratings yet

- FRAP 30mmDocument97 pagesFRAP 30mmSkeevekillerNo ratings yet

- Homework Solutions/Kinetics 1Document11 pagesHomework Solutions/Kinetics 1Eduardo Rosado HerreraNo ratings yet

- Cleaning Validation ProtocolDocument6 pagesCleaning Validation ProtocolVega life sciences100% (1)

- 1 - SetsDocument2 pages1 - SetsHerald MulanoNo ratings yet

- Fundatii Turbine EolieneDocument8 pagesFundatii Turbine EolieneTudor PopNo ratings yet

- Eye TrackingDocument13 pagesEye TrackingRohit KoulNo ratings yet

- Calculating The Heating Value of BiogasDocument5 pagesCalculating The Heating Value of BiogasAnonymous MVHQ97KEoPNo ratings yet

- IJEAS0205034Document6 pagesIJEAS0205034erpublicationNo ratings yet