Professional Documents

Culture Documents

EC-01 Technical Writeup

Uploaded by

Ameet KudcheOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EC-01 Technical Writeup

Uploaded by

Ameet KudcheCopyright:

Available Formats

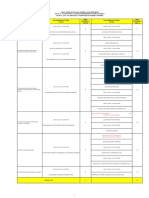

TECHNICAL WRITE-UP IMCO make Digital Pick-cum-Length Counter Model EC-01

EC-01 is basically a Digital Counter for measuring the number of pick units (1 unit=100 picks) and length of cloth produced on a weaving loom. Functions performed by digital counter Model EC-01 :1) Pick Units recording : a) It measures and records the no. of pick units (1 unit = 100 picks) in each of the three shifts A, B & C exactly the same function as performed by a mechanical three shift pick counter. The readings can be reset to 00000 if and when desired. b) It measures & records the Total no. of pick units of all the shifts- like a Totalizer. The readings can be reset to 00000 if and when desired. 2) Length measuring and recording :a) It measures and records the length of the cloth produced ( in metres upto 1 decimal place) in each of the three shifts A,B & C exactly the same function as performed by a mechanical three shift Loom length measuring counter. The length readings can be reset to 00000 if and when desired. b) It measures and records the Total (cumulative) length (in metres) of the cloth produced continuously- like a Totalizer. The readings can be reset to 00000 if and when desired.

3)

Preset Length :The loom can be stopped by the counter whenever a desired length, which is preset on the counter, is wound on the cloth roll of loom- thus any no. of batches/doffings of desired equal length can be obtained exactly the same function as performed by a Predetermined Loom length measuring counter.

Contd. Page-2

-24) RPM :The counter displays in one of the modes, displayed as rpn on the screen, the RPM of the loom i.e. no. of revolutions of the crank shaft of the loom per minute, which is equal to the no. of picks inserted per minute ( as one rev. of crank shaft = 1 pick ) Calibration and Measurement system of the counter:The drive, or the pulse imparting to the counter is done from the crank shaft or bottom shaft of the loom. A Pulse Generating Ring is fitted on either of the two shafts of the loom and the Proximity Switch (sensor) is fitted opposite to the face of the same. The pulses generated are transmitted to the counter. The programme fed in the counter then converts the pulses to various production readings which are then displayed on the screen of the counter. Features of the counter :1) Running Length:- In the r l mode, the counter will record and display the current length of the batch/lot (out of the set length which is preset on the counter) at that point of time when you are viewing it. This is called running length r l. This r l will be equal to the Set Length SL, when the set length S L is reached. True Length measurement of the cloth (measured in shrunk condition after it has been removed from the loom):When the cloth is woven on the loom, weights are attached to keep the cloth tight and thus stretched. On removal of the cloth from the loom, it shrinks to a certain extent by a certain %. The length after this shrinkage is the True Length. This % true length (i.e. 100 - % shrinkage) can be fed in the programmable parameter (LS) in the counter. The counter will display only this true length (i.e. shrunk length) in all length displays, including the set length (SL) mode.

2)

3)

Viewing:- By pressing key no. 3 anytime (even if the loom is running), you can view the following current production readings as recorded upto the time of viewing, and also review all the programmable parameters already preset in the counter: i) Current pick units and length in each of the three shifts A, B, and C, in the modes AP, bP, CP, AL, bL & CL respectively and also the Total of these readings in Totalizer modes tP & tL. Running length (r l) as mentioned above Current RPM of the loom.

ii) iii)

Contd. Page-3

-3-

iv) v) vi)

Current shift in operation (whether A or B or C) Preset batch/lot length S L (as already preset in the counter) Preset Scale Factor S F (picks per inch of the cloth which is preset in the counter, and is being woven in the cloth on the loom) The value of LS (as already preset in the counter)

vii) 4)

Resetting :- As mentioned earlier all production readings can be independently (but in case of pick unit & length - both together) reset to 00000 if and whenever desired.

5) Memory Back Up :- The counter can store in its memory the Set Programmable Parameters & Production readings in the event of failure of the power supply to the counter, and reproduce the same when power supply is restored . 6) Shift Change Knob :- The shift change from A to B to C and back to A can easily be done simply by pressing key no. 2, even without stopping the loom. Feeding & Setting of Programmable Parameters:- It is done very conveniently by using the three keys on the screen i.e. key no.1 ( SET key) , key no.2 (INC key) and key no.3 (SFT key) . Sensing Speed :The sensor can sense rpm upto & approx. 3000.

7)

8) 9)

Idle Mode:The counter can be put in idle mode whenever, for any reason production is not required to be recorded in the counter, even if the loom is made to run eg. i) when setting of the loom is to be done ii) when repairing of the loom is to be done iii)when rectification of the defective cloth being woven is done. After that, when production is again required to be recorded in the counter the idle mode can be reversed to recording mode. This way, the unwanted production will not get recorded in the counter.

10) Password:- A 5 digit password can be fed and set in the counter, which will be operated by the supervisor only. The programmable parameters which are preset in the counter shall be locked and unlocked by the supervisor by using his password. There is a separate permanent password also, like a master key, to be used if the already fed password is forgotten. Counter Assembly:The complete counter assembly comprises of the following items :The main digital Counter :It is encased inside a heavy duty dust free metal box with a mounting bracket welded on to its bottom. This counter is normally fitted in the same manner and at the same place where the mechanical pick counter is fitted. Contd. Page-4

1)

-4-

2)

Pulse Generating Ring :It is mounted on the crank or bottom shaft of the loom(exactly in the same way as the worm assembly of a mechanical pick counter) Please see sketch of P.G. Ring attached with this write-up. Proximity Switch ( sensor) :It is fitted on a sheet metal bracket , which in turn is fitted on the frame(wall) of the loom in such a way that the face of the sensor is opposite to the face of the step of the Pulse generating ring, with a gap of 2-2.5mm.Please see sketch of sensor attached with this write-up. Low Voltage Transformer 220-240 / 15-24v :voltage power supply to counter. It is required to supply low

3)

4)

5)

Counter Mounting Rod :- It is provided for the mounting the counter on this rod (exactly in the same manner as in case of a mechanical pick counter). Electrical Wiring connection :- The wiring connections to the digital counter are done as shown in the sketch attached with this write-up.

6)

Detailed operation manual is supplied for easy understanding of this counter.

Kindly see the attached separate file for various sketches as per following details:Sketch Sl. No. 1. Sketch Details Sketch of the digital counter encased in a metal box Front view, side view and back view Sketch of Pulse generating ring & Sketch of Proximity switch (sensor) fitted on a standard bracket & Sketch of electrical wiring connections of the counter Sketch of digital counter fitted on any loom on LH side Sketch of digital counter fitted on any loom on RH side

2.

3. 4.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- ASTM Hardness Standards Reference GuideDocument2 pagesASTM Hardness Standards Reference GuideJosé SandovalNo ratings yet

- V N - 2 (2012), I N - 7 (J) : Olume O Ssue O ULYDocument14 pagesV N - 2 (2012), I N - 7 (J) : Olume O Ssue O ULYAmeet KudcheNo ratings yet

- Computerised Vickers Hardness TesterDocument2 pagesComputerised Vickers Hardness TesterAmeet KudcheNo ratings yet

- Analog Cum ELECTRONIC UniversalDocument2 pagesAnalog Cum ELECTRONIC UniversalAmeet KudcheNo ratings yet

- Getting Started Agritourism CornellextDocument20 pagesGetting Started Agritourism Cornellextgirandola79No ratings yet

- Sugar Cane Fertilizer Chart For Coming YearDocument2 pagesSugar Cane Fertilizer Chart For Coming YearAmeet Kudche100% (1)

- Biofertilizers PDFDocument18 pagesBiofertilizers PDFAmeet Kudche100% (1)

- Comparative Study of Bullock Driven TractorsDocument53 pagesComparative Study of Bullock Driven TractorsAmeet Kudche100% (1)

- Department of Scientific and Industrial Reaserch Reconition of in House Resaearch and Development R&D UnitDocument1 pageDepartment of Scientific and Industrial Reaserch Reconition of in House Resaearch and Development R&D UnitAmeet KudcheNo ratings yet

- Servo Control Ele. Universal Testing MachineDocument2 pagesServo Control Ele. Universal Testing MachineAmeet KudcheNo ratings yet

- Computerised Vickers Hardness TesterDocument2 pagesComputerised Vickers Hardness TesterAmeet KudcheNo ratings yet

- Test Report (Sample) - Vickers Hardness TesterDocument1 pageTest Report (Sample) - Vickers Hardness TesterAmeet KudcheNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Scorpion Z4120C Z6020C Z8020C Installer ManualDocument23 pagesScorpion Z4120C Z6020C Z8020C Installer ManualNazriNo ratings yet

- ESD5522E Generator Speed Control UnitDocument2 pagesESD5522E Generator Speed Control UnitKhaled KamelNo ratings yet

- N TypeDocument3 pagesN TypeTayyaba ButtNo ratings yet

- General : Group 00EDocument16 pagesGeneral : Group 00Eopa952ya.ruNo ratings yet

- 8 DtekDocument5 pages8 DtekAlexander WieseNo ratings yet

- Manual CL-3022WKDocument11 pagesManual CL-3022WKDario ZainNo ratings yet

- Battery Reading ProfarmaDocument1 pageBattery Reading Profarma220KVISPR2 SANGJANINo ratings yet

- VFD ReportDocument36 pagesVFD ReportChirag jNo ratings yet

- Data Aire Brochure Web Version v4Document4 pagesData Aire Brochure Web Version v4dnps2011No ratings yet

- Ilct6/ Mct6: Optocoupler, Phototransistor Output, Dual ChannelDocument8 pagesIlct6/ Mct6: Optocoupler, Phototransistor Output, Dual Channeli_need_moneyNo ratings yet

- BGR PSRRDocument3 pagesBGR PSRRsachin saxenaNo ratings yet

- Yta310 & Yta320 YokogawaDocument8 pagesYta310 & Yta320 Yokogawahenryhariyadi100% (1)

- 1000-400-933 - D-X8000 Light Source Service GuideDocument84 pages1000-400-933 - D-X8000 Light Source Service GuideHichem NaghmouchiNo ratings yet

- Description General Specifications: Photoswitch Photoelectric SensorsDocument8 pagesDescription General Specifications: Photoswitch Photoelectric Sensorsmekhman mekhtyNo ratings yet

- Applying the commutator transformation C2 for synchronous machinesDocument8 pagesApplying the commutator transformation C2 for synchronous machinesAli AldesogeNo ratings yet

- Bersemuka LDocument7 pagesBersemuka LPK K0% (1)

- PSC WP Energising Ireland A Guide To Grid Code Compliance K.YumakDocument14 pagesPSC WP Energising Ireland A Guide To Grid Code Compliance K.Yumakp61466365No ratings yet

- Bulb AssignmentDocument2 pagesBulb AssignmentJamie McGregorNo ratings yet

- FYP Project 2jkmkDocument24 pagesFYP Project 2jkmkMarjanNo ratings yet

- CEPT Novice 1Document26 pagesCEPT Novice 1Ster RncNo ratings yet

- GSM Frequency Bands Table ExplainedDocument2 pagesGSM Frequency Bands Table Explainedamits_aumNo ratings yet

- Conventional FireDocument5 pagesConventional FiremohammadNo ratings yet

- MC14528B Dual Monostable Multivibrator: PDIP-16 P Suffix CASE 648Document12 pagesMC14528B Dual Monostable Multivibrator: PDIP-16 P Suffix CASE 648catsoithahuong84No ratings yet

- Engineering Division: FF/HART ConfigurationDocument34 pagesEngineering Division: FF/HART ConfigurationJorge Pérez FrisanchoNo ratings yet

- Spec25051 - Teck CableDocument4 pagesSpec25051 - Teck Cablecrfg2003No ratings yet

- EXC - RTX18B - 2-25, Data Sheet en Rev 2 - 3Document2 pagesEXC - RTX18B - 2-25, Data Sheet en Rev 2 - 3William RamirezNo ratings yet

- Transformer FundamentalsDocument6 pagesTransformer FundamentalsAditya TiwariNo ratings yet

- ASUS ROG RAMPAGE VI EXTREME ENCORE MANUAL Compressed PDFDocument116 pagesASUS ROG RAMPAGE VI EXTREME ENCORE MANUAL Compressed PDFchenchozarangolloNo ratings yet

- DSBSCDocument23 pagesDSBSCrajimerigalaNo ratings yet

- Hcia Lte GeralDocument48 pagesHcia Lte Geralvictor kudidissaNo ratings yet