Professional Documents

Culture Documents

Artificial Sources of Light

Uploaded by

jdipbhadraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Artificial Sources of Light

Uploaded by

jdipbhadraCopyright:

Available Formats

ARTIFICIAL SOURCES OF LIGHT Natural light from sun is the best source of light.

However we need artificial sources of light during the periods of absence of natural light. Incandescent Lamps: It is based on the principle that when electric current is passed through fine metallic wire it gets heated and as temperature rises & it radiates light energy. The material of wire selected should have high melting point, low temperature coefficient and high resistivity. Tungston is usually preferred as it has melting temperature of 3500oC and other preferable factors. Construction:

It is formed of a glass globe completely evacuated. The globe has a cap at the top. A tungsten filament remains suspended supported form the cap. The cap is provided with holding pins and power contact points for fixing up with lamp holder. The glass bulb is evacuated to prevent oxidation of filament. However a vacuum filled (evacuated) bulb can work only upto 2000oC without evaporation of filament. Evaporation of filament blackens the inside of bulb and reduces efficiency. The lamp suffers ageing problem as the diameter of filament reduces. To overcome this the bulb is filled with inert gas argon or a mixture of helium and hydrogen. With this the evaporation of filament is controlled upto 2700oC thus getting better heating and light energy. The inert gas however leads to some heat loss due to convection. This heat loss is dependent on exposed surface of filament. To contain this, coiled coil filament is used. With this whole length of filament is more while exposed length is less. Incandescent lamps have low luminous efficiency of 10 lumens per watt. They have poor life of about 1000 hours. They are good in colour rendering. The disadvantage with these lamps is that they radiate heat outside. Also the glare from the filament irritates eyes. With milky white bulbs the filaments are not visible and hence the glare is avoided. Incandescent lamps are voltage sensitive. A 5 percent increase in voltage leads to about 20% more light but about 50% reduction in life. Similarly 5% decrease in voltage gives 20% less life but with no appreciable increase in life. Fluorescent Lamps : Fluorescent lamp contains a tube inside of which is coated with fluorescent powder like phosphor. There are different powders for giving different coloured lights.

The tube is filled with argon gas and a drop of mercury. Oxide coated tungsten filaments are used as electrodes at the two ends of the long tube. The circuit is completed through choke or ballast and a starter. Glow starters are commonly used. It is a voltage operated device and has two bi metallic contacts (electrodes) enclosed in a glass tube filled with argon or mixture of helium and hydrogen. When the supply voltage is applied discharge takes place in the glow starter as their electrodes are closer. The gas inside gets heated and this closes the bi metallic contacts. Current flows through the closed circuit of choke, main electrodes and starter and the main electrodes are heated with this current. Now with closed contacts in the glow starter no more voltage exists between the bi metallic contacts and the discharge ceases. The gas cools down and the contacts open. The circuit is now open and the current does not flow. This making and breaking of circuit momentarily induces high voltage of the order of 1000 volts in the choke which added with supply voltage initiates discharge between the main electrodes through argon gas and the fluorescent lamp starts giving light. Once the discharge is initiated a much lower voltage than normal voltage is sufficient to maintain the discharge. Thereafter the choke acts only to reduce voltage available across the main electrodes. The capacitor connected across the starter helps to suppress electromagnetic waves generated at the gap due to sparking which may have radio interference with other device connected. Fluorescent lamps produces white light. The average life is 7500 hours. The light output is 70 lumens per watt. They have poor colour rendering especially for red colour. Sodium Vapour Lamp: Sodium lamp is a double glass container, the inner glass tube filled with neon gas and some metallic sodium drops. The wiring diagram for a sodium lamp is shown in figure.

When the supply is switched on, the lamp would not start as the supply voltage is too low to start the discharge. The leak transformer connected across the mains produces a starting voltage of about 400V. The neon gas starts the discharge, and afterwards the sodium vapourises and the discharge continues. The discharge in neon gas gives red-

orange glow. Once the metallic sodium vapourises it produces mono-chromatic yellow light. The lamp will come up to its rated light output in approximately 15 minutes. The power factor is very low, about 0.3; hence a capacitor is used to raise it. The efficiency is approximately 75 lumens per watt and the lamp has an average life of 6000 hrs. The lamp must be operated horizontally, or nearly so, to keep the sodium well spread out along the tube. The major application of this type of lamp is for high way and general out door lighting where colour discrimination is not required, such as street lighting, parks, railway yards, storage yards etc. They have very poor colour rendering characteristic. High Pressure Mercury Vapour Lamp: Such lamps consist of an inner discharge tube and an outer evacuated tube. The inner tube is provided with two main electrodes and an auxiliary electrode. It contains a small amount of argon and a little mercury. The wiring diagram of mercury vapour lamps is shown in figure.

When the supply is switched on, the supply voltage is applied across the electrodes, but is not sufficient enough to cause discharge between the two main electrodes. But this voltage is high enough for initiating a discharge over the very short distance between the main electrode and the auxiliary electrode. This discharge then spreads rapidly and sets up discharge between the main electrodes. The argon initiates the discharge, vaporizes the mercury and after some time mercury vapor takes the place. The choke is provided to limit the current to a safe value. This choke lowers the power factor. So a capacitor is connected across the circuit to improve power factor. The lamp gives greenish blue color light. It takes 3 to 4 minutes for the full light output to appear. When the supply is interrupted, the lamp must cool down and the vapor pressure be reduced for it to be restarted. The efficiency of mercury vapour lamp is about 40 lumens per watt. These lamps must be operated vertically, since if they are used horizontally convection will cause the discharge to touch the glass bulb, which will fail. Lamps of this type are used for general industrial lighting, railway yards, ports, work areas, shopping centres etc. They are used flood lights to improve the architectural beauty of buildings, hoardings etc.

You might also like

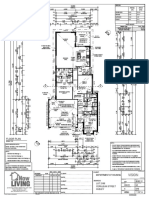

- Longitudinal Section: Ceiling LineDocument1 pageLongitudinal Section: Ceiling LineMJian VergaraNo ratings yet

- Model House 1 Floor PlanDocument1 pageModel House 1 Floor PlanMark Anthony Anunciacion LumbaNo ratings yet

- Dhvsu: Isip, Kenneth P. Chapel Building A-1Document1 pageDhvsu: Isip, Kenneth P. Chapel Building A-1kenneth isipNo ratings yet

- 02 02 Plan of Basketball CourtDocument1 page02 02 Plan of Basketball CourtJennifer Salonga ManinangNo ratings yet

- Lighting Layout Power Layout: Carza, Ma. Jenselle D. Commercial Building (Outlet Layout) Engr. Jike AlcainDocument1 pageLighting Layout Power Layout: Carza, Ma. Jenselle D. Commercial Building (Outlet Layout) Engr. Jike AlcainJenselle CarzaNo ratings yet

- Day Care Center 3Document1 pageDay Care Center 3mharieNo ratings yet

- ESSENTIALS OF WALK-UP APARTMENTSDocument13 pagesESSENTIALS OF WALK-UP APARTMENTSViktor Mikhael Roch BarbaNo ratings yet

- Lecture 3 - Tropical Architeture Design Strategies PDFDocument18 pagesLecture 3 - Tropical Architeture Design Strategies PDFWadz HarNo ratings yet

- Sy-Plumbing-For Print Building PermitDocument7 pagesSy-Plumbing-For Print Building PermitBryan Rudolph PascualNo ratings yet

- Foundation, Floor and Roof Framing PlansDocument1 pageFoundation, Floor and Roof Framing PlansDanica Mae Amicay100% (1)

- Electrical Drawing For 2BHK HouseDocument1 pageElectrical Drawing For 2BHK HousesmallhouseconstructionsNo ratings yet

- 8 2-Storey-Res Acosta PDFDocument1 page8 2-Storey-Res Acosta PDFMel FNo ratings yet

- Two Storey Residence Foundation and Floor PlansDocument1 pageTwo Storey Residence Foundation and Floor PlansNina Angelica FianzaNo ratings yet

- A.Ebal Cand - Zamb.pg1of14Document1 pageA.Ebal Cand - Zamb.pg1of14LESTER PAOLO APINONo ratings yet

- C-PURLINS 75MM X 50MM X 1.2 THK SPACED @ 600MMDocument1 pageC-PURLINS 75MM X 50MM X 1.2 THK SPACED @ 600MMalezandro del rossiNo ratings yet

- A3 FLOOR PLAN - Layout - 2105Document8 pagesA3 FLOOR PLAN - Layout - 2105Peter WestNo ratings yet

- Architectural, Structural & Mep Drawings FORDocument35 pagesArchitectural, Structural & Mep Drawings FORNana Barima100% (1)

- A B C D E F G H I J K L: Building 1 Typical Front ElevationDocument1 pageA B C D E F G H I J K L: Building 1 Typical Front ElevationAlija AndesNo ratings yet

- Building Structure: RC BungalowDocument11 pagesBuilding Structure: RC BungalowHeng Yee TanNo ratings yet

- 37.2 SQ M Residential BuildingDocument1 page37.2 SQ M Residential BuildingKent BasigaNo ratings yet

- Romeo A1Document1 pageRomeo A1glenn villacruzNo ratings yet

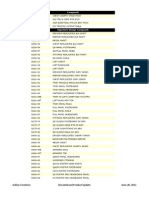

- General Notes: Electrical Symbol Legend: Fire Alarm/Detection System Basic Materials Cont. Basic MaterialsDocument16 pagesGeneral Notes: Electrical Symbol Legend: Fire Alarm/Detection System Basic Materials Cont. Basic Materialsjohn benedict orbeNo ratings yet

- Front Elevation Rear Elevation: SCALE 1:100 SCALE 1:100Document1 pageFront Elevation Rear Elevation: SCALE 1:100 SCALE 1:100Sasheen Dela CruzNo ratings yet

- 2 Storey - STRUCT ResidentialDocument4 pages2 Storey - STRUCT Residentialjohn rey toledoNo ratings yet

- Sewer & Drainage Layout Sewer & Drainage Layout: Franklin M. CaleDocument1 pageSewer & Drainage Layout Sewer & Drainage Layout: Franklin M. CaleDanica Mae AmicayNo ratings yet

- Sample Complete Set of PlansDocument8 pagesSample Complete Set of PlansAira Lyn RombaoaNo ratings yet

- First Floor Plumbing Plan (Sanitary Works) Second Floor Plumbing Plan (Sanitary Works)Document1 pageFirst Floor Plumbing Plan (Sanitary Works) Second Floor Plumbing Plan (Sanitary Works)John Lloyd ReyesNo ratings yet

- For Expansion of Other Chapel Branches Access Entry Will Be The Multi-Purpose Open SpaceDocument7 pagesFor Expansion of Other Chapel Branches Access Entry Will Be The Multi-Purpose Open SpaceIc Rose2No ratings yet

- Floor Plan: Project Title Sheet Content Designed by Sheet No. 1 5Document5 pagesFloor Plan: Project Title Sheet Content Designed by Sheet No. 1 5Pamaypay NaasulNo ratings yet

- Building floor plans and elevationsDocument2 pagesBuilding floor plans and elevationsruel buntogNo ratings yet

- Sampson Sba PDFDocument12 pagesSampson Sba PDFKristenNo ratings yet

- Roof Framing Plan PasamanoDocument1 pageRoof Framing Plan PasamanojdvalmontNo ratings yet

- Proposed Beach Resort Hotel Complex 2: Site Development PlanDocument1 pageProposed Beach Resort Hotel Complex 2: Site Development PlanAlija AndesNo ratings yet

- Perspective: Land Use and ZoningDocument1 pagePerspective: Land Use and ZoningMark Allan RojoNo ratings yet

- Kitchen: Detail 07 - Kitchen Cabinet Scale 1:5Document1 pageKitchen: Detail 07 - Kitchen Cabinet Scale 1:5Laika MagbojosNo ratings yet

- Stair Foundation Detail at Beam: Rosario L. RostataDocument1 pageStair Foundation Detail at Beam: Rosario L. RostataJesusAntonioJugosNo ratings yet

- Construction and Materials TestingDocument1 pageConstruction and Materials TestingBlue RainNo ratings yet

- Floorplan 3 StoreyDocument1 pageFloorplan 3 StoreyMarielSevillaNo ratings yet

- Cassette R407C 4 Way Installation ManualDocument20 pagesCassette R407C 4 Way Installation ManualKranthi Kumar Chowdary ManamNo ratings yet

- C-Purlins Spaced at 600mm O.CDocument1 pageC-Purlins Spaced at 600mm O.Calezandro del rossiNo ratings yet

- Sample Architectural PlanDocument1 pageSample Architectural PlanAl DrinNo ratings yet

- DDDDDDDDDD : Ad 112 Architectural DesignDocument9 pagesDDDDDDDDDD : Ad 112 Architectural DesignMichael PosadasNo ratings yet

- Roof Framing Plan at Top Chord Level Roof Framing Plan at Bottom Chord LevelDocument1 pageRoof Framing Plan at Top Chord Level Roof Framing Plan at Bottom Chord LevelJuan IstilNo ratings yet

- Cotabato A3 Elevations 1Document1 pageCotabato A3 Elevations 1greecelyNo ratings yet

- Structural plans for building right wing roofDocument1 pageStructural plans for building right wing roofArjelyNo ratings yet

- Philippines parking loading requirements architect blogDocument4 pagesPhilippines parking loading requirements architect blogJohn Rae R. DomingoNo ratings yet

- House Type - D5: Kingdom of BahrainDocument3 pagesHouse Type - D5: Kingdom of BahrainAqua LakeNo ratings yet

- A06-02 Bay SectionsDocument1 pageA06-02 Bay SectionsMark John DrilonNo ratings yet

- D Quezon City 01/05/2021 173-387-787: RA. 9266 (ART. 4, SEC. 33)Document1 pageD Quezon City 01/05/2021 173-387-787: RA. 9266 (ART. 4, SEC. 33)ven villanuevaNo ratings yet

- A B C document analysisDocument1 pageA B C document analysisAeron AcioNo ratings yet

- 3.lecture 3 Flexure Singly Reinforced BeamsDocument59 pages3.lecture 3 Flexure Singly Reinforced BeamsmdaashuNo ratings yet

- Friction - Engineering Mechanics ReviewDocument5 pagesFriction - Engineering Mechanics Reviewleonard dela cruz100% (1)

- Two Storey Apt Electrical PlanDocument1 pageTwo Storey Apt Electrical PlanMAE ANN MAGDADARO0% (1)

- New Ligao City HallDocument45 pagesNew Ligao City HallrrpenolioNo ratings yet

- Architectural and Floor Plan With Details For Buildings PDFDocument1 pageArchitectural and Floor Plan With Details For Buildings PDFWilbert ReuyanNo ratings yet

- Details of Wall Footing: Proposed Two-Storey Residential Mr. & Mrs. Julius Cesar ClaravallDocument1 pageDetails of Wall Footing: Proposed Two-Storey Residential Mr. & Mrs. Julius Cesar ClaravallChester AtienzaNo ratings yet

- Bungalow and Row Houses PDFDocument1 pageBungalow and Row Houses PDFSalahuddin ShaikhNo ratings yet

- Uee Unit-5Document14 pagesUee Unit-5scrapmail9No ratings yet

- Illumination 2Document20 pagesIllumination 2Waqas AhmadNo ratings yet

- TLEEIM Grade9 QTR3 Module1 Part1 Lighting Fixtures and Lamps Modular 1Document23 pagesTLEEIM Grade9 QTR3 Module1 Part1 Lighting Fixtures and Lamps Modular 1Lorde FloresNo ratings yet

- Module 5 Test B: Write S, Is, Re, Isn't or Aren'tDocument5 pagesModule 5 Test B: Write S, Is, Re, Isn't or Aren'tbewranNo ratings yet

- English File 3e - Intermediate SB Páginas-119Document1 pageEnglish File 3e - Intermediate SB Páginas-119Ana MaríaNo ratings yet

- 2...... - Light Emitting Diodes' Applications PDFDocument2 pages2...... - Light Emitting Diodes' Applications PDFIoana TanasescuNo ratings yet

- Floor Floor PlanDocument1 pageFloor Floor PlanJoshua YaoNo ratings yet

- 7 Lighting Systems P7Document26 pages7 Lighting Systems P7Natalie CorpuzNo ratings yet

- Checklist Cleaning: Complete HouseholdDocument2 pagesChecklist Cleaning: Complete HouseholdAdrienne Charuel100% (1)

- Iatdm Magic Sheet 7Document1 pageIatdm Magic Sheet 7api-536495690No ratings yet

- Au Furniture CatalogDocument16 pagesAu Furniture CatalogiulianhansaNo ratings yet

- 02 036 TBS600Document6 pages02 036 TBS600warwarkingNo ratings yet

- Disco Products 06.20.11Document3 pagesDisco Products 06.20.11Laura WoudstraNo ratings yet

- Explore the vibrant King's Cross neighborhood from your spacious home at CapellaDocument32 pagesExplore the vibrant King's Cross neighborhood from your spacious home at CapellaSubfra Group LtdNo ratings yet

- Dinglasan - Worldbex2019 Reaction PaperDocument2 pagesDinglasan - Worldbex2019 Reaction PaperJeric DinglasanNo ratings yet

- Strand Century Lighting 2341-2342 6x6-Inch Lekolite Ellipsoidal Spotlight Spec Sheet 6-77Document2 pagesStrand Century Lighting 2341-2342 6x6-Inch Lekolite Ellipsoidal Spotlight Spec Sheet 6-77Alan MastersNo ratings yet

- SOAL PTS Bahasa Inggris IVDocument3 pagesSOAL PTS Bahasa Inggris IVkomang kardiyasaNo ratings yet

- WS Polished Catalog 2021Document20 pagesWS Polished Catalog 2021Merdelin LinNo ratings yet

- The Smiths HouseDocument2 pagesThe Smiths HouseSofia CUBIDES VILLABONANo ratings yet

- Construction Progress and CostsDocument139 pagesConstruction Progress and CostsFarrukh RazaNo ratings yet

- DLP 22 2nd QDocument4 pagesDLP 22 2nd QKemArconadaNo ratings yet

- Street Lighting Design Layout & Calculations Electrical4UDocument45 pagesStreet Lighting Design Layout & Calculations Electrical4UpriyankaNo ratings yet

- A. Reading: Read The Text CarefullyDocument2 pagesA. Reading: Read The Text CarefullyJohn Leader PandiaNo ratings yet

- UEE Unit 3Document29 pagesUEE Unit 3simbi arseneNo ratings yet

- Unit2 Interior Decoration PDFDocument7 pagesUnit2 Interior Decoration PDFTushar100% (1)

- TrickleStar Energy Saving LED Lighting SolutionsDocument20 pagesTrickleStar Energy Saving LED Lighting SolutionsBernard EmbyNo ratings yet

- Calculation and Specification of Lightings and Electrical TerminalsDocument26 pagesCalculation and Specification of Lightings and Electrical TerminalsMuzami ThahirNo ratings yet

- Minotti Consumer Catalogue The CollectionDocument183 pagesMinotti Consumer Catalogue The CollectionCarmilla CecillionNo ratings yet

- Installation Manual LED Downlight Quick Start GuideDocument1 pageInstallation Manual LED Downlight Quick Start GuideRic NadoNo ratings yet

- TO, Agarwal Packers & Movers Ltd. SubDocument3 pagesTO, Agarwal Packers & Movers Ltd. SubJagdish RanaNo ratings yet

- FAMED LO-23 BROCHURE INGLES - UnlockedDocument1 pageFAMED LO-23 BROCHURE INGLES - UnlockedKatyaNo ratings yet