Professional Documents

Culture Documents

General Properties of Elastomers

Uploaded by

PHAM Duong HungOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Properties of Elastomers

Uploaded by

PHAM Duong HungCopyright:

Available Formats

Custom & Standard Rubber Extrusions

300 Martinel Dr. | Kent, OH 44240 | Phone: (877) 302-0423 | Fax: (330) 673-3235 | www.elbex-us.com

GENERAL PROPERTIES OF ELASTOMERS

ELASTOMER

Butyl EPDM (Ethylene-Propylene-Diene Modified) Natural Rubber Neoprene Nitrile (Buna-N) Polyisoprene SBR (Styrene Butadiene) Silicone

PAGE

2 3 4 5 6 7 8 9

Summary Chart

10

Custom & Standard Rubber Extrusions

300 Martinel Dr. | Kent, OH 44240 | Phone: (877) 302-0423 | Fax: (330) 673-3235 | www.elbex-us.com

BUTYL

GENERAL DESCRIPTION: Butyl is produced by copolymerizing isobutylene with small amounts of isoprene (typically 98% polyisobutylene and 2% isoprene). Butyl rubber was first commercialized in the early 1940s. With excellent gas impermeability and air retention along with good flex properties, the first major application of butyl rubber was tire inner tubes. Butyl rubber has a typical service temperature range between 75 F and +250 F. ADVANTAGES: Butyl rubber has exceptional resistance to gas and moisture (water and steam) permeation. Butyl rubber also has excellent resistance to oxygenated solvents (ketones and alcohols), alkalis, flexing, and abrasion. Butyl is capable of providing high energy absorption (damping) and thus has excellent electrical isolation performance. Butyl has good resistance to sunlight, ozone, heat aging, animal and vegetable oils, oxidizing chemicals, silicone fluids and greases, ammonia, hydrazine, and phosphate ester type hydraulic fluids (e.g., Skydol, Fyrqeul, Pydraul). The molecular structure of butyl rubber can be oriented to resist stress. Mechanical properties are retained over a relatively wide stiffness range since reinforcement is not required for good tensile and tear strength. LIMITATIONS: Butyl rubber is difficult to handle during manufacturing because of its tendency to trap air, blister, and creep. Cold flow characteristics and flame resistance are poor. Butyl is not recommended for use with petroleum oils, fluids, or solvents. Butyl has poor resistance to aromatic hydrocarbons (e.g., Benzol, Toloul), aliphatic hydrocarbons (e.g., kerosene, turpentine), coal, tar, and diester-based lubricants. Cold weather properties for butyl rubber are fair. COMMON APPLICATIONS: Butyls excellent impermeability to gas makes it very useful in seals for vacuum applications. Butyls gas impermeability coupled with its air retention capabilities make butyl popular for use in tire inner liners and inner tubes. Butyl is also used in hydraulics applications where synthetic fluids are used.

Custom & Standard Rubber Extrusions

300 Martinel Dr. | Kent, OH 44240 | Phone: (877) 302-0423 | Fax: (330) 673-3235 | www.elbex-us.com

EPDM (Ethylene-Propylene-Diene Modified)

GENERAL DESCRIPTION: There are two basic types of EP rubber available in today's marketEP and EPDM. EP is a copolymer of ethylene and propylene, while EPDM is a terpolymer combining ethylene, propylene and a diene monomer. EP uses a peroxide cure system. EPDM uses a sulfur cure system. EPDM has a typical service temperature range between 65 F and +300 F. ADVANTAGES: EPDM exhibits exceptionally good resistance to weather aging, ozone, UV exposure, water, heat, phosphate ester base hydraulic fluids (Skydrol, Fyrquel, Pydraul), dilute acids, electrical insulation. EPDM has good to very good resistance to steam, oxygenated solvents (acetone, methyl, ethyl ketone and other ketones), animal and vegetable oils, alkalis, brake fluids, and compression set. EPDMs dynamic and mechanical properties are, in general, between natural rubber and SBR. LIMITATIONS: EPDM is not recommended for use with petroleum oils, fluids, or solvents because significant swelling would result. EPDM has poor resistance to aromatic hydrocarbons (e.g., Benzol, Toloul) and aliphatic hydrocarbons (e.g., kerosene, turpentine). COMMON APPLICATIONS: EPDM is one of the most widely used synthetic rubbers in many static and dynamic applications. EPDM is used extensively in outdoor applications where weather and water resistance is required. It can be found in several industries ranging from automotive to HVAC. Gaskets, bumpers, auto parts, auto brake systems, electrical installation, dust covers, weather stripping and conveyor belts are just of the many products that use EPDM.

Custom & Standard Rubber Extrusions

300 Martinel Dr. | Kent, OH 44240 | Phone: (877) 302-0423 | Fax: (330) 673-3235 | www.elbex-us.com

NATURAL RUBBER

GENERAL DESCRIPTION: Crude natural rubber is found in the juices of many plants (shrubs, vines, and trees), the principal of which is the Hevea Brasiliensis tree, native to Brazil. After the latex is processed, natural rubber becomes an elastomer with excellent mechanical properties. Natural Rubber has a typical service temperature range between 67 F and +180 F. ADVANTAGES: Natural rubber has excellent tensile, elongation, tear resistance, resilience, and electrical insulation. Natural rubbers high resilience is only outperformed by some of the more recent man-made polyisoprenes and polybutadienes. Natural rubber exhibits excellent resistance to water and cold flow. Natural rubber has low compression set and can be bonded to a wide range of materials. It also has good flexing qualities at low temperatures that are better than most synthetics, but it is not as good as silicone or some of the special butadiene and SBR compounds. Natural rubber has superb abrasion resistance when it is compounded with carbon black. LIMITATIONS: Natural rubber deteriorates when exposed to oils, fuels, solvents, petroleum derivatives, and hydraulic fluids. Without special additives, natural rubber has poor resistance to sunlight, oxygen, ozone, and high temperatures. COMMON APPLICATIONS: Natural rubber can be easily bonded to a wide variety of materials, including fabric and metal. Natural rubber is widely used where many types of acids and bases, except those types that are highly oxidizing, are present. Common applications include tires, tubing, gaskets, belts, hoses, seals, shock mounts, rolls, vibration isolators, electrical components, bumpers, and drive wheels.

Custom & Standard Rubber Extrusions

300 Martinel Dr. | Kent, OH 44240 | Phone: (877) 302-0423 | Fax: (330) 673-3235 | www.elbex-us.com

NEOPRENE

GENERAL DESCRIPTION: Neoprene was created in 1930 by DuPont as an air and oil resistant substitute for natural rubber. It was the first massproduced synthetic rubber. Neoprene is a polymer of chloroprene and is considered a general or all-purpose rubber. Neoprene is available in many varieties including non-sulfur modified "W" and the more common sulfur modified "GN" types. Neoprene has a typical service temperature range between 50 F and +275 F. ADVANTAGES: Neoprene is known for its versatility. It provides good resistance to moderate exposure to ozone, sunlight, oxidation, weather, oils, gasoline, greases, solvents, petroleum oils, animal and vegetable oils, compression set, silicone oil, refrigerants, ammonia, carbon dioxide, water, and steam. Certain compounds of neoprene are flame resistant and will not support combustion. The tear resistance is equal to natural rubber at room temperature; at elevated temperatures tear resistance is poor but can be improved to some extent by compounding with reinforcing materials. Resilience and abrasion strength are good. Adhesion to metals and fabrics is very good. LIMITATIONS: The cost of neoprene is its greatest disadvantage. It is a good multipurpose rubber, but there are other types that offer much better oil, ozone, weather and oxidation resistance at a lower cost when they are used for specific applications. Neoprene has poor resistance to strong oxidizing acids, esters, ketones, chlorinated, aromatic, and nitro hydrocarbons. COMMON APPLICATIONS: Neoprene is primarily used in applications when the seal is exposed to weathering refrigerants, silicate ester lubricants and high aniline point petroleum oils. Neoprene can be formulated for use in mass transit industries due to its ability to meet ASTM c1166, e162, e662 and SMP800C standards. Common applications include refrigeration seals, Freon/air conditioning, motor mounts, engine coolants, petroleum and chemical tank linings, automotive gaskets and seals, and weather stripping.

Custom & Standard Rubber Extrusions

300 Martinel Dr. | Kent, OH 44240 | Phone: (877) 302-0423 | Fax: (330) 673-3235 | www.elbex-us.com

NITRILE (Buna-N)

GENERAL DESCRIPTION: Nitrile, or Buna-N, is a copolymer of butadiene and acrylonitrile. It is a general purpose oil-resistant polymer. Nitrile has a typical service temperature range between 40 F and +275 F. ADVANTAGES: Nitrile has excellent resistance to oil, gasoline, solvents, mineral and vegetable oils, hydraulic fluid, and fuels. It is recommended for applications that require good oil and grease resistance as well as moderate ozone resistance. With compounding, it is possible to get a fairly good balance between low creep, good resilience, low permanent set and good abrasion resistance. Nitrile is superior to most elastomers with regard to compression set or cold flow, tear and abrasion resistance. Nitrile resists acids and bases with the exception of those having strong oxidizing effects. Nitrile is resistant to a broader range of aromatic hydrocarbons than neoprene. Resistance to heat aging is good. LIMITATIONS: Nitrile has poor resistance to ketones, chlorinated hydrocarbons, and nitro hydrocarbons. It does not have good ozone, oxygen or sunlight resistance without the addition of special additives. Nitriles low-temperature resistance is inferior to natural rubber, and although nitrile can be compounded to give improved performance in this area, the gain is normally at the expense of oil and solvent resistance. Conversely, with higher acrylonitrile contents, the solvent resistance is increased but low-temperature flexibility is decreased. Nitrile, like SBR, does not crystallize on stretching. Thus, reinforcing materials, such as carbon blacks, are required to obtain high strength. Tear resistance is inferior to that of natural rubber and electrical insulation is lower. COMMON APPLICATIONS: Nitrile is recommended when excellent resistance to petroleum oils, gasoline, and/or greases is needed. Nitrile is the most widely used elastomer for sealing products due to its excellent resistance to petroleum products and its wide temperature range. More than 50% of the o-rings sold are nitrile o-rings. Nitrile is also widely used with hydraulic fluid and alcohol applications. Nitrile is commonly used for industrial and automotive applications, in products such as fuel and oil handling hoses, petroleum oil seals, grommets, hydraulic hoses, hydraulic fluid seals, transmission fluid seals, rollers, shock and vibration mounts, and o-rings. Typical applications of the premium grades of NBR include carburetor gaskets, fuel pumps, diaphragms and aircraft hose gaskets. The commercial grades of NBR are usually blends of NBR with other polymers. These less costly blends accommodate less demanding applications where oils and heat are prevalent. Ozone-resistant nitriles are recommended where extended exposure to air and ozone is anticipated.

Custom & Standard Rubber Extrusions

300 Martinel Dr. | Kent, OH 44240 | Phone: (877) 302-0423 | Fax: (330) 673-3235 | www.elbex-us.com

POLYISOPRENE

GENERAL DESCRIPTION: Polyisoprene is a synthetic elastomer with characteristics equal to, or similar to, those of natural rubber. ADVANTAGES: Synthetic polyisoprene exhibits excellent resilience and its color uniformity from one batch to another is easy to maintain because of the uniformity of the polymer. LIMITATIONS: Tensile strength is slightly lower than the tensile strength of natural rubber. COMMON APPLICATIONS: This elastomer is similar in composition to natural rubber and serves many applications requiring uniform quality and performance especially where color is concerned.

Custom & Standard Rubber Extrusions

300 Martinel Dr. | Kent, OH 44240 | Phone: (877) 302-0423 | Fax: (330) 673-3235 | www.elbex-us.com

SBR (Styrene Butadiene)

GENERAL DESCRIPTION: SBR, also known as Buna-S, is a synthetic copolymer of styrene and butadiene. SBR was originally developed to replace natural rubber in tires and its use in the manufacture of tires continues to the present day. SBR and natural rubber account for 90% of the total world rubber consumption. SBR has a typical service temperature range between 50 F and +225 F. ADVANTAGES: SBR has similar properties to natural rubber, but SBR has superior water resistance, heat resistance, abrasion resistance, low-temperature flexibility, and heat aging properties (i.e., in excess heat SBR hardens and becomes brittle instead of softening like natural rubber does). SBR also has good electrical insulation, alcohol resistance, oxygenated solvent resistance, and mild acid resistance. SBR can be successfully bonded to a wide range of materials. LIMITATIONS: SBR has poor resistance to oils, fuels, hydraulic fluids, strong acids, greases, fat, and most hydrocarbons. Without special additives, SBR is vulnerable to ozone, oxygen and sunlight. COMMON APPLICATIONS: SBR is recommended for applications where water, automotive brake fluid, or alcohols with a low molecular weight are present. Common applications include tire, tubes, gaskets, belts, hoses, seals, shock mounts, skirtboard rubber, lining rubber, and conveyor belt covers. SBR is not normally produced in o-ring form.

Custom & Standard Rubber Extrusions

300 Martinel Dr. | Kent, OH 44240 | Phone: (877) 302-0423 | Fax: (330) 673-3235 | www.elbex-us.com

SILICONE

GENERAL DESCRIPTION: Silicone rubber is a semi-organic synthetic made from sand and alkyl or aryl halides. While silicone rubber looks and feels like organic rubber, it has a completely different type of structure than other elastomers. Silicone rubber consists of a chain of silicon and oxygen atoms rather than carbon and hydrogen atoms as found in other types of rubber. This structure gives silicone rubber a very flexible but weak chain. Silicones structure also provides a material that has very small change in dynamic characteristics over a wide range of temperature. Silicone has a typical service temperature range between 150 F and +450 F. ADVANTAGES: Silicone has a broad temperature range and is generally odorless / non-toxic. Silicone offers excellent resistance to high temperatures, ozone, oxygen, UV light, moisture, and fungus. Silicone also has excellent vibration damping and maintains its dielectric strength. Silicone has low compression set and offers good fatigue resistance, flex resistance, and elongation. LIMITATIONS: Silicone has poor tensile, tear and abrasion resistance, and is not recommended for use in dynamic applications. Although high strength silicones have been developed, tear and tensile strengths remain relatively low. Silicone has poor resistance to most concentrated solvents, concentrated acids, concentrated alkalines, oils, fuels, hydrocarbons, and steam. COMMON APPLICATIONS: Silicone is recommended for applications subjected to extremely high or low temperatures. Silicone is often used in industrial applications due to its long service life. Common applications include gaskets, seals, o-rings, and bellows.

Custom & Standard Rubber Extrusions

300 Martinel Dr. | Kent, OH 44240 | Phone: (877) 302-0423 | Fax: (330) 673-3235 | www.elbex-us.com

GENERAL PROPERTIES OF ELASTOMERS SUMMARY CHART

The chart below provides general information for various common elastomeric compounds and very general features of the most common elastomers. Rubber compounding is a broad field. Basic elastomers are mixed with a variety of chemicals and ingredients to obtain desired physical properties. Many basic polymers are available that can yield compounds with unique physical properties.

Common Name Butyl Designation2 IIR Composition2 Isobutyleneisoprene General Properties1 Very good weathering resistance Excellent dielectric properties Low permeability to air Good flex properties Poor resistance to petroleum-based fluids EPDM EPDM, EPM EthylenePropyleneDiene Modified Isoprene, natural Excellent ozone, chemical, weather, UV, and aging resistance Poor resistance to petroleum-based fluids Excellent physical properties including abrasion and low temperature resistance Poor resistance to petroleum-based fluids Neoprene CR Chloroprene Good weathering resistance, resilience, and abrasion strength Flame retarding Moderate resistance to petroleum-based fluids Nitrile (Buna-N) NBR Nitrilebutadiene Excellent resistance to petroleum-based fluids Good physical properties such as resistance to tear, abrasion, and heat aging Excellent resilience Characteristics equal to, or similar to, those of natural rubber Tensile strength is slightly lower than the tensile strength of natural rubber Good electrical insulation and resistance to alcohol, oxygenated solvents, and mild acids Similar properties to natural rubber, but has superior low-temp flexibility, heat aging properties, and resistance to water, heat, and abrasion Silicone Q, Si Polysiloxane Abrasion resistance to petroleum-based fluids Excellent high and low temperature properties Excellent vibration damping and maintains its dielectric strength Poor tensile, tear, and abrasion resistance Generally odorless and non-toxic Good fatigue resistance, flex resistance, and elongation

1

Natural Rubber

NR

Polyisoprene

IR

Isoprene, synthetic

General Chemical Resistance3 Resistant to: Attacked by: Animal and vegetable fats, Petroleum oils, fluids, and oils, greases, oxygenated solvents; coal, tar, and solvents, alkalis, ozone, diester-based lubricants strong and oxidizing and solvents; aliphatic chemicals, silicone fluids and aromatic and greases, ammonia, hydrocarbons phosphate ester type hydraulic fluids Animal and vegetable oils, Mineral oils and solvents; ozone, strong and oxidizing petroleum oils, fluids, or chemicals, alkalis, brake solvents; aliphatic and fluids, phosphate ester type aromatic hydrocarbons hydraulic fluids Most moderate chemicals, Ozone, strong acids, fats, wet or dry, organic acids, oils, fuels, solvents, alcohols, ketones, petroleum derivatives, aldehydes hydraulic fluids, greases, most hydrocarbons Moderate chemicals and Strong oxidizing acids, acids, ozone, oils, fats, esters, ketones, gasoline, greases, solvents, chlorinated, aromatic, and petroleum oils, animal and nitro hydrocarbons vegetable oils, refrigerants, steam, carbon dioxide Many hydrocarbons, fats, Ozone (except PVC oils, gasoline, solvents, blends), ketones, esters, mineral and vegetable oils, aldehydes, chlorinated fuels, greases, hydraulic and nitro hydrocarbons fluids, chemicals Most moderate chemicals, Ozone, strong acids, fats, wet or dry, organic acids, oils, fuels, solvents, alcohols, ketones, petroleum derivatives, aldehydes hydraulic fluids, greases, most hydrocarbons Most moderate chemicals, wet or dry, organic acids, alcohols, ketones, aldehydes Ozone, strong acids, fats, oils, fuels, greases, most hydrocarbons

SBR

SBR

Styrene Butadiene

Moderate or oxidizing chemicals, ozone, oxygen, UV light, moisture, fungus, concentrated sodium hydroxide

Many solvents, oils, concentrated acids and alkalines, fuels, dilute sodium hydroxide, hydrocarbons, steam

Sheet Rubber Handbook Gasket and Packing Materials publication #IP-40 of the Rubber Manufacturers Association (RMA). ASTM C 1418-79 3 1979 Yearbook of the Los Angeles Rubber Group, Inc.

2

10

You might also like

- Essential Rubber Formulary: Formulas for PractitionersFrom EverandEssential Rubber Formulary: Formulas for PractitionersRating: 3 out of 5 stars3/5 (1)

- Oil-Resistant Rubbers: Machine DesignDocument5 pagesOil-Resistant Rubbers: Machine Designrajeevup2004No ratings yet

- Highly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesFrom EverandHighly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesNo ratings yet

- Materials - Viton, Nitrile, Silicone, Polyurethane, EPDM, Fluorosilicone, Teflon, PTFE Filled, PEEK, Nylon, AcetalDocument14 pagesMaterials - Viton, Nitrile, Silicone, Polyurethane, EPDM, Fluorosilicone, Teflon, PTFE Filled, PEEK, Nylon, Acetalpankaj_pawar89No ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- M Bilal & Afaq Alam Week 1 ReportDocument8 pagesM Bilal & Afaq Alam Week 1 ReportsaudNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Material Selection Guide: NBR Nitrile RubberDocument2 pagesMaterial Selection Guide: NBR Nitrile RubberNAMOGRENA DIAZNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Zeon Productguide 20150717Document16 pagesZeon Productguide 20150717khushboo.mamtani2932No ratings yet

- Synthetic Rubber: High Styrene Rubber / HSRDocument1 pageSynthetic Rubber: High Styrene Rubber / HSRGaneshperumal VaradharajanNo ratings yet

- Product Guide 2012Document16 pagesProduct Guide 2012Daniele BoscoNo ratings yet

- Natural Rubber V Butyl RubberDocument4 pagesNatural Rubber V Butyl Rubbersamdelacruz1030No ratings yet

- Oring - Rubber GuidebookDocument87 pagesOring - Rubber GuidebookThai KhangNo ratings yet

- Butyl & Chloroprene 2003Document16 pagesButyl & Chloroprene 2003Suyash TrivediNo ratings yet

- General Rubber Compounds: By: Jim Ward, BRP ManufacturingDocument4 pagesGeneral Rubber Compounds: By: Jim Ward, BRP Manufacturing최승원No ratings yet

- Rubber Material Reference, Neoprene, EPDM, Buna-N, Silicone, SBR, Butyl, Natural Rubber, Gum Rubber, Hypalon, Urethane, Viton, Fluoroelastomer, Fluoro Silicone, Hydrogenated Nitrile, Carboxylated NitrileDocument3 pagesRubber Material Reference, Neoprene, EPDM, Buna-N, Silicone, SBR, Butyl, Natural Rubber, Gum Rubber, Hypalon, Urethane, Viton, Fluoroelastomer, Fluoro Silicone, Hydrogenated Nitrile, Carboxylated NitrileDv Maria Pradhika0% (1)

- Viton VS NBRDocument13 pagesViton VS NBRKathiravan PalanisamyNo ratings yet

- Nitrile Rubber ApplicationsDocument6 pagesNitrile Rubber ApplicationsFelix CatNo ratings yet

- Basic Non-Metallic Gasket Types - Elastomers/Rubber MaterialsDocument2 pagesBasic Non-Metallic Gasket Types - Elastomers/Rubber MaterialsSteven LiparotoNo ratings yet

- Rubber Type: Teknologi KaretDocument13 pagesRubber Type: Teknologi KaretlarasatiNo ratings yet

- Rubber Mining HoseDocument12 pagesRubber Mining HoseStephenNo ratings yet

- Materiale GarnituriDocument3 pagesMateriale GarnituriFabius PopNo ratings yet

- O Ring BrochureDocument36 pagesO Ring BrochureJesus N RodriguezNo ratings yet

- 17rubbercompoundingpptkiran 150318135628 Conversion Gate01Document16 pages17rubbercompoundingpptkiran 150318135628 Conversion Gate01Madan Saini100% (1)

- Hydrogenated NitrileDocument2 pagesHydrogenated Nitrileomar shadyNo ratings yet

- Section6 Material Selection GuideDocument15 pagesSection6 Material Selection GuidenewmanNo ratings yet

- Rubber GuideDocument5 pagesRubber Guidekanthar972No ratings yet

- 2.synthetic Rubber TRG DR - JACOB K VARKEYDocument40 pages2.synthetic Rubber TRG DR - JACOB K VARKEYbodekizNo ratings yet

- Raj Rubber ProductsDocument35 pagesRaj Rubber Productsnaveenraj mNo ratings yet

- Epdm Rubber Gasket HydrotechDocument3 pagesEpdm Rubber Gasket Hydrotechmusafir mufiNo ratings yet

- Choose The Right RollerDocument7 pagesChoose The Right Rollerkartik spectomsNo ratings yet

- Rubber Compounds TableDocument2 pagesRubber Compounds TablestrganeshkumarNo ratings yet

- Bpxe 9PPHCNDocument2 pagesBpxe 9PPHCNNarges alikhaniNo ratings yet

- 14 AbrasionDocument12 pages14 AbrasionDesign V-Tork ControlsNo ratings yet

- AsmDocument13 pagesAsmVivekanandan JNo ratings yet

- Technology Liquid Coating Resins Liquid Coating Resins Product Range Emea EnglishDocument8 pagesTechnology Liquid Coating Resins Liquid Coating Resins Product Range Emea EnglishUsama AwadNo ratings yet

- Oilfield JetlubeDocument24 pagesOilfield JetlubeHany AhmedNo ratings yet

- 08 Satori Technical Article - Basic O-Ring Design CiteriaDocument5 pages08 Satori Technical Article - Basic O-Ring Design CiteriaOscar SupelanoNo ratings yet

- RUBBER NewDocument10 pagesRUBBER NewAleem AhmedNo ratings yet

- Catalogue - KRIDocument20 pagesCatalogue - KRIkaustubh_dec17No ratings yet

- Automobile Sealants and Their Applications: Submitted by D.Thiruvarutchelvan 12MS35 I Yr M.E Automotive EnggDocument21 pagesAutomobile Sealants and Their Applications: Submitted by D.Thiruvarutchelvan 12MS35 I Yr M.E Automotive EnggsrithiruvarulNo ratings yet

- Butyl Rubber-IIRDocument26 pagesButyl Rubber-IIRreilyshawnNo ratings yet

- Rubber and Sealants Market SurveyDocument16 pagesRubber and Sealants Market SurveyAnirudh MalpaniNo ratings yet

- Valve Material Selection GuideDocument15 pagesValve Material Selection GuideAhmad Fadhil ReviansyahNo ratings yet

- CSTR Oring Catalog Or2009Document48 pagesCSTR Oring Catalog Or2009roccandradoNo ratings yet

- Material Properties of EPDM, NBR, and FPM Rubber Seals - Technical - Resources - BLUCHERDocument3 pagesMaterial Properties of EPDM, NBR, and FPM Rubber Seals - Technical - Resources - BLUCHERManish Pareek100% (1)

- Shell Morlina Oil: Advanced Spindle, Hydraulic and Bearing OilDocument2 pagesShell Morlina Oil: Advanced Spindle, Hydraulic and Bearing OiltribolasNo ratings yet

- Filtros de Mangas para DespoeiramentoDocument3 pagesFiltros de Mangas para DespoeiramentoEder PereiraNo ratings yet

- Rubber Linings OverviewDocument10 pagesRubber Linings OverviewhabibNo ratings yet

- Rubber Expansion JointsDocument32 pagesRubber Expansion JointssailbirdNo ratings yet

- Epdm O-Rings: (Ethylene Propylene)Document1 pageEpdm O-Rings: (Ethylene Propylene)Mechanical SealsNo ratings yet

- Corena S4 P 100 TDS Formerly Corena AP 100Document2 pagesCorena S4 P 100 TDS Formerly Corena AP 100Ganesh AnandNo ratings yet

- Dupont Packaging & Industrial PolymersDocument3 pagesDupont Packaging & Industrial PolymersAlan FerreiraNo ratings yet

- NeopreneDocument48 pagesNeoprenest_calvoNo ratings yet

- Bber Compounding LPE 4th Year 2022Document20 pagesBber Compounding LPE 4th Year 2022afia rahmanNo ratings yet

- Resilient Seat/Seal Materials: VITON® (Fluorocarbon, FKM, or FPM)Document1 pageResilient Seat/Seal Materials: VITON® (Fluorocarbon, FKM, or FPM)automettNo ratings yet

- SBR General Introduction: HistoryDocument3 pagesSBR General Introduction: Historyanvesha raoNo ratings yet

- Redux 312: Product DataDocument4 pagesRedux 312: Product Dataaman guptaNo ratings yet

- DWG No. A4 SQ 12/3/2018 Plate / Section: Next ProcessDocument1 pageDWG No. A4 SQ 12/3/2018 Plate / Section: Next ProcesshadeNo ratings yet

- s33 Rail Data Sheet MetricDocument1 pages33 Rail Data Sheet MetrichadeNo ratings yet

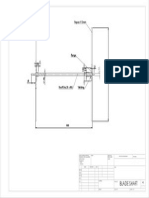

- Potongan B - B: EL +4.50 MAB EL +4.00Document1 pagePotongan B - B: EL +4.50 MAB EL +4.00hadeNo ratings yet

- CTP r21Document2 pagesCTP r21hadeNo ratings yet

- Potongan B - B: EL +4.50 MAB EL +4.00Document1 pagePotongan B - B: EL +4.50 MAB EL +4.00hadeNo ratings yet

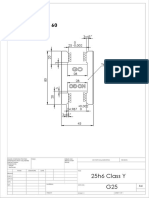

- SKD 11, HRC 60: 25h6 Class Y G25Document1 pageSKD 11, HRC 60: 25h6 Class Y G25hadeNo ratings yet

- Din 15093Document2 pagesDin 15093hadeNo ratings yet

- Gantrex BumperrsDocument1 pageGantrex BumperrshadeNo ratings yet

- KX3300 DataSheetDocument5 pagesKX3300 DataSheethadeNo ratings yet

- Blade ShaftDocument1 pageBlade ShafthadeNo ratings yet

- Reamer Ahm Reamer: Material Carbide Coating TialnDocument1 pageReamer Ahm Reamer: Material Carbide Coating TialnhadeNo ratings yet

- Boiler AhuDocument1 pageBoiler AhuhadeNo ratings yet

- Rwin 17Document1 pageRwin 17hadeNo ratings yet

- Shaft Assy RWIN-32: 7 15 Flange 1 BushingDocument3 pagesShaft Assy RWIN-32: 7 15 Flange 1 BushinghadeNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tFrom EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tRating: 4.5 out of 5 stars4.5/5 (27)

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneFrom EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneRating: 4.5 out of 5 stars4.5/5 (5)

- Laws of UX: Using Psychology to Design Better Products & ServicesFrom EverandLaws of UX: Using Psychology to Design Better Products & ServicesRating: 5 out of 5 stars5/5 (9)

- UX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesFrom EverandUX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesNo ratings yet

- Design Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessFrom EverandDesign Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessNo ratings yet

- Designing for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionFrom EverandDesigning for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionNo ratings yet

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsFrom EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsRating: 5 out of 5 stars5/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- Debugging Embedded and Real-Time Systems: The Art, Science, Technology, and Tools of Real-Time System DebuggingFrom EverandDebugging Embedded and Real-Time Systems: The Art, Science, Technology, and Tools of Real-Time System DebuggingRating: 5 out of 5 stars5/5 (1)

- Iconic Advantage: Don’t Chase the New, Innovate the OldFrom EverandIconic Advantage: Don’t Chase the New, Innovate the OldRating: 4 out of 5 stars4/5 (1)

- Reciprocating Compressors:: Operation and MaintenanceFrom EverandReciprocating Compressors:: Operation and MaintenanceRating: 4 out of 5 stars4/5 (7)

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsFrom EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNo ratings yet