Professional Documents

Culture Documents

Speed Control of DC Motor Using Pulse Width Modulation

Uploaded by

Syed muhammad zaidiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Speed Control of DC Motor Using Pulse Width Modulation

Uploaded by

Syed muhammad zaidiCopyright:

Available Formats

SPEED CONTROL OF DC MOTOR USING PULSE WIDTH MODULATION : SPEED CONTROL OF DC MOTOR USING PULSE WIDTH MODULATION Submitted

by SHAKTI MOHAN PATNAIK(06-3261) ABINASH PADHI(06-3273) RITESH KUMAR LENKA(06-3262) EIE, 7th SEM Under Guidance of Mr. Rakesh Kumar Patnaik

Content : : Content : Introduction D.C. motor Working principle Types of motor Method of speed control Pulse width modulation Circuit diagram & its description Advantages & Disadvantages Application Conclusion

Introduction : : Introduction : Almost all the machine in industries operated using electrical motors. Among them most of motors are DC motors. DC series motor is specially used for traction, electric locomotive, trolley systems, cranes and conveyor belt. All these works require frequent speed control for preparation of job. A PWM (Pulse Width Modulation) wave can be used to control the speed of the motor.

Working Principle: : Working Principle: A machine that convert d.c power into mechanical power. It is based on electromagnetism i.e. when a current carrying conductor is placed in the magnetic field there is some mechanical force exerted on the current carrying conductor which is perpendicular to both the conductor and the magnetic filed. The most common DC motor types are the shunt wound and series wound types.

Shunt wound motor : : Shunt wound motor : Shunt wound motor are used for driving constant speed shafts, centrifugal pumps, blower & pumps etc. The characteristics of a DC shunt wound motor give it very good speed regulation, and it is classified as a constant speed motor, even though the speed does slightly decrease as load is increased. Shunt-wound motors are used in industrial and automotive applications where precise control of speed and torque are required.

Series wound motor : : Series wound motor : The advantage of a Series Wound Motor is that it develops a large torque and can be operated at low speed. It is a motor that is well-suited for starting heavy loads; it is often used for industrial cranes and winches where very heavy loads must be moved slowly and lighter loads moved more rapidly. DC series motor is specially used for traction, electric locomotive, trolley systems, cranes hoists and conveyor

Speed control of dc motor : : Speed control of dc motor : The purpose of a motor speed controller is to take a signal representing the required speed, and to drive a motor at that speed. Motor speed can be controlled by controlling- Armature voltage (Va) Armature current (Ia)

Cont : Cont It is obvious that th resistance Ra of armature circuit (Rheostatic Control) applied voltage V (Voltage Control)

Cont : Cont The above methods have some demerits i.e A large amount of power is wasted in the controller resistance. Hence, efficiency is decreased. It needs expensive arrangement for dissipation of heat produced in the controller resistance. It gives speeds below the normal speed.

Electronic Speed Control Methods for DC Motors : : Electronic Speed Control Methods for DC Motors : compared to the electric and electromechanical systems of speed control, the electronic methods have higher accuracy greater reliability quick response higher efficiency

Principle : : Principle : The main principle is control of power by varying the duty cycle. Here the conduction time to the load is controlled. Let for a time t1, the input voltage appears across the load ie ON state. for t2 time the voltage across the load is zero. The average voltage at output is given by Va = period =t1+t2 k = t1/T is the duty cycle

Cont : Cont The rms value of output voltage is V0 = ( i/ t1, T or f. Therefore, the output voltage V0 can be varied from 0 to Vs by controlling k, and the power flow can be controlled. As the time t1 changes the width of pulse is varied and this type of control is called pulse width modulation (PWM) control.

Pulse Width Modulation : : Pulse Width Modulation : Pulse width modulation (PWM) is a method for binary signals generation, which has 2 signal periods (high and low). The width (W) of each pulse varies between 0 and the period (T). The duty cycle (D) of a signal is the ratio of pulse width to period. D=(t1+t2) / T

Pictures of the Waveform : : Pictures of the Waveform : The motor is on for most of the time and only off a short while, so the speed is near maximum The switch is on 50% and off 50%. The motor will only rotate slowly.

High Speed Signal (90%) : High Speed Signal (90%) The signal at the right shows the motor on for most of the time. The white dips indicate when the motor isnt receiving power.

Signal With The Motor Half Speed (50%) : Signal With The Motor Half Speed (50%) The signal at the right shows the motor receiving power half the time.

Low Speed Signal (10%) : Low Speed Signal (10%) The signal at the right shows the low speed signal which turns the motor slowly

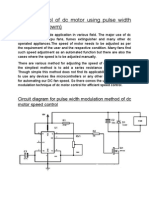

Circuit Description : : Circuit Description : Power supply Motor Controller

Power Supply : : Power Supply :

Circuit Description: : Circuit Description: The transformer is a center tap 12-0-12V 500mA and supply 12v to the circuit. The i/p sine wave is rectified by using full wave rectifier which convert it to one constant purpose. The three terminal voltage regulators 7812 provides regulated DC 12 v outputs for the operation of the circuit.

Circuit Diagram : (Motor Controller Sections) : Circuit Diagram : (Motor Controller Sections)

Circuit Description : : Circuit Description : The design is based on astable multivibrator IC1a. output is low for a period determined by R1 and high for a period set by R2 and P1. When C1 is discharged, the level at the input of IC1a is below the lower threshold, so that the output of this stage is high. The capacitor is then charged rapidly via D1 and R1, and reaches the upper threshold in about t = ln(2)RC = ln(2).(22k).(100nf) =1.5 ms

Cont.. : Cont.. As output of IC1a goes low, whereupon C1 is discharged via D2, R2, and P1. The discharge time could be set between 0.2ms and 25ms. the duty factor of the output signal may be varied between 5% and 90%. The signal is inverted again and then applied to the input of transistor BC557 through 4k7. The transistor Bc557 act as a buffer which transfer electrical impedance from one circuit to another circuit i.e. it act as a pre amplifier.

Cont : Cont The o/p of Bc557 is given to the power transistor 2N3055 which is used in a circuit as an amplifier, detector, or switch. The diode connected across the motor is for freewheeling purpose i.e. the diode used to eliminate flyback, the sudden voltage spike seen across an inductive load when its supply voltage is suddenly reduced or removed. The resistance of P1(Potentiometer) is at a minimum, the rotary speed of the motor is at a maximum.

Advantage : : Advantage : PWM duty cycle control techniques enable greater efficiency of the DC motor . PWM switching control methods improve speed control and reduce the power losses in the system. The pulses reach the full supply voltage and will produce more torque in a motor by being able to overcome the internal motor resistances more easily.

Disadvantages : : Disadvantages : The main Disadvantages of PWM circuits are the added complexity and the possibility of generating radio frequency interference . It can give speed below the full speed, not above. It cannot be used for fast controlling of speed.

Applications : : Applications : Traction application Conveyor Belt carrying loads Various motors requiring smooth speed control DC motors of all range can be controlled, which are used for the production of materials Electric locomotives DC motor using precise job preparations

Conclusion : Conclusion The present project is practical one and high feasibility according to economic point of view, reliability & accuracy. It is programmable one therefore it can control various motors ranging small one to several hp motors.

You might also like

- Speed Control of DC Motor Using Pulse Width Modulation (PWM) Technique.Document7 pagesSpeed Control of DC Motor Using Pulse Width Modulation (PWM) Technique.Sai Ram0% (1)

- Speed Control of DC Motor Using Pulse Width ModulationDocument2 pagesSpeed Control of DC Motor Using Pulse Width ModulationNaman NepalNo ratings yet

- Utilization of Electrical Energy (1-100) 11Document100 pagesUtilization of Electrical Energy (1-100) 11Gopala Krishna YadavNo ratings yet

- DC Motor S: Anand 08338958770Document79 pagesDC Motor S: Anand 08338958770Rohit AvasthiNo ratings yet

- Shubham SeminarDocument19 pagesShubham SeminarShubham BodadeNo ratings yet

- Geneva Mechanism AbstractDocument1 pageGeneva Mechanism AbstractHari Tej AvvaruNo ratings yet

- PROJCTDocument32 pagesPROJCTSwati Agarwal100% (1)

- Induction Motor Braking Regenerative Dynamic Braking of Induction Motor - Electrical4u PDFDocument7 pagesInduction Motor Braking Regenerative Dynamic Braking of Induction Motor - Electrical4u PDFbalajiNo ratings yet

- Unit 3Document5 pagesUnit 3Narasimman DonNo ratings yet

- MOTORING AND GENERATING MODE OF 3-Φ INDUCTION MACHINE - A COMPARATIVE EVALUATION FOR ENERGY EFFICIENCY PDFDocument64 pagesMOTORING AND GENERATING MODE OF 3-Φ INDUCTION MACHINE - A COMPARATIVE EVALUATION FOR ENERGY EFFICIENCY PDFIjabi0% (1)

- PX7203-Special Electrical Machines PDFDocument11 pagesPX7203-Special Electrical Machines PDFvaishnavisriNo ratings yet

- Construction and Working of Brushless DC PDFDocument12 pagesConstruction and Working of Brushless DC PDFaswardi8756No ratings yet

- Em 1 TestingDocument13 pagesEm 1 TestingAravindNo ratings yet

- Questio N 1 2 3 4 5 6 7 8 9 10 Answer Questio N 11 12 13 14 15 16 17 18 19 20 AnswerDocument5 pagesQuestio N 1 2 3 4 5 6 7 8 9 10 Answer Questio N 11 12 13 14 15 16 17 18 19 20 AnswerGhaith AlqudahNo ratings yet

- Principles For Controlling HarmonicsDocument7 pagesPrinciples For Controlling HarmonicsEyad A. FeilatNo ratings yet

- Eeeviews: Unit Iv Synchronous Motor DrivesDocument26 pagesEeeviews: Unit Iv Synchronous Motor Driveskrithikgokul selvamNo ratings yet

- Fuzzy Logic Control of Three Phase Induction Motor: A ReviewDocument3 pagesFuzzy Logic Control of Three Phase Induction Motor: A ReviewInternational Journal of Innovative Science and Research Technology100% (1)

- Braking of DC MotorDocument18 pagesBraking of DC MotorBangariNo ratings yet

- Speed Control of Induction Motor by Using IR11Document16 pagesSpeed Control of Induction Motor by Using IR11Anuj TripathiNo ratings yet

- Substation Layout and EquipmentDocument44 pagesSubstation Layout and Equipmentjohn100% (2)

- Designing Field-Oriented Control for an Induction Motor DriveDocument93 pagesDesigning Field-Oriented Control for an Induction Motor DriveEdwardElric100% (2)

- PCEG 403 Lab No. 1 Title: Simulation of Single Phase Half Wave Converter DC DriveDocument5 pagesPCEG 403 Lab No. 1 Title: Simulation of Single Phase Half Wave Converter DC DriveJanup PokharelNo ratings yet

- Electric Drive Course OutcomesDocument9 pagesElectric Drive Course OutcomesAbhíñåv PrâjãpätîNo ratings yet

- 17ee82 - Ida - Mod 4 NotesDocument18 pages17ee82 - Ida - Mod 4 NotesManish Kumar SahaniNo ratings yet

- IDS NewDocument128 pagesIDS NewShahbaz Ali100% (1)

- Speeed ControlDocument3 pagesSpeeed ControlChristine GomezNo ratings yet

- Questions & Answers On S-Domain AnalysisDocument33 pagesQuestions & Answers On S-Domain Analysiskibrom atsbhaNo ratings yet

- Short Notes On Servo MotorDocument2 pagesShort Notes On Servo MotorHimansu Goswami100% (3)

- Part BDocument10 pagesPart BVenkat ManiNo ratings yet

- Chap1 Special MachinesDocument23 pagesChap1 Special MachinesHell Maax100% (2)

- Four Quadrant Chopper OperationDocument5 pagesFour Quadrant Chopper OperationSAIKAT100% (1)

- Auto Roll Punching MachineDocument42 pagesAuto Roll Punching MachineANAND KRISHNAN100% (1)

- Induction Type Relay GuideDocument14 pagesInduction Type Relay GuideAnilNo ratings yet

- Commutation TechniquesDocument13 pagesCommutation TechniquesSantosh SinghNo ratings yet

- Literature Review of BLDC MotorDocument25 pagesLiterature Review of BLDC MotorOcean PaudelNo ratings yet

- Adigrat University: Advisor Name: Ins: G/Medhin GDocument35 pagesAdigrat University: Advisor Name: Ins: G/Medhin GSileshNo ratings yet

- Design and Implementation of Conveyor Belt Speed Control Using PID For Industrial ApplicationsDocument6 pagesDesign and Implementation of Conveyor Belt Speed Control Using PID For Industrial ApplicationsEditor IJTSRDNo ratings yet

- Modeling and Simulation of BLDC Motor in MATLABDocument5 pagesModeling and Simulation of BLDC Motor in MATLABvishiwizardNo ratings yet

- Single Phase Induction Motor Speed ControlDocument35 pagesSingle Phase Induction Motor Speed ControlHarshit Sengar100% (2)

- HPED Assignment 2: DC DrivesDocument4 pagesHPED Assignment 2: DC DrivesShadNo ratings yet

- BLDC Motor Control ANfpgaDocument8 pagesBLDC Motor Control ANfpgasraamu2k55068100% (1)

- Brown Final PPT FinalDocument36 pagesBrown Final PPT FinalDarshan100% (2)

- GSM Mobile Based Speed Control of DC MotorDocument12 pagesGSM Mobile Based Speed Control of DC MotorShubam RajputhNo ratings yet

- How electrical drives precisely control motor speedDocument6 pagesHow electrical drives precisely control motor speedkaushik9595No ratings yet

- Speed Control of DC Motor Using PWM TechniqueDocument42 pagesSpeed Control of DC Motor Using PWM TechniqueParmar Rahul83% (6)

- Project Report On Speed Control of DC Motor by Using PWM TechniqueDocument77 pagesProject Report On Speed Control of DC Motor by Using PWM TechniqueSBONGISENI MASONDO100% (2)

- Magenetic Chip Collector New 2Document27 pagesMagenetic Chip Collector New 2Hemasundar Reddy JolluNo ratings yet

- Working Principle of Hydroelectric Power PlantDocument4 pagesWorking Principle of Hydroelectric Power PlantGummadi AmarNo ratings yet

- FulltextThesis 2Document209 pagesFulltextThesis 2Kean PagnaNo ratings yet

- Pulse Width Modulation PWMTechinqueDocument16 pagesPulse Width Modulation PWMTechinqueAhmed M H Al-YousifNo ratings yet

- Model Predictive Direct Torque Control Methods For SpeedDocument25 pagesModel Predictive Direct Torque Control Methods For SpeedAayush PatidarNo ratings yet

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsFrom EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsNo ratings yet

- Speed Control of DC Motor Using Pulse Width ModulationDocument30 pagesSpeed Control of DC Motor Using Pulse Width ModulationRatul SarkarNo ratings yet

- Speed Control of DC Motor Using PWM 555 TimerDocument20 pagesSpeed Control of DC Motor Using PWM 555 TimerDEBABRATA DASNo ratings yet

- Electric Traction RailwaysDocument34 pagesElectric Traction Railwayssaurabh8435100% (1)

- of PWM DC MotorDocument21 pagesof PWM DC Motorabhay_131250% (4)

- Speed Control of DC Motor Using Pulse Width ModulationDocument23 pagesSpeed Control of DC Motor Using Pulse Width Modulationarnav060419891190No ratings yet

- DC Motor Control LabDocument5 pagesDC Motor Control Labdks697bvhcNo ratings yet

- Design and Fabrication of 3-Phase Ac Voltage Controller Fed Speed Control of 3-Phase Sqim L. Joseph Anil Kumar B. Krishna ChaitanyaDocument5 pagesDesign and Fabrication of 3-Phase Ac Voltage Controller Fed Speed Control of 3-Phase Sqim L. Joseph Anil Kumar B. Krishna ChaitanyaSahabat SimatupangNo ratings yet

- Engineering Design 5Document2 pagesEngineering Design 5Syed muhammad zaidiNo ratings yet

- Powerpoint Engineering Design 4Document2 pagesPowerpoint Engineering Design 4Syed muhammad zaidiNo ratings yet

- Gunn DiodeDocument46 pagesGunn DiodeSyed muhammad zaidi50% (2)

- Gunn DiodeDocument46 pagesGunn DiodeSyed muhammad zaidi50% (2)

- Project Report DC Motor Control (Compatibility Mode)Document12 pagesProject Report DC Motor Control (Compatibility Mode)Syed muhammad zaidiNo ratings yet

- Heinrich Rudolf HertzDocument8 pagesHeinrich Rudolf HertzSyed muhammad zaidiNo ratings yet

- Digital AbstractionDocument35 pagesDigital AbstractionSyed muhammad zaidiNo ratings yet

- Engineering Design 3Document4 pagesEngineering Design 3Syed muhammad zaidiNo ratings yet

- LaplaceDocument33 pagesLaplaceravindarsinghNo ratings yet

- Electronic Devices and CircuitDocument28 pagesElectronic Devices and CircuitSyed muhammad zaidi50% (2)

- LaplaceDocument33 pagesLaplaceravindarsinghNo ratings yet

- Signal and System34Document38 pagesSignal and System34Syed muhammad zaidiNo ratings yet

- Storage MediaDocument36 pagesStorage MediaSyed muhammad zaidiNo ratings yet

- Buzzer ExampleDocument6 pagesBuzzer ExampleSyed muhammad zaidiNo ratings yet

- Presentation 1Document16 pagesPresentation 1Syed muhammad zaidiNo ratings yet

- Primary & SecondaryDocument13 pagesPrimary & SecondarySyed muhammad zaidiNo ratings yet

- Peripheral Devices and PortsDocument22 pagesPeripheral Devices and PortsSyed muhammad zaidiNo ratings yet

- Storage Devices: Iintroduction To ComputingDocument4 pagesStorage Devices: Iintroduction To ComputingSyed muhammad zaidiNo ratings yet

- OsDocument25 pagesOsSyed muhammad zaidiNo ratings yet

- Optical StorageDocument16 pagesOptical StorageSyed muhammad zaidiNo ratings yet

- Memory ModelsDocument9 pagesMemory ModelsSyed muhammad zaidiNo ratings yet

- Op StorageDocument9 pagesOp StorageSyed muhammad zaidiNo ratings yet

- Input and Out Put Devices: Input Devices Accept Data and Instructions From Users and From Other Computer SystemDocument4 pagesInput and Out Put Devices: Input Devices Accept Data and Instructions From Users and From Other Computer SystemSyed muhammad zaidiNo ratings yet

- Nonvolatile Memory 2Document14 pagesNonvolatile Memory 2Syed muhammad zaidiNo ratings yet

- LCDDocument40 pagesLCDSyed muhammad zaidiNo ratings yet

- Data Types Presentation 1Document25 pagesData Types Presentation 1Syed muhammad zaidiNo ratings yet

- MicroprocessorDocument13 pagesMicroprocessorSyed muhammad zaidiNo ratings yet

- IntroductionDocument5 pagesIntroductionSyed muhammad zaidiNo ratings yet

- Essential Computer HardwareDocument16 pagesEssential Computer HardwareSyed muhammad zaidi0% (1)

- Installation Manual: Tcs-Net Relay InterfaceDocument10 pagesInstallation Manual: Tcs-Net Relay InterfaceMuhammad FarhanNo ratings yet

- Oscilla - Excellence Since 1960Document24 pagesOscilla - Excellence Since 1960Pau Choon HockNo ratings yet

- Pure Sine Wave Inverter Manual PDFDocument13 pagesPure Sine Wave Inverter Manual PDFmuhaned190100% (1)

- Catalogue Battery Chargers-A4 PDFDocument8 pagesCatalogue Battery Chargers-A4 PDFdinhvuNo ratings yet

- JUNIOR V4 Manual PDFDocument69 pagesJUNIOR V4 Manual PDFmirelaNo ratings yet

- Service Manual: STR-DB925Document62 pagesService Manual: STR-DB925Yonny MunozNo ratings yet

- Holtek E-Link For 8-Bit MCU OCDS User S Guide enDocument17 pagesHoltek E-Link For 8-Bit MCU OCDS User S Guide enHardware HbeonlabsNo ratings yet

- Service Manual Fornax TDocument4 pagesService Manual Fornax Tluis angel chamez liceaNo ratings yet

- Posiflex Pp-7000iiiDocument23 pagesPosiflex Pp-7000iiisend2ipodNo ratings yet

- Connecting Your Arduino To WiFi Via An ESP-8266 ModuleDocument7 pagesConnecting Your Arduino To WiFi Via An ESP-8266 ModuleJaphet GabatanNo ratings yet

- Hasee z6 n850hj n850hj1 SM z6-Kp5s1 n850hjmb-0dDocument114 pagesHasee z6 n850hj n850hj1 SM z6-Kp5s1 n850hjmb-0dOmar Avancini NievesNo ratings yet

- Nexus Control System - IODocument4 pagesNexus Control System - IOAndrian ArifinNo ratings yet

- SLDocument5 pagesSLLingga SuhadhaNo ratings yet

- SH-18-18 IPS, UPS, Dehumidifier, Energy Meter. (Final)Document8 pagesSH-18-18 IPS, UPS, Dehumidifier, Energy Meter. (Final)Md. Nobin KhanNo ratings yet

- Magnetron 2M246: 1.general DataDocument6 pagesMagnetron 2M246: 1.general Datacesar luis gonzalez rodriguezNo ratings yet

- SEO-OPTIMIZED TITLEDocument40 pagesSEO-OPTIMIZED TITLEravigupt2100% (1)

- Protronic PS - ManualDocument56 pagesProtronic PS - ManualJose Maria Rodriguez Morales100% (1)

- Wiring Instructions enDocument8 pagesWiring Instructions envizanteaNo ratings yet

- NBN 8000 Installation Manual enUS 16258691467Document52 pagesNBN 8000 Installation Manual enUS 16258691467corneli@No ratings yet

- DYNEX-MRX II Reader User ManualDocument75 pagesDYNEX-MRX II Reader User ManualshopmanNo ratings yet

- HUAWEI MediaPad 10 FHD Maintenance Manual V1.0Document78 pagesHUAWEI MediaPad 10 FHD Maintenance Manual V1.0Kawee UsmanNo ratings yet

- PRC 138Document2 pagesPRC 138ahbamaNo ratings yet

- Kenwood KDC 2031 SG Service ManualDocument32 pagesKenwood KDC 2031 SG Service ManualVangelis BoulasikisNo ratings yet

- Fastcool: en Da de Es Fi FR It NL No PL PT Ru SV ZHDocument12 pagesFastcool: en Da de Es Fi FR It NL No PL PT Ru SV ZHElia S.r.l.No ratings yet

- DIY Synth ManualDocument24 pagesDIY Synth ManualOtávio Guercia Mesquita Coelho100% (4)

- System MDR 8400Document150 pagesSystem MDR 8400JESUSCALVILLONo ratings yet

- LC 75341Document20 pagesLC 75341Melanie BernardoNo ratings yet

- Tripod Turnstile System ProposalDocument7 pagesTripod Turnstile System ProposalArman NaiemNo ratings yet

- Kxtda 600 BXDocument133 pagesKxtda 600 BXNguyen Thanh NamNo ratings yet

- Nice Industrial Doors A Complete Range of Control Units and Gearmotors For Industrial Doors. Even Easier Installation and ProgrammingDocument28 pagesNice Industrial Doors A Complete Range of Control Units and Gearmotors For Industrial Doors. Even Easier Installation and ProgrammingtskumarNo ratings yet