Professional Documents

Culture Documents

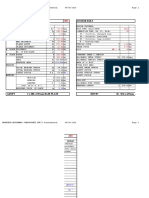

Double Angle Connection V2

Uploaded by

runkirCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Double Angle Connection V2

Uploaded by

runkirCopyright:

Available Formats

Fu Fy e s Ab d t Du hsc Ns Tb Nb Tu Ag Anv Ae An Ant t1 l

Ultimate stress of the material (Ksi) Yield stress of the material (Ksi) edge distance (in) bolt spacing (in) Load resistance Factor 2 Nominal area of bolt (in ) Nominal diameter of bolt (in) thickness of the critical material mean slip coefficeint multiplier hole factor Number of Slip Planes minimum bolt tension (kips) number of bolts carrying the applied tension tension force due to LRFD combinations (kips) Gross sectional area (in2) Net area subjected to shear (in ) Effective net area (in2) Net area (in2) Net area subjected to tension (in2) End Projection angle length

2

Inputs Units Length force stress Beam End reactions Rd= inch kips ksi Dead load (D) Criteriea

Inputs

Rl= live load (L) Rw= Wind load (W) Rs= Snow Load (S) Rlr= Roof live load (Lr) Re= Eq. Load (E) Rr= Nominal load due to initial rainwater or ice exclusive of the ponding contribution (R) Ru= as per the load combination defined below LRFD Load Combinations 1.4D 1.2D + 1.6L + 0.5(Lr or S or R) 1.2D + 1.6(Lr or S or R) + (0.5L or 0.8W) 1.2D + 1.3W + 0.5L + 0.5(Lr or S or R) 1.2D 1E + 0.5 L + 0.2S 0.9D (1.3W or 1E) Bolt Type Bolt Dia Material Properties Elements Beam Column Angles Designation W36x231 W14x90 2L5x3 1/2 Specifications ASTM A992 ASTM A992 A36 Fy (ksi) 50 50 36 Fu (ksi) 65 65 58 ASTM A325-N 3/4 inch=

Calculate Bolt design Strength (Rn)

Minimum number of Bolts, n1=Ru / Rn

Assume suitable Number of Bolts (n), edge (e), spacing (s) and gauge (g)

0.75 inch

Assume angle thickness (t)

Design Check

Geometric Properties Beam W36x231 Column Angles Criterias Connection type = Force Type = W14x90 2L5x3 1/2

tw = tf =

0.76 0.71

Design not safe

Bolts

No

limiting shear strength nRn Ru

Yes

of bolt groups (nRn)

Bearing Type connection Shear and torsion

Angle

Bolt bearing on angle (Rn)

Shear yielding (Rn)

shear rupture (Rn)

block shear rupture (Rn)

Design is Safe

Beam

Bolt bearing on Beam Web (Rn) Bolt bearing on Rn Ru

Yes

Design is Safe

Column

Beam Web (Rn)

No

Design not safe

Design of Double angle connection is complete

Angle lengthAngle thickness Minimum spacing in any directionMinimum edge distanceAnet= t (W-dh) for single row of bolt t(W-ndh) Anet can never be lesser than 0.85Ag s= g=

Minimum angle length shoud be one half of the "T" dimension of the beam to be su Maximum is 5/8 inch 2 2/3 (2.667) d (AISC J 3.3) Sheared edge is the worst case (from table J 3.4)

for n number of bolts across the section

centre to centre spacing of fastener in a row, also called fastner pitch centre to centre spacing of bolts along perpendicular direction to the line of force In lap joint it is the centre to centre distance between rows of fastener ref. Steel Buildings (Green Book) pg 210 total shear strength of the section (Fv) =

Check Shear on net Area of Angles

0.3*FuAv

(when tension is there strength strength is reduced to 30% of the minimum specified tensile strength)

the thickness required for shear=

Fu= Minimum specified tensile strength t=Ru/[Fv(l-ndh)n1] l= length of angle Fv= Shear strength of one angle dh= hole diameter n1= number of angles

half of the "T" dimension of the beam to bePg 1481 LRFD Manual supported

f the minimum specified tensile strength)

8.5 inch

t, Angle Thickness

t1, End Projection

Lev

s, bolt spacing

l, Angle length Leh

Column

Beam

Beam

l, Angle length d

g, gauge distance

Beam

Beam

Double Angle Connections

Inputs Notations Fy Fu Fy Fu Leh Pu Vu t d n Definition of Beam of Beam of Column of Column horizontal edge distance Axial force Shear Force angle thickness bolt diameter = 7/8" number of bolts units stress stress stress stress length force force length length no unit

Outputs D/C ratio

1. Check strength of bolts and angles Rn= Rn From Table1 R n = design strength of bolt will be selected from table( pg 1521-1533)

Ru= ( Pu2+Vu2)1/2 1. Check strength of bolts and angles D/C = Ru/(Rn) 2. Check the Beam Web for bolt bearing D/C < 1 TRUE o.k FALSE Review the design

3. Check Supporting Member Flange for bolt bearing

2. Check the Beam Web for bolt bearing

Rn= t* Rn From Table 2 R n = Beam Web design strength will be selected from table( pg 1521-1533) Ru= ( Pu2+Vu2)1/2

D/C = Ru/(Rn)

D/C < 1 TRUE o.k

FALSE

Review the design

3. Check Supporting Member Flange for bolt bearing

Rn= t* Rn From Table 3 R n = Support design strengthwill be selected from table( pg 1521-1533) Ru= ( Pu2+Vu2)1/2

D/C = Ru/(Rn)

D/C < 1 TRUE o.k

FALSE

Review the design

3. Design strength of Beam 3a. Beam Web Bearing strength already done 4. Design strength of Beam 4a. Column Web Bearing strength already done

Table 1

For Fy=36 ksi & Fu=58 ksi number of rows 8 7 6 5 4 3 2 angle thickness 3\8 1\2 3\8 1\2 3\8 1\2 3\8 1\2 3\8 1\2 3\8 1\2 3\8 1\2

Table 2

For Fy=36 ksi & Fu=58 ksi number of rows 8 7 6 5 4 3 2 Leh 1.5 1.75 1.5 1.75 1.5 1.75 1.5 1.75 1.5 1.75 1.5 1.75 1.5 1.75

Table 3

Number oF rows 8 7

Support Design strength/t 1462 1279

6 5 4 3 2

1096 914 731 548 365

For Fy=50 ksi & Fu=65 ksi Bolt and angle strength 303 346 264 352 225 300 186 248 147 196 108 144 68.5 86.6 number of rows 8 7 6 5 4 3 2 angle thickness 3\8 1\2 3\8 1\2 3\8 1\2 3\8 1\2 3\8 1\2 3\8 1\2 3\8 1\2

For Fy=50 ksi & Fu=65 ksi Beam Web Design strength/t 731 731 639 639 548 548 457 457 365 365 274 274 183 183 number of rows 8 7 6 5 4 3 2 Leh 1.5 1.75 1.5 1.75 1.5 1.75 1.5 1.75 1.5 1.75 1.5 1.75 1.5 1.75

Number oF rows 8 7

Support Design strength/t 1638 1433

6 5 4 3 2

1229 1024 819 614 410

Bolt and angle strength 340 433 296 379 252 325 208 271 165 216 121 161 76.8 86.6

Beam Web Design strength/t 819 819 717 717 614 614 512 512 410 410 307 307 205 205

You might also like

- AISC Tension MemberDocument3 pagesAISC Tension Membermodulor3dNo ratings yet

- End Plate ConnectionDocument10 pagesEnd Plate ConnectionMohamed Tahar Allagui100% (1)

- Moment Splice - BackupDocument74 pagesMoment Splice - BackupKiran AcharyaNo ratings yet

- Connection Design SheetDocument47 pagesConnection Design SheetStephen James100% (1)

- Combined Gusset Plate DesignDocument3 pagesCombined Gusset Plate Designkalpanaadhi100% (3)

- 2 ConnectionDocument18 pages2 Connectionssikha100% (1)

- Beam Column Connection-Design2Document16 pagesBeam Column Connection-Design2abdul kareeNo ratings yet

- Ub 254 Fin Plate To Column Web - LRFDDocument10 pagesUb 254 Fin Plate To Column Web - LRFDihpeterNo ratings yet

- Hollow Section Bracing Connetion - LRFDDocument5 pagesHollow Section Bracing Connetion - LRFDkalpanaadhiNo ratings yet

- Larsen & Toubro Ltd. Rev Ltem Structural Design Calculations of Radiant SectionDocument24 pagesLarsen & Toubro Ltd. Rev Ltem Structural Design Calculations of Radiant SectionAkshay Patil100% (1)

- Pinned Base Plate DesignDocument12 pagesPinned Base Plate DesignvtalexNo ratings yet

- Eccentric Shear Connection Analysis of Bolt GroupDocument4 pagesEccentric Shear Connection Analysis of Bolt GroupjaffnaNo ratings yet

- Astm Steel Grade: RN FNV Ab RN 2.4 D T Fu (Critical RN Will Be The Least of The Two RN'S)Document5 pagesAstm Steel Grade: RN FNV Ab RN 2.4 D T Fu (Critical RN Will Be The Least of The Two RN'S)Kim TrixieNo ratings yet

- Rafter Splice DesignDocument2 pagesRafter Splice DesignkalpanaadhiNo ratings yet

- Att-5 - End-Plate Shear ConnectionDocument7 pagesAtt-5 - End-Plate Shear Connectioncravikumar1971100% (3)

- Base Plate Design Fixed RevisedDocument8 pagesBase Plate Design Fixed RevisedEngDbt80% (5)

- Base Plate Design (From RCC ColDocument9 pagesBase Plate Design (From RCC ColJanya AssociatesNo ratings yet

- b2b SpliceDocument21 pagesb2b SplicePrasad Dayalamoorthy DNo ratings yet

- Standard BaseplateDocument133 pagesStandard BaseplateMohamad AmirulbaharudinNo ratings yet

- FinPlate Type Cleat ConnectionDocument81 pagesFinPlate Type Cleat ConnectionRajveer SinghNo ratings yet

- Standard - BaseplateDocument139 pagesStandard - BaseplateWelcomePopeFrancis100% (2)

- Design of Chequered Plate DesignDocument2 pagesDesign of Chequered Plate DesignadihindNo ratings yet

- Steeltek ConnectionDocument5 pagesSteeltek ConnectionSudip ShresthaNo ratings yet

- Steel Column Base PlateDocument17 pagesSteel Column Base PlateVAN HUNG TRANNo ratings yet

- Beam SpliceDocument17 pagesBeam SpliceBoddu Ramakrishna100% (1)

- Cap Plate Trial CalculationDocument18 pagesCap Plate Trial CalculationStar100% (1)

- AISC Connection Design With StiffnerDocument8 pagesAISC Connection Design With StiffnerVinayak PatilNo ratings yet

- Moment Connection Design BS CODEDocument5 pagesMoment Connection Design BS CODEALPHYL BALASABASNo ratings yet

- LRFD Steel BeamDocument30 pagesLRFD Steel Beam정영철No ratings yet

- Column Base Plate DesignDocument1 pageColumn Base Plate DesignBunkun15No ratings yet

- Portal FrameDocument42 pagesPortal Framesurendra_pangaNo ratings yet

- Input: KN.M 59.00 ### KN KN MM 500 MM 200 MM 24 MM 16 MM 24 MM 100 MM 100Document11 pagesInput: KN.M 59.00 ### KN KN MM 500 MM 200 MM 24 MM 16 MM 24 MM 100 MM 100maheshbandhamNo ratings yet

- 6-Bracing Connection - TDocument2 pages6-Bracing Connection - TMUTHUKKUMARAMNo ratings yet

- Connection ScheduleDocument192 pagesConnection ScheduleNikitaBhattaraiAcharyaNo ratings yet

- Design of Builtup SectionDocument4 pagesDesign of Builtup SectiondsanandaNo ratings yet

- RCCe11 Element DesignDocument8 pagesRCCe11 Element DesignZayyan RomjonNo ratings yet

- Base Plate - FixedDocument4 pagesBase Plate - Fixedbhaskardharani80% (5)

- Design of Base PlateDocument258 pagesDesign of Base PlateDushyantha Jayawardena100% (2)

- Bolted Moment ConnectionDocument18 pagesBolted Moment ConnectionAlpha50% (2)

- Moment Connection Design-BS CODEDocument5 pagesMoment Connection Design-BS CODEMuthukumaran SivalingamNo ratings yet

- Base Plate-PinnedDocument34 pagesBase Plate-PinnedSohaibNo ratings yet

- Base Plate Dan Anchor Bolt Calculation: Connection DesignDocument21 pagesBase Plate Dan Anchor Bolt Calculation: Connection DesignSurya FahmiNo ratings yet

- 1.wind Load BNBC Aisc Open Code 60mDocument9 pages1.wind Load BNBC Aisc Open Code 60mAnonymous ep7LE5ZdP5No ratings yet

- 321 Chapter 5 Splice DesignDocument91 pages321 Chapter 5 Splice DesignHemant Ramesh NarkarNo ratings yet

- Steel Composite 1 VERY GOOD MahfuzDocument5 pagesSteel Composite 1 VERY GOOD MahfuzLivian TeddyNo ratings yet

- Beam To Beam Web - Shear ConnectionDocument2 pagesBeam To Beam Web - Shear ConnectionGautam SharmaNo ratings yet

- Base Plate Design (Fixed Base)Document3 pagesBase Plate Design (Fixed Base)Saravana NNo ratings yet

- C1 Design of Column With Biaxial Bending: B MZ MyDocument4 pagesC1 Design of Column With Biaxial Bending: B MZ MyDario Federico Noguez Gonzaléz100% (1)

- Beam End Connection Using Clip Angles Per AISC 9th Edition (ASD)Document36 pagesBeam End Connection Using Clip Angles Per AISC 9th Edition (ASD)cengizNo ratings yet

- Fin Plate - Beam To ColumnDocument78 pagesFin Plate - Beam To ColumnHemant Ramesh NarkarNo ratings yet

- Design of Base PlateDocument14 pagesDesign of Base Plateruel galutanNo ratings yet

- Connections in Steel Structures PDFDocument54 pagesConnections in Steel Structures PDFsmmsajediNo ratings yet

- Single Shear Steel ConnectionDocument36 pagesSingle Shear Steel ConnectionNatalie WestNo ratings yet

- Base Plate Design - BS CodeDocument3 pagesBase Plate Design - BS Codemicheleling669667% (3)

- Tension Member Design - Tuks NotesDocument65 pagesTension Member Design - Tuks NotesgilmoremunroNo ratings yet

- PF2Document4 pagesPF2nhulugallaNo ratings yet

- Design of pile cap - PC2 (For 750x300 column) a Φ/5 a: cu 2 m y 2 mDocument8 pagesDesign of pile cap - PC2 (For 750x300 column) a Φ/5 a: cu 2 m y 2 mtheunknown076No ratings yet

- Aisc 28Document4 pagesAisc 28Ramesh SahasrabudheNo ratings yet

- Shear Strength Controls 21.65 Kips/bolt RN : Section at ADocument4 pagesShear Strength Controls 21.65 Kips/bolt RN : Section at ASuneesh PNo ratings yet

- AITC-H - Direct Shear Strength Test (15!09!14)Document9 pagesAITC-H - Direct Shear Strength Test (15!09!14)runkirNo ratings yet

- New Classrooms ConstructionDocument4 pagesNew Classrooms ConstructionrunkirNo ratings yet

- The Projection and Construction of New SchoolsDocument2 pagesThe Projection and Construction of New SchoolsrunkirNo ratings yet

- AITC-H - Flexural Tensile Strength of Brick Unit (15!09!14)Document8 pagesAITC-H - Flexural Tensile Strength of Brick Unit (15!09!14)runkirNo ratings yet

- AITC-H - Compression Strength of Individual Bricks (15!09!14)Document9 pagesAITC-H - Compression Strength of Individual Bricks (15!09!14)runkir100% (1)

- AITC-H - Flexural Tensile Strength of Brick Unit (15!09!14)Document8 pagesAITC-H - Flexural Tensile Strength of Brick Unit (15!09!14)runkirNo ratings yet

- AITC-H - Flexural Tensile Strength of Brick Unit (15!09!14)Document8 pagesAITC-H - Flexural Tensile Strength of Brick Unit (15!09!14)runkirNo ratings yet

- Autocad ShortcutsDocument13 pagesAutocad ShortcutsKriscel CaraanNo ratings yet

- Lump MassDocument10 pagesLump Masspkshrawal1976No ratings yet

- Bentley CodeDocument1 pageBentley CoderunkirNo ratings yet

- Autocad ShortcutsDocument13 pagesAutocad ShortcutsKriscel CaraanNo ratings yet

- Nikon BrochureDocument9 pagesNikon BrochureMihaela ScarlatNo ratings yet

- Fire Resistance Durability Test Impact Test Green LabelingDocument1 pageFire Resistance Durability Test Impact Test Green LabelingrunkirNo ratings yet

- 03DiI 03Document26 pages03DiI 03runkirNo ratings yet

- Bridge Design Eurocodes Worked Examples Annex OnlyDocument150 pagesBridge Design Eurocodes Worked Examples Annex OnlyAhmed AjelNo ratings yet

- Behaviour of Masonry Wall Constructed Using Interlocking Soil Cement BricksDocument7 pagesBehaviour of Masonry Wall Constructed Using Interlocking Soil Cement BricksrunkirNo ratings yet

- In-Plane Cyclic Shear Performance of Interlocking Compressed EartDocument144 pagesIn-Plane Cyclic Shear Performance of Interlocking Compressed EartrunkirNo ratings yet

- Adb Nep Kiran Jnbs v1Document8 pagesAdb Nep Kiran Jnbs v1runkirNo ratings yet

- AITC-Alphaland Makati-UHS (20130904)Document2 pagesAITC-Alphaland Makati-UHS (20130904)runkirNo ratings yet

- ResidentialDocument2 pagesResidentialrunkirNo ratings yet

- Hem Engineering StructureDocument1 pageHem Engineering StructurerunkirNo ratings yet

- ASCE31 and ASCE41 What Good Are They FinalDocument8 pagesASCE31 and ASCE41 What Good Are They FinalrunkirNo ratings yet

- Laptop Contract Agreement: If I Am An EmployeeDocument1 pageLaptop Contract Agreement: If I Am An EmployeerunkirNo ratings yet

- Rule of Thumb Concrete DesignDocument54 pagesRule of Thumb Concrete DesignrunkirNo ratings yet

- House Plan (Mezzanine) - 23rd June, 2013Document3 pagesHouse Plan (Mezzanine) - 23rd June, 2013runkirNo ratings yet

- Data SheetDocument4 pagesData SheetrunkirNo ratings yet

- Quakeguard Earthquake Early Warning System: January 17, 1994Document2 pagesQuakeguard Earthquake Early Warning System: January 17, 1994runkirNo ratings yet

- MOE OrganogramDocument18 pagesMOE OrganogramrunkirNo ratings yet

- Concrete Design AidsDocument20 pagesConcrete Design AidsumtancwNo ratings yet

- Tie ConnectionDocument1 pageTie ConnectionrunkirNo ratings yet

- Digest of Agrarian From DAR WebsiteDocument261 pagesDigest of Agrarian From DAR WebsiteHuzzain PangcogaNo ratings yet

- ExSchutzkatalog Englisch 1Document61 pagesExSchutzkatalog Englisch 1marius_brkt6284No ratings yet

- 02 Adaptive Tracking Control of A Nonholonomic Mobile RobotDocument7 pages02 Adaptive Tracking Control of A Nonholonomic Mobile Robotchoc_ngoayNo ratings yet

- Lets Talk About Food Fun Activities Games Oneonone Activities Pronuncia - 1995Document1 pageLets Talk About Food Fun Activities Games Oneonone Activities Pronuncia - 1995IAmDanaNo ratings yet

- Rosmary PollockDocument4 pagesRosmary PollockhbNo ratings yet

- 3471A Renault EspaceDocument116 pages3471A Renault EspaceThe TrollNo ratings yet

- QP02Document11 pagesQP02zakwanmustafa0% (1)

- BNBC 2017 Volume 1 DraftDocument378 pagesBNBC 2017 Volume 1 Draftsiddharth gautamNo ratings yet

- Businesses ProposalDocument2 pagesBusinesses ProposalSophia Marielle MacarineNo ratings yet

- ManagementLetter - Possible PointsDocument103 pagesManagementLetter - Possible Pointsaian joseph100% (3)

- Nilfisck SR 1601 DDocument43 pagesNilfisck SR 1601 DGORDNo ratings yet

- Practice Career Professionalis PDFDocument29 pagesPractice Career Professionalis PDFRo Ma SantaNo ratings yet

- Lesson 2 - Graphing Rational Numbers On A Number LineDocument9 pagesLesson 2 - Graphing Rational Numbers On A Number Linehlmvuong123No ratings yet

- Problemas Del Capitulo 7Document26 pagesProblemas Del Capitulo 7dic vilNo ratings yet

- 7779 19506 1 PBDocument24 pages7779 19506 1 PBAyessa FerrerNo ratings yet

- MN502 Lecture 3 Basic CryptographyDocument45 pagesMN502 Lecture 3 Basic CryptographySajan JoshiNo ratings yet

- Leyson vs. OmbudsmanDocument12 pagesLeyson vs. OmbudsmanDNAANo ratings yet

- Graphene/Metal Organic Framework Composites As Adsorbents For Adsorption Chiller ApplicationsDocument88 pagesGraphene/Metal Organic Framework Composites As Adsorbents For Adsorption Chiller ApplicationsNajam Ul QadirNo ratings yet

- For Visual Studio User'S Manual: Motoplus SDKDocument85 pagesFor Visual Studio User'S Manual: Motoplus SDKMihail AvramovNo ratings yet

- PDF 24Document8 pagesPDF 24Nandan ReddyNo ratings yet

- TEMI880&850 Manual (Eng)Document122 pagesTEMI880&850 Manual (Eng)Mihir PrajapatiNo ratings yet

- Fss Operators: Benchmarks & Performance ReviewDocument7 pagesFss Operators: Benchmarks & Performance ReviewhasanmuskaanNo ratings yet

- Chapter 2: Static Routing: Instructor MaterialsDocument63 pagesChapter 2: Static Routing: Instructor MaterialsAhmad Mustafa AbimayuNo ratings yet

- Gr7 3rd PeriodicalDocument2 pagesGr7 3rd PeriodicalElle GonzagaNo ratings yet

- Sonos 5500 Service ManualDocument565 pagesSonos 5500 Service ManualScott Fergusson50% (2)

- Fuel Supply Agreement - First DraftDocument104 pagesFuel Supply Agreement - First DraftMuhammad Asif ShabbirNo ratings yet

- BT5Document17 pagesBT5Katkat MarasiganNo ratings yet

- G6Document14 pagesG6Arinah RdhNo ratings yet

- To. Whom It May Concern: Available Mentioned Position in IndonesiaDocument8 pagesTo. Whom It May Concern: Available Mentioned Position in IndonesiaGreen Sustain EnergyNo ratings yet

- SYLVANIA W6413tc - SMDocument46 pagesSYLVANIA W6413tc - SMdreamyson1983100% (1)