Professional Documents

Culture Documents

Rilprj 1

Uploaded by

Sneha KanadeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rilprj 1

Uploaded by

Sneha KanadeCopyright:

Available Formats

Reliance industries limited

A PROJECT REPORT ON PERFECT WEIGHING OF BAGGED MATERIAL (DISTRIBUTION NETWORK OF RIL-NMD) AT RELIANCE INDUSTRIES LIMITED NAGOTHANE MANUFACUTURING DIVISION, NAGOTHANE

SUBMITTED BY KEDAR LELE. SUBMITTED TO MR.ATANU CHATOPADHYAY (HOD ,OCG)

FOR THE REQUIRMENT OF MASTER OF MANAGEMNENT STUDIES (MMS) 2011-2012

Reliance industries limited

CONTENTS

i. ii. iii. iv. v. vi. vii. viii. ix. x. xi. xii.

Introduction to reliance History Background RIL-NMD Introduction about plants. Safety PPES Location of RIL-NMD Overview of plants Findings Recommendations References

Reliance industries limited

Reliance industries limited

Reliance Group

The Reliance Group, founded by Dhirubhai H. Ambani (1932-2002), is India's largest private sector enterprise, with businesses in the energy and materials value chain. Group's annual revenues are in excess of US$ 58 billion. The flagship company, Reliance Industries Limited, is a Fortune Global 500 company and is the largest private sector company in India. Backward vertical integration has been the cornerstone of the evolution and growth of Reliance. Starting with textiles in the late seventies, Reliance pursued a strategy of backward vertical integration - in polyester, fiber intermediates, plastics, petrochemicals, petroleum refining and oil and gas exploration and production - to be fully integrated along the materials and energy value chain. The Group's activities span exploration and production of oil and gas, petroleum refining and marketing, petrochemicals (polyester, fiber intermediates, plastics and chemicals), textiles, retail and special economic zones.

Reliance industries limited

Reliance enjoys global leadership in its businesses, being the largest polyester yarn and fiber producer in the world and among the top five to ten producers in the world in major petrochemical products. Major Group Companies are Reliance Industries Limited (including main subsidiary Reliance Retail limited) and Reliance Industrial Infrastructure Limited.

HISTORY:

Indian petrochemical corporation limited today is a one of the largest business corporation in the country, RIL-NMD portfolio comprise of petrochemical, plastic, synthetic rubber, engineering plastic, corrosion and inspection consultancy and external contacts. RIL-NMD being a public sector undertaking is a world best performance amongst petrochemical companies having 3 complexes situated in vadodara formally boroda, halothane and gandhar. It also had 7 regional offices in Mumbai,

Reliance industries limited

Delhi, Calcutta, madras, vadodara, Ludhiana and Bangalore and many sale centers. There are also many sales centers under regional offices. The company was incorporated on 22 march 1969 in the public sector as a consequence of the failure of the several rounds of negotiations with prospective translation companies since RIL-NMD has undergone a metamorphosis four times. The complex produced a variety of the polymers, fibers intermediates surfactant intermediates chemicals and solvents. When RIL -NMD entered in the petrochemical market in India. Market were almost nonexistent for the many products such as xylences, diethyl terpt and linear alkyl, benzene detergent intermediates the production capacities of the commodity plastic were introduction in the market. The companies manufacturing facilities were located near Indian oil corporation Gujarat refinery in vadodara, the company narrowed down on the investment for a gas cracker complex at nagothane near Mumbai by mid 1980 the nagothane complex was operational by te early 1990s Between the mid 1980 and 1990 the success and growth of the petrochemical business to attract several players. Amongst them was Dhirubhai Ambani. It largest petrochemical manufacturing in India by the late 1990.

Reliance industries limited

BACKGROUND:

The foundation stone of this complex was laid Mr. N. D. Tiwari, Minister of industry, and government of India on the January 8, 1986. The large quantity of the associated hydrocarbon gas available from the Mumbai high off shore in the seventies threw open new vistas for hydrocarbons processing industries. Presence of economically exploitable of ethane and propane in gas led the govt to permit industries based on ethane components. Ministry of petrochemical of the India constituted a task force under the oil industries development board. The task force entirely comprised personnel drown from RIL NMD and functioning from the last quarters of 1981. The task assigned to this force was to plane for optimal utilization of these osseous resources and to work out pre-project activates. Initial studies by the different agencies indication the 400000 TPA ethylene plant based on this stock from uran. Ethane and propane is available from the uran which is transported by the pipeline which is of 70+32 km long and has 46 inches is send the tanks and ISBL for cracking/ ethane and propane are store in storage tanks in the OSBL lean gas is taken from the RCF thal, it is used in CPP plant for power generation of whole

Reliance industries limited

RIL-NMD. It is 50km long and has width of 10 inches. Only propane is also taken the HPCL which is also stored in the 3 spheres in the OSBL.

RELIANCE NAGOTHANE MANUFACTURING DIVISION

Reliance industries limited Nagothane formerly known as Indian Petrochemical Corporation limited, the pioneering chemical company in India was incorporated on March 22, 1969. It produces over one million tons of merchant products and generates turnover close to INR 90 billion. Its business comprises of polymers synthetic fiber intermediates surfactants commodity chemicals catalysts. Backed by innovation from its technology management center, research center and product application centers, the company is continually upgrading its processes and products. The company owns and operates three petrochemical complexes, a naphtha based complex at Vadodara and a one gas based complex each at Nagothane near Mumbai and Dahej on Narmada estuary in bay of Khambhat. The company also owns a catalyst, manufacturing facilitate at Navi Mumbai. The company is member of the reliance group set up by late Mr. Dhirubhai Ambani. Dhirubhais pioneering vision and over three decades of successful operations ingrain in us unique level of expertise. Making us complacently engineered for the future.

8

Reliance industries limited

Nagothane manufacturing division located in Raigad, Maharashtra is spread over 1860 acres. It comprises of an ethane and propane gas cracker and five downstream plants for the manufacturing of polymers, fibers intermits and chemicals.

INTRODUCTION TO PLANTS IN THE RIL-NMD

GAS CRACKER [GC]

LINEAR LOW DENSITY POLYETHYLENE [LLDPE]

ETHYLENE OXIDE/ETHELENE GLYCOL [EO/EG]

LOW DENSITY POLYETHYLENE [LDPE]

AIR SEPARATION [N2O2]

9

Reliance industries limited

POLY PROPYLENE [PP]

BUTANE 1

CAPTIVE POWER PLANT [CPP]

SAFTY:

Safety is important for every industry rules must be obeyed by every one in the industry to avoid armful hazard. Each company has safety manager. Safety manager and supervisor maintain safety environment and employees as well as factory, the safety culture in reliance is one of its kind has been developed looking into many potential hazard of nay manufacturing industry.

PERSONAL PROTECTIVE EQUIPMENTS:

GAS MASK:

10

Reliance industries limited

Gas mask is provided with suitable absorbing chemical. This chemical absorbs exile gases and alloy only to oxygen. They filters the gases which dangerous for breathing.

DUST MASK: It protects respiratory system from harmful chemical for breathing. APRON: Apron is used for protective of body and cloths clean. Aprons are made up of different material like PVC, cotton, rubber etc. HAND GLOVES: Hand gloves are used for protective hand from heat chemical cut etc. the rubber hand gloves and PVC hand gloves used for hazard chemical handing. GOGGLES: Goggles are used for protecting eyes from heat chemical dust etc. HELMET: Helmet is used for protecting of head.

11

Reliance industries limited

EAR PLUG: Ear plug are used for safety of the ear from the high noise in the industries.

SAFTY SHOES: Safety shoes are for protection of the feet and lags from heat, electricity and filling any hard martial on the leg

TO BE ASSURED BEFORE EXECUTION OF JOBS:

1) Wind direction 2) Escape route 3) Assembly point 4) Fire extinguisher 5) Manual call point

12

Reliance industries limited

6) Loudo phone 7) safety shower 8) Work carried out.

CARE TO BE TAKEN BY EMPLOYEES: 1. Understanding the job properly before working on it 2. Learn carefully the chemical used their hazard properties 3. Read and understanding notice board around factory 4. Use apron helmet safety goggles gas mask safety bleats whenever necessary 5. Safety away from drug while working.

13

Reliance industries limited

LOCATION OF COMPANY::

According to map 2, we will get a clear idea about correct location of the company. The company is situated near to Nagothane village which is an on Mumbai Goa road that is NH 17 . Nagothane is just 4km away from this petrochemical complex.

NEAREST CITIES

MUMBAI PUNE

110km 140 km

NEAREST TOWN

ROHA ALIBAG PANVEL PEN

18 km 35 km 60 km 28 km

14

Reliance industries limited

MAHAD

70 km

NEAREST BUS SATATION

NAGOTHANE

6 km

NEAREST RAILWAY STATION

NAGOTHANE ROHA

12 km 20 km

RIL-NMD LAND AND ESTATE:

Total land of 743.35 ha on 95 years lease from MIDC. Nagothane may will hold the record of being the greenest manufacturing plant not found anywhere else - Laurens a. biji. RIL_NMD complex is situated in large area having main petrochemical complex, huge and well maintained Township, Security Township, green belt and land subleased to sun petrochemical company. Though the land is distributed in different areas but the total area is very big

15

Reliance industries limited

Township is situated in 100HA area. Which is a very big area? Township provides accommodation facilities to RIL-NMD employees. It also has huge cricket stadium, football stadium and many small grounds to play. Township have a very well maintained health club provides facilities of swimming, table tennis, batmen ton and many other games. Township also has a hospital for RIL_NMD employees. By keeping a social aspect in mind company did the plantation at various place like in township, petrochemical complex security township, also they have one area for plantation.

LAND TOWNSHIP LAND PLANT LAND NON PLANT LANT VACCANT LANT SECURITY TOWNSHIP MINITOWNSHIP GREEN BELT LAND SUB LEASED TOSUN PETRO COMPANY

AREA HA 100 265 30 30 6 5 298.55 8.8

16

Reliance industries limited

ABOUT MANPOWER:: The total manpower of this petrochemical complex is about 2054 from management to worker. RIL_NMD total manpower Supervisory Non-supervisory 2054 667 1387

Supervisory total Technical Non-technical

667 560 107

Non-supervisory Skilled Semi-skilled Un-skilled

1387 870 190 326

17

Reliance industries limited

OVERVIEW OF PLANT PROCESS:

1.

GAS CRAKER PLANT ::

Ethane and propane selectively cracked in alter selective cracking furnace to produce ethylene and propylene. Each consists of two parts.

Radiation section:: consist of 14 coils of w configuration. Each w coil comprises of 4 Tube each 36 feet long Coil is of swaged design.

Convection section.

Recovers the heat in fuel gases leaving the reaction section convection section. Consist of 6 zones. Furnaces are operates on zone philosophy, each furnace consist of 3 zones{8 w coil per zone with no of barriers bet zones.}

18

Reliance industries limited

The outlet of each pair of coil passes thought a single USX quench exchanger. There are total 12USX per furnace followed tem 840c to 232c in this quench exchanger. USX exchanger double pipe exchanger. TLX exchanger shall and tube exchanger. Fuel gas is fired to provide the heat for cracking. There are total 144 wall and 24 floor burners.

BASIC THEORY OF CRACKING REACTION::

During cracking free radicals are produced, which propagates the reaction of certain components that are heavier than feedstock being cracked C2H6 C2H5+H C2H6 2CH3

PROPAGATION REACTION::

These comprises chain reaction in which each large radicals associate to give olenfinic molecule and small radical C2H5 C2H4+H The radical adds on to an unsaturated molecule to give large molecule C4H5+CH3 C5H11

19

Reliance industries limited

in the opposite situation if the bed is too cold, the partials can become brittle and may fracture forming unwanted small fragments. The elucidative with the gas. Hence heat and mass transfers to the sportive surface controls the local partial tem and rates of agglomeration and breakage.

Grades produced Ll20fs010 film Ll36ra045 roto Hd55ef010 monofilament Hd50ma180 injection molding

BUTENE1 PLANT:

Butane is produced by demonization of ethylene in double Coolum reactor. The alpha butyl catalyst converse gaseous ethylene dissolved in a liquid phase which is the product of reaction, into butene1. The demonization is achieved by a titanium compound activated by alkyl aluminum. Zenger type catalyst based on titanium have tendency to polymerize ethylene to high molecular weight material. This polymerization reaction is inhibited in the alphabutanol catalyst by adding a modifying agent to the

20

Reliance industries limited

catalyst formula to stabilized the titanium complex, thus preventing formation of ti{3}, responsible for polymerization. The modifier and titanium are mixed under a well defined ratio lc2253 catalyst. The achieve species are realized by mixing TEAL and LC2253 catalyst ethylene pressure. For an optimum performance of the catalyst the molar ratio of AL/TI must be equal to 2.5. if the ratios low the activity will decreased. A high ratio wills increases the activity but decreases selectivity towards butene1. By product either hexanes formed by either by reaction of butyne1 With ethylene or by trimerization of ethylene some small amount of polymer also formed. The reaction takes place at very mild temperature.

LLDPE/HDPE PLANT::

The low pressure polymerization of ethylene to linear polyethylene take s place by coordination polymerization using a catalyst suspended in gaseous ethylene in fuel bed reactor. The ethylene polymerization to the

21

Reliance industries limited

solid phase with the small amount of catalyst required remaining in the solid polymer. Fluidized bed reactor are widely used in industry due to there superior heat and mass transfer characteristics. However in Fluidized bed Polymerization reactors problems associated with local overheating of polymer partials still persist and limit the range of operating condition that can be softly achieved in plant scale reactor. Compared to other reactor, fluidized bed have several advantages such as the capability of continuous operations and transform of solid in and out of the bed, high heat and mass transfer rates from gas to particles leaving to fact reaction and uniform temperature in bed and high solid mixing rate. In gas phase polymerization, small catalyst partials after prepolymerization are introduced at a point above the gas distributor and when exposed to the gas flow containing the monomer polymerization occurs. At early stage of polymerization the catalyst partials fragment into a large number of small partials, which are quickly encapsulated by the newly formed polymer and grow continuously reaching a typical of 1000 -2000nm. Due to different in the polymer partials sizes segregation occurs and fully grows polymer partials migrates to the bottom where they are removed from the reactor. The smaller pre polymerized partials and fresh catalyst partials

22

Reliance industries limited

tend to migrates to the upper partings of the reactor and continue to react with monomers. Because polymerization is exothermic, the temp of the polymer tends to rise and sometimes it will exceed the melting point of the polymer, then polymer partials can become sickly and during collision can from large agglomerates that can possibly undergo sintering and caules defluidization.

STEP2 PROPOGATION::

The double bond successive monomers are opened up when monomer is reacted to reactive polymer chain. The free electron is successively passed down the line of chain to outside carbon atom. This reaction is able to occur continually because the energy in chemical system is lowered as the chain grows. The modinamically the sum of the energies of the individuals monomers.simly put the single bonds in polymeric chain are more stable than double bond of monomer.

STEP TERMINATION::

Termination occurs when another free radicals left over from the original splitting of the organic peroxide, meets the ends of the rowing chain.

23

Reliance industries limited

This free radicals terminates the chain by linking with the last ch2 commonest of polymer chain, this reaction produce a complier chain. This exothermic reaction occurs extremely fast forming individual chain of polyethylene often less than 0.1 second. The polymer created has relatively high molecular weights. It is not unusual for branches or cross links with other chain to occurs along the long chain.

CSTR::

High pressure thanked wall vessel running under nearly adiabatic condition. Good striving. Protection against over pressure due to possible run away reactions in case of miss operations. CSTR run at sneaky stat with continuous flow of reactions and products , the feed assumes a uniform composition throughout the reactor, exit stream has same composition as in tank. The structure and properties of polymer can be precisely adjusted to operators need by multi zone arrangement.

GRADES PRODUCED

1020FA20 FILM GRADE. 103FS20 GENRAL PURPOSE FILM GRADE

24

Reliance industries limited

100FY20 MILK PACKAGING GRADE 1070LA17 LAMINATION COATING GRADE

LOW DENSITY POLYETHEYLENE

LINEAR LOW DENSITY POLYETHYLENE [LLDPE] ::

The LLDPE range of products as a wide spread of density from 0.916 to 0.925 grams. And melt index from 0.9 to 25.0 grams the excellent drawn properties of LLDPE film result from lack chain branching compared with convertentinal LDPE, the narrow molecular weight distribution accounts for the superior strength properties of LLDPE film

ADVANTAGEOUS OF LDPE

1. Impact resistance 2. Tear strength resistance 3. puncture resistance 4. Better ESCR.

25

Reliance industries limited

LDPE PRODUCT

Density polyethylene product has a range of product wide spread of density from 0.94 to 0.96 gms melts index from 3.0 to 32.0gms/10 minute.

26

Reliance industries limited

PRODDUCTS AND SERVICES

The company expanded into textile in 1975. Since its initial public offering in 1977, the company has expanded rapidly and integrated backwards into other industries sectors, most notably the products of petrochemicals and the refining of crude oil. The company now has operations that span from the exploration and production of oil and gases to the manufacturing of petrochemical products, polyester, polyester intermediates, plastics, polymer intermediates, chemical and synthetic textile and fabrics. The company from time to time seeks to further diversify onto other industrials. In Jan 2006 the company approved a plan to establish a retail business, through a subsidiary reliance retail limited that will operate, among other things,, supermarkets convenistores and specially stores across India. The company approved initial expedition of us $ 750 million to fund the initial stages of this plan.

27

Reliance industries limited

The companys subsidiary reliance infrastructure limited is currently established infrastructure facilities such as roads and buildings of the proposed specialized economic zone at Jamnagar Gujarat. The companys major products and brands from oil and gas textile are tightly integrated and benefit from synergies the company. Central to the companys operations is its vertical integration strategy, raw material such as PTA MEG, ethylene, propylene and normal paraffin that were previously important at a higher cost and subject to import duties are now sourced from within the company. This has a positive effect on the companys operation margins and interest cost and decreased the companys exposure to the cyclicality of the markets and raw material prices. The company believes that strategy is also important in maintaining a accelerating learning of mission critical procedures to achieve 100 completion at RIL- NMD.Domestic market leadership position in its major lines and in providing competitive advantages. The commands operation can be classified into four segments Petroleum refining and marketing business Petrochemicals business Oil and gas exploration and production business Others.

28

Reliance industries limited

RELIANCE IS:

The worlds largest producer of the polyester fiber and yarn. 4th largest producer of paraxylene and purified terepathalic acid. 6th largest producer of mono ethylene glycol 7th largest producer of polypropylene.

HONOURED FOR..

Shri Mukesh Ambani was awarded the Defence India excellence award 2007. The award is a salute to those who have made the country proud.

Shri Mukesh Ambani was conferred the outstanding business leader of the year award by CNBC TV18

Shri Mukesh Ambani was awarded the business leadership award 2007 by NDTV profit.

29

Reliance industries limited

FOR CORPORATE RANKING AND RATINGS:

Reliance featured in the fortune global 500 list of world largest corporation for the fourth consecutive year Rank 26th within the refining industry. Among the top 25 climbers for two years in a row.

FOR EXPORTS:

The plastics export promotion council PLEXCOUNCIL export award in the category of the plastic polymers for the year 2006-2007 was awarded to reliance benign the exporter in this category.

FOR HEALTH, SAFTY AND ENVIROMENT:

30

Reliance industries limited

RIL gets double golden peacock awards 2009 for environment management and occupational health and safety. Jamnagar manufacturing division was conferred the golden peacock award for occupational health and safety 2007 by institute of director.

Dahej manufacturing division received BSC 5-star rating from British safety council, UK. Nagothane manufacturing division received the shristi g-cube award for good green governance from ministry for commerce and industry on world earth day.

RIL NMD awarded for high standards in the management of fire systems and procedures by FPK UK in 2009. RIL NMD awarded for perfect record award of safety VY national safety council uk,2003 .

FOR TRAINING AND DEVLOPMENT:

Jamnagar refinery was adjudged the winner of the golden peacock national training award 2007

31

Reliance industries limited

Reliance won the CNBC tv18 instituted jobstreet.com jobseekers employers of choice award. RIL NMD won the ASTD best award, 08 for achieving eateries success trough employee learning and development.

FOR ENERGY EXCELLENCE:

Hazira manufacturing division was adjured excellent efficient nit at energy summit 2007 by CII. Patalagana manufacturing division won the the first prize in energy conservation in the state of Maharashtra organized by Maharashtra energy development agency. Jamnagar manufacturing division was the recipient of the ingrained energy award 2007 by ministry of per.

FOR QUALITY:

32

Reliance industries limited

For the first time ever, globally a petrochemical company bagged the Deming prize for management quality practicing total quality management awarded the quality control award for operational business unit 2007 to the Hazira manufacturing division for outstanding performance.

Allahabad manufacturing division won the excellent category award at national convention of quality circle.

FOR SIX SIGMA:

Brabanki manufacturing division won the 3rd prize in all India six sigma case study contests 2008 for the case study on reduction of waste of plant 2 from 16% to 8%.

Vadodra manufacturing division six sigma projects won the 1st prize as the best six sigma projects at national level by CII.

33

Reliance industries limited

FOR TECHNOLOGY R&D AND INNOVATION

Reliance technology group Hazira awarded for prestigious international award for creating world class research and technology center by r and d published by renowned Hal Avery publisher.

Dsir national award for r and d efforts in industry was conferred Hazira manufacturing division for cycle hexane recovery project.

Patalganga manufacturing division project titled augmentation of ETP and use of biogas in fired heters won the best innovative project from cii

Reliance bagged the innovation at tech converge 2007 for innovative development in short cut fibers.

hazira manufacturing division won the golden peacock innovation award for its cyclohexane recovery process.

34

Reliance industries limited

FOR INFORMATION TECHNOLOGY

Cio of the year award for the best it enabled organization in India for the year 2007 Ones of watch cio use award for figuring among the top 20 organizations excellence in it team. The scotch challenger award conferred for the best it head of the year 2007.

Best it implementation award by pc quest for knowledge management system portal.

FOR SOCIAL INVIATIVES:

Hazirta manufacturing division won the golden peacock global award for corporate social responsibility 2008

MISSION CRITICAL

35

Reliance industries limited

All of us know that reliance industry limited is one of the largest industries in the world. Reliance is the world polyester fiber and yarn producer. Now company aims to achieve first rank in safety. Being as of sensitivity industry, company has decided to provide safety to all employees as well as contractor, and the companies aim is to achieve ZERO INCIDENTS.

To achieve that goal company had tied up with DuPont, which is a fortune 500 companies and worlds number one safety resources provider. DuPont, after analyzing companies work environment for more than 18 companys camp up with 71 critical standards and procedures out if those, companies focus is on 30 prioritized modules.

While doing any kind of job employee can meet minor or major accident that may be because of any minute mistake that result into major or minor damage to the working employees, to the plant, to the environment will get affect. To avoid every major as well as minor mistake DuPont has came up with such standards and procedures were no chance to meet with accidents. According to those standards, reliance has developed the training modules with the help of internal talent and DuPont expert. Today the help of those modules, each and every employee of reliance taking the training.

36

Reliance industries limited

INTRODUCTION

As part of curriculum of the Master Degree in Management Studies course at Prabhakar Patil Institute of Management Studies, students are required to do a project in any reputed organization. For this reason, I did my project research in Reliance Industries Limited, Nagothane Manufacturing Division. The project work was titled Effectiveness of Logistics Management in Nagothane and to suggest ways and means to improve the management strategic decisions.

OBJECTIVE OF THE STUDY

The objectives of the Project are: To know about Logistics Industries To have a thorough understanding of how logistics and freight industries work. To know whether the customers are satisfied with the existing range of service pattern

37

Reliance industries limited

Introduction to Logistics Management Logistics management is that part of the supply chain which plans, implements and controls the efficient, effective forward and reverse flow and storage of goods, services and information between the point of origin and the point of consumption in order to meet customers' requirements. A professional working in the field of logistics management is called a logistician. Logistics as a business concept evolved only in the 1950s. This was mainly due to the increasing complexity of supplying one's business with materials and shipping out products in an increasingly globalized supply chain, calling for experts in the field who are called Supply Chain Logisticians. This can be defined as having the right item in the right quantity at the right time at the right place for the right price and it is the science of process having its presence in all sectors of the industry. The goal of logistics work is to manage the fruition of project life cycles, supply chains and resultant efficiencies.

b. Origin and Definition of Logistics:

The term "logistics" originates from the ancient Greek "" ("logos" "ratio, word, calculation, reason, speech, oration"). Logistics is considered to have originated in the military's need to supply themselves with arms, ammunition and rations as they moved from their base to a forward position. In ancient Greek, Roman and Byzantine empires, there were military officers with the title Logistikas who were responsible for financial and distribution of supplies. The Oxford English dictionary defines logistics as: The branch of military science having to do with procuring, maintaining and transporting material, personnel and facilities.Another dictionary definition is: "The time related

38

Reliance industries limited

positioning of resources." As such, logistics is commonly seen as a branch of engineering which creates "people systems" rather than "machine systems"....

RESONS FOR THE WASTE GENERATION IN THE BAGING PLANT 1. BAGS NOT FIT PROPERLY IN THE MACHINE AT FILLING STATION. 2. MANUFACTURING DEFECTS IN THE BAGS. 3. STITCHING NOT DONE PROERLY. 4. BAGS GETS DAMAGE ON THE ROLING MACHINE. 5. NAILS OF THE WOODEN PALLETS. 6. NOT PROPERLY LIFTED BY THE FOLKLIFTS. 7. BAGS FALLING ON GROUNDS FROM PALLETIZER.

39

Reliance industries limited

MASURES FOR THE REDUCING THE WASTE. 1. TAKE CARE THAT BAGS GETS FITED IN SPOUT PROPERLY 2. TAKE CARE THAT BAGS ARE MAUFACTURED PROPERLY 3. TAKE CARE THAT BAGS STITCHING DONE PROPERLY 4. TAKE CARE THAT BAGS DOES NOT GET DAMAGE ON THE ROLLING MACHINE 5. TAKE CARE THAT NO NAILS ON THE WOODEN PALLETS 6. TAKE CARE THAT BAGS LIFT PROPERLY BY LIFT.

40

Reliance industries limited

BAGGING MACHINE SECTION 1. Net Weigher Section 2. Bag Magazine Section 3. Bag Filling Section 4. Transportation 5. Stitching Machine 6. Printer 7. Metal Detector 8. Check Weigher 9. Rejection Conveyor. 10.Discharge Conveyor.

41

Reliance industries limited

NET WEIGHTER a) Weight housing b) Weight hopper c) Level switch d) Load cells e) Proximity switch f) Pneumatic cylinders. g) Speed controller. OPERATION SEQUENCE. 1. Feeding device delivers material into weight hopper at full rate. 2. At predetermined weight value feeder charges into reduce the material flow on to time feed rate. 3. At the off weight, material flow stops. 4. On ok to discharge signal is present, hoppers doors open and weightiest discharged. 5. doors close after present time

42

Reliance industries limited

AUTOMATIC BAG FITLER 1. Lifting table for presenting of bag magazine. 2. Vacuum system with signal out and bag opening suckers. 3. Rubbers Chan and positioning motor. 4. Swinging frame with bag opening device.

SPRELDING SPOUT Bag filling spout SPK Integrated clamp Closet clamp.

INTEGRATED BAG TRANSPOTATION SYSTEM. 1. Two swinging arms with transportation belt. 2. Link belt conveyor. 3. Lateral guide plate.

43

Reliance industries limited

SEUUENCE OF OPERATION 1. Magazine lift 2. Single line out 3. Rubber position 4. Vacuum pump 5. Bag operation 6. Swing forward 7. Clamping 8. SF clamping 9. ISAS opening 10.Swinging down 11.Take over 12.Clamp 13.Clamp together 14.SF2 clamping 15.ISAS closing 16.Pressure roller.

44

Reliance industries limited

STITCHING MACHINE 1. Photo sensor 2. Proximity sensor 3. Cylinder 4. Timers 5. Thread sensor SG25 electronic card

MATERIAL DETECTOR: Sensitivity -2.5 mm of metal

CHECK WEIGHER

Dynamic weighing Under weighting- 25.09 kg Over weighting 25.20 kg REJECTION CONVEYOR Reject under weighted and over weighted ,

45

Reliance industries limited

Also bag containing metal particles.

PALLETIZER SECTION 1. Inclined bag conveyor 2. Gravity feeder 3. In feed conveyor 4. Bag turning unit 5. Layer forming belt. 6. Row pusher 7. Shifters on sides and rear 8. Unloading plate 9. Elevator 10.Palate roller conveyor 11.2nd discharge conveyor. 12.Transfer to the palletizes 13.Bag forming and pressing unit 14.Pacing conveyor

46

Reliance industries limited

IMPROVEMENT IN OPERATION.

1. Ps reduction from 0.1% to below 0.04% over last 5 to 6 years 2. AVG cycle time reduced from 400 min to below 250 min. 3. 8 out of 16 DFL decommissioned brought down. 4. Forklift maintenance cost from 90 lakhs to 50 lakhs.

47

Reliance industries limited

REFERENCES:

I have taken references for project report from following ways. 1. 2. 3. 4. 5. Intranet facility available at our system. Data fro SAP system. Discussion with related authorities. Discussion with Mentor sir. Discussion with Supervisor.

48

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

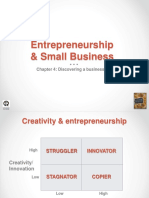

- Entrepreneurship & Small Business: Chapter 4: Discovering A Business IdeaDocument42 pagesEntrepreneurship & Small Business: Chapter 4: Discovering A Business IdeaPooja SheoranNo ratings yet

- PSB - List of Accredited DFFs - 31dec2012Document29 pagesPSB - List of Accredited DFFs - 31dec2012ofwwatchNo ratings yet

- Entrepreneurship PaperDocument5 pagesEntrepreneurship PaperNuman ButtNo ratings yet

- 31 Startup Business Models You Must Know With Examples 1696077578Document32 pages31 Startup Business Models You Must Know With Examples 1696077578Jairo LópezNo ratings yet

- DHL Glo DGF Rail FreightDocument4 pagesDHL Glo DGF Rail FreightGita HindrawatiNo ratings yet

- WAREHOUSE - Research (Oct. 7,2019) (AutoRecovered)Document46 pagesWAREHOUSE - Research (Oct. 7,2019) (AutoRecovered)Mary ColangoNo ratings yet

- Real Estate Market Outlook - Belgrade 2011Document25 pagesReal Estate Market Outlook - Belgrade 2011Zana SipovacNo ratings yet

- T&T Continues Global Expansion: Hiok Liang, Alex Ang Yew Boon, and Hussain Shah, To Its Singapore-Based TeamDocument3 pagesT&T Continues Global Expansion: Hiok Liang, Alex Ang Yew Boon, and Hussain Shah, To Its Singapore-Based Teamapi-219367334No ratings yet

- LG Project ReportDocument65 pagesLG Project ReportVinodDubeyNo ratings yet

- Specifying Multiple Account AssignmentDocument8 pagesSpecifying Multiple Account AssignmentGopalakrishnan KuppuswamyNo ratings yet

- Book 2002Document177 pagesBook 2002Dario Vivanco HuaytaraNo ratings yet

- An Integrated Model For Logistics Network DesignDocument31 pagesAn Integrated Model For Logistics Network DesignsanzitNo ratings yet

- Network Planning in SCMDocument4 pagesNetwork Planning in SCMRajalakshmi VelNo ratings yet

- Technology Driven Routing and Logistic Management Customer's FulfillmentDocument2 pagesTechnology Driven Routing and Logistic Management Customer's Fulfillmentshanayasharma3301No ratings yet

- "TOP 10" Key Issues Principles in Logistic and Supply Chain Management and Apply To A Real World SituationDocument11 pages"TOP 10" Key Issues Principles in Logistic and Supply Chain Management and Apply To A Real World SituationPovenesan Krishnan100% (1)

- Chapter 7 Warehouse Operations & ManagementDocument69 pagesChapter 7 Warehouse Operations & ManagementKhánh Đoan Lê Đình100% (1)

- Assignment MarketingDocument14 pagesAssignment MarketingHuzaifaNo ratings yet

- Consumer Behaviour Towards Shoppers StopDocument24 pagesConsumer Behaviour Towards Shoppers StopAditi Jindal100% (2)

- Transport Statistics WorkshopDocument10 pagesTransport Statistics WorkshopexcelallNo ratings yet

- Malabar Cements Internship Report Malabar Cements Internship ReportDocument79 pagesMalabar Cements Internship Report Malabar Cements Internship ReportrajeevreddyaNo ratings yet

- Sustainable Supply ChainDocument41 pagesSustainable Supply ChainNirvan SharmaNo ratings yet

- MRPDocument27 pagesMRPRAMAKRISHNA.GNo ratings yet

- BA 108 9th Session - Warehouse ManagementDocument21 pagesBA 108 9th Session - Warehouse ManagementAnne Marieline BuenaventuraNo ratings yet

- Resume VP Procurement Supply Chain - Detroit, MI - Information TechnologyDocument3 pagesResume VP Procurement Supply Chain - Detroit, MI - Information TechnologyStevenWelshNo ratings yet

- Loose Fill - : Packaging Chips For Working ComfortDocument8 pagesLoose Fill - : Packaging Chips For Working Comforteqt slhlNo ratings yet

- Emerging Trends in WarehousingDocument21 pagesEmerging Trends in Warehousingvineetmg50% (2)

- Stage 1 - Surya 121901042 - Mini ProjectDocument8 pagesStage 1 - Surya 121901042 - Mini ProjectCrazy MechonsNo ratings yet

- Case Teaching NotesDocument95 pagesCase Teaching NotesRishu SinghNo ratings yet

- EPC RTIPalletTagging ImpGuide I2Document21 pagesEPC RTIPalletTagging ImpGuide I2Banacu DanielNo ratings yet

- SCM in HotelDocument7 pagesSCM in Hotelmushtaque61No ratings yet