Professional Documents

Culture Documents

QCS 2010 Ammendments

Uploaded by

Puneeth DevadigaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QCS 2010 Ammendments

Uploaded by

Puneeth DevadigaCopyright:

Available Formats

QCS 2007

Section 5 Part 2 Aggregates 2.1.4 Sampling in accordance with BS 812 Part 101

QCS 2010

Sampling in Accordance with relevant standards in QCS

Table 2.1 Limits for Physical, Chemical and mechanical Properties of Aggregates for Concrete 1.Grading BS 812 Part 103 (dry) No ASTM standard BS EN 933 Tests for geometrical properties of aggregates ASTM C 136 Test Method for Sieve Analysis of Fine and Coarse Aggregates 2. Material finer than 0.075 mm. Natural, Uncrushed/Crushed Crushed Rock BS 812 Part 103 (wet) No ASTM standard BS EN 933 Tests for geometrical properties of aggregates ASTM C 136 Test Method for Sieve Analysis of Fine and Coarse Aggregates & ASTM C117- Standard Test Method for Materials Finer than 75-m (No. 200) Sieve in Mineral Aggregates by Washing Or Material finer than 0.063 mm. Natural, Uncrushed/Crushed or used for foundations, retaining structures and structure elements Exposed to the weather. Permissible Limits for Fines 3% max and Coarse 1.5 % max Crushed Rock or used for structure elements not exposed To the weather.

3. Clay lumps and friable particles

C 142 3% Max for Fines 2% Max for Coarse

6.Water Absorption (saturated surface dry)

C 142 2% Max for Fines 2% Max for Coarse

BS 812 Part 2 BS EN 1097-6 Tests for mechanical and physical properties of aggregates. Determination of particle density and water absorption Does Not exist 7. Sand Equivalent value BS EN 933, ASTM D2419. Permissible Limits for Fines Min 70% 8. Specific Gravity BS EN 1097-6 Used for Reinforced Concrete 2.6 min for fines and coarse Used for non reinforced concrete 2.4 min for fines and Coarse 8. Shell Content - BS 812 Part 106 9.Particle shape: Flakiness Index : BS 812 Part 105.1 - 30% Elongation Index: BS 812 Part 105.2- 35% 9. BS EN 933-7 10. BS EN 933-7 For reinforced concrete Flakiness Index : 30% Elongation Index: 35% For Non-reinforced Concrete: Flakiness Index : 40% Elongation Index: 45% ASTM D4791- Standard Test Method for Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregate 11.Acid Soluble Chlorides BS EN 1744 - Tests for chemical properties of aggregates, Chemical analysis 12.Acid Soluble Sulphate BS EN 1744

7..Specific Gravity (apparent) BS 812 Part 2 2.6 min for Fines and Coarse

No ASTM standard 10.Acid Soluble Chlorides BS 812 Part 117 11.Acid Soluble Sulphate BS 812 Part 118

12.Loss by magnesium sulphate soundness (5cycles) ASTM C88 -15% Max for both Fines and Coarse

13. Loss by magnesium sulphate soundness (5cycles) ASTM C88 -15% Max for both Fines and Coarse 12% Loss by Sodium Sulphate 14. Mechanical strength: BS 812- Part 111 BS EN 1097-2 BS EN 1097-2, C131/C535 Aggregate Crushing ValueBS 812-110 15. BS EN 1367-4

13. Mechanical strength: 10% fines value (dry condition)-BS 812 Part 111 Aggregate Impact value BS 812 Part 112 Loss by Los Angeles abrasionASTM C131/C535 14. Drying shrinkage BS Part 120

Table 2.2 Frequency of Tests on Aggregates have been removed and been replaced by: 1-Use of a fine aggregate failing in the test is not prohibited, provided that: a) The discoloration is due principally to the presence of small quantities of coal, lignite, or similar discrete particles. b) When tested for the effect of organic impurities on strength of mortar, the relative strength at 7 days, calculated in accordance with ASTM C87, is not less than 95 %. 2- Air-cooled blast-furnace slag aggregate shall meet the requirements in BS EN 12620:2002 for acid-soluble sulfate category AS1,0. In accordance with BS PD 6682-1 and BS EN 12620, air cooled blast-furnace slag shall be free from dicalcium disintegration and from iron disintegration when tested in accordance with BS EN 1744-1 3- The limit of 10% fines value (dry condition) is for 20 mm aggregates. Reference BS 812-111. 4- AIV The impact test can be used as an alternative to the Los Angeles test but a correlation with the Los Angeles test should first be established to avoid double testing and ensure mutual recognition of results. The Los Angeles test (reference method) should be used in cases of dispute 5- It is applicable only for 20mm aggregates, for high

Section 6 Part 3 Earthworks

strength concrete using 10 mm aggregates the 10% fines value will be at least 100 KN 3.3.2 Fill Material No changes 3.3.3 Unsuitable material (f) deposits of sabkha with more than 5% water-soluble salts or more than 10% acid-soluble salts

(f) Deposits of sabkha with more

3.3.5 Selected Fill 3.3.8 Work Over Sabkha Type 1 & 2 Backfill Material

than 5% water-soluble salts (individually, water soluble chloride exceeding 1% or water soluble sulphate exceeding 1.5%) or more than 10% acid-soluble salts (individually, acid soluble chloride exceeding 2% or acid soluble sulphate exceeding 3.0%) as determined by BS 1377: part 3.

No changes No changes

Section 6 Part 4 Unbound Pavement Materials

4.2.4 Fine Aggregate 6. The aggregate bases shall have a minimum sand equivalent value of 31 and the aggregate subbase shall have a minimum sand equivalent value of 28, as determined by ASTM D2419. 4.2.5 Coarse/ Combined aggregate: The minimum CBR value obtained when preparing samples of aggregate base and aggregate sub-base at optimum moisture content and at 100% relative compaction and soaking them for 4 days shall be 80% and 60%. The maximum permitted swell shall be 0.5% and 1.0%; respectively. 7. The acid soluble chloride in the combined aggregate shall not exceed 1%, as determined by BS 1377: part 117.

6. The aggregate bases shall have a minimum sand equivalent value of 25 and the aggregate subbase shall have a minimum sand equivalent value of 25, as determined by ASTM D2419. 4.2.5 Coarse/ Combined aggregate: The minimum CBR value obtained when preparing samples of aggregate base and aggregate sub-base at optimum moisture content and at 100% relative compaction and soaking them for 4 days shall be 80%. The maximum permitted swell shall be 0.5% and 1.0%; respectively. 7. The water soluble chloride in the combined aggregate shall not exceed 1%, or the acid soluble chloride in the combined aggregate shall not exceed 2% as

The acid soluble sulphate in the combined aggregate shall not exceed 0.5% as determined by BS 812: part 118.

determined by BS 1377: part 3. The water soluble sulphate in the combined aggregate shall not exceed 1.5% or the acid soluble sulphate in the combined aggregate shall not exceed 3% as determined by BS1377: part 3.

Section 6 Part 6 Concrete Road Pavements

6.5 Requirement For Cement Bound Materials

CBM 1, CBM 2, CBM 3, CBM 4 The particle size distribution BS The particle size distribution 812 BS 812 : Part 103 CBM2 10% fines value BS 812: Part 111 10% fines- BS 812 No changes

Section 6 Part 14 Road Drainage Section 8 Part 2 Earthworks

14.6 Soakaways

2.3 Backfill- 2.3.1 Pipe Bedding. 3.(d) Granular bedding and backfill to French drains shall be 20mm nominal size single size coarse aggregate conforming to BS 882 and Section 5 of the QCS 3. (F) Chloride and sulphate levels for bedding materials shall conform to BS 6906/3.

Granular bedding and backfill to French drains shall be 20mm nominal size single size coarse aggregate conforming to BS EN 12620 - Aggregates for concrete and Section 5 of the QCS. 3.(f) chloride and sulphate levels for bedding materials shall conform to BS EN ISO 10319 --Geosynthetics No changes 3.2.3 (e)Material containing more than 5% of water soluble salts by weight of dry soil (individually, water soluble chloride exceeding 1% or water soluble sulphate exceeding 1.5%) or more than 10% of acid-soluble

Section 12 Part 3 Filling

3.2.2 Suitable fill 3.2.3 Unsuitable Material (e) Material containing more than 5% of water soluble salts by weight of dry soil as tested in accordance with BS 1377 ( Method 7 and 5 water soluble chloride and sulphate

respectively)

salts (individually, acid soluble chloride exceeding 2% or acid soluble sulphate exceeding 3.0%) as determined by BS 1377: part 3

You might also like

- Methodology For Convreting WorksDocument7 pagesMethodology For Convreting WorksLokesh SaranNo ratings yet

- Dimensional BlockworkDocument4 pagesDimensional BlockworkdavidongpongNo ratings yet

- Guide To Standards and Tolerances 2002Document27 pagesGuide To Standards and Tolerances 2002Brad La PortaNo ratings yet

- Electrical SpecificationsDocument4 pagesElectrical Specificationsjoe rommel riveraNo ratings yet

- Procedure - Concrete Pouring & CuringDocument12 pagesProcedure - Concrete Pouring & CuringjabpunNo ratings yet

- 02-Pre-Concreting Inspection RequestDocument2 pages02-Pre-Concreting Inspection RequestJohn Oliver GuiangNo ratings yet

- Sheet 1 of 1 Rev 1 Equipment Grounding Installation and Connection ChecklistDocument1 pageSheet 1 of 1 Rev 1 Equipment Grounding Installation and Connection ChecklistnayumNo ratings yet

- Inspection Checklist For Concrete Placement Pre & Post PlacementDocument4 pagesInspection Checklist For Concrete Placement Pre & Post PlacementUsman ShahidNo ratings yet

- Method Statement Striking FormworkDocument3 pagesMethod Statement Striking FormworkSurya HeriwijayaNo ratings yet

- Itp Civil WorkDocument9 pagesItp Civil WorkChristian Albert Sinaga RumajarNo ratings yet

- General Specification: B. Plans and SpecificationsDocument5 pagesGeneral Specification: B. Plans and Specificationsmichael nabusNo ratings yet

- Concrete & Highway Material LAB Manual: Marri Laxman ReddyDocument17 pagesConcrete & Highway Material LAB Manual: Marri Laxman ReddyNatarajan SaravananNo ratings yet

- S2 - Demolition (Jan 2013)Document17 pagesS2 - Demolition (Jan 2013)msyan1965100% (1)

- ASME B18.31.4M Threaded Rod MetricDocument4 pagesASME B18.31.4M Threaded Rod MetricJEff MNo ratings yet

- New Beam To Old Column Connection PDFDocument6 pagesNew Beam To Old Column Connection PDFVan BGNo ratings yet

- Utility Material Table (QCS 2014) PDFDocument1 pageUtility Material Table (QCS 2014) PDFSinan İcikNo ratings yet

- Concrete Floor Breaking MSDocument6 pagesConcrete Floor Breaking MSBilalNo ratings yet

- 014 - G.I Duct, Accessories and FittingsDocument14 pages014 - G.I Duct, Accessories and FittingsJomy JohnyNo ratings yet

- Saudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 30-Oct-17 CivilDocument10 pagesSaudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 30-Oct-17 CivilJagdishNo ratings yet

- .018 - Method Statement - Plumbing and Sanitary SystemsDocument14 pages.018 - Method Statement - Plumbing and Sanitary SystemsUmut YilmamNo ratings yet

- Contract For ConstructionDocument4 pagesContract For ConstructionFe Magpantay-VillaNo ratings yet

- Punch List Civil Jan.13Document10 pagesPunch List Civil Jan.13Azam Islam KhanNo ratings yet

- Replacing Rotted SillsDocument3 pagesReplacing Rotted SillsrfidtoyzNo ratings yet

- No Description QTY P/Unit Total WallDocument2 pagesNo Description QTY P/Unit Total WallROmarico IGotNo ratings yet

- Reinforcement Work Proc.Document5 pagesReinforcement Work Proc.Akhilesh Kumar0% (1)

- 8 1SA8A-Paint WorkDocument19 pages8 1SA8A-Paint WorkdophongxdNo ratings yet

- MS For Waterproofing of CulvertsDocument29 pagesMS For Waterproofing of CulvertsAdrian Frantescu100% (2)

- Sub-Base & Base (241199)Document14 pagesSub-Base & Base (241199)Aziz ul Hakeem100% (1)

- Chapter - 2 - Sheet PileDocument28 pagesChapter - 2 - Sheet PilebeleteNo ratings yet

- Eim Ncii Lmg9 p147-217Document70 pagesEim Ncii Lmg9 p147-217LleojVanceAguasClava100% (3)

- Analisa Cipta Karya 2020 RevisiDocument122 pagesAnalisa Cipta Karya 2020 RevisiAlfiyaNo ratings yet

- Indian Standards List For Civil-2020Document185 pagesIndian Standards List For Civil-2020SRINIVASAN T100% (1)

- Anti Termite TreatmentDocument99 pagesAnti Termite TreatmentPja ShanthaNo ratings yet

- MS 05Document21 pagesMS 05unnicyriacNo ratings yet

- Conventional Block Pavement DesignDocument5 pagesConventional Block Pavement DesignPeyman MznNo ratings yet

- MasterSeal 550Document38 pagesMasterSeal 550Ahmad ElghazolyNo ratings yet

- 01 - Codes ListDocument6 pages01 - Codes ListSanthoshKumarSharmaCHNo ratings yet

- STANDARD ComparisonDocument10 pagesSTANDARD Comparisonsarath6725No ratings yet

- L4-QAT-087C Method Statement For Patch Repair WorkDocument10 pagesL4-QAT-087C Method Statement For Patch Repair WorkrajaNo ratings yet

- Sikagrout - 214: High Performance, Non Shrink, Expanding Cementitious Grouting MortarDocument3 pagesSikagrout - 214: High Performance, Non Shrink, Expanding Cementitious Grouting MortarSulaim Al KautsarNo ratings yet

- QCS 2010 Part 6.03 EarthworksDocument21 pagesQCS 2010 Part 6.03 EarthworksRotsapNayrb100% (2)

- QCS PDFDocument32 pagesQCS PDFقناة الرياضة العربية والعالمية - Sport ChannelNo ratings yet

- Qcs 2007 0117Document3 pagesQcs 2007 0117RotsapNayrbNo ratings yet

- Site Survey - Method of StatementDocument11 pagesSite Survey - Method of StatementEng hassan hussienNo ratings yet

- Blockwork and Plastering - HalulDocument14 pagesBlockwork and Plastering - HalulDindo QuintanNo ratings yet

- 1 MS - Pouring of ConcreteDocument8 pages1 MS - Pouring of ConcreteFauzi MastamNo ratings yet

- Henscha Phils. Inc.: Concrete Pouring ChecklistDocument4 pagesHenscha Phils. Inc.: Concrete Pouring Checklistchester carpioNo ratings yet

- Abacus FoundationsDocument9 pagesAbacus FoundationsNath GunasekeraNo ratings yet

- A-U00-C-Ms-2042-000-Crs-00c - Method Statement For Shoreline Protection - DaDocument14 pagesA-U00-C-Ms-2042-000-Crs-00c - Method Statement For Shoreline Protection - DaKurnia AryadiNo ratings yet

- SpecificationsDocument152 pagesSpecificationsAhmed AL-ChadrchiNo ratings yet

- Attachment 4 Scope of WorkDocument5 pagesAttachment 4 Scope of WorkMathias OnosemuodeNo ratings yet

- De Tablan, Dan Alfonso (Boq)Document10 pagesDe Tablan, Dan Alfonso (Boq)Dan Alfonso de TablanNo ratings yet

- Method Statement Concrete Coring (ASTM C 142)Document2 pagesMethod Statement Concrete Coring (ASTM C 142)Twin Bulls100% (1)

- Corrosion-Resistant High-Silicon Iron Castings: Standard Specification ForDocument5 pagesCorrosion-Resistant High-Silicon Iron Castings: Standard Specification Forrobert gridleyNo ratings yet

- Weida Subsoil PipeDocument4 pagesWeida Subsoil PipeOngNo ratings yet

- Comments 015295Document1 pageComments 015295Sampath S. WickramanayakaNo ratings yet

- Masteremaco S 422Document3 pagesMasteremaco S 422shahidNo ratings yet

- SL - No Location/Area Work DescriptionDocument2 pagesSL - No Location/Area Work Descriptionshyamsundar_ceNo ratings yet

- 33 05 13 Manholes and Structures 10Document4 pages33 05 13 Manholes and Structures 10salamNo ratings yet

- Daily Construction Report (DCR) : Project ManagerDocument5 pagesDaily Construction Report (DCR) : Project ManagerMoath AlhajiriNo ratings yet

- A Simple Guide On How To Become A Registered Engineer in NigeriaDocument4 pagesA Simple Guide On How To Become A Registered Engineer in NigeriaOLUWASEUN QUADRINo ratings yet

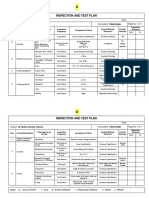

- Inspection and Test Plan ConcreteDocument2 pagesInspection and Test Plan Concreteavikshit yNo ratings yet

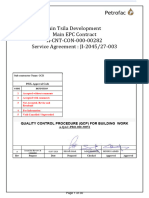

- A Qac Pro 000 38951Document30 pagesA Qac Pro 000 38951Amin GNo ratings yet

- Technical Bid FormatDocument4 pagesTechnical Bid FormatSunny Kumar GuptaNo ratings yet

- Comments 015619 RejectDocument1 pageComments 015619 RejectSampath S. WickramanayakaNo ratings yet

- Concure WBDocument2 pagesConcure WBR.ThangarajNo ratings yet

- Concrete GuideDocument38 pagesConcrete GuideAdnan JadoonNo ratings yet

- Marine Concrete Specs-HkDocument5 pagesMarine Concrete Specs-HkMohammed Faisal TNo ratings yet

- Imo-202en 01-12Document8 pagesImo-202en 01-12HASBUL AZIZI BIN MAHMUNNo ratings yet

- Castech PP-8000.E: Technical Data SheetDocument2 pagesCastech PP-8000.E: Technical Data SheetDileepa DissanayakeNo ratings yet

- Bruchure Metal SolutionDocument10 pagesBruchure Metal Solutionanibal rey brito lopezNo ratings yet

- Ohe Mast Fixing Arrangement On Pier Cap at Bridge No:46 For New Proposed Double LineDocument1 pageOhe Mast Fixing Arrangement On Pier Cap at Bridge No:46 For New Proposed Double LineRVNLPKG6B VBL-GTLMNo ratings yet

- CAB Solar Tube Hangers SalesSheet5 AUG2022ADocument2 pagesCAB Solar Tube Hangers SalesSheet5 AUG2022AtammamshNo ratings yet

- A 581 - A581M - 95b R00 - QTU4MS9BNTGXTQDocument3 pagesA 581 - A581M - 95b R00 - QTU4MS9BNTGXTQDeepak JNo ratings yet

- Katalog EnglischDocument12 pagesKatalog EnglischadrianNo ratings yet

- Carbon Steel Forgings, For General-Purpose PipingDocument3 pagesCarbon Steel Forgings, For General-Purpose PipingedwinbadajosNo ratings yet

- Uni MechDocument2 pagesUni MechSAMPATHUNo ratings yet

- PacifiCorp Spec TD041Document16 pagesPacifiCorp Spec TD041alexayala5151No ratings yet

- Effect of Aggregate Size and Gradation o PDFDocument5 pagesEffect of Aggregate Size and Gradation o PDFZain Ali AwanNo ratings yet

- Sheet Metal Gauge Calibre PDFDocument1 pageSheet Metal Gauge Calibre PDFHectorNo ratings yet

- Silo DesignDocument42 pagesSilo Designchaithra_14No ratings yet

- Conek Pneumatic Co., Ltd.Document19 pagesConek Pneumatic Co., Ltd.juridocNo ratings yet

- Ateneo Innovation Center: Innovation Class: Business Week: Melgar: SNEZ XLDocument5 pagesAteneo Innovation Center: Innovation Class: Business Week: Melgar: SNEZ XLMatthew CuaNo ratings yet

- 23 - Pressure ConduitsDocument9 pages23 - Pressure ConduitsYahya KhanNo ratings yet

- Franke Sinfonia Parts Breakdown - 032515Document133 pagesFranke Sinfonia Parts Breakdown - 032515Juan Carlos MunozNo ratings yet

- BMC V - Unit-4-Advanced Construction Techniques and MaterialsDocument13 pagesBMC V - Unit-4-Advanced Construction Techniques and Materialsaurora krishreddyNo ratings yet

- Corrosion Resistant Steels: Stainless Steel AlloysDocument11 pagesCorrosion Resistant Steels: Stainless Steel AlloysPraveen SamarthiNo ratings yet

- PFS Question Bank WatermarkDocument94 pagesPFS Question Bank WatermarkManjuladevi PNo ratings yet

- Plain and Steel-Laminated Elastomeric Bearings For BridgesDocument1 pagePlain and Steel-Laminated Elastomeric Bearings For BridgesMirza SakibNo ratings yet

- 08 - Underpinning Piles of Segmental Precast ConcreteDocument2 pages08 - Underpinning Piles of Segmental Precast ConcreteaggibudimanNo ratings yet