Professional Documents

Culture Documents

FSAE RaceCar SizeOpti

Uploaded by

Ravi KodwaniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FSAE RaceCar SizeOpti

Uploaded by

Ravi KodwaniCopyright:

Available Formats

Student Race Car

The objective of this demo is to provide insight into the typical modeling steps related to the size optimization of a student racing car subjected to bending-, shear-, and torsion loads. Please note, that the load cases, geometry of the frame, the dimensions of the 1D element cross sections, material parameters etc. are just conceptual.

In case you are new to HyperWorks we recommend viewing the video series: HyperWorks Starter Kit first. The StarterKit vides, provide a basic insight into the work flow and philosophy of HyperWorks and is available for free in the Academic Blog: http://www.altairuniversity.com/2011/09/22/hyperworks-starterkit-video-series/ Also this tutorial is available (in a slightly modified version) as a demo video at: http://www.altairuniversity.com/2012/03/09/simulation-driven-design-of-a-student-race-car-freevideo-series/

The following working steps are briefly shown: o Size Optimization set-up o Size Optimization Run o Postprocessing

Right at the beginning of the demo the User Profile is set to OptiStruct

Linear Static Analysis Base Design Summary Base Design: Total mass: 42.1 kg ro= 12.5 mm ri=10.5 mm (Note, the initial radii used in the base design are just a first guess). Load Step Bending Shear Torsion Max. Displacement (mm) 1.45 2.03 6.29 Node 2764 2678 2085

Size Optimization Lets assume that all the displacements related to the 3 load steps are acceptable. In this case we may say: Job done. Or, we may try to find an even lighter designed frame (by employing the same material). This leads us to size optimizing of the cross-sectional properties ro and ri of the tubes cross section. The two parameters ro and ri represent the design variables, and will be varied within the following range: Lower bound (mm) 5 1

2

ro ri

Upper bound (mm) 15 14

Initial value (mm) 12.5 10.5

As stated before, the parameters which will be changed is the tubes outer ro and inner radius ri which in turn affect the elements cross-sectional properties i.e. area, moments of inertia, and torsional stiffness. The design variables are defined via the main menuOptimizationCreateSize Desvars.

The inner radius ri may vary between its lower bound 1 mm up to its upper bound of 14 mm.

The outer radius ro is allowed to vary from 5 mm up to 15 mm. Of course, the definition of the design variables is not completed yet as we just specified a name and a range of possible values. In other words, we still need to relate the design variables d_ri and d_ro to the cross-sectional properties of the 1D elements. These properties are given as DIM1 and DIM2.

Note that DIM1 corresponds to ro and DIM2 to ri. Also recall: DIM1 (at node A) was used earlier already just view the property collector again:

Tolink the design variables to DIM1 and DIM2 to d_ro and d_ri, we need to activate the generic relationship option. At OptimizationCreateDesvar RelationshipGeneric

In here the design variable d_ro becomes related to Dimension 1 (DIM1) which in turn corresponds to the intrinsic definition of the outer radius of the tube. (designvars = d_ro); prop = property collector, here with ID =2)

The same steps apply to the inner radius which is defined as Dimension 2.

This completes the definition of the Design Variable Property Relationship (and thus the design variables)

While during the size optimization these design parameters are varied, we need to observe the mass of the frame (=objective is lighter frame) and the nodal displacements (i.e. we want to know how the changes of the radii will affect the displacements at certain nodes of the structure). This leads us to the definition of optimization responses: Main MenuOptimizationCreateResponses

Next we define the response regarding the total displacement of node 2085. Type in a name used to reference this response, then specify the node ID, and define whether a single translational displacement component or its magnitude should be tracked. The responses for nodes 2678 and 2764 are defined just the same way. As the objective of the size optimization is to find a lighter design, the mass needs to tracked during the optimization. Just change the response type to mass.

Note: If we ask the optimizer to minimize the frames mass the result is quite predictable Any ideas already? The outer radius will be set to its lower boundary whereas the inner radius will be at its upper bound - which is not exactly the solution we are looking for. Thus, we need to define optimization constraints. As design constraints the displacements from the base design, as listed in the table above will be applied. Main MenuOptimizationCreateConstraints

The maximum allowed displacement (magnitude) at node 2085 (regarding the load step torsion) is 6.3 mm. The displacement constraints regarding the loadsteps Bending and Shear are defined in the same way. And finally, we need to define the objective of the size optimization study. Main MenuOptimizationCreateObjective

That completes the size optimization set up. Postprocessing In the *.out file we learn that the mass of the frame is now down at 36.24 kg which corresponds to weight savings of 16% (base design: 42.12 kg) while the displacements match the values of the base design.

In the working directory we need to open the file with the extension*.prop in order to view the optimized PBEAML properties

The final dimensions (which are continuous) could be rounded off to: Outer tube radius (DIM1): 15 mm (base value: 12.5 mm) Inner tube radius (DIM2): 13.6 mm (base value 10.5 mm)

This property file can be read into HyperMesh (as a solver deck) with the settings: Import Custom (then specify to import beamsection, beamsection collector and property). Eventually, check the model and assign the property collector again

*.prop

In the above shown size optimization study the displacements of the base design have been artificially used as design constraints to better compare base design and optimized design. Naturally, the design constraints may be more relaxed or tighter depending on your requirements. Discrete Size Optimization Due to the simple set up of the size optimization, the optimization results for ro and ri had to be manually rounded off. Of course, we can run the same optimization study aiming for discrete values for ro and ri. In addition to the optimization set-up from above one fundamental addition is required: We need to define discrete design values

OptimizationCreateDiscrete Design Values

Assign a name, specify lower and upper bound (here the outer radius varies between 5 mm and 15 mm) and a suited increment of e.g. 0.1 mm.

7

The same process is applied to the design values of the inner radius

Next, the discrete design values are assigned/linked to the design variables, respectively. This is accomplished in the desvar panel: select the design variable of interest (=desvar) and activate the ddval option in here. In this subpanel the discrete design value (as defined before) is referenced. Dont forget to click on update.

The same working steps are then applied with respect to the design variable of the outer radius.

That is all it takes to create a discrete design variable. Time to start the size optimization over. In this example the *.prop file lists the following information:

Outer radius (DIM1) = 15 mm, inner radius (DIM2) = 13.6 mm. From the outfile we can readily extract the information about the mass of the frame, which is slightly increased to 36.66 kg.

Of course in a real model you have many different cross-sectional properties. Some parts of the frame may even not be part of the design space etc. So there is lots of space for improvements. At the bottom line, this simple tutorial should help you getting started. Good luck and enjoy CAE with HyperWorks

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Chapter 2 Conceptualized InteractionDocument32 pagesChapter 2 Conceptualized InteractionnancyNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- How To Create FaceplateDocument12 pagesHow To Create FaceplateDadan Hamdani100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Project ManagementDocument10 pagesProject ManagementVanessa NacarNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Management Studies (CP-202) : Unit IDocument2 pagesManagement Studies (CP-202) : Unit IArman KhanNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Formulae For Vendor RatingDocument3 pagesFormulae For Vendor RatingMadhavan RamNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Kisi-Kisi Web Technologies 2023Document36 pagesKisi-Kisi Web Technologies 2023Erhamna noor riskiNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Puana Cell Phone Search WarrantDocument24 pagesPuana Cell Phone Search WarrantHNN67% (3)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Sap MM PDFDocument2 pagesSap MM PDFMurali TungaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- COAL Lectures Week 13 Pat ADocument33 pagesCOAL Lectures Week 13 Pat AK213156 Syed Abdul RehmanNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Strapack I-10 Instruction-Parts Manual MBDocument26 pagesStrapack I-10 Instruction-Parts Manual MBJesus PempengcoNo ratings yet

- Aadhaar Update Form: Aadhaar Enrolment Is Free & VoluntaryDocument4 pagesAadhaar Update Form: Aadhaar Enrolment Is Free & VoluntaryShankar HirekarNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 12 PandasDocument21 pages12 PandasArshpreet SinghNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- TraceDocument318 pagesTraceJonathan EvilaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Home Appliance: Household Cooking Cleaning Food PreservationDocument5 pagesHome Appliance: Household Cooking Cleaning Food PreservationSachin NandeNo ratings yet

- Syllabus 2017Document3 pagesSyllabus 2017sandman21No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Simple 4k Wallpaper - Google SearchDocument1 pageSimple 4k Wallpaper - Google SearchElix3rNo ratings yet

- Determine HWM and Reduce It by Shrink SpaceDocument6 pagesDetermine HWM and Reduce It by Shrink SpaceSiva KumarNo ratings yet

- f2806x Dev User GuideDocument148 pagesf2806x Dev User GuidedavidNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Home Visit Record (HVR) #1Document2 pagesHome Visit Record (HVR) #1Nicole Arriana ResumaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- 840Dsl NCU Base Commiss Man en-US PDFDocument1,342 pages840Dsl NCU Base Commiss Man en-US PDF류성하No ratings yet

- ESD Short Sleeve SmocksDocument12 pagesESD Short Sleeve Smocksbeach_lover_1970No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Investigation of The Condominium Building Collapse in Surfside, Florida: A Video Feature Tracking ApproachDocument27 pagesInvestigation of The Condominium Building Collapse in Surfside, Florida: A Video Feature Tracking ApproachSparkly DraigNo ratings yet

- Sample Consent FormDocument1 pageSample Consent FormMaira HassanNo ratings yet

- CE-EMC CERT SHEM1806004552IT Network Camera DS-2CD2045FWD-I 20180710Document1 pageCE-EMC CERT SHEM1806004552IT Network Camera DS-2CD2045FWD-I 20180710DaniellMargaritNo ratings yet

- Script-For-Library-Tour. 7.13.22Document1 pageScript-For-Library-Tour. 7.13.22Cyrus CorpuzNo ratings yet

- 5/2 and 5/3 Valves Solenoid and Pilot Actuated Sub-Base Mounted ISO 5599-1 #1, #2, #3, #4Document8 pages5/2 and 5/3 Valves Solenoid and Pilot Actuated Sub-Base Mounted ISO 5599-1 #1, #2, #3, #4Hdhm TdhNo ratings yet

- International Automotive Task Force TS16949 To IATF16949 Transition StrategyDocument44 pagesInternational Automotive Task Force TS16949 To IATF16949 Transition StrategyyatheendravarmaNo ratings yet

- Power BI DesktopDocument7 pagesPower BI DesktopZaklina TrajkovskaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

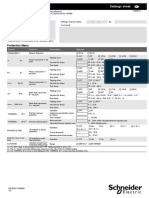

- VIP400 Settings Sheet NRJED311208ENDocument2 pagesVIP400 Settings Sheet NRJED311208ENVăn NguyễnNo ratings yet

- Low-Cost Dual-Band E-Shaped Patch Antenna For Energy Harvesting Applications Using Grey Wolf OptimizerDocument5 pagesLow-Cost Dual-Band E-Shaped Patch Antenna For Energy Harvesting Applications Using Grey Wolf Optimizermubeen khanNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)