Professional Documents

Culture Documents

Iv Report

Uploaded by

Nandu SurendranOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Iv Report

Uploaded by

Nandu SurendranCopyright:

Available Formats

IV REPORT Industry: Euro marine products India limited, Puthenthope Trivandrum The company imports the marine products

to different countries.The important operations in the industry are, processing of the marine products and its storage in cold storages where a vapour compression refrigeration system is employed. The temperatures of these freezers are -400C and -180C. The term refrigeration may be defined as the process of removing heat from a substance under controlled conditions. It also includes the process of reducing and maintaining the temperature of a body below the general temperature of its surrounding. The substance which works in arefrigeration system to extract heat from acold body to deliver it to a hot body is called a refrigerant. Vapour compression system with refrigerant ammonia (NH3) is used for refrigeration in this industry. A vapour compression refrigeration system is an improved type of air refrigeration system in which a suitable working substance termed as refrigerant is used. It condenses and evaporates at tempertures and pressures close to the atmospheric conditions. The refrigerent used is ammonia (NH3). The refrigerent used doesnot leave the system, but is circulated throughtout the system alternately condensingand evaporating. In evaporating the refrigerant absorbs its latent heat from the brine (salt water) which is used for circulating it around the cold chamber, while condensing it gives out it latent heat to the circulating water of the cooler. The vapour compression refrigeration system is now a day used for all purpose refrigeration. It is generally used for all industrial purposes from a small domestic refrigerator to a big air conditioning plant. The advantages of using the vapour compression system are:- It has smaller size for the given capacity of refrigeration - It has less running cost - It can be employed over a large range of temperatures. - The co-efficient of performance is quite high The disadvantages are:- The initial cost is high - The prevension of leakage of the refrigerant is the major problem in vapour compression system Here in this industry, there are two sections of refrigeration systems; one is for the production of ice flakes and other for cold storage of food item (marine products). The production of ice flakes

can be seperately done by using single cylinder two compressior and its other components or it can be done in conjunction with the main system in using 4 cylinder compressor for food preservation. This is done according to the load. If the load on the system is less the ice flake production is carried out in conjunction with main system of the load is high then it is done seperately. The main components of a vapour compression system are, 1. Compressor: The low pressure and temperature vapour refrigerant from evaporator is drawn into the compressor through theinlet or a suction valve. Where it compressed to a high pressure and temperature. This high pressure and tempreture vapour refrigerant is discharged into the condenser through the delivery or discharge valve. Here foe the ice flakes production two cylinder single stage compressor is used and for preservation of marine products. 4 cylinder and single stage compressor is used. 2. Condenser: The condenser or cooler consists of coils of pipe in which the high pressure and temperture vapour refrigerant is cooled and condensed. The refrigerant while passing through the condenser gives up the latent heat to the surrounding condensing medium, here tubes carrying water are alternately provided in between condenser tubes. Through the pores in the water tubes the water is sprayed to are condenser tubes carrying refrigerant 3. Receiver: The condensed liquid refrigerant from the condenser is stored in a vessel known as receiver from where it is supplied to the evaporator through expansion valve. 4. Expansion valve: It is also called throttle valve or refrigerant control valve. The function of the expansion valve is to allow the liquid refrigerant under hidg pressure and temperature to pass at a controlled rate after reducing its pressure and temperture. Some of the liquid refrigerant evaporates as it passes through theexpansion valve, but the greater portion is vaporised in the evaporator at the low pressure and temperture. 5. Evaporator: An evaporator consists of coils of pipe in which the liquid vapour refrigerant at low pressure and temperature. In evaporating the liquid vapour refrigerant absorbs its latent heat of vapourisation from the medium which is to be cooled.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Combined Cycle Gas-TurbinesDocument5 pagesCombined Cycle Gas-TurbineswarshipvnNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

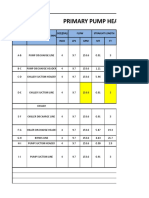

- 12.primary Pump Head CalculationDocument4 pages12.primary Pump Head CalculationZain ShariffNo ratings yet

- Symbols - STD 134Document32 pagesSymbols - STD 134Joaquim MonteiroNo ratings yet

- Afterburner - Gas Turbine, Turbojet, Turbofan) Rolls Royce - T PDFDocument11 pagesAfterburner - Gas Turbine, Turbojet, Turbofan) Rolls Royce - T PDFEstevam Gomes de Azevedo100% (1)

- Cooling & Heating: ShellmaxDocument3 pagesCooling & Heating: Shellmaxvijaysirsat2007No ratings yet

- Tube Side Velocity CalculationDocument20 pagesTube Side Velocity CalculationNitin KurupNo ratings yet

- Solar Product Brochure PDFDocument8 pagesSolar Product Brochure PDFAsad van LeonNo ratings yet

- ENERSYSDocument2 pagesENERSYSJose MvlNo ratings yet

- 201810presentationESSnidec PDFDocument34 pages201810presentationESSnidec PDFYip DavidNo ratings yet

- Thermodynamics 7 Steam TurbineDocument5 pagesThermodynamics 7 Steam Turbinep_nicks89No ratings yet

- Smart automatic irrigation with soil moisture sensorsDocument15 pagesSmart automatic irrigation with soil moisture sensorsDebashishParidaNo ratings yet

- HVAC Commissioning AHU Thailand FarmDocument7 pagesHVAC Commissioning AHU Thailand FarmCITACOM UTAMANo ratings yet

- Electrical Energy Storage Systems (MIET2131) : Session 3: PEM Electrolysers, Hydrogen Storage and SafetyDocument46 pagesElectrical Energy Storage Systems (MIET2131) : Session 3: PEM Electrolysers, Hydrogen Storage and SafetyAster J.No ratings yet

- AspenIcarusPIDV11 RefDocument286 pagesAspenIcarusPIDV11 RefParth PatelNo ratings yet

- Submersible Pump CatalogueDocument2 pagesSubmersible Pump CatalogueMehmet Akif GülNo ratings yet

- Present Scenario of Solar Energy in India and Scope in FutureDocument17 pagesPresent Scenario of Solar Energy in India and Scope in FutureAbhishek Ranjan100% (3)

- Commissioning of major unitsDocument17 pagesCommissioning of major unitsbikas_sahaNo ratings yet

- Catalogo Val MTSDocument33 pagesCatalogo Val MTSrcuitivasNo ratings yet

- Steam Injector For Boiler Feed Water PDFDocument13 pagesSteam Injector For Boiler Feed Water PDFMuhammad Munir Ahmed100% (1)

- 2014 1984 Chart and CodesDocument2 pages2014 1984 Chart and Codesnubaz0% (1)

- DynaWave SuperClausDocument2 pagesDynaWave SuperClausNKNo ratings yet

- Full Report Refrigeration UnitDocument24 pagesFull Report Refrigeration UnitNabil ImranNo ratings yet

- NCID MEP Trade Colour Code - R2 With CompareDocument2 pagesNCID MEP Trade Colour Code - R2 With CompareWun Na ThuzarNo ratings yet

- Operating Manual: Vapour Compression Cycle Test RigDocument11 pagesOperating Manual: Vapour Compression Cycle Test Rigp09me128No ratings yet

- Tunprotec BrochureDocument16 pagesTunprotec BrochureTung H PhamNo ratings yet

- Solar Hybrid Power System ProposalsDocument25 pagesSolar Hybrid Power System ProposalsShane CapstickNo ratings yet

- Internal Combustion Engines GuideDocument216 pagesInternal Combustion Engines GuideRohit ThoratNo ratings yet

- Fan Coil Unit 1) Box EnclosureDocument2 pagesFan Coil Unit 1) Box EnclosureRUSHALI SRIVASTAVANo ratings yet

- Natural Gas Production and OperationsDocument2 pagesNatural Gas Production and OperationsHossam M. Abd El RahmanNo ratings yet

- A Steam EngineDocument3 pagesA Steam Engineuserako21No ratings yet