Professional Documents

Culture Documents

Stress Thermal

Uploaded by

Sipra KelkarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stress Thermal

Uploaded by

Sipra KelkarCopyright:

Available Formats

JITENDRA SURVE

PIPING GUIDE

03/04/03

STRESS ANALYSIS

LAYOUT SOLUTIONS FOR THERMAL LOADS

For piping connected to nozzles of pumps or other equipments, the stress analysis concerns with finding out the length of perpendicular piping required to absorb the expansion of concerned piping span using nomo-graphs and checking whether sufficient absorbing length is available or not. Routing pipe to satisfy thermal criteria usually involves adding more absorbing legs and reducing the number of guides and anchors, which makes the system looser, and therefore lowers the system stress. Two separate nomographs for pumps and other equipments are used.

To enter the nomograph, the data required is: 1. Total thermal expansion of the concerned span. 2. Allowable loading on the nozzle. 3. Type of equipment. (Pump or other to decide nomograph used). 4. NPD of pipe. Step 1: Calculate total thermal expansion of piping span Determine the temperature to use. Determine the material of pipe. Determine the thermal growth between the anchors for each global direction (north-south, east-west and up-down) using growth chart.

Temperature to use Choosing correct temperature is critical. For preliminary layout purposes, use the operating temperature for piping attached to rotating equipment nozzles. For other piping systems, use maximum upset temperatures. Initially, if correct temperatures are not available, use PFD shown temperatures. Design temperature shown on pieces of equipment are too conservative. Find out growth Use growth chart, design temperature and material of pipe. Growth per 100 linear ft of pipe determined.

-1-

JITENDRA SURVE

PIPING GUIDE

03/04/03

Step 2 : Calculate allowable loading on Nozzle. Use equipment manufacturers published allowable loads. If not available at the planning stage of the layout, make assumptions as: 1. Material : Carbon Steel (CS) Rotating Equipment Nozle o Max allowed load: 200lb X Nominal nozzle size. (Upto maximum of 2000 lb). o Example: 2, 300# RF, CS nozzle: 200 X 2 = 400 lb. o Example: 18 150# RF, CS nozzle: 200 X 18 = 3600 lb (Exceeds 2000 lb hence use 2000 lb). 2. Material : Cast iron (CS) Equipment Nozzle o Max allowed load: 50lb X Nominal nozzle size. (Upto maximum of 500 lb). o Example: 4 , 125# FF, CI nozzle 50 X 4 = 200 lb. o Example: 12 , 250 # FF, CI nozzle 50 X 12 = 600 lb, use 500 lb. Using the Nomograph Mark total thermal expansion of the span on Total thermal expansion line. Mark allowable nozzle load on the Force line. Connect two points to get point on Pivot line. Mark NPD of pipe on the Nominal pipe diameter line. Connect pivot point and NPD point to get point on Pipe length line. This is the leg required to absorb expansion of the span.

1. 2. 3. 4. 5. 6.

-2-

JITENDRA SURVE

PIPING GUIDE

03/04/03

-3-

You might also like

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Process Heat Transfer: Principles, Applications and Rules of ThumbFrom EverandProcess Heat Transfer: Principles, Applications and Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (11)

- 4 JJ1 ManualDocument154 pages4 JJ1 Manualsamsularief03100% (11)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Review of Reactor Piping Systems - R1 To R2 Piping Report PDFDocument37 pagesReview of Reactor Piping Systems - R1 To R2 Piping Report PDFChristopher Brown0% (1)

- Exxon - EXXON PDC VOL IDocument281 pagesExxon - EXXON PDC VOL IKhalid Iqbal97% (33)

- Pipe Stress Manual CalcDocument62 pagesPipe Stress Manual CalcEsapermana Riyan100% (2)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsFrom EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (6)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Unit 12 (REINFORCED CONCRETE COLUMNS)Document30 pagesUnit 12 (REINFORCED CONCRETE COLUMNS)Zara Nabilah100% (4)

- Lab 3 Exp 4Document16 pagesLab 3 Exp 4dennisalejaga08No ratings yet

- M.E LAB 3 Experiment 4 Heat Losses From PipesDocument14 pagesM.E LAB 3 Experiment 4 Heat Losses From PipesDrw ArcyNo ratings yet

- Process Equipment Design-05Document42 pagesProcess Equipment Design-05PARAG DAHARWAL 20CH10020No ratings yet

- Pipe DesignDocument48 pagesPipe Designdineshkumar1234No ratings yet

- D 5334 - 92 - Rduzmzqtukve PDFDocument8 pagesD 5334 - 92 - Rduzmzqtukve PDFchabibNo ratings yet

- D 5334 - 92 - RduzmzqtukveDocument8 pagesD 5334 - 92 - Rduzmzqtukvegrats_singcoNo ratings yet

- Shell and Tube Heat Exchanger Design PDFDocument3 pagesShell and Tube Heat Exchanger Design PDFBaha Eddine Gharbi100% (1)

- M E LAB 3 Experiment 4 Heat Losses From Pipes 3Document20 pagesM E LAB 3 Experiment 4 Heat Losses From Pipes 3Alister Mae ZafraNo ratings yet

- Zinq - AnalysisDocument116 pagesZinq - AnalysisAimiNo ratings yet

- Heat Transfer Systems Calculation: December 2016Document18 pagesHeat Transfer Systems Calculation: December 2016joshua surbaktiNo ratings yet

- Heat Pipe SelectionDocument6 pagesHeat Pipe SelectionSridhar RaoNo ratings yet

- Heat Transfer Systems CalculationDocument18 pagesHeat Transfer Systems CalculationAshish SutharNo ratings yet

- Design Shell TubeDocument3 pagesDesign Shell TubeAKSHEYMEHTANo ratings yet

- Expansion Loop DesignDocument61 pagesExpansion Loop DesignTauqueerAhmadNo ratings yet

- API 570 - Mockup OP - Paper 2 + MDocument13 pagesAPI 570 - Mockup OP - Paper 2 + MShanawas Abdul Razak80% (5)

- 01 ASME Sec VIII Div 1 - GEN PresentationDocument112 pages01 ASME Sec VIII Div 1 - GEN Presentationinatt101No ratings yet

- To Study of Parametric Analysis of Shell and Tube Heat ExchengerDocument9 pagesTo Study of Parametric Analysis of Shell and Tube Heat ExchengerManish PrajapatiNo ratings yet

- Design and Analysis of Heat ExchangerDocument34 pagesDesign and Analysis of Heat ExchangerAkshat Rathi100% (2)

- Shell and Tube Heat Exchanger DesignDocument3 pagesShell and Tube Heat Exchanger Design1AdityaPathania1No ratings yet

- CAESAR II - Ver 7.0 Class NoteDocument50 pagesCAESAR II - Ver 7.0 Class NoteAnonymous 9fNuCpaO8100% (4)

- Above Ground Pipeline DesignDocument15 pagesAbove Ground Pipeline DesigndilimgeNo ratings yet

- How To Select A Heat PipeDocument3 pagesHow To Select A Heat PipeAdrian NiżnikowskiNo ratings yet

- Thermal Specification SheetDocument12 pagesThermal Specification SheetUgonna100% (1)

- Experiment No. 5 Heat Losses From Bare and Lagged PipesDocument5 pagesExperiment No. 5 Heat Losses From Bare and Lagged Pipesdanena88No ratings yet

- Procedure For Fired Heater DesignDocument72 pagesProcedure For Fired Heater DesignKanagarajNKNo ratings yet

- Day1 - 3 - Piping Stress AnalysisDocument10 pagesDay1 - 3 - Piping Stress Analysisramaswamy konarNo ratings yet

- Aterial Specification & All Thickness CalculationDocument35 pagesAterial Specification & All Thickness CalculationPanjiUte100% (1)

- The Basic of Electric Process HeatingDocument8 pagesThe Basic of Electric Process HeatingAmir AmkaNo ratings yet

- Oil and Gas Piping Codes and StandardDocument14 pagesOil and Gas Piping Codes and StandardTushar LanjekarNo ratings yet

- Piping Stress AnalysisDocument10 pagesPiping Stress AnalysisM Alim Ur Rahman100% (1)

- Topsoe High Flux Steam ReformDocument6 pagesTopsoe High Flux Steam ReformAnissa Nurul BadriyahNo ratings yet

- Optimization of Piping Layout With Respect To Pressure and Temperature Using Caeser-IiDocument6 pagesOptimization of Piping Layout With Respect To Pressure and Temperature Using Caeser-IichabibNo ratings yet

- Stress B313 PDFDocument2 pagesStress B313 PDFFRANCISCONo ratings yet

- Current Carrying CapacityDocument2 pagesCurrent Carrying CapacityAnonymous SkU7PyNo ratings yet

- Issn: 2349-3860Document18 pagesIssn: 2349-3860Pat TejNo ratings yet

- Comparative Study Summary 07 2004 enDocument32 pagesComparative Study Summary 07 2004 enthmaraishriNo ratings yet

- Hts Song Presentation2011Document46 pagesHts Song Presentation2011Anonymous 8te2h1No ratings yet

- Punch Points API RP 578 Material Verification Program (DAY 5)Document7 pagesPunch Points API RP 578 Material Verification Program (DAY 5)vishal bailurNo ratings yet

- TCS ThermoelementeDocument4 pagesTCS ThermoelementeStephen SanthoshNo ratings yet

- Comparitive StudyDocument32 pagesComparitive StudyEalumalai MuthuNo ratings yet

- Thermal Conductivity ReportDocument10 pagesThermal Conductivity ReportAmos Onyepuruikoluchukwu Ngwoke100% (1)

- STRESS in PipeDocument2 pagesSTRESS in PiperssambhiNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationFrom EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNo ratings yet

- A Treatise on Meteorological Instruments: Explanatory of Their Scientific Principles, Method of Construction, and Practical UtilityFrom EverandA Treatise on Meteorological Instruments: Explanatory of Their Scientific Principles, Method of Construction, and Practical UtilityNo ratings yet

- For The Steam and Condensate Loop - 01Document4 pagesFor The Steam and Condensate Loop - 01zoraze32No ratings yet

- Ramset SARB ANZ Ed.3 DynaBolt Plus SLEEVE ANCHORSDocument2 pagesRamset SARB ANZ Ed.3 DynaBolt Plus SLEEVE ANCHORSScott McCallumNo ratings yet

- Water Pipe Sizing Flow L/s Flow m3/s Flow m3/hr Area Velosity M/s Pipe Size (MM)Document2 pagesWater Pipe Sizing Flow L/s Flow m3/s Flow m3/hr Area Velosity M/s Pipe Size (MM)saroat moongwattanaNo ratings yet

- Classified 20230730 1Document4 pagesClassified 20230730 1Qamar SikandarNo ratings yet

- Division 9 - Materials and Finishes: Page 1 of 8Document8 pagesDivision 9 - Materials and Finishes: Page 1 of 8UmarNo ratings yet

- Inspection & Test Plan: Project Name: Main Activity: Date: W Witness H Hold Point T Test R RandomDocument1 pageInspection & Test Plan: Project Name: Main Activity: Date: W Witness H Hold Point T Test R RandomKasinadh KarraNo ratings yet

- Florida Heat PumpDocument12 pagesFlorida Heat PumpGhiban ConstantinNo ratings yet

- Cons Accident Monthly 1218Document68 pagesCons Accident Monthly 1218rosa gNo ratings yet

- Full Overlay European Concealed Hinges Model Description Opening HDocument2 pagesFull Overlay European Concealed Hinges Model Description Opening HMel TorresNo ratings yet

- Jaisalmer: Case StudyDocument27 pagesJaisalmer: Case Studyhudco kaamNo ratings yet

- Rubber BellowDocument20 pagesRubber BellowPrateek100% (1)

- SlopeDesignGuidelines JKRDocument37 pagesSlopeDesignGuidelines JKRtanchuanngan100% (9)

- Greater Bridgeport Combined Sewer Overflow Guide For ResidentsDocument2 pagesGreater Bridgeport Combined Sewer Overflow Guide For ResidentsBridgeportCT100% (1)

- Bridgette (OTC)Document31 pagesBridgette (OTC)mhel vianney bariquitNo ratings yet

- Growing Under Glass Choosing and Equipping A Greenhouse, Growing Plants Successfully All Year Round (Simon and Schuster Step-By-Step Encyclopedia of Practical Gardening) by Kenneth A. BeckettDocument79 pagesGrowing Under Glass Choosing and Equipping A Greenhouse, Growing Plants Successfully All Year Round (Simon and Schuster Step-By-Step Encyclopedia of Practical Gardening) by Kenneth A. BeckettOldoxNo ratings yet

- Fathom CV For Flowserve Valves PDFDocument248 pagesFathom CV For Flowserve Valves PDFdford8583No ratings yet

- Pressures Acting On Retaining WallsDocument3 pagesPressures Acting On Retaining WallsSupritha KNo ratings yet

- Tigges Catalogue PDFDocument119 pagesTigges Catalogue PDFwal1547No ratings yet

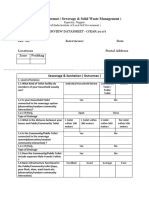

- Field Survey Format (Sewerage & Solid Waste Management) : Equicity, NagpurDocument3 pagesField Survey Format (Sewerage & Solid Waste Management) : Equicity, Nagpurritesh MishraNo ratings yet

- Asco Valves Series T298Document2 pagesAsco Valves Series T298OceanexNo ratings yet

- 4.8 Appendix-3h Color CodeDocument4 pages4.8 Appendix-3h Color CodeSubrata DasNo ratings yet

- B.O.Q of Electro-Mechanical Works 26Document1 pageB.O.Q of Electro-Mechanical Works 26asdsd dsdaNo ratings yet

- Papercrete4 PDFDocument9 pagesPapercrete4 PDFPrasad TekadeNo ratings yet

- Report On Bridge Development in PakistanDocument8 pagesReport On Bridge Development in Pakistankhawaja Ali100% (1)

- Memorandum: Project: Library Archives Museum Project Date: 11 30 2010 Subject: Alternate Sites Feasibility StudyDocument7 pagesMemorandum: Project: Library Archives Museum Project Date: 11 30 2010 Subject: Alternate Sites Feasibility StudyECI HyerNo ratings yet

- LT Pipeline Ball ValvesDocument19 pagesLT Pipeline Ball ValvessiswoutNo ratings yet