Professional Documents

Culture Documents

5.2. Dilatometric Methods: 5.2.1. Fluid Confinement Dilatometry

Uploaded by

sonia161990Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5.2. Dilatometric Methods: 5.2.1. Fluid Confinement Dilatometry

Uploaded by

sonia161990Copyright:

Available Formats

82 discussed below when calorimetric techniques are discussed.

Unfortunately, there is not complete agreement among practitioners on the preferred method of measurement, but it is of primal importance to specify the experiment as completely as is possible. In the following sections we describe some typical techniques for measuring the glass transition temperature and attempt to indicate the strengths and weaknesses of each. We also indicate the ability of such techniques to measure kinetic properties associated with the glassy structure. We do not look at methods such as dynamic mechanical or dielectric measurements as they have been widely described elsewhere and their interpretation is, in fact, more difficult than the methods presented here that provide a transition in "thermodynamic" properties.

5.2. Dilatometric methods

Dilatometry is a method for measuring volume. Although dilatometry is not the most common method of measurement in glass forming systems, we discuss it first here because the data first presented in the prior sections was obtained in very elegant experiments performed by A. J. Kovacs using fluid confinement dilatometry methods for a poly(vinyl acetate) polymer. Generally, dilatometric measurements can be made either in a confining fluid to obtain the volume change of the sample or through length change measurements. It is common, particularly in fluid confinement dilatometry experiments, to report the first derivative of the free energy state variable, the volume. The data can then, if appropriate, be analyzed in terms of the coefficient of thermal expansion. Hence, in Fig. 2, we see a volume-temperature plot and the Tx is estimated from the intersection of the slopes of lines drawn through the points at high temperature and low temperature (above and below the apparent transition). In addition, dilatometric techniques, including the length change methods, are often continuous or semi-continuous measurements in which volume (or its change relative to a reference) can be measured as functions of time, temperature or pressure. This can lead to very good accuracy in both the change and in the derivative of the change with time, temperature or pressure. (See, for example, references 9, 10, 11, 3 9, 40, 41 ).

5.2.1. Fluid confinement dilatometry

The methods used by Kovacs in his studies were based on the Bekkedahl [73] dilatometer depicted schematically in Fig. 24. The apparatus is essentially a quartz tube in which a sample is placed and then surrounded by an appropriate fluid. The tube is attached to a capillary of known (calibrated) diameter and volume changes are observed by measuring the height change of the fluid column in the capillary. However, despite the simplicity, the method is somewhat cumbersome and few people carry out such dilatometric measurements today because they are

83 not as convenient as other techniques. Perhaps the biggest disadvantages of the method lie in the need to evacuate the system in order to fill it with the confining fluid and the fact that, for polymers, the fluid should not interact with the polymer, which leads, commonly, to the use of mercury, a material whose physical properties are well known, as the confining fluid. Mercury has the advantage of excellent thermal conductivity there minimizes temperature gradients in the sample cell. Also, the temperature range over which mercury can be used is fairly broad (melting point is -39~ and the one atmosphere boiling point is 357~ ) [74]. Toxicity of the vapors, however, reduce the upper limit somewhat. An advantage of mercury confinement dilatometry is that the system can be immersed in a liquid bath, which lends itself to relatively easy temperature control and stability when high precision in the measurements is required. Typical estimates [40,41 ] for the accuracy of the Kovacs measurements, for example, are that the long time volume stability was approximately 2 x 10 .5 cm3/cm 3. This limitation is related to the fact that liquid mercury has a relatively high coefficient of thermal expansion and generally makes up 50 % or more of the total sample cell volume. Finally, the fluid confinement dilatometer has a significant advantage over linear measurements. Because the material is under very small hydrostatic stresses there is little tendency to change dimensions due to creep. Therefore, measurements are readily made through the glass transition where the material might flow. The reader is referred

Fig. 24. Schematic of the Bekkedahl fluid confinement dilatometer. (After Reference 73).

84 to Figures 2-4, 6-8, 10-14 for typical data taken using fluid confinement dilatometers. From the Figures 3, 4, 6 showing volume-temperature plots at different pressures, it is clear that the confinement technique also lends itself well to measurements under hydrostatic pressure. The actual measurement of the glass transition is made by taking the point of intersection of the liquid state v-T line with that of the glassy state v-T line. Typical errors in the estimates of Tg from isobaric measurements are reported to be of the order of+(1 to 2~ ), due primarily to the uncertainty of the estimates of the slopes in the v-T behavior and corresponding extrapolation of the uncertain lines to a point of intersection (See reference 11 for a discussion of the statistical methods used to make the error estimates). An advantage of the fluid confinement measurement is that it can be made on cooling, which reduces some of the difficulties which occur due to structural recovery in heating experiments. It is important, as in all T~ measurements, to fully specify the thermal history applied to the sample. For example, recalling Fig. 2, the Tg depends on the time-scale of the experiment. We also note that special, deformation dilatometers have been built for fundamental studies [75-78] of the effects of deformation on volume changes and could, conceivably, be used to examine the influence of deformation on the glass transition temperature.

5.2.2. Length change dilatometry

The most straight forward means of measuring the change in volume of an isotropic sample is to measure the change in length with temperature. This is evidently a popular method as reflected by three different standard test methods published by the ASTM [79-81 ]. Furthermore, when sample flow (creep) is not a potential problem, length change measurements can be more accurate than the fluid confinement techniques discussed above. [The reason for this is that, in the confinement method, the fluid volume changes make up a significant part of the measured volume change and these need to be taken into account.] The problem of sample flow is normally not a big effect far below the glass transition, but when the T~ is approached it becomes an issue. Most of the standard length change methods all require some sort of mass be applied to the sample. Furthermore, the mass of the sample itself can lead to flow when the viscosity ofthe sample becomes small enough. When flow becomes a problem, the fluid confinement methods are the best techniques because they measure the volume of the sample. The accuracy of the length change methods is determined by the ability to measure the absolute length, L, and the magnitude of the length change. If one is interested in the coefficient of thermal expansion, the interferometric methods lead to an estimated expanded uncertainty of 40 nm/m/K. Comparing this with a typical coefficient of thermal expansion of 3 .5 m/m/K, the relative expanded

85 uncertainty of the measurement is then approximately 1.3x10 3. This would assume, of course, that the sample did not flow and that the sample temperature is known perfectly. Additional errors in the measurement would result from fluctuations or gradients in temperature. A typical uncertainty, which is valid for all of the methods of measurement, can be estimated based on the coefficient of thermal expansion of the material and the sample length. Additionally, errors of measurement can be due to other factors, such as the actual temperature fluctuations, thermal expansion of the apparatus supports and, perhaps most importantly near to the glass transition, flow of the sample under the sample weight and weights of any instrument parts, such as mirrors in the interferometric method. In the case of less sophisticated methods [79,80] in which the length change is measured with a micrometer or a linear variable differential transformer (LVDT) displacement transducer, one needs to be concerned with flow and with the sample geometry. For example, a resolution of the sample length change of 1 gm would correspond to a 3~ temperature change for the above material ifthe sample length were approximately 1 cm. On the other hand, measurements with thin films by such a technique would require temperature accuracy of approximately 3 x 105~ if the film had a thickness of 100 gm. Clearly, such "push rod" methods are not made for measuring the change of coefficient of thermal expansion of thin films in the thickness direction. On the other hand, for research purposes, the expansion of films of thickness of hundreds ofnm can be measured using X-ray [82,83] or neutron [84] reflectivity or ellipsometry [85]. Such techniques are clearly not for routine use. In the case of measurement of the thermal expansion coefficients of films having thicknesses between several gm and 100's ofgm, there are interferometric methods [86] which are reasonably sophisticated. In addition, current research at NIST [87] and elsewhere [88] also suggests that very careful capacitance methods may be possible for measurement of the coefficient of thermal expansion in the thickness direction of thin films. Also, for kinetic studies of structural recovery, dilatometry is the only method for which it is relatively easy to obtain more or less continuous data. When structural recovery is measured in, for example, differential scanning calorimetry (described below), one is required to make a separate measurement for each data point in time. This can be very cumbersome and time consuming.

5.3. Calorimetric techniques Absolute calorimetry to measure the enthalpy is extremely difficult to carry out and it is much more common to measure the constant pressure heat capacity. Since the Cpis a second derivative (of the free energy) parameter, what is observed experimentally is a "jump" in going from the liquid to the glass. Modern scanning calorimetric apparatuses exist that make such measurements easy. In addition,

You might also like

- Volume DilatometryDocument12 pagesVolume DilatometryengroniyideNo ratings yet

- Dilatometry BhadeshiaDocument5 pagesDilatometry BhadeshiazairaNo ratings yet

- Volumetric DilatometryDocument14 pagesVolumetric DilatometryNasim MalekiNo ratings yet

- Differential Scanning CalorimetryDocument7 pagesDifferential Scanning CalorimetryKenesei GyörgyNo ratings yet

- Diffusion Coefficient Full Report TiqaDocument19 pagesDiffusion Coefficient Full Report TiqaprmzNo ratings yet

- Effect of Temperature on Acetone DiffusivityDocument11 pagesEffect of Temperature on Acetone DiffusivitySharing CaringNo ratings yet

- Astm D5930.1207343-1 Condutividade Termica PDFDocument5 pagesAstm D5930.1207343-1 Condutividade Termica PDFtadeuafNo ratings yet

- Hydrodynamics and Heat Transfer Around A Horizontal Tube Immersed in A Geldart B Bubbling Fluidized BedDocument15 pagesHydrodynamics and Heat Transfer Around A Horizontal Tube Immersed in A Geldart B Bubbling Fluidized BedMuhamad IkhsanNo ratings yet

- Experimental and Theoretical Study of Dryout in Annular Ow in Small Diameter ChannelsDocument20 pagesExperimental and Theoretical Study of Dryout in Annular Ow in Small Diameter ChannelsHavocFireNo ratings yet

- CFD Investigation of Heat Transfer and Flow Patterns in Tube Side Laminar Flow and The Potential For EnhancementDocument6 pagesCFD Investigation of Heat Transfer and Flow Patterns in Tube Side Laminar Flow and The Potential For EnhancementRipmi KamandanuNo ratings yet

- Heat Transfer To Down Flowing Viscous Films With Evaporation From The InterfaceDocument8 pagesHeat Transfer To Down Flowing Viscous Films With Evaporation From The InterfaceinventionjournalsNo ratings yet

- Time Temperature Superposition PrincipleDocument2 pagesTime Temperature Superposition PrinciplebilzinetNo ratings yet

- Sample Computation: Aluminum CopperDocument5 pagesSample Computation: Aluminum CopperJohn MegryanNo ratings yet

- Analysis Creep BehaviorDocument4 pagesAnalysis Creep BehaviorRamesh SantanaNo ratings yet

- Fast method predicts slow crack growth in HDPE pipeDocument7 pagesFast method predicts slow crack growth in HDPE pipeMehboob ulHaqNo ratings yet

- ABS Capillary RheometerDocument17 pagesABS Capillary RheometersharontanasNo ratings yet

- Name: Date Performed: October 7, 2014 Section: Group: Date Submitted: November 4, 2014Document7 pagesName: Date Performed: October 7, 2014 Section: Group: Date Submitted: November 4, 2014apaulitikoNo ratings yet

- AbstractDocument10 pagesAbstractmarkNo ratings yet

- Experiment 105 Linear ExpansionDocument5 pagesExperiment 105 Linear ExpansionRuthdel KazumiNo ratings yet

- Faculty of Engineering and Green Technology Bachelor of Engineering (HONS) Petrochemical EngineeringDocument9 pagesFaculty of Engineering and Green Technology Bachelor of Engineering (HONS) Petrochemical EngineeringDevakan BalaganeshNo ratings yet

- Chemical Degradation of Cellulosic Insulation Paper For Power TransformersDocument4 pagesChemical Degradation of Cellulosic Insulation Paper For Power TransformersFari PratomosiwiNo ratings yet

- LabReport Gas DiffusionDocument21 pagesLabReport Gas DiffusionSharing Caring83% (6)

- Sieverts Apparatus and Methodology For Accurate Determination of Hydrogen Uptake by Light-Atom HostsDocument6 pagesSieverts Apparatus and Methodology For Accurate Determination of Hydrogen Uptake by Light-Atom HostsSaumya SinhaNo ratings yet

- Krishnamurthy and Peles 2010 Flow Boiling Heat Transfer On Micro Pin Fins Entrenched in A MicrochannelDocument10 pagesKrishnamurthy and Peles 2010 Flow Boiling Heat Transfer On Micro Pin Fins Entrenched in A MicrochannelChong Jen HawNo ratings yet

- Experimental Study of Pressure Gradients Occurring During Continuous TwoDocument2 pagesExperimental Study of Pressure Gradients Occurring During Continuous TwoAbdulrahman NasirudeenNo ratings yet

- ASTM D 1329 - 88 (Reapproved 1998) Evaluating Rubber Property-Retraction at LowerDocument4 pagesASTM D 1329 - 88 (Reapproved 1998) Evaluating Rubber Property-Retraction at Loweralin2005No ratings yet

- SPE 166222 Pressure and Temperature Transient Analysis: Hydraulic Fractured Well ApplicationDocument21 pagesSPE 166222 Pressure and Temperature Transient Analysis: Hydraulic Fractured Well Applicationjuan joseNo ratings yet

- Experimental Fluid Mechanics PDFDocument11 pagesExperimental Fluid Mechanics PDFTheja RajuNo ratings yet

- Effect Scale Formation in Boiler Water Wall TubesDocument7 pagesEffect Scale Formation in Boiler Water Wall TubesRishabh ChaureNo ratings yet

- Fluorimetry AsignDocument7 pagesFluorimetry Asignshonu2009No ratings yet

- GC PDFDocument27 pagesGC PDFViper ThroughNo ratings yet

- Gas DiffusionDocument15 pagesGas DiffusionLindaAmharis100% (3)

- A Method For The Temperature Calibration of Pushrod DilatometersDocument9 pagesA Method For The Temperature Calibration of Pushrod DilatometerszairaNo ratings yet

- TMA (Thermomechanical Analysis) and Its ApplicationDocument18 pagesTMA (Thermomechanical Analysis) and Its Applicationbt19108055 Amarjeet KumarNo ratings yet

- Art of CalorimDocument17 pagesArt of CalorimNydia Ivette BurgosNo ratings yet

- Principal Methods of Thermal Conductivity MeasurementDocument5 pagesPrincipal Methods of Thermal Conductivity MeasurementRaistlin1No ratings yet

- A New Approach To Derive Relative Permeability Data While Measuring Resistivity IndexDocument12 pagesA New Approach To Derive Relative Permeability Data While Measuring Resistivity IndexRosa K Chang HNo ratings yet

- Long-Term Behaviour of GRP PipesDocument13 pagesLong-Term Behaviour of GRP PipesNassif Abi AbdallahNo ratings yet

- Microrheometer J Rheology2008Document12 pagesMicrorheometer J Rheology2008api-3827827No ratings yet

- Absorption and Sorptivity TestsDocument5 pagesAbsorption and Sorptivity Testsourebooks100% (1)

- Thermal Conductivity Determination of Small Polymer Samples by Differential Scanning CalorimetryDocument5 pagesThermal Conductivity Determination of Small Polymer Samples by Differential Scanning Calorimetrycarlette11No ratings yet

- SchaweDocument9 pagesSchawezhor El hallaouiNo ratings yet

- Modelling SAGD ProcessDocument7 pagesModelling SAGD ProcessAli ShahNo ratings yet

- 3-D Numerical simulation of swirling flow and convective heat transferDocument24 pages3-D Numerical simulation of swirling flow and convective heat transferVenkat Rajesh AnapuNo ratings yet

- Polymer Testing: Frédéric Achereiner, Kurt Engelsing, Martin Bastian, Peter HeidemeyerDocument8 pagesPolymer Testing: Frédéric Achereiner, Kurt Engelsing, Martin Bastian, Peter HeidemeyerNigar AkçayNo ratings yet

- Epoxy CureDocument7 pagesEpoxy CuregdritzNo ratings yet

- SHMT Project Report: Flux Enhancement Using Vacuum Assisted Direct Contact Membrane DistillationDocument14 pagesSHMT Project Report: Flux Enhancement Using Vacuum Assisted Direct Contact Membrane DistillationMuhammad AaqibNo ratings yet

- Exp301 Linear ExpansionDocument4 pagesExp301 Linear ExpansionJhenz Santos Bayadas0% (1)

- Glass-Rubber Transition Behavior MethodsDocument9 pagesGlass-Rubber Transition Behavior Methodschiuchan888No ratings yet

- Viscosity and Density Measurement Methods For Polymer Melts: R. Kažys, R. RekuvienėDocument6 pagesViscosity and Density Measurement Methods For Polymer Melts: R. Kažys, R. RekuvienėAbdul Falahitawan UfalNo ratings yet

- Liquid Phase Heat Transfer in Helical Coiled Heat ExchangerDocument66 pagesLiquid Phase Heat Transfer in Helical Coiled Heat ExchangerTushar Mahale50% (2)

- International Journal of Computational Engineering Research (IJCER)Document19 pagesInternational Journal of Computational Engineering Research (IJCER)International Journal of computational Engineering research (IJCER)No ratings yet

- Heat exchanger performance reportDocument18 pagesHeat exchanger performance reportKeith QuinnNo ratings yet

- By David R. Veazie and Thomas S. Gates: Langley Research Center, Hampton, VirginiaDocument33 pagesBy David R. Veazie and Thomas S. Gates: Langley Research Center, Hampton, Virginiaac.diogo487No ratings yet

- Traceability and uncertainty in volume calibrationDocument6 pagesTraceability and uncertainty in volume calibrationEliana TorresNo ratings yet

- Vacuum Contact Drying of Crystals: Multi-Scale Modelling and ExperimentsDocument6 pagesVacuum Contact Drying of Crystals: Multi-Scale Modelling and ExperimentsNishant Kumar GuptaNo ratings yet

- Ie 990141 DDocument9 pagesIe 990141 DEmmy Naz EzzureenNo ratings yet

- Lecture 8 Creep and RuptureDocument8 pagesLecture 8 Creep and RuptureAzhar AliNo ratings yet

- Hydrothermal Analysis in Engineering Using Control Volume Finite Element MethodFrom EverandHydrothermal Analysis in Engineering Using Control Volume Finite Element MethodNo ratings yet

- EN 25 - 2016 - TT-BCT - 339051 THÔNG TƯ 252016TT-BCT NGÀY 30112016 QUY ĐỊNH HỆ THỐNG ĐIỆN TRUYỀN TẢI DO BỘ TRƯỞNG BỘ CÔNG THƯƠNG BAN HÀNHDocument48 pagesEN 25 - 2016 - TT-BCT - 339051 THÔNG TƯ 252016TT-BCT NGÀY 30112016 QUY ĐỊNH HỆ THỐNG ĐIỆN TRUYỀN TẢI DO BỘ TRƯỞNG BỘ CÔNG THƯƠNG BAN HÀNHngomanhlinh2009No ratings yet

- FluidsDocument10 pagesFluidslara alghamdiNo ratings yet

- Dual Operational Amplifier: Semiconductor Technical DataDocument9 pagesDual Operational Amplifier: Semiconductor Technical DataRafael Jaime GonçalvesNo ratings yet

- Machinery Breakdown InsuranceDocument20 pagesMachinery Breakdown InsuranceRumman Arshad DarNo ratings yet

- ManualDocument1 pageManualBorza DorinNo ratings yet

- 4.1 Site Roads Crane Spec 3MW-DFIG-120 130 137-xxHz EMEA EN r08Document44 pages4.1 Site Roads Crane Spec 3MW-DFIG-120 130 137-xxHz EMEA EN r08Georgescu MirceaNo ratings yet

- Hein Chem12 Ch2 AnsDocument9 pagesHein Chem12 Ch2 AnsPyNo ratings yet

- VM 3156 Eriez Feeder Model HS46 HS66 IOMDocument12 pagesVM 3156 Eriez Feeder Model HS46 HS66 IOMMaintenanceNo ratings yet

- Proportional Valve Group: Technical InformationDocument76 pagesProportional Valve Group: Technical Informationsinou.25No ratings yet

- MEGGER DET 5 - 4 EARTH TESTER - Manual PDFDocument72 pagesMEGGER DET 5 - 4 EARTH TESTER - Manual PDFBenabidNo ratings yet

- Static ElectricityDocument20 pagesStatic ElectricityPanagiotis MouzenidisNo ratings yet

- Head Loss Lab ReportDocument15 pagesHead Loss Lab ReportMajak MarialNo ratings yet

- Mitsubishi Electric PLFY-P VBM-E Service Manual EngDocument44 pagesMitsubishi Electric PLFY-P VBM-E Service Manual Engengenharia proclimaNo ratings yet

- Basic USIT Interpretation - SLB Presentation, 2009Document18 pagesBasic USIT Interpretation - SLB Presentation, 2009alizareiforoushNo ratings yet

- Cleaning and Inspection For Oxygen Service: B. Haribabu Inox Air ProductsDocument54 pagesCleaning and Inspection For Oxygen Service: B. Haribabu Inox Air ProductskanchanabalajiNo ratings yet

- 2 5465417202091951228Document4 pages2 5465417202091951228_Asylum_No ratings yet

- Luchtmassameter StoringDocument4 pagesLuchtmassameter StoringpepeladazoNo ratings yet

- Intelligent Building Automation SystemsDocument27 pagesIntelligent Building Automation SystemsManu Manohar0% (1)

- Mansoor Ali Khan: Summary of QualificationsDocument6 pagesMansoor Ali Khan: Summary of QualificationsMansoor Khanali100% (1)

- WIND ENERGY: HARNESSING THE POWER OF NATUREDocument47 pagesWIND ENERGY: HARNESSING THE POWER OF NATUREHimanshu KhannaNo ratings yet

- Magazine-ETC (SANCHAR-2023)Document38 pagesMagazine-ETC (SANCHAR-2023)Ajit PatraNo ratings yet

- Quick Start Guide for Twin Tec TC88 Twin Cam IgnitionDocument2 pagesQuick Start Guide for Twin Tec TC88 Twin Cam Ignitionhrrt GarageNo ratings yet

- 2009 PI Piezo Actuators Components Nano Positioning CatalogDocument48 pages2009 PI Piezo Actuators Components Nano Positioning CatalogburakbalciNo ratings yet

- 700r4 Cable Adjustment InstructionsDocument3 pages700r4 Cable Adjustment InstructionsTito Tales100% (1)

- Illuminazione Gallerie Stradali Uni 11095 - Rev.2 IngDocument14 pagesIlluminazione Gallerie Stradali Uni 11095 - Rev.2 Ingiaiscan1009No ratings yet

- EHB en File 7.4.8 Fire Case and Hydraulic Thermal Expansion Acc To API 521 and ISO 23251Document8 pagesEHB en File 7.4.8 Fire Case and Hydraulic Thermal Expansion Acc To API 521 and ISO 23251mNo ratings yet

- Chvcm4 Instructions NaDocument1 pageChvcm4 Instructions NaCarlos CabralesNo ratings yet

- NL8.4MF Standard Compressor R134a 220-240V 50Hz & 208-230V 60HzDocument2 pagesNL8.4MF Standard Compressor R134a 220-240V 50Hz & 208-230V 60HzRabah RebouhNo ratings yet

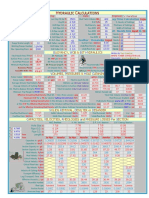

- Hydraulic Calculations MudpumpDocument1 pageHydraulic Calculations MudpumpSudish BhatNo ratings yet

- STUDENT_LISTDocument34 pagesSTUDENT_LISTShravan KumarNo ratings yet