Professional Documents

Culture Documents

Hinton Lecture 02

Uploaded by

mrminchanmonOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hinton Lecture 02

Uploaded by

mrminchanmonCopyright:

Available Formats

The 2002 Hinton Lecture

Delivering the National Rail Infrastructure

Speaker: John Armitt CBE FREng Chief Executive, Railtrack PLC 1 October 2002

The Hinton Lecture

The Hinton Lecture, the premier annual lecture of The Royal Academy of Engineering, is named after the late Lord Hinton of Bankside OM KBE FRS FEng, the first President of The Academy which, on its formation in 1976, was known as The Fellowship of Engineering. Lord Hinton was one of the 20th centurys most eminent engineers. Starting in engineering in 1917 as a sixteen-year old apprentice with the Great Western Railway at Swindon, Christopher Hinton gained first class honours at Cambridge in the Mechanical Sciences Tripos, then worked for Brunner Mond (later ICI), being seconded to the Ministry of Supply during the Second World War. In 1946 he was appointed Deputy Controller of Production, Atomic Energy, and in 1954 Member for Engineering and Production when the United Kingdom Atomic Energy Authority was formed. His organisation was responsible for designing and building the factory at Springfields for extracting uranium, for building Windscale with its production piles and complex chemical plants, the diffusion plants at Capenhurst, the first industrial nuclear plan at Calder Hall and the fast breeder reactor at Dounreay. In 1957 Christopher Hinton became the first chairman of the newly-created Central Electricity Generating Board. Following the conferment of a Life Peerage in 1965 he was an active member of the House of Lords and a highly successful first Chancellor of the University of Bath. His achievements throughout a long and distinguished career were recognised by honours and awards from the nation, from countries overseas, from the engineering and scientific establishments and from academia. He remained active in retirement until his death in 1983 at the age of 82. During his retirement, as President of the Council of Engineering Institutions (CEI) from 1976, Lord Hinton was involved in the final stages of the creation of The Fellowship of Engineering in that year. Under the CEI Charter, its President was also the President of the newly-formed Fellowship. Lord Hinton assumed that post with enthusiasm and energy, and over the next five years was instrumental in developing The Fellowships activities and administration. One of the activities was the introduction in 1977 of an annual Distinction Lecture which was given each year until 1981 when it was renamed the Hinton Lecture in his honour, following his retirement as President.

The 2002 Hinton Lecture Delivering the National Rail Infrastructure John Armitt CBE FREng ISBN 1-903496-06-3 October 2002

Published by THE ROYAL ACADEMY OF ENGINEERING 29 Great Peter Street, Westminster, London SW1P 3LW Telephone 020 7222 2688 Facsimile 020 7233 0054 www.raeng.org.uk The Royal Academy of Engineering is a Registered Charity (No. 293074)

Delivering the National Rail Infrastructure

John Armitt CBE FREng Chief Executive, Railtrack PLC

John Armitt was appointed Chief Executive of Railtrack PLC on 14 December 2001. He has extensive experience in the building, civil engineering and industrial construction markets, having joined John Laing in 1966 as a civil engineer. From 1987 1993 he was Chairman (International and Civil Engineering Divisions) for John Laing plc. From 1993 to 1997 Mr Armitt was Chief Executive of Union Railways where he was responsible for developing the Channel Tunnel Rail Link. In 1997 he joined the Costain Group plc, also as Chief Executive, and is credited with rescuing the company. He was awarded the CBE in 1996 for his contribution to the rail industry. He is a Fellow of The Royal Academy of Engineering and of the Institution of Civil Engineers.

The Royal Academy of Engineering 3

The 2002 Hinton Lecture

Delivering the National Rail Infrastructure

Britains railways have gone through considerable upheaval in the last ten years but it is worth remembering that it is not for the first time. To start, I would like to briefly remind ourselves of the past, as what seems new today is not necessarily that original. The development of Britains rail network had helped to create, and then support, the phenomenal industrial revolution of the 19th Century. The founding engineers, some such as George Stephenson self-taught, others like Brunel educated sons of academic engineers, fuelled by speculative equity, laid down track and developed engines in an orgy of raw energy. Between 1820 and 1870, 15,000 route miles of track were thrown down and 100,000 tunnels, major viaducts and bridges erected in a highly competitive environment. Whilst steam driven construction plant was emerging, the vast bulk of the work was hand built by thousands of men known as navigators or navvies whose industrial origins could be found in the building of the canal system, itself now consigned to literal backwaters by the iron horse and the railway. The origins of the separation of the engineer and the contractor came at this time as early engineers realised they could not organise and finance the physical work, at the same time as their energies were required to survey, design, obtain parliamentary consents and keep their financiers happy. Major contractors such as William Brassey built corporate empires which did not always survive the major risks they took on at home and overseas, building to tighter prices and more demanding programmes. Finance and politics were central to the process. Fortunes were made and lost in a frenzy of speculation. The engineers forecasts of the costs were like todays, often underestimated, whilst the demand and revenue forecasts were equally optimistic. The railway had as many objectors as supporters and so politicians became engaged in lending either their support or opposition. The first Act of Parliament permitting the building and operation of a passenger railway was for the Stockton to Darlington in 1821. Thousands of separate Acts were consequently passed, with 272 in 1846 alone. The major lines were developed for the carriage of goods as much as for passengers, taking over from the canals at a time when roads were useless for carrying the raw materials and finished products of the revolution. The owners of the Midland Line, when building St Pancras station, ensured that it utilised stone and bricks from the Midlands, thus earning revenue as they built their fantastic station and hotel. The undercroft of the station was specifically laid out to ensure the efficient storage of the beer barrels of the Trent Valley brewers.

The Royal Academy of Engineering

Delivering the National Rail Infrastructure

The network, 20,000 miles long and twice as long as the one we have today, was essentially complete by 1920. A series of mergers and acquisitions between the numerous owners created in 1923 the great railway companies of the interwar years. The Great Western, Southern, London North Eastern Railway and London Midland and Scottish dominated. Each employed tens of thousands of lowly paid workers within military style hierarchies. By the late 1930s competition from the road transport was real and some companies were beginning to face hard times. In 1946 the Railway companies were nationalised into a single entity, their infrastructure exhausted by wartime demand with minimal upkeep. There can be little doubt that fervent nationalisers did not realise the demands the Railway would put on the Exchequer, nor did they realise the scale of the infrastructure which needed more than an uncertain annual allowance to allow for a proper maintenance and renewal programme. By 1964 reduced demand as motor car use expanded meant that a review of real need was required. The result was Dr Beechings programme which saw 5,000 miles of the network closed in 5 years along with 2,000 stations closed, and 250 train services withdrawn. In engineering terms the railway was changing. Electrification had first appeared on the underground as early as 1890 (the City and South London Railway). Above ground on the mainline railway the Southern had adopted the third rail 750 DC system in the 1920s, the prime motivation being low running costs and greater efficiency. Steam, however, held on to the intercity routes until the 1960s, replaced by a diesel building programme over the decade from 1955. Before the Second World War, work started on overhead electric schemes. The first - from London Liverpool Street and Shenfield - was completed in 1948 at 1500V DC. In the 1950s the overhead line was standardised on AC at 50 Hz and the early lines converted to 6.25 kV, the maximum given small electrical clearances under bridges. As the Clean Air Acts reduced pollutants, the lines were further uprated to 25 kV within the same clearances between 1976 and 1987. Behind the scenes the real controllers of the railway have always been the signallers and their control system. The block system, whereby a train cannot enter a section of track until the preceding one has left the section, has developed from tokens given to the driver on entry, handed over on exit, to flags, to semaphore signals controlled by wires, to electrical control of lights. The principle of interlockings whether by mechanical means or today by computer programmes creating the block or safe routing to protect against collision has been consistent. When accidents do occur it is very rarely due to system failure but human error overriding or ignoring the systems. I end this introduction by bringing us to 1993 and privatisation. This privatisation was, however, not simply a transfer of ownership from the state to private equity and debt but also for the first time a separation of track from rolling stock with train access by commercial contract. Britain was not in fact the first country to create this split. Sweden had created Banverket as infrastructure controller but it was and still is, state owned. The arguments for and against separation continue.

The Royal Academy of Engineering

The 2002 Hinton Lecture

It is probably fair to say that within the railway industry the majority view is held by those opposed to separation, their argument being that effective and efficient operation is through an integrated railway. Other countries have also separated but none to the same degree of complexity as the UK. So, what is todays railway? Physically it consists of 20,000 track miles, 2,500 stations, 65,000 bridges and tunnels, and thousands of miles of cabling for signalling and communications. All of this is the responsibility of its owner, Railtrack. The rolling stock consists of 1150 engines of which 80% are diesel powered, together with 1000 diesel and 1700 electric passenger multiple units. 60% of the latter work on the third rail DC network south of London. In 1994 the majority of rolling stock was bought by three companies known as the ROSCOS (Rolling Stock Companies), who lease the trains to 26 train operating companies, the TOCs (Train Operating Companies). Of these, 23 are passenger carriers and three freight. The TOCs ability to operate is by virtue of a licence and a franchise, bid for in competition and typically of seven years duration. New trains are specified by the TOCs but actually owned by the ROSCOS. The last eight years has seen 4bn of orders for 1,400 new trains, a scale of investment unlikely to have been witnessed under state ownership. In the previous 8 years, British Rail had placed orders for 582 trains to the value of 2.5bn. The introduction of new trains onto the network is a complex process of engineering and safety approvals. A process criticised by many as being slow, cumbersome, over cautious and consequently unnecessarily expensive. It is one of many elements of todays Railway which we have to improve. The train operators gain access to the network through Track Access Agreements negotiated with Railtrack and approved by the Rail Regulator. These Agreements permit access on given routes during particular periods of the day. With as many as ten companies having access to the same route sections, the potential of conflicting needs is high and the development of the six monthly timetable with Train Operators, who bid for their preferred slots is lengthy and complex and takes place a year ahead of the actual timetable period. Whilst the Strategic Rail Authority (SRA) let the franchises to the TOCs, Railtracks activities are controlled by the Rail Regulator. Railtrack as a monopoly supplier of track is regulated in order to ensure the TOCs are fairly treated and competition between them fair and open. Several billion pounds circulates around the railways in a year, so what are the actual flows and controls in this process? In its simplest form the passenger or owners of goods pays a fare to the Train Operator. He in turn uses the fare to pay for the lease of the trains, his operating costs and to Railtrack for access to the network of track and stations. The balance is his profit. Railtrack in turn uses the track access charge to maintain, renew and enhance the network to meet the needs of the Train Operators.

The Royal Academy of Engineering

Delivering the National Rail Infrastructure

Simple in theory but rather more difficult in practice. The fares that are considered acceptable for passengers to pay are not enough to meet the payments the Train Operators must pay Railtrack which in turn are insufficient for Railtrack to meet its obligation of providing a safe, reliable and improved network. Hence a set of subsidy payments to the Train Operators, grants to Railtrack and an increasing debt burden for Railtrack as it borrows to meet its obligations. The contracts between Railtrack and the Operators involve penalty payments for delays and poor performance. Disputes over these can be appealed to the Regulator. The sums of money involved run into hundreds of millions. So it is not surprising that a very commercial and sometimes adversarial environment has developed. The Rail Regulator approves fares, access charges, sets penalties and decides how much money Railtrack should be allowed over a five year period to operate the network. Very simply, this financial and contractual cocktail, together with the impact of first the Ladbroke Grove and then Hatfield accidents on passenger revenues and costs arising led last year to Railtrack concluding that it faced severe financial problems. This led to various options being considered and discussions with the Government and the Regulator, the result of which was the Governments decision to ask the courts to make a Railway Administration Order over Railtrack. I do not intend this evening to pour over the entrails of that particular episode, which have probably used more printers ink than any other political/business issue in the last year. Today we are on the verge of a new financial structure for Railtrack. Network Rail, a purpose built not for dividend company, has created a debt driven financial structure with the SRA as guarantor of last resort, which has enabled them to offer to buy the shares of Railtrack PLC, the operating company from Railtrack Group and hopefully to persuade the court that there is a business plan supported by access to sufficient funding to enable Railtrack to be released from Administration. What to spend that money on, and how we expect to deliver a more efficient and reliable infrastructure is what I would now like to describe. The rail network in the UK consists of 20,000 miles of track and communications systems, 2,500 stations, 65,000 bridges and tunnels. The majority of the stations, structures and tunnels are over 100 years old, the underlying earthworks and cuttings of similar age. The elements which have been regularly replaced and upgraded are the ballast, the sleepers still 25% of timber, the rails 70% continuously welded but in parts of the network still joined by steel fish plates and the signalling and communications systems. Even today there are 325 manually operated signal boxes utilising their Victorian operated iron interlock frames requiring the same maintenance and adjustment as the day they were built. Nearly 5,000 miles of track has overhead 25 kV power systems much of it 30 to 40 years old, whilst in Southern, 2,500 miles of track utilises the 750 DC system. However, the improvement in modern turbo-diesel rolling stock, leaves a question mark over further major electrification in the UK.

The Royal Academy of Engineering

The 2002 Hinton Lecture

Much has been made in the last couple of years of the fact that Railtrack does not have a full knowledge of its assets. The current reality is that we do have, on a zonal basis, a good understanding of the quantum, age and general condition of the assets but this knowledge is held in different forms and does not provide a detailed record of maintenance history and current physical condition. One of the consequences of privatisation and the total outsourcing of maintenance means that today most records are held on various contractors own systems with no automatic rights of access to Railtrack. We are now putting that situation right with the introduction of our own network wide system called MIMS. Engineering activity on the network can be split into three types. Maintenance, renewal and enhancement. Each of these requires safe access to the network to carry out the work. Ideally, safe access means that trains are not allowed to run on the section of track being maintained. Renewal and enhancement activity is nearly all carried out in Green Zone working. With regard to maintenance, a significant proportion is carried out in Red Zone working. However, a recently introduced standard will reduce to a necessary minimum this type of work. Green-zone working requires Railtrack to agree with the train operators possession of the track. The majority of these possessions are taken during mid-week nights between 11 pm and 6 am or at the weekends. This means most work is done under artificial light with low levels of efficiency. There are many opportunities for efficiency improvements. Major improvements require more access and more automation. To know the condition of the network requires regular inspection. Today basic inspection is carried out by patrolmen walking the track looking for obvious faults and, if possible, making an immediate repair or adjustment. This is the approach which the public can relate to, feel comfortable with and want to believe is happening on a continuous basis. However, it is far from perfect and with an increasing volume of traffic, carries personal risk to the inspector. Increasing use is being made of non destructive testing, utilising rolling contact hockey sticks which provide data on the internal structure of the rail and its welded connections. We are also building special track vehicles to carry out this vital work at higher speed and with greater reliability. A safe environment is provided by train borne inspection. For track engineers an enjoyable day out of the office is a cab ride during which they visually inspect encroaching lineside vegetation, cutting condition and directly experience the quality of the ride and therefore the alignment of the track. Detailed understanding of the geometry is achieved by the use of automatic track recording trains which can provide a trace record of horizontal and vertical alignment to an accuracy of 1mm. GPS technology is now enabling these same trains to physically relate the track to its surroundings so that monitoring of track clearances vital for safe running is available. Looking forward we will soon have digital cameras mounted on examination trains which will provide a visual record of track and its surrounding area condition. The quality of these photographs is very high, better in fact than can be achieved with hand held cameras. We also plan to mount these cameras on passenger trains with automatic remote download to our systems.

The Royal Academy of Engineering

Delivering the National Rail Infrastructure

A recently exposed rail defect, the cause of the Hatfield derailment, is rolling contact fatigue or gauge corner cracking. Simply described this is the propagation of short cracks across the surface of the rail which over time can develop at an angle down into the rail, join up and in the severe stages vertically migrate with eventual failure and collapse of the rail. This is an increasing problem in other countries and all the causes are not yet fully understood but it is believed different types of train with different suspension and rolling contact characteristics can generate these defects at different rates. In rail treatment terms the solution is to grind off fatigued metal before cracks can develop. Inspection and testing of points or switch and crossings sets with their many moving parts can only be done properly physically, it is time consuming and ideally requires possession of the track. Signalling and communication systems are in the main monitored remotely although one of our largest problems today is wire degradation in systems 30 to 40 years old which also need to be physically monitored. From all the inspection data, knowledge of system age and traffic intensity, maintenance programmes can be developed and possessions planned as much as 60 weeks in advance. Immediate possessions are taken for emergency repairs. On an average day we will have 82 system failures causing significant delay, the most common being points and cracked rails, track circuit failures, signalling faults and supply failures. Every night a programme of immediate and long term planned maintenance takes place utilising approximately 10,000 engineers and operatives. This year we will spend approximately 1.25bn on maintenance. Maintenance work provides the opportunity for mechanisation primarily in relation to the track system. The sleepers are supported and held in place by the ballast. This crushed stone, typically granite or limestone, works less effectively as its voids become full of dirt, the stone moves or slowly breaks down. It can be automatically placed back into position under and around the sleepers or totally replaced by rail borne machines. The track alignment can be improved by automatic machines known as tampers which move the track to its proper alignment and tamp the ballast. A British development is the stone blower which achieves the same end without damaging the ballast through mechanical action. In recent months we have ordered two automatic high output ballast cleaning trains at a cost of 40m each and 9 stone blowers at a cost of 2m each. One of the most effective ways to maintain rail life is to grind the rail surface. This removes surface defects and can reprofile the rail to its ideal shape so causing a smooth ride for the train and its passengers. Grinding can be done by hand held machines or at the extreme by rail mounted trains capable of grinding and reprofiling rail to an accuracy of microns at a speed of up to 12 mph utilising 64 computer controlled carborundum grinding stones. We recently took delivery of a 10m plain line grinder from America and have two more plus 5 Switch & Crossing grinders on order. These machines are essential in the task of keeping on top of gauge corner cracking and rail quality generally. Our objective is to have them working 95% of available time. Eventually elements of the system have to be renewed. This year we will spend 2.5bn on system renewal. The majority of this work is carried out during weekends in longer possessions.

The Royal Academy of Engineering

The 2002 Hinton Lecture

Automatic equipment can replace ballast, sleepers and rail separately or all at the same time. The average life cycle for ballast is 15 years, 35 years for sleepers and 25 years for rail. However, track life can range from as low as seven years in highly corrosive environments such as the Severn Tunnel to 65 years in outlying parts of the network. The last period of major track renewal was between 1965 and 1985. Given the average life of track, it is clear that we now face another period of track renewal across the network. Switch and Crossing renewals are major activities often involving several hundred metres of track and heavy lifting equipment. Renewal decisions are based on inspection information and life cycle factors. Today we are developing decision tools which will enable us to optimise age, condition, possession costs and outputs to deliver the most effective solutions. The shortest life cycle elements of the system are signalling and telecoms. However, continuous technological development together with improvements arising from major incident enquiries means that renewal invariably becomes what is known as enhancement of the system. Enhancement is when the system capacity or security is increased or improved from its current state. It is treated differently in financial terms by the Rail Regulator and given that any system renewal by the latest model may well in some way improve and enhance, definitions become important. I mentioned earlier that signalling is the key to control of the network. Ironically, there is currently a shortage of signalling design engineers and any investment decision is always influenced by the availability of this resource. Given its safety critical nature, design is very carefully controlled, checked and carried through many, sometimes too many, iterations. The desire of engineers to use the latest and best, sometimes unproven, technology has led to some embarrassing time and cost overruns and we are currently reviewing our signalling strategy with the focus on what works and can be effectively delivered. However, it must be admitted, overruns have as much to do with good project management, particularly in the scope definition and design development stage as it has with the choice of technical system. A major issue in recent years in signalling and train control terms has been Automatic Train Protection (ATP). ATP monitors train speed and will automatically stop a train which is in danger of passing a red signal. ATP was rejected by British Rail on cost benefit grounds in 1993. The cost of the system valued a life saved at 14m. After the Ladbroke Grove accident in 1999, the Cullen Report recommended the installation of ATP within ten years. However, after 1993 Railtrack had supported the development of an alternative, more cost effective warning system known as TPWS which, in its advance form, stops trains travelling at up to 100 mph. We are now on programme to complete next year a target set by the HSE in 1998, the installation across the network of TPWS at a cost of approximately 500m. This, however, has not stopped the pressure for full ATP. The most recent industry wide report commissioned by the SRA has recommended that through the introduction of the European Rail

10 The Royal Academy of Engineering

Delivering the National Rail Infrastructure

Traffic Management System (ERTMS), particularly on high speed lines and now mandated by a European Interoperability Directive, full ATP is delivered over a longer period. This report is now with the Department of Transport. ERTMS is a signalling control system that enables the information to be displayed in the drivers cab rather than on lineside posts and can take control from the driver if necessary. The system can be implemented in several different ways potentially using radio. Trials are currently underway in Europe. UK network implementation is currently costed at between 4 6bn. It will save 1 2 lives per year over TPWS but the same options will also enable better utilisation of network capacity through improved signalling control. Another important planned improvement to the rail network is to the communication system between the driver and signal control. Today this is effected by a mixture of line side telephones and in-cab radio systems. The in-cab systems are up to 18 years old and not all of them work in tunnels and certain locations. We are currently introducing a scheme known as GSM-R which will provide a new in-cab system capable of operating anywhere on the network. Target completion is 2006. In addition, a new fixed telecoms network is being planned for completion in 2008 which will replace the current life expired system. This has inevitably involved do you own or lease, do you utilise off track systems choices. Our view is that we should have our own track side system for these vital safety controls. Major upgrades to the rail network are long term projects often attracting considerable publicity. The Channel Tunnel Rail Link, West Coast Route Modernisation, Thameslink 2000, the East Coast upgrade, Cross Country Route Modernisation represent billions of investment, with time frames in construction up to 10 years and several years of prior engineering development. In some cases improvements in rolling stock generate the need for infrastructure improvement. Thus the replacement on the Southern region of the slam door trains will require at least 500m of investment in improvements to power supplies to cope with the extra demand of high acceleration, heavier, air conditioned new trains. Cost and programme on major developments is significantly influenced by the nature of access to the railway. Naturally train operators want maximum access for their services but unless long term blockades are introduced, construction work is done on a piecemeal basis. Recent research, however, indicates that perhaps passengers are more willing to accept major closures or preferably diversions in return for more certainty once work is complete. The train operators, however, remain nervous of the long term loss of passengers who switch to other transport modes. Smaller enhancement schemes can often produce excellent operating improvements and looking ahead there is a crucial balance to be struck between major, high profile, long term schemes and achieving improvements through smaller quickly delivered schemes. I have, on several occasions so far, referred to different aspects of safety on the railway and I would now like to address that issue in rather more detail.

The Royal Academy of Engineering 11

The 2002 Hinton Lecture

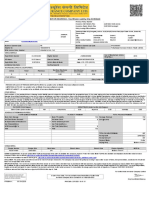

There is no doubt that when people travel on trains their expectation of a safe journey is greater than when driving, travelling by plane or even by ship. There may well be some simple explanations. For example, we recognise our own and others driving errors. Subconsciously, many are still puzzled by the ability of hundreds of tons to be raised in the air, whilst whenever we board a ship we are reminded of life boat drill and often experience the full force and discomfort of the elements. On trains we jump on at the last minute, there is no security control, little if any safety instruction, we often stand up throughout the journey and accidents are rare. So rare, in fact, that in the last 50 years less than 1000 people have died travelling on our railways. In the same period, 250,000 have died on the roads. Some recent work on why people have died in rail accidents shows that 80% has been due to operational rather than technical causes. The principal causes of accidents are: Signals passed at danger Level crossing mis-use Irregular working Derailment due to infrastructure defects. In seeking to prevent accidents we must identify the risks and then the ways to minimise those risks. The minimisation of risk must be considered within a rational framework under the 1974 Health and Safety at Work Act. The approach in the UK is that risks should be reduced to As Low as Reasonably Practicable or ALARP, a concept initially developed for the Nuclear Industry. Clearly we need a basis of reasonably practicable and tolerability. Here you see a representation of Levels of Risk tolerability, which in turn we have applied to three exposed groups. Employees, regular commuter passengers and other members of the public. These levels of safety performance are expressed as individual risk of fatality as a result of exposure to railway operations.

Levels of Risk Tolerability Risk cannot be justified on any grounds

Intolerable

As Low as Reasonably Practicable (ALARP) Region

Tolerable Only if risk reduction is impracticable or if its cost is grossly disproportionate to the improvement gained

Broadly

Negligible Risk

12 The Royal Academy of Engineering

Delivering the National Rail Infrastructure

Intolerable

Broadly Acceptable

A key requirement of interpreting ALARP is applying an economic test. This test is defined as the cost being grossly disproportionate to the improvement gained. If our objective is to reduce the risk of death, then we must put a value on life or the level of investment appropriate to prevent a fatality. This in personal terms is very difficult but a rational view is important and for the railways we are currently using 1-3m. This compares with 1m for roads and 10m for the nuclear industry. Thus the 1993 decision not to invest in ATP at a cost of 14m can be put in context. These values are, of course, open to challenge and in the aftermath of a major accident, what has been described as the outrage factor can push these values up exponentially. TPWS, represents a cost of 5m per life saved, above the normal level but less than that which could be called excessive or based on outrage. Derailment and train collision can be catastrophic events. Collisions can typically follow from unprotected signal failure. TPWS and ATP are designed to stop trains in the overrun length before a collision can occur but there are other aspects of signal design such as sight lines, luminosity and separation of lights which, carefully considered, can reduce the risk of a driver missing a signal. Every time we have a signal passed at danger, or SPAD, an investigation is carried out and where there is any possibility that it was a cause other than by pure driver inattention, a review of the signal and appropriate modification is made. Derailments are caused by a variety of failures. Typically broken rails, line obstructions, structural or earthwork failures. Broken rails can, as I described earlier, follow from the recently recognised phenomena of Gauge Corner Cracking or from impact loading due to wheel flats. We have recently increased our own detection of train wheel defects and the consequent action by train operators has co-incided with a drop in the number of rail breaks. A good example of a lineside obstruction are Level Crossing Incidents. Apart from the fact that nearly 10 people a year die in road vehicles from these incidents, the risk to passengers from

The Royal Academy of Engineering 13

The 2002 Hinton Lecture

derailment is considerable. We therefore have a risk assessment for every one of the 8,000 crossings on the network, many of which, such as farm crossings, are user controlled. Continuous research is undertaken to identify more effective ways of providing warnings, whilst the installation of CCTV and prosecution of those who misuse or jump crossings has resulted in reduced misuse at those crossings. When budgets are tight maintenance of our 65,000 structures is often the first area to suffer, whilst every day several bridges will be struck by lorries and buses whose drivers ignore warnings or are unaware of the height of their vehicles. Earthworks failure has not been a major issue in the past but recent changing weather patterns have caused deterioration to embankments, particularly in the south and west where they are most likely to be of clay construction. We are currently increasing our expenditure forecasts to ensure stability of these structures which can be up to 150 years old. The engineering process flowing through policy, standards, inspection, execution and verification is totally dependant on resources, particularly engineers. I have already referred to the shortage of signalling engineers but the combination of split responsibilities, increasing expenditure on a long neglected infrastructure and the need to reduce risk and improve quality has increased demand in all areas. Engineers working on the railways are now recruited from around the world and at Railtrack we have initiated conversion courses for engineers trained in other disciplines to become track engineers. The first 30 are now at work. It is inevitable that the network is not always wholly compliant with standards. This is dealt with either by considered and permitted derogations or by placing restrictions, typically on the speed, on operating trains. Temporary speed restrictions (TSR) of 20 mph were imposed across the network in the immediate aftermath of the Hatfield incident. Today TSR numbers are still in excess of preHatfield levels. This is due to the continuation of gauge corner cracking, an increasing engineering workload, risk aversion, the stricter application of standards, inadequate maintenance, or of course, an increase in defects. The impact of TSRs on daily performance is high. Numerically, it represents 20% of the delay minutes attributed to Railtrck but indirectly reduces recovery capacity in the event of other system failures and incidents. The identification of defects, which will lead to new TSRs or the quick removal of applied TSRs, is therefore the highest priority, after direct safety, work for our track engineers and contractors. Within Railtrack we refer to Health Safety and Environment. So any presentation would be incomplete without a description of the key environmental issues for Railtrack. The key drivers for our Environmental policy are EU and UK Transport Policy, Environmental Regulation and Directives, Government taxation policy, Government Targets e.g. CO2 emissions and Directions and Guidance we receive from the SRA. The major environmental issues for us are: operational noise, construction noise, discarded materials, contaminated land, fuel storage, used ballast, surface water drainage, protected sites, graffiti and lineside vegetation. The key risks for us likely to lead to prosecution today are contaminated land and noise.

14 The Royal Academy of Engineering

Delivering the National Rail Infrastructure

Contaminated land exists in may rail depots as the result of a 100 years of activity. Today the management of diesel and oil storage and distribution in the depots is a key issue. This year we have had 45 recorded spills. An increasing risk for the railway industry is noise. A new European Noise Directive will potentially lead to significant cost. The primary source of noise, is the wheel rail interface. If it cannot be resolved at source then the alterative is a noise barrier as close to the line as is practicable. The first task is to understand current noise levels and we will shortly be starting a major noise mapping exercise. On the positive side, Railtrack recycles ballast, rail and sleepers. We manage 330 sites of special scientific interest, whilst the growing use of rail reflects either a real reduction, or at least reduced growth, of road journeys and CO2 emissions. Finally, I would like to return to the organisational structure and contractual arrangements for operating and maintaining the railway. One element of privatisation was the sale of the maintenance and engineering organisations within British Rail, typically to UK construction companies. British Rails design engineering capability infrastructure was also sold leaving Railtrack with a core resource. In numerical terms 20,000 people had been transferred out of BRs engineering capability and Railtrack retained 500. The result is that Railtrack, in order to met its obligations to provide the infrastructure to the Train Operators has to buy in engineering and construction services. Railtrack, however, retained the actual operation of the network. Today, of the 13,000 people in the company, 6,500 are responsible for the signalling operation and control, electrical control centres and communication control of the network. Whilst the majority of the stations are manned by the Train Operators, Railtrack manages the largest 16. The network timetable is created by Railtrack, modified according to demand and reissued every six months as the current Winter or Summer timetable. Railtrack itself consists of a centre based at Euston and six regional units called Zones. The centre sets engineering policy standards and operating procedures and oversees procurement of all services. The infrastructure is maintained, renewed or enhanced through a series of contracts between the Company and external consultants and contractors managed directly by the Zones. The maintenance contracts today are typically let for five years and the contractor, having been set standards to be achieved by Railtrack, inspects the Railway, decides on an annual programme of work which is agreed with Railtrack, plans and executes the work and ensures it is carried out to the required standard. Separate contracts are let for renewal or enhancement of the network. Hundreds of separate work packages are carried out every day by 20 major contractors with most of the materials and construction plant being delivered to location by rail. In order to bring some

The Royal Academy of Engineering 15

The 2002 Hinton Lecture

order to this major logistical exercise, Railtrack operates a National Control Centre which, contracting with the freight train operators and suppliers of bulk materials, ensures that materials and plant are in the right place at the right time. Following the Hatfield accident, concern was expressed both by Railtrack and its various stakeholders as to whether Railtrack had sufficient control of the engineering works carried out on the network. The result was a restatement of Engineering Policy, set out in these principles : set detailed engineering policies, specifications and key work instructions for maintenance, renewal and enhancements specify the technical competence required to work on the infrastructure directly control examination of the network and automate it where possible take charge of asset information including current condition data and infrastructure records make or control work decisions and prioritisation. In support of these principles, we are now reviewing and revising the relationship with our Maintenance contractors. In future, Railtrack will set out in more detail the inspection regime to be followed and specify the competences required of the individuals carrying out inspection. Railtrack will interpret the results and determine the work to be carried out on the network by the contractors and it will take a more intrusive role in the verification of the work. This is a significant shift of risk and responsibility from the contractors to Railtrack and we are engaged in agreeing the detail of the contracts, the necessary shift of engineering personnel and adjustments to the safety case for each maintenance area. There have been calls for all maintenance to be carried out directly by Railtrack. This would be a massive change and one we do not intend to pursue. The majority of Railtrack expenditure is spent on maintenance and construction and whilst we believe we should make the key engineering decisions that ensure the safety and sustainability of the infrastructure, the physical work should be organised and managed by contractors who have the necessary skills and resources. This is no different from the oil industry and other utility suppliers such as water, gas and electricity. Looking forward, working with our contractors, we have to improve efficiency and productivity in all aspects of the maintenance process. We have already started by reviewing our approach to possessions management and control. Possessions are booked months in advance but last minute changes, cancellations of work and too much time spent setting up and demobilising work all serve to reduce planned access to the network. Looking forward, there is much to be done to achieve a stable sustainable network, but I believe we could be in that position in 3 to 5 years time. Future expansion and enhancement of the network will be strategic decisions for the SRA. The last five years have witnessed a 30% increase in passenger miles travelled with a growth in freight of nearer to 50%. The Government has set a target of a 50% increase from the year 2000 by 2010 together with an 80% increase in freight tonnes carried. The further pressure on the infrastructure is obvious. With the increasing expenditure on maintenance and renewal, the funding of major enhancements will be difficult and the intention is to turn to privately funded Special Purpose Vehicles. SPVs will entail considerable risk which I believe will ultimately involve Government. The railway, past and present, has always required tough decisions, they will continue to need to be made but with the new sense of direction and control at the SRA, I am confident that with flexibility and pragmatism by everyone in the industry, we can engineer and deliver a safe, reliable railway for the next 100 years.

16 The Royal Academy of Engineering

The Royal Academy of Engineering

The objectives of The Royal Academy of Engineering are to pursue, encourage and maintain excellence in the whole field of engineering in order to promote the advancement of the science, art and practice of engineering for the benefit of the public. The Academy comprises the United Kingdoms most eminent engineers of all disciplines. It is able to take advantage of their wealth of knowledge and experience which, with the interdisciplinary character of the membership, provides a unique resource with which to meet the objectives. Its activities include an extensive education programme, research chairs and fellowships, visiting professorships, industrial secondments and international travel grants. It provides expert advice on engineering matters to government and other bodies and awards the UKs premier annual prize for innovation in engineering, The Royal Academy of Engineering MacRobert Award. Election to The Academy is by invitation only. Up to sixty Fellows may be elected annually, together with Honorary Fellows and Foreign Members who have made exceptional contributions to engineering. All are elected by their peers for personal achievement of exceptional merit and distinction. Fellows are distinguished by the title Fellow of The Royal Academy of Engineering and use the designatory letters FREng. The Academy was founded in 1976 as The Fellowship of Engineering on the initiative of HRH The Duke of Edinburgh and a group of distinguished engineers. It was granted its Royal Charter in 1983 and, with the consent of HM The Queen, adopted the present title in 1992.

The Royal Academy of Engineering 29 Great Peter Street, Westminster, London SW1P 3LW Telephone: 020 7222 2688 Facsimile: 020 7233 0054 Website: www.raeng.org.uk Registered Charity No. 293074

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Production - The Heart of Organization - TBDDocument14 pagesProduction - The Heart of Organization - TBDSakshi G AwasthiNo ratings yet

- ICSI-Admit-Card (1) - 230531 - 163936Document17 pagesICSI-Admit-Card (1) - 230531 - 163936SanjayNo ratings yet

- Section 26 08 13 - Electrical Systems Prefunctional Checklists and Start-UpsDocument27 pagesSection 26 08 13 - Electrical Systems Prefunctional Checklists and Start-UpsMhya Thu UlunNo ratings yet

- SAS SamplingDocument24 pagesSAS SamplingVaibhav NataNo ratings yet

- Tradingview ShortcutsDocument2 pagesTradingview Shortcutsrprasannaa2002No ratings yet

- ESG NotesDocument16 pagesESG Notesdhairya.h22No ratings yet

- Manual 40ku6092Document228 pagesManual 40ku6092Marius Stefan BerindeNo ratings yet

- TSR KuDocument16 pagesTSR KuAngsaNo ratings yet

- EnerconDocument7 pagesEnerconAlex MarquezNo ratings yet

- The Rise of Populism and The Crisis of Globalization: Brexit, Trump and BeyondDocument11 pagesThe Rise of Populism and The Crisis of Globalization: Brexit, Trump and Beyondalpha fiveNo ratings yet

- Introduction To Motor DrivesDocument24 pagesIntroduction To Motor Drivessukhbat sodnomdorjNo ratings yet

- Reflections On Free MarketDocument394 pagesReflections On Free MarketGRK MurtyNo ratings yet

- P 1 0000 06 (2000) - EngDocument34 pagesP 1 0000 06 (2000) - EngTomas CruzNo ratings yet

- 4109 CPC For ExamDocument380 pages4109 CPC For ExamMMM-2012No ratings yet

- Ishares Core S&P/TSX Capped Composite Index Etf: Key FactsDocument2 pagesIshares Core S&P/TSX Capped Composite Index Etf: Key FactsChrisNo ratings yet

- Expense Tracking - How Do I Spend My MoneyDocument2 pagesExpense Tracking - How Do I Spend My MoneyRenata SánchezNo ratings yet

- Securitron M38 Data SheetDocument1 pageSecuritron M38 Data SheetJMAC SupplyNo ratings yet

- Walmart, Amazon, EbayDocument2 pagesWalmart, Amazon, EbayRELAKU GMAILNo ratings yet

- Newsletter 289Document10 pagesNewsletter 289Henry CitizenNo ratings yet

- Gardner Denver PZ-11revF3Document66 pagesGardner Denver PZ-11revF3Luciano GarridoNo ratings yet

- Reverse Engineering in Rapid PrototypeDocument15 pagesReverse Engineering in Rapid PrototypeChaubey Ajay67% (3)

- MOTOR INSURANCE - Two Wheeler Liability Only SCHEDULEDocument1 pageMOTOR INSURANCE - Two Wheeler Liability Only SCHEDULESuhail V VNo ratings yet

- 5 Deming Principles That Help Healthcare Process ImprovementDocument8 pages5 Deming Principles That Help Healthcare Process Improvementdewi estariNo ratings yet

- Aitt Feb 2017 TH Sem IIIDocument6 pagesAitt Feb 2017 TH Sem IIIMadhu KumarNo ratings yet

- Lab Session 7: Load Flow Analysis Ofa Power System Using Gauss Seidel Method in MatlabDocument7 pagesLab Session 7: Load Flow Analysis Ofa Power System Using Gauss Seidel Method in MatlabHayat AnsariNo ratings yet

- CH 1 India Economy On The Eve of Independence QueDocument4 pagesCH 1 India Economy On The Eve of Independence QueDhruv SinghalNo ratings yet

- 48 Volt Battery ChargerDocument5 pages48 Volt Battery ChargerpradeeepgargNo ratings yet

- Internship ReportDocument46 pagesInternship ReportBilal Ahmad100% (1)

- Address MappingDocument26 pagesAddress MappingLokesh KumarNo ratings yet

- SPH4U Assignment - The Wave Nature of LightDocument2 pagesSPH4U Assignment - The Wave Nature of LightMatthew GreesonNo ratings yet