Professional Documents

Culture Documents

Pile Cap-4 Pile

Uploaded by

cnt_chanddanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pile Cap-4 Pile

Uploaded by

cnt_chanddanCopyright:

Available Formats

6.

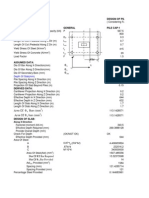

Design of Pile Cap for Normal Case: Height of Tower Base Width of Tower Total Vertical Load (Compression) Total Vertical Load (Uplift) Longitudinal BM Transverse BM HF at top of pile cap Ht of Column Size of column Dia of Pile No of Piles C/c dist between piles in LL dir C/c dist between piles in TT dir Length of Pile cap in LL dir Length of Pile cap in TT dir Depth of Pile cap Section Properties of Pile cap: No of Piles Section Modulus Section Modulus A ZLL ZTT XL 1.000 1.000 -1.000 -1.000 = =( = 4 2 2 XT -1.000 1.000 -1.000 1.000 = = = = = = = = = = = = = = = = 60 4.41253 78.20 -68.66 -5.50 -5.50 -6.12 0.90 0.750 0.40 m m t t tm tm t m x 0.750 m

ty

m 4 2.00 m 2.00 m x x m 1 1 + + 0.4 0.4 x x 2 2 = = 2.80 2.80 m m

2.00 2.00 0.90

x x

1.000 1 P/A 19.55 19.55 19.55 19.55

^2 + ^2x

0 2

0.00

^2 ) x = =

2 4.00 m^3 4.00 m^3

Load on Pile 1 Load on Pile 2 Load on Pile 4 Load on Pile 5

-17.17 -17.17 -17.17 -17.17

ML/ZT * XL -1.38 -1.38 1.38 1.38

Depth of pile

MT/ZL * XT 1.38 -1.38 1.38 -1.38

Total load -17.17 19.55 -19.93 16.79 -14.41 22.31 -17.17 19.55 78.20 = 1.21 t (Comp) (Uplift)

Self wt of pile Max Axial load on Pile Min Axial load on Pile 6.1.1 Bending Moment in Longitudinal direction: Total Upward load from piles Distance from cl of pile to edge of pier Upward Moment at face of pier Self wt of pile cap + soil Downward moment at face of pier Net Upward moment Area of steel required Ast required/m width Min area of tension steel required (As per Cl. 707.2.7 of IRC:78) Area of steel to be provided

= = =

0.785 22.31 16.79

x + +

0.40 1.21 1.21

^2 x = =

2.4

23.52 < t 18.00 > t (As per Geotech Report)

= (From Piles 1& 2) = 1.00 = 36.34 x = = = = = = = 0.90 2.70 22.71 18.74 1508 0.15 x x x / x

0.375 0.63 2.40 2.80 3.97 1.E+07 2.80 1000 x 709 / 100 /( 200 x 0.877 + x 0.30 1.025 x ^2 / 1.80 2

= = = = = = x = = = = =

36.34 t 0.63 m 22.71 tm 2.70 t/m^2 3.97 tm 18.74 tm 709.0 ) 1508 mm^2 539 mm^2 1064 mm^2 1064 mm^2 250 mm^2/m

Min area of steel on other face = (As per Cl. 707.2.8 of IRC:78) Provide 12mm dia bars @ 130mm c/c in longitudinal direction at bottom. (Ast = 870 mm^2) Provide 12mm dia bars @ 130mm c/c in longitudinal direction at top. (Ast = 870 mm^2)

6.1.2 Shear Force in Longitudinal direction: Shear is checked at a distance 'd' from face of pier Effective depth of pile cap Vertical pile reaction = = 0.709 0.000 ( As Effective d 0.709 > 0.625 m)

Hence no shear reinforcement is required. 6.2.1 Bending Moment in Transverse direction: Total Upward load from piles Distance from cl of pile to edge of pier Upward Moment at face of pier Self wt of pile cap + soil Downward moment at face of pier Net Downward moment Area of steel required = (From Pile 1 & 4) = 1.00 = 41.86 x = = = = 0.90 2.70 26.16 22.19 x x x = = = + x 0.3 1.03 x ^2 / 1.80 2 = = = /( 200 x 0.877 x = = x 709 / 100 = = = 41.86 t 0.63 m 26.16 tm 2.70 t/m^2 3.97 tm 22.19 tm 702.0 ) 1803 mm^2 644 mm^2 851 mm^2 851 mm^2 250 mm^2/m

0.375 0.63 2.40 2.80 3.97 1.E+07

Ast required/m width Min area of tension steel required (As per Cl. 707.2.7 of IRC:78) Area of steel to be provided

= = =

1803 0.12

/ x

2.80 1000

Min area of steel on other face = (As per Cl. 707.2.8 of IRC:78) Provide 12mm dia bars @ 125mm c/c in transverse direction at bottom. (Ast = 905 mm^2) Provide 12mm dia bars @ 125mm c/c in longitudinal direction at top. (Ast = 905 mm^2) Shear Force in Transeverse direction: Shear is checked at a distance 'd' from face of pier Effective depth of pile cap Vertical pile reaction = = 0.709 m 0.000 ( As Effective d 0.709 > 0.625 m)

Hence no shear reinforcement is required. 6.3 Check for Two way Shear: Axial load on the pier Effective depth of pile cap Size of pier Size of pile cap at a distance d/2 Perimeter at critical shear section Punching Shear Stress Max Punching Shear Stress = = = = =( = = = 78.20 t

0.709 m 0.75 1.46 1.46 78 0.16 0.16 x x + x x x 0.75 1.46 0.75 1.E+04 fck 30 (Limited to size of clear dimension) ) x / ( 2 4418 x 709 )= = 4.418 m 0.250 N/mm^2

= >

0.880 N/mm^2 0.250

You might also like

- RCC Design Sheets 1Document437 pagesRCC Design Sheets 1Bang JoyNo ratings yet

- Pile Cap - Pedestal - Beam Design - Add-On Ammonia ConverterDocument22 pagesPile Cap - Pedestal - Beam Design - Add-On Ammonia ConverterShuvam SarkarNo ratings yet

- Retaining Wall DesignDocument9 pagesRetaining Wall DesignEngr Benalito A Catap IIINo ratings yet

- Pile Cap Design (4-Piles)Document4 pagesPile Cap Design (4-Piles)Uttam Kumar GhoshNo ratings yet

- Foundation Design SheetDocument12 pagesFoundation Design SheetShridhar BabuNo ratings yet

- Retaining Wall Design CalculationsDocument14 pagesRetaining Wall Design CalculationsMonjit GogoiNo ratings yet

- Foundation Design f1Document2 pagesFoundation Design f1Sampath Kumar KandasamyNo ratings yet

- Axially Loaded FTNG DSNDocument12 pagesAxially Loaded FTNG DSNKanaiyalal N. ShethNo ratings yet

- Job Pile Design-450 (R1)Document3 pagesJob Pile Design-450 (R1)Kyle Foreman100% (1)

- Design of Steel Strcture, Is-800-2007Document48 pagesDesign of Steel Strcture, Is-800-2007srinivasNo ratings yet

- Pilecap Design for 300mm Single PileDocument27 pagesPilecap Design for 300mm Single PileThaung Myint OoNo ratings yet

- Pile Cap ForDocument3 pagesPile Cap ForSunil SinghNo ratings yet

- Admin Block: Pile Cap (3pile Group) Design by Bending Theory To Bs 8110 Part 1Document3 pagesAdmin Block: Pile Cap (3pile Group) Design by Bending Theory To Bs 8110 Part 1Saifulazreen Mahyan100% (1)

- TH - 2 (Floor Slab) : Wall 68.00 500.00 1000.0 50.00 12.00 150.00 2E+5 2E+5 10.98Document2 pagesTH - 2 (Floor Slab) : Wall 68.00 500.00 1000.0 50.00 12.00 150.00 2E+5 2E+5 10.98UjwalaNo ratings yet

- Slab DesignDocument3 pagesSlab DesignMagdy BakryNo ratings yet

- Brick Wall Footing Design-1Document12 pagesBrick Wall Footing Design-1mumarbsc7244No ratings yet

- JSW Severfield Structure Ltd. composite column design EC4Document3 pagesJSW Severfield Structure Ltd. composite column design EC4RonakShahNo ratings yet

- Upgradation and Relocation of Karakorum Highway For Basha Diamer Dam ProjectDocument14 pagesUpgradation and Relocation of Karakorum Highway For Basha Diamer Dam ProjectkuttakhaoNo ratings yet

- Case - 1: DL+CL+LL+CR: Sample Calculation (P10)Document15 pagesCase - 1: DL+CL+LL+CR: Sample Calculation (P10)Srishti Project ConsultantsNo ratings yet

- Design of Two Cell Box StructureDocument15 pagesDesign of Two Cell Box StructureHarish Kumar MahavarNo ratings yet

- IRC Class A and 70R Bending Moment CalculationDocument15 pagesIRC Class A and 70R Bending Moment CalculationTashi TamangNo ratings yet

- Water Tank Design - B-300mmDocument59 pagesWater Tank Design - B-300mmrachana0% (1)

- Corbel DesignDocument2 pagesCorbel Designsidiq7No ratings yet

- Design Two Way Slab ReinforcementDocument5 pagesDesign Two Way Slab ReinforcementVinod RevankarNo ratings yet

- Design of Cantilever Retaining Wall: Preliminary ProportionsDocument6 pagesDesign of Cantilever Retaining Wall: Preliminary ProportionsMuhammed NaseefNo ratings yet

- 3.abutment - WingsDocument12 pages3.abutment - WingsBilal A BarbhuiyaNo ratings yet

- Design of square box culvert and RCC slab bridgeDocument25 pagesDesign of square box culvert and RCC slab bridgeAnonymous cYcLLOmmk80% (1)

- Design of Pile CapDocument3 pagesDesign of Pile Capabhi aroteNo ratings yet

- Analysis and Design of Secondary Crusher House ConnectionsDocument298 pagesAnalysis and Design of Secondary Crusher House Connectionsamitkumar8946No ratings yet

- Crack Width Check for Beam Section as per IS 456-2000Document1 pageCrack Width Check for Beam Section as per IS 456-2000karthikmr85No ratings yet

- SEO Structural Design of Box CulvertsDocument8 pagesSEO Structural Design of Box CulvertscoreteamNo ratings yet

- Design of Pedestal For Seismological Stations: Slenderness Ratio of The ColumnDocument2 pagesDesign of Pedestal For Seismological Stations: Slenderness Ratio of The ColumnAdarsh Kumar SNo ratings yet

- Retaining WallDocument6 pagesRetaining WallRahayu Jati PermanaNo ratings yet

- GLSR Design 11 06 04 1Document7 pagesGLSR Design 11 06 04 1Varad SonawadekarNo ratings yet

- Analysis and Design of Raft Foundation (4 Columns in 1 Foundation Only)Document5 pagesAnalysis and Design of Raft Foundation (4 Columns in 1 Foundation Only)Andro RebuyasNo ratings yet

- Design of underground water tank reinforcement detailsDocument10 pagesDesign of underground water tank reinforcement detailsBiju KolleriNo ratings yet

- RR Masonary Retaing Wall DesignDocument41 pagesRR Masonary Retaing Wall DesignAbhay KumarNo ratings yet

- Stair CaseDocument19 pagesStair CaseVanu VamalaiNo ratings yet

- Design of Retaining Wall HT 6.0 MDocument7 pagesDesign of Retaining Wall HT 6.0 Mkingsuk1980No ratings yet

- DECK SLAB DESIGN CALCULATIONSDocument10 pagesDECK SLAB DESIGN CALCULATIONSdulanbackup1No ratings yet

- Combined footing design 1000 knDocument480 pagesCombined footing design 1000 knAnonymous HJ7hmihhNo ratings yet

- Lacing 1Document1 pageLacing 1Purnima ArkalgudNo ratings yet

- Standard Small OpeningDocument7 pagesStandard Small OpeningPon Chew LengNo ratings yet

- Water TankDocument26 pagesWater Tankabhi aroteNo ratings yet

- Pile Cap of CrystalDocument19 pagesPile Cap of CrystalPriyank MotivarasNo ratings yet

- Pile Cap DesignDocument14 pagesPile Cap DesignSreeraja SreevilasanNo ratings yet

- Pipe Conveyor System To Transport Coal From WCL Coal Mines To Koradi & Khaperkheda TpsDocument36 pagesPipe Conveyor System To Transport Coal From WCL Coal Mines To Koradi & Khaperkheda Tpsஅம்ரு சாந்திவேலு100% (1)

- Base Plate With Shear KeyDocument3 pagesBase Plate With Shear Keyvpjagannaath100% (1)

- Design of PCC toe wall for retaining structureDocument6 pagesDesign of PCC toe wall for retaining structurePrabha KaranNo ratings yet

- Design of Counterfort Retaining Wall (Empty Condition) On D/S)Document18 pagesDesign of Counterfort Retaining Wall (Empty Condition) On D/S)Jeevan HingneNo ratings yet

- Chequred PlateDocument2 pagesChequred PlateKumar Prasanna HNNo ratings yet

- PedestalP2 - (350x350) 7Document23 pagesPedestalP2 - (350x350) 7Feroz Khan PatthanNo ratings yet

- Design of U Type Return Wall - 10.9mDocument15 pagesDesign of U Type Return Wall - 10.9mdipoksinghaNo ratings yet

- Calculation Sheet: 71197 Design For Pile Cap - Two Piles PP DJM MVLDocument3 pagesCalculation Sheet: 71197 Design For Pile Cap - Two Piles PP DJM MVLV.m. RajanNo ratings yet

- Depth of Fixity & Pile DesignDocument2 pagesDepth of Fixity & Pile DesignSoumya BandyopadhyayNo ratings yet

- Isolated FootingDocument59 pagesIsolated Footingsrinivasa raoNo ratings yet

- Abut DesignDocument32 pagesAbut DesignSubir Kunda100% (2)

- Purlin Cleat 220908Document24 pagesPurlin Cleat 220908kalpanaadhi100% (2)

- Combined Gusset Plate DesignDocument3 pagesCombined Gusset Plate Designkalpanaadhi100% (3)

- OHSRDocument48 pagesOHSRsachingadage100% (2)

- Boilers TutorialDocument1 pageBoilers TutorialVaibhaw HirawatNo ratings yet

- Specific Heat CapacityDocument3 pagesSpecific Heat CapacityfidahNo ratings yet

- CavitationDocument3 pagesCavitationTara JenkinsNo ratings yet

- Nitoseal 280Document2 pagesNitoseal 280shanon33No ratings yet

- Attached PubblicazioniDocument9 pagesAttached PubblicazioniAnonymous 0mXnmNRNo ratings yet

- En M Wikipedia OrgDocument37 pagesEn M Wikipedia OrgPalashSharmaMcubeNo ratings yet

- MERKx Ke2Document3 pagesMERKx Ke2TaniaGhinaNo ratings yet

- Straw Bale Is Future House Building MaterialDocument14 pagesStraw Bale Is Future House Building MaterialJcdenaesNo ratings yet

- Prob 1Document2 pagesProb 1abd amoriNo ratings yet

- Chapter 10 - Testing of Welded JointsDocument18 pagesChapter 10 - Testing of Welded JointsFauzan BenraxidNo ratings yet

- L - Nebosh Oil and Gas Possible Exam QuestionsDocument8 pagesL - Nebosh Oil and Gas Possible Exam QuestionsLala Kamarudheen86% (14)

- Furnace GMP100-3 SeriesDocument77 pagesFurnace GMP100-3 SeriesEduardo OrnelasNo ratings yet

- Bridge Inspection and MaintenanceDocument156 pagesBridge Inspection and MaintenanceGovinda Raj100% (1)

- Securope On Standing Seam Roof: Installer ManualDocument20 pagesSecurope On Standing Seam Roof: Installer ManualDpto Ingenieria PROINTENo ratings yet

- C1043-06 (2010) Standard Practice For Guarded-Hot-Plate Design Using Circular Line-Heat SourcesDocument16 pagesC1043-06 (2010) Standard Practice For Guarded-Hot-Plate Design Using Circular Line-Heat SourcesÀngel RodriguezNo ratings yet

- QW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) ExaminationDocument8 pagesQW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) Examinationডঃ শুভম চ্যাটার্জীNo ratings yet

- VPF Rhoss: A Step Forward in The Variable Flow SystemsDocument12 pagesVPF Rhoss: A Step Forward in The Variable Flow Systemsvn_hung3137No ratings yet

- Method Statement Bottom Up Roof Slab Concreting: Page 1 of 10Document10 pagesMethod Statement Bottom Up Roof Slab Concreting: Page 1 of 10J. Kumar Infraprojects LtdNo ratings yet

- 7-1 (Combined Bending and Axial Load)Document10 pages7-1 (Combined Bending and Axial Load)Ruben Ham Caba HizukaNo ratings yet

- Sarnafil Ts 77-15 Er, SitacDocument2 pagesSarnafil Ts 77-15 Er, Sitacamiri hamisNo ratings yet

- A941-13b Standard Terminology Relating To Steel, Stainless Steel, Related Alloys, and FerroalloysDocument8 pagesA941-13b Standard Terminology Relating To Steel, Stainless Steel, Related Alloys, and FerroalloysChuthaNo ratings yet

- Electrical Hazard and PreventionDocument24 pagesElectrical Hazard and PreventionDembelo DagimNo ratings yet

- Sabp Q 005 PDFDocument33 pagesSabp Q 005 PDFAngel Gonzalez AguilarNo ratings yet

- Standard Practice For Selection and Use of Emulsified AsphaltsDocument4 pagesStandard Practice For Selection and Use of Emulsified Asphaltsjun floresNo ratings yet

- Manualul Pentru Incalzire Danfoss - Chapter8Document25 pagesManualul Pentru Incalzire Danfoss - Chapter8valicanNo ratings yet

- Jacobs Zate: Drawing Control 14-Sep-21Document1 pageJacobs Zate: Drawing Control 14-Sep-21WaqarNo ratings yet

- LPI CatDocument31 pagesLPI CatantonyNo ratings yet

- Staircase design calculations for residential buildingDocument9 pagesStaircase design calculations for residential buildingNishan GajurelNo ratings yet

- Footing AsymmetricalDocument20 pagesFooting AsymmetricalRakesh SapkotaNo ratings yet