Professional Documents

Culture Documents

Files 2-Lectures LEC 17 Coulomb-Mohr Theory

Uploaded by

sahooraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Files 2-Lectures LEC 17 Coulomb-Mohr Theory

Uploaded by

sahooraCopyright:

Available Formats

1

ME ME 307 307 MACHINE DESIGN I MACHINE DESIGN I

Dr. A. Aziz Bazoune

King Fahd University of Petroleum & Minerals King Fahd University of Petroleum & Minerals King Fahd University of Petroleum & Minerals King Fahd University of Petroleum & Minerals

Mechanical Engineering Department

Slide #

ME ME 307 307 MACHINE DESIGN I MACHINE DESIGN I

2

Slide #

ME ME 307 307 MACHINE DESIGN I MACHINE DESIGN I

3

FAILURE CRITERIA

Failure Criteria Failure Criteria ( (Static Load Static Load ++Ductile Material Ductile Material) )

66- -66- - Coulomb Mohr Theory for Ductile Materials Coulomb Mohr Theory for Ductile Materials

Not all materials have their tensile strength equal to their

compressive strength. Examples are

Magnesium

Cast Iron

0.5

uc ut

S S =

( )

3 4 S S

Slide #

ME ME 307 307 MACHINE DESIGN I MACHINE DESIGN I

4

Cast Iron

This section deals with materials

( )

3 4

uc ut

S S

uc ut

S S

sy

S

Practical difficulties to

construct 3 Mohr circles

for three tests.

Figure 6-20 Three Mohr

circles, one for the

uniaxial compression

test, one for the test in

pure shear, and one for

Slide #

ME ME 307 307 MACHINE DESIGN I MACHINE DESIGN I

5

pure shear, and one for

the uniaxial tension test

are used to define failure

by the Mohr hypothesis.

The compressive and

tensile strengths,

respectively; they can be

used for yield or ultimate

strength .

Slide #

ME ME 307 307 MACHINE DESIGN I MACHINE DESIGN I

6

Figure 6-20 Three Mohr circles, one for the uniaxial compression test, one

for the test in pure shear, and one for the uniaxial tension test are used to

define failure by the Mohr hypothesis. The compressive and tensile

strengths, respectively; they can be used for yield or ultimate strength

Coulomb Mohr Theory for Ductile Materials Coulomb Mohr Theory for Ductile Materials

1 2 3

Failure will occur if

Mohrs circle (3-D)

describing a state of

Slide #

ME ME 307 307 MACHINE DESIGN I MACHINE DESIGN I

7

describing a state of

stress in a body grows

until it becomes tangent

to the failure envelope.

1 3

1 3

1 0, 0

t c

S S

= >

Coulomb Mohr Theory for Ductile Materials Coulomb Mohr Theory for Ductile Materials

Failure will occur if

1 3

1 3

1 0, 0

t c

S S

= >

Failure criteria

according to

Coulomb-Mohr

Theory

Slide #

ME ME 307 307 MACHINE DESIGN I MACHINE DESIGN I

8

Factor of safety

1 3

1

t c

S S n

=

Special Cases: Application of Coulomb Special Cases: Application of Coulomb- -Mohr for Mohr for

Plane Stress (Failure will occur if Plane Stress (Failure will occur if

Case Case 11: :

A t

S

A B

0

A B

1 2 3

, , 0

A B

= = =

Case Case 22: :

0

A B

1 2 3

, 0,

A B

= = =

Slide #

ME ME 307 307 MACHINE DESIGN I MACHINE DESIGN I

9

0

A B

1 2 3

, 0,

A B

= = =

1

A B

t c

S S

Case Case 33: :

B c

S

0

A B

1 2 3

0, ,

A B

= = =

Slide #

ME ME 307 307 MACHINE DESIGN I MACHINE DESIGN I

10

Factor of safety

1 3

1

t c

S S n

=

For Coulomb-Mohr Theory we do not need the torsional shear

strength circle, we can deduce it from Eq.(6-22). For pure

shear .

The torsional yield strength occurs when

1 3

, = =

Slide #

ME ME 307 307 MACHINE DESIGN I MACHINE DESIGN I

11

The torsional yield strength occurs when

For yielding, Eq. (6-22) gives

y t y c

s y

y t y c

S S

S

S S

=

+

max sy

S =

Example Example 66- -2 2 ( (Textbook Page Textbook Page 268 268) )

Slide #

ME ME 307 307 MACHINE DESIGN I MACHINE DESIGN I

12

Slide #

ME ME 307 307 MACHINE DESIGN I MACHINE DESIGN I

13

66- -7 7 Failure of Ductile Materials Summary Failure of Ductile Materials Summary

This study is limited

materials and parts

that are known to

fail in a ductile

manner.

Experimental data

Slide #

ME ME 307 307 MACHINE DESIGN I MACHINE DESIGN I

14

Experimental data

collected for several

materials from many

sources are shown in

Figure 6-23.

Figure 6-23

Experimental data

superposed on failure

theories

66- -7 7 Failure of Ductile Materials Summary Failure of Ductile Materials Summary

Figure 6-23 shows that either the Maximum Shear Stress

Theory (MSS) or the Distortion Energy Theory (DE) is acceptable

for design and analysis of materials that would fail in a ductile

manner.

The selection of one or the other of these theories is something

Slide #

ME ME 307 307 MACHINE DESIGN I MACHINE DESIGN I

15

The selection of one or the other of these theories is something

that you, the engineer, MUST DECIDE.

66- -7 7 Failure of Ductile Materials Summary Failure of Ductile Materials Summary

For Design Purposes:

Maximum Shear Stress (MSS) Theory is

easy

quick to use

conservative

Slide #

ME ME 307 307 MACHINE DESIGN I MACHINE DESIGN I

16

If the problem is to learn why a part failed, then the

Distortion Energy (DE) Theory may be best to use. Figure 6-23

shows that the locus of the DE passes closer to the central area

of the data points, and thus is generally a better predictor of

failure.

66- -7 7 Failure of Ductile Materials Summary Failure of Ductile Materials Summary

For ductile materials with , the Mohr Theory is the

best available. However, the theory requires the results from

three separate modes of tests, graphical construction of the

failure locus, and fitting the largest Mohrs circle to the failure

locus.

yt yc

S S

Slide #

ME ME 307 307 MACHINE DESIGN I MACHINE DESIGN I

17

Coulomb-Mohr Theory (CM) which requires only tensile and

compressive yield strengths and represents an alternative to

Mohr Theory. It is easily dealt with in equation form.

Example Example 66- -33

A certain force F applied at D near

the end of the 15-in lever shown

in Fig. 6-24, which is quite similar

to a socket wrench, results in

certain stresses in the

cantilevered bar OABC. The bar

OABC is of AISI 1035 steel, forged

and heat treated so that it has a

Slide #

ME ME 307 307 MACHINE DESIGN I MACHINE DESIGN I

18

and heat treated so that it has a

minimum (ASTM) yield strength of

81 Kpsi. We presume that this

component would be of no value

after yielding. Thus the force F

required to initiate yielding can

be regarded as the strength of the

component part. Find this force.

Figure. 6-24

Example Example 66- -3 3 (Cont. d) (Cont. d)

Assuming lever DC strong enough

( )

( )

( )

( )

( )

( )

( )

( )

3 4 3

3 4 3

2 32 14

32

142.6

64

1

2 16 15

16

76.4

32

x

zx

M d F

Mc M

F

I d d

T d F

Tr T

F

J d d

= = = = =

= = = = =

Slide #

ME ME 307 307 MACHINE DESIGN I MACHINE DESIGN I

19

( )

( )

3 4 3

76.4

32

1

zx

F

J d d

= = = = =

Using the DE theory, we find, from Eq. (6-15)

Equating the Von Mises stress to , we solve for and get

( )

( ) ( )

1 2

1 2

2 2

' 2 2

3 142.6 3 76.4 194.5

x zx

F F F

(

= + = + =

y

S

81, 000

416

194.5 194.5

lbf

y

S

F = = =

F

Example Example 66- -3 3 (Cont. d) (Cont. d)

In this example the strength of the material point A is . The strength

of the assembly or component is .

Using the MMS Theory, for a point undergoing plane stress with only one non-zero

normal stress and one shear stress, the two nonzero principal stresses and

will have opposite signs and hence fit case 2 for the MSS Theory. From Eq. (4-13)

( )

1 2

2

(

| |

81kpsi

y

S =

416 lbf F =

A

Slide #

ME ME 307 307 MACHINE DESIGN I MACHINE DESIGN I

20

case 2 for the MSS Theory, Eq. (6-5) applies and hence

( )

2

1 2

2 2 2

2 4

2

x

A B zx x zx

(

| |

= + = +

(

|

\

(

( )

( ) ( )

1 2

2 2

1 2

2 2

4

142.6 4 76.4 209 81, 000

388lbf

x zx y

S

F F F

F

+ =

(

+ = =

=

Example Example 66- -4 4 ( (Textbook Page Textbook Page 271 271) )

The cantilever tube shown in

Fig. 6-25 is to be made of

2014 aluminum alloy treated

to obtain a specified minimum

yield strength of 276 MPa. We

wish to select a stock-size

tube from Table A-8 using a

Slide #

ME ME 307 307 MACHINE DESIGN I MACHINE DESIGN I

21

tube from Table A-8 using a

design factor . The

bending load is F=1.75 kN, the

axial tension is P = 9.0 kN, and

the torsion is T = 72 N.m.

What is the realized factor of

safety?

4

d

n =

Figure 6-25

Example Example 66- -4 4 ( (Textbook Page Textbook Page 271 271) )

( )( )

120 1.75 2

9 9 105

o

o

x

d

P Mc d

A I A I A I

= + = + = +

SOLUTION

The normal stress for an element on the top surface of the tube at the origin is

(1)

Slide #

ME ME 307 307 MACHINE DESIGN I MACHINE DESIGN I

22

The torsional stress at the same point is

( ) ( )

72 2 36

o o

zx

d d

Tr

J J J

= = =

(2)

Example Example 66- -4 4 ( (Cont.d Cont.d) )

0.276

S

For accuracy, we choose the DE as the design basis. The Von Mises stress is

(3)

( )

1 2

2 2

' 3

x zx

= +

On the basis of the given design factor, the goal for is

'

Slide #

ME ME 307 307 MACHINE DESIGN I MACHINE DESIGN I

23

ME ME 307 307 MACHINE DESIGN I MACHINE DESIGN I

23

0.276

' 0.0690

4

GPa

y

d

S

n

= =

Programming Using MATLAB or EXCEL , entering metric sizes from Table A-8 reveals

that a 42-X 5- mm is satisfactory. The Von Mises stress is found to be

for this size. Thus the realized factor of safety is

(4)

' 0.06043 GPa =

0.276

4.57

' 0.06043

y

S

n

= = =

You might also like

- Intersection Geometry, DrawingDocument21 pagesIntersection Geometry, DrawingArnela HodzicNo ratings yet

- M4336Document14 pagesM4336sahooraNo ratings yet

- Zielke E521 ProjectDocument44 pagesZielke E521 ProjectsahooraNo ratings yet

- 8Document85 pages8sahooraNo ratings yet

- SPE CyclicDocument16 pagesSPE CyclicsahooraNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Week 1 Familiarize The VmgoDocument10 pagesWeek 1 Familiarize The VmgoHizzel De CastroNo ratings yet

- Solid Waste Management in The World's Cities, UN-HABITAT: January 2010Document17 pagesSolid Waste Management in The World's Cities, UN-HABITAT: January 2010Rajasri SNo ratings yet

- (Bruno Bettelheim) Symbolic Wounds Puberty RitesDocument196 pages(Bruno Bettelheim) Symbolic Wounds Puberty RitesAmbrose66No ratings yet

- Lab 1Document51 pagesLab 1aliNo ratings yet

- Performance Task 2Document3 pagesPerformance Task 2Edrose WycocoNo ratings yet

- Case Study McsDocument4 pagesCase Study McsManjushree PatilNo ratings yet

- Essay On Stem CellsDocument4 pagesEssay On Stem CellsAdrien G. S. WaldNo ratings yet

- KM170, KM171, KM172, F3A21, F3A22: 3 SPEED FWD (Lock Up & Non Lock Up)Document4 pagesKM170, KM171, KM172, F3A21, F3A22: 3 SPEED FWD (Lock Up & Non Lock Up)krzysiek1975No ratings yet

- Monster Hunter: World - Canteen IngredientsDocument5 pagesMonster Hunter: World - Canteen IngredientsSong HoeNo ratings yet

- Construction Claims and Contract Admin CPDDocument40 pagesConstruction Claims and Contract Admin CPDCraig FawcettNo ratings yet

- CLT Apllications NewestDocument49 pagesCLT Apllications NewestMackBrideNo ratings yet

- Swiss Army Triplet 1Document2 pagesSwiss Army Triplet 1johnpwayNo ratings yet

- 835 (Health Care Claim PaymentAdvice) - HIPAA TR3 GuideDocument306 pages835 (Health Care Claim PaymentAdvice) - HIPAA TR3 Guideअरूण शर्माNo ratings yet

- WoundVite®, The #1 Most Comprehensive Wound, Scar and Post-Surgical Repair Formula Receives Amazon's Choice High RatingsDocument3 pagesWoundVite®, The #1 Most Comprehensive Wound, Scar and Post-Surgical Repair Formula Receives Amazon's Choice High RatingsPR.comNo ratings yet

- Final Lesson PlanDocument3 pagesFinal Lesson Planapi-510713019No ratings yet

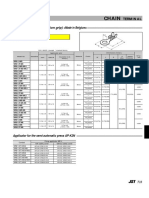

- Chain: SRB Series (With Insulation Grip)Document1 pageChain: SRB Series (With Insulation Grip)shankarNo ratings yet

- Oral Communication in ContextDocument19 pagesOral Communication in ContextAzory ZelleNo ratings yet

- Technical Rockwell Automation FactoryTalk HistorianDocument6 pagesTechnical Rockwell Automation FactoryTalk HistorianAmit MishraNo ratings yet

- Chapter 6 Strategy Analysis and Choice: Strategic Management: A Competitive Advantage Approach, 16e (David)Document27 pagesChapter 6 Strategy Analysis and Choice: Strategic Management: A Competitive Advantage Approach, 16e (David)Masum ZamanNo ratings yet

- Ishrana Studenata I Nastavnika Visoke Škole U Subotici Tokom Pandemije COVID-19Document4 pagesIshrana Studenata I Nastavnika Visoke Škole U Subotici Tokom Pandemije COVID-19DejanNo ratings yet

- Hand Winches 122 Load Sheaves 126 Gear-And Worm Gear Winches 127 Electric Worm Gear Winches 131 Snatch Blocks 133Document14 pagesHand Winches 122 Load Sheaves 126 Gear-And Worm Gear Winches 127 Electric Worm Gear Winches 131 Snatch Blocks 133Rajaram JayaramanNo ratings yet

- Masking Conventional Metallic Cast Post For Enhancing EstheticsDocument5 pagesMasking Conventional Metallic Cast Post For Enhancing EstheticsleilyanisariNo ratings yet

- A-1660 11TH Trimester From Mcdowell To Vodafone Interpretation of Tax Law in Cases. OriginalDocument18 pagesA-1660 11TH Trimester From Mcdowell To Vodafone Interpretation of Tax Law in Cases. OriginalPrasun TiwariNo ratings yet

- Unit 3: Theories and Principles in The Use and Design of Technology Driven Learning LessonsDocument5 pagesUnit 3: Theories and Principles in The Use and Design of Technology Driven Learning Lessons서재배No ratings yet

- The Limits of The Sectarian Narrative in YemenDocument19 pagesThe Limits of The Sectarian Narrative in Yemenهادي قبيسيNo ratings yet

- On The Wings of EcstasyDocument79 pagesOn The Wings of Ecstasygaya3mageshNo ratings yet

- 12 Logarithm Approximate FloatingDocument6 pages12 Logarithm Approximate FloatingPhilippe Englert VelhaNo ratings yet

- Earth Science NAME - DATEDocument3 pagesEarth Science NAME - DATEArlene CalataNo ratings yet

- IoT Security Checklist Web 10 17 r1Document39 pagesIoT Security Checklist Web 10 17 r1SubinNo ratings yet

- 8 Adam AmuraroDocument28 pages8 Adam Amurarokmeena73No ratings yet