Professional Documents

Culture Documents

Voltage Fluctuation Limits

Uploaded by

Electromacnetist ElectrodOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Voltage Fluctuation Limits

Uploaded by

Electromacnetist ElectrodCopyright:

Available Formats

Engineering Recommendation No.

7 of the Electricity Distribution Code

Limits for Voltage Fluctuations in the Electricity Supply System.

Version 1.0 30th November 2005

Prepared by: Al Ain Distribution Company, Abu Dhabi Distribution Company, Abu Dhabi Supply Company for Remote Areas (RASCO) Approved by: Regulation and Supervision Bureau for the Water and Electricity Sector of the Emirate of Abu Dhabi

[Eng Rec No. 7 - Voltage Fluctuations v1.0a]

Page 1 of 16

CONTENTS

1.0 Preface 2.0 Definitions 3.0 Introduction 3.1 3.2 3.3 3.4 Assessment Process Basis Of Limits Influence Of System Impedance On Voltage Fluctuations The Combination Of Disturbances From Various Sources.

4 4 5 5 6 6 7 7 7 7 8 9 9 9 9 10 10 14 14 14 15 16

4.0 Stage 1 Assessment 4.1 Household Appliances And Similar Equipment <16a Per Phase Conforming To Bs5406 Part 3. 4.2 Special Consents (Stage 1 Procedure) 4.3 Electric Motors 5.0 Stage 2 Assessment 5.1 General 5.2 Stage 2 Assessment Techniques 5.2.1 Software Simulation 5.2.2 Memory-Time Calculation Method 5.2.3 Flicker Meter Method 6.0 Stage 3 Assessment 6.1 Stage 3 Limits 6.2 Special Considerations Under Stage 3 7.0 Summary 8.0 References

[Eng Rec No. 7 - Voltage Fluctuations v1.0a]

Page 2 of 16

1.0

PREFACE

This document has been prepared in accordance with the Electricity Distribution Code and forms part of Annex 1 of the Code. It applies to all Users of the Electricity Distribution System. The purpose of this document is to define limits for voltage fluctuations that can be permitted from customers equipment such that these do not cause nuisance to other nearby customers. Typical equipment that is likely to cause voltage fluctuations are large motors, heating loads and furnaces. This document also outlines a 3 stage assessment process which should be used by Distribution Companies to assess the potential impact of disturbing loads prior to allowing connections to the distribution system. The technical limits contained within this Engineering Recommendation are based on document P28 issued by the Energy Networks Association in the UK.

2.0

DEFINITIONS

For the purpose of this Engineering Recommendation the following definitions apply. All other definitions are as stated in the Electricity Distribution Code. Voltage Change: A single variation of the rms value or the peak value of the supply voltage (unspecified with respect to form and duration). Voltage Fluctuation: A series of voltage changes which may be regular or irregular. [Note: a single variation or a series of variations of 10% or more of the rms voltage are termed voltage dips]. Flicker: Impression of fluctuating luminance occurring when the supply to an electrically powered light source is subjected to voltage fluctuation. Flicker meter: An instrument meeting the specification of IEC 868 which gives a measure of the visual severity of the flicker that would be caused by voltage fluctuations when applied to a 60W 230V tungsten filament lamp. The output of such a meter is termed the flicker visibility and is calibrated such that 1 unit represents marginal flicker to 50% of observers. Short Term Severity Value Pst: A measure of the visual severity of flicker derived from the time series output of a flicker meter over a 10 minute period; this provides an indication of the risk of customer complaints. Its calibration is such that Pst =1 for any point on the limit curve of BS 5406 part 3 (fig. 4A) for rectangular voltage changes of magnitude less than 3%. Long Term Severity Value Plt: A value derived from the short term severity values, Pst, in accordance with the following formula:

[Eng Rec No. 7 - Voltage Fluctuations v1.0a]

Page 3 of 16

Plt =

1 n

(P

j =1

j =n

stj

)3

Where n = number of Pst values in the time over which Plt is evaluated. (in this recommendation a period of 2 hours is used i.e. n = 12)

PCC (Point of common Coupling): the point on an Electricity Distribution Companys system electrically nearest to a customers installation at which other customers loads are, or may be connected.

3.0 3.1

INTRODUCTION Assessment process

In order to assess potential voltage fluctuations caused by new loads this Engineering Recommendation uses a three stage approach whereby defined types of small loads, unlikely to cause problems, can be connected without detailed assessment and more complex loads are assessed in detail. This approach aims to minimise the cost and time required for assessment both for the Distribution Company and the Customer. Stage 1 assessment and limits relate to smaller sizes of equipment which can be connected to defined parts of the supply system without individual consideration of flicker effects. Stage 2 assessment and limits relate to the acceptance of new disturbing loads which are likely to cause a short term flicker severity of Pst 0.5. There is no requirement to check existing back ground flicker severity at the PCC. Stage 3 assessment and limits apply to new disturbing loads where limits under stage 2 are exceeded. A full assessment of existing and projected flicker severity is required. Background levels are included in the assessment and the resulting flicker severity must be less than the stage 3 limits. Where it is shown that the expected flicker severity due to a new load will exceed the recommended upper limits, remedial action can take the form of changes in the system arrangement so as to vary the short circuit level, or changing the PCC with other customers. Alternatively, for some types of distribution loads, compensation equipment can be installed so as to limit the resultant voltage fluctuation to an agreed acceptable value. The extra cost of such remedial action should be borne by the customer owning the new load concerned.

[Eng Rec No. 7 - Voltage Fluctuations v1.0a]

Page 4 of 16

3.2

Basis of Limits

The limits used in this Engineering Recommendation have been set to allow the maximum utilization of the supply systems capacity to accept fluctuating loads without an excessive risk of causing nuisance or other adverse affects to customers. Tungsten filaments lamps have historically been taken as a reference for flicker that is noticeable to the human eye and this recommendation uses limits based on this phenomena. The affect of flicker on fluorescent and other types of discharge lighting has not been studied in detail but it is expected that problems will not occur if flicker levels are kept within the limits of this Engineering Recommendation. A 3% general limit on the allowable magnitude of voltage changes, regardless of shape, caused by fluctuating loads has been adopted even though voltage changes in excess of 3%, if of sufficiently low frequency, may not give rise to flicker severity levels (Pst) in excess of the limits in this recommendation. In certain cases where special circumstances apply, the DISCO may at its discretion, allow larger voltage changes to occur, e.g. continues process plant where the larger motors are only started once in several months. Such cases must be reported to the Bureau.

3.3

Influence of system impedance on voltage fluctuations

Some parts of this recommendation require knowledge of the system impedance in order to calculate the magnitude of voltage changes or the severity values at the PCC. The fault level provides a readily available measure of the system impedance through which the fluctuating load is supplied and enables an estimate to be made of the voltage fluctuation resulting from load variations. In estimating the voltage fluctuation which will be imposed on the supply to other customers, only the conditions from the supply source up to the PCC need be taken into account. For a balanced 3-phase systems the voltage drop at the PCC can be defined as:

Vdrop =

Where: and

m .100% 1000 S

S is the short circuit level in MVA m is the load change in KVA.

It will be noted that this expression implicitly assumes that the power factor of the load is equal to the resistance / impedance ratio of the source

[Eng Rec No. 7 - Voltage Fluctuations v1.0a]

Page 5 of 16

impedance up to the PCC. This is the worst possible condition. Appendices B and C of the UK document P28 give examples of a more accurate calculation of voltage changes for cases where this may be required.

3.4

The combination of disturbances from various sources.

It has been shown by experience that the cumulative affect of several flicker producing loads is normally limited by the diversity experienced between customer loads and the timing of actual flicker events (i.e. it is unlikely for short flicker events to occur at the same instant from two unrelated loads). In general the limits used in this Engineering Recommendation allow for the possibility of other flicker producing loads being introduced after a new load has been assessed and accepted. Where there is concern that 2 or more flicker producing loads may be directly additive the method described in Appendix A of P28 should be used to derive an overall flicker severity value Pst. An example of such a situation could be where two adjacent factories are using electric furnaces or other large equipment with the same operating characteristics and running times.

4.0 4.1

STAGE 1 ASSESMENT Household appliances and similar equipment <16A per phase conforming to BS5406 part 3.

Household appliances and similar equipment with an input current of <16A per phase may be connected without reference to the DISCO if they conform to BS 5406 part 3. This standard defines a limit curve of the magnitude of step voltage changes against time between occurrences for automatically controlled household and similar appliances when measured against a phase-neutral loop impedance of 0.4 + j0.25 ohm or 3-phase impedance of 0.24 + j0.15 ohm per phase . Although the scope of BS 5406 is limited to household and similar equipment it is recommended that all equipment with rated input current of <16A should be assessed using the procedure from BS 5406.

4.2

Special consents (stage 1 procedure)

Certain types of equipment which are outside the scope of BS 5406 such as, electric heaters, boilers, heat pumps, shower units etc or equipment rated above 16A per phase may be given special consent by the DISCO. This allows for common types of high capacity equipment which are unlikely to cause voltage fluctuations to be connected without detailed assessment but these must be specified by the DISCO. Where the DISCO has not identified any equipment types for which a special consent has been provided then all

[Eng Rec No. 7 - Voltage Fluctuations v1.0a]

Page 6 of 16

loads/equipment not covered by item 4.1 above must be assessed under the stage 2 procedure.

4.3

Electric Motors

The following types of direct-on-line LV Motors, which are small enough to be unlikely to cause flicker problems, can be connected under stage 1 without detailed assessment. (a) Frequent starting (less than 1 minute intervals)

Type

Normal rating expressed in terms of either: Output kW Input kVA 1.0 3.0 4.0

Single phase 230V Single phase 480V 3 phase 400V

0.37 1.50 2.25

(a) Infrequent starting (more than 1 minute intervals)

Type

Normal rating expressed in terms of either: Output kW Input kVA 1.7 4.5 6.0

Single phase 230V Single phase 480V 3 phase 400V

0.75 3.0 4.5

[Eng Rec No. 7 - Voltage Fluctuations v1.0a]

Page 7 of 16

5.0 5.1

STAGE 2 ASSESSMENT General

It is anticipated that the majority of applications to connect loads which do not come under the Stage 1 procedure will be evaluated using the procedure explained in this section. The procedure is applicable to most equipment which causes step voltage changes as shown in figure 1 or ramp voltage changes as shown in figure 2 or simple combinations of these two types. Stage 2 also covers the forms of voltage changes caused by motor starting as shown in figure 3. It should be noted that short transients caused by motor starting (i.e. less that 30ms) are not considered to be a voltage fluctuation and are therefore ignored (see figure 3). Under the Stage 2 procedure, individual loads which cause a short term flicker severity Pst 0.5 when assessed using the applicable supply impedance at the PCC can be connected without further assessment. Figure 4 gives limits for the size and time between step voltage changes such that all points on or below the curve have a short term severity value of Pst 0.5. Since ramp voltage changes are less noticeable in terms of flicker than step voltage changes of the same size, figure 5 provides a simple means of converting the time between ramp voltage changes into the equivalent time between step voltage changes of the same size. The limit of Pst 0.5 which is used for Stage 2 does not represent the maximum tolerable flicker severity for the supply system but is a value which generally allows individual items of equipment which comply to be connected without the need for on site measurement of flicker severity. The limit takes into account the possibility of other loads contributing additional flicker levels at the PCC as discussed under 3.4 above.

5.2

Stage 2 assessment techniques

Under the Stage 2 procedure no on-site measurement of the flicker severity at the PCC is necessary. However an assessment of the expected flicker must be made, either by software simulation, by calculation or by measurement, described as follows: 5.2.1 Software simulation

Under this procedure the pattern of voltage changes caused by the load is calculated using the expected load profile characteristic and the system impedance value at the PCC. A suitable software programme from those commercially available is then used to convert the typical voltage change pattern expected from the load into corresponding values of flicker severity Pst. The resulting value should be 0.5.

[Eng Rec No. 7 - Voltage Fluctuations v1.0a]

Page 8 of 16

5.2.2

Memory-time calculation method

For simple combinations of step and/or ramp type voltage changes the short term flicker severity can be calculated by observing the worst 10 minute operating period of a fluctuating load and calculating as follows: (a) from figure 4 read the minimum time interval allowed for each voltage change over the worst 10 minute of the load cycle. E.g. a step voltage change of 1% would be allowed every 20 seconds; a ramp voltage change of 2%, with a 0.5 second width would be allowed every 8.8sec (200sec x 0.044 ramp factor from figure 5). (b) Take the sum of the allowed times for all the voltage changes within the worst 10 minutes of the load cycle (28.8 sec in the above example). (c) If the actual load cycle is longer than the time calculated in (b) above then the connection is allowed.

5.2.3

Flicker meter method

If the load to be investigated is already installed or can be supplied temporarily then a flicker meter can be used to monitor the actual voltage fluctuation over a period of time. The flicker meter should be calibrated according to IEC868 and the measured value of Pst should be 0.5. If the flicker meter is used at a test location the values can be transferred to another location (e.g. final location of the equipment) by using the following formula:

Pst1 = Pst 0 .

where:

VD1 VD 0

VD0 = magnitude of voltage change where Pst0 was measured VD1 = magnitude of voltage changes caused by the same load

at the location where Pst1 is required

[Eng Rec No. 7 - Voltage Fluctuations v1.0a]

Page 9 of 16

Figure 1: Step voltage change

Voltage

Voltage change VD

Time

Figure 2: Ramp voltage change

Voltage change VD Voltage

Fall time Time

Figure 3: typical voltage change due to motor starting

= 30 ms

Voltage

Voltage change VD

Short transient

Time

Note: short transient is ignored for assessment of voltage fluctuation due to motor starting.

[Eng Rec No. 7 - Voltage Fluctuations v1.0a]

Page 10 of 16

Figure 4 RECOMMENDED TIME LIMIT FOR THE SIZE OF STEP VOLTAGE CHANGES WITH RESPECT TO THE TIME BETWEEN CHANGES 4.0

3.0

2.0

1.5

SIZE OF VOLTAGE CHANGE (%)

1.0

0.8

0.6

0.4

0.3

0.2

0.15 0.02 0.05 0.1 0.2 0.5 1 2 5 10 20 50 100 200 500 1000

TIME BETWEEN EACH CHANGE (seconds)

[Eng Rec No. 7 - Voltage Fluctuations v1.0a]

Page 11 of 16

Figure 5 MULTIPLICATION FACTOR FOR DERIVING THE MAXIMUM TIME BETWEEN RAMP TYPE VOLTAGE CHANGES FROM THE STEP CHANGE LIMITS IN FIGURE 4 1.0 0.8 0.7 0.6 0.5 0.4

0.3 TIME MULTIPLICATION FACTOR

0.2

0.1 0.08 0.06 0.05 0.04 0.03

0.02

0.01 0.03 0.04 0.06 0.08 0.1 0.2 0.3 0.4 0.6 0.8 1.0 2.0

RISE / FALL TIME (seconds) Minimum time between voltage changes = TIME (from figure 4) x TIME MULTIPLICATION FACTOR

[Eng Rec No. 7 - Voltage Fluctuations v1.0a]

Page 12 of 16

6.0 6.1

STAGE 3 ASSESSMENT Stage 3 limits

Where expected voltage fluctuations exceed Stage 1 and 2 levels, it may still be possible to connect the load after a detailed analysis of existing severity levels and an assessment of the additional effects of the new and future load. Information should first be obtained on the level of background flicker using a flicker meter during the times the proposed load is likely to be in operation. The short term severity values (Pst) of the new load should be found either from known values derived from previous tests, from scaled characteristics of similar loads or by using a flicker meter simulation program which can derive Pst from given theoretical or measured voltage change patterns (see methods described for stage 2 section 5.2). The Pst values of the new load (and any known future load) should then be superimposed on the background Pst values using the method given in Appendix A of the UK document P28. The resultant long term severity values, Plt may then be calculated (see definitions for formula). The limits for both Pst and Plt in Table 1 should not be exceeded.

Table 1: Stage 3 limits for Short Term Severity Values Pst and Long Term Severity Values Plt

Supply System Voltage at PCC

Pst Absolute Maximum Value

Plt (integrated value in any two hours) 0.8

132 kV and below

1.0

6.2

Special considerations under stage 3

The following points should be noted regarding the application of Table 1 in any stage 3 assessment: (a) The limits of table 1 apply to any point on the distribution system (up to 132kV) but the flicker measurements should be taken at the point where they are likely to be most severe. This would normally be at the PCC with other customers. However, where the PCC is at 33kV or above it may be the case that flicker levels are highest on a lower voltage part of the network and this possibility should also be checked.

[Eng Rec No. 7 - Voltage Fluctuations v1.0a]

Page 13 of 16

(b) Attention is drawn to section 3.3 which explains the system impedance to be used in assessing Pst and Plt. In particular due consideration should be given to the higher system impedance occurring during abnormal network running arrangements or outage conditions; such conditions may give rise to flicker levels above those predicted / measured for normal network conditions. (c) Since lighting is generally connected as single phase, and is the type of load most prone to flicker, the assessment of flicker levels should be made for all phases. (d) Assessment using a flicker meter should be over a sufficient period of time to capture the worst 2 hours of a load operating cycle. If the equipment is not connected to a clean flicker free supply then the level of background flicker should be deducted using the method in Appendix A of the UK document P28. (e) Where a load is assessed to have flicker values close to the limits of table 1 the local network should be regularly monitored by the DISCO (e.g. every year). This will ensure that other fluctuating loads are not connected to the same PCC in the future so as to cause the overall flicker levels to rise above the limits of Table 1. It is also recommended for loads assessed under stage 3 to be kept in a record by the DISCO.

7.0

SUMMARY

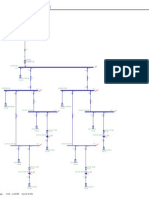

The following diagram summarises the assessment process described in the preceding sections:

[Eng Rec No. 7 - Voltage Fluctuations v1.0a]

Page 14 of 16

Figure 5: flow diagram of voltage fluctuations assessment procedure

Start

KEY: Plt Pst

- long term flicker severity - short term flicker severity

Stage 1

Stage 2

Stage 3

Rated load <16A

NO

Small motor complying with 4.3 YES

NO

Subject to special consent from DISCO YES

NO

Assess predicted flicker levels according to 5.2

DISCO determines background levels

YES

5.2.1 software simulation Complies with BS5406

5.2.2 memory-time method

5.2.3 flicker meter method

Find Pst for load as in stage 2 (5.2)

NO Is Pst less than or equal to 0.5 YES NO

YES

Combine Pst for load with background levels

Calculate Plt

Pst and Plt less than stage 3 limits (table 1)

NO

YES Connect to network

No Connection possible without mitigation

[Eng Rec No. 7 - Voltage Fluctuations v1.0a]

Page 15 of 16

8.0

REFERENCES

1. The Electricity Distribution Code Version 3.0 [2005] 2. BS 5406 [1988]: Disturbances in Supply Systems Caused by Household Appliances and Similar Equipment (3 parts) British Standards Institute, UK [Note: this document is also published as: IEC 555] 3. IEC 868 [1985]: Flicker meter Functional Design and Specifications International Eurotechnical Commission. 4. P28 [1989]: Planning Limits for Voltage Fluctuations caused by Domestic, Industrial and Commercial Equipment in the UK Energy Networks Association1, UK

1: the Energy Network Association was previously known as the Electricity Association. All documents issued by EA have now been re-labeled under the ENA, but keeping the same document number. These can be purchased online from www.energynetworks.org.

[Eng Rec No. 7 - Voltage Fluctuations v1.0a]

Page 16 of 16

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Calculation of Short-Circuit CurrentsDocument35 pagesCalculation of Short-Circuit CurrentsdaodoquangNo ratings yet

- Calculation of Short-Circuit CurrentsDocument35 pagesCalculation of Short-Circuit CurrentsdaodoquangNo ratings yet

- FLD 14Document32 pagesFLD 14guest100% (1)

- Corporate Corona Competence: True Output Power DisplayDocument2 pagesCorporate Corona Competence: True Output Power DisplaySantosh Kadam100% (1)

- Electrical Systems Transfer Function ModelsDocument58 pagesElectrical Systems Transfer Function ModelsNoor Ahmed86% (7)

- RE - 615 - Oper - 756708 - ENm 146 PDFDocument1 pageRE - 615 - Oper - 756708 - ENm 146 PDFElectromacnetist ElectrodNo ratings yet

- OBSTRUCTION LIGHT CONTROLDocument1 pageOBSTRUCTION LIGHT CONTROLElectromacnetist ElectrodNo ratings yet

- BELLUS Kunsiri เครื่องใช้ไฟฟ้าDocument4 pagesBELLUS Kunsiri เครื่องใช้ไฟฟ้าElectromacnetist ElectrodNo ratings yet

- Section 8 Commissioning: Block Name and PressDocument1 pageSection 8 Commissioning: Block Name and PressElectromacnetist ElectrodNo ratings yet

- Appendix ExtractDocument59 pagesAppendix ExtractElectromacnetist ElectrodNo ratings yet

- One-Line Diagram - Olv1 (DC Load Flow Analysis) : Dummy Source 1 Mvasc Dummy Source 1 MvascDocument1 pageOne-Line Diagram - Olv1 (DC Load Flow Analysis) : Dummy Source 1 Mvasc Dummy Source 1 MvascElectromacnetist ElectrodNo ratings yet

- OTI OverviewDocument42 pagesOTI OverviewHimdad TahirNo ratings yet

- 18 - Ground GridDocument27 pages18 - Ground GridElectromacnetist ElectrodNo ratings yet

- Oc Concept 1Document42 pagesOc Concept 1Electromacnetist ElectrodNo ratings yet

- Basler Transformer Protection Application Guide PDFDocument33 pagesBasler Transformer Protection Application Guide PDFAbrakain69No ratings yet

- MANUAL ภาษาไทย Fire Pump With Firetrol ControllerDocument50 pagesMANUAL ภาษาไทย Fire Pump With Firetrol ControllerElectromacnetist ElectrodNo ratings yet

- Spark Gaps: Dehn (Uk) LTDDocument8 pagesSpark Gaps: Dehn (Uk) LTDElectromacnetist ElectrodNo ratings yet

- The Age of ReasonDocument102 pagesThe Age of ReasonbomcdreamyNo ratings yet

- 21 Spec Ls CV N 13 0 6!1kv Xlpe LSHF (N)Document7 pages21 Spec Ls CV N 13 0 6!1kv Xlpe LSHF (N)Electromacnetist ElectrodNo ratings yet

- NEC and ATEXDocument8 pagesNEC and ATEXRobin ZwartNo ratings yet

- GE Multilin Relay Selection GuideDocument40 pagesGE Multilin Relay Selection GuideSaravanan Natarajan100% (1)

- GUWA DatasheetDocument5 pagesGUWA DatasheetElectromacnetist ElectrodNo ratings yet

- SMCC (Thailand) CO., LTDDocument7 pagesSMCC (Thailand) CO., LTDElectromacnetist ElectrodNo ratings yet

- Balanced Three-Phase Circuits: Assessment ProblemsDocument35 pagesBalanced Three-Phase Circuits: Assessment ProblemstkfdudNo ratings yet

- Validating Surge TestDocument9 pagesValidating Surge Testquality10No ratings yet

- Electrical Engineering Problems SolutionsDocument176 pagesElectrical Engineering Problems SolutionsBambang Sujanarko95% (20)

- Determination of Coating Deterioration With EIS: Part II. Development of A Method For Field Testing of Protective CoatingsDocument12 pagesDetermination of Coating Deterioration With EIS: Part II. Development of A Method For Field Testing of Protective CoatingsOmar MorteoNo ratings yet

- Lesson 2 Operational AmplifiersDocument37 pagesLesson 2 Operational AmplifiersJonjeffrey AgustinNo ratings yet

- Shortwave Antennas by G. Z AyzenbergDocument714 pagesShortwave Antennas by G. Z Ayzenbergcase100% (1)

- LM 4871Document24 pagesLM 4871Lauro SouzaNo ratings yet

- CaddDocument2 pagesCaddQuazi Warish AhmadNo ratings yet

- SVS COLLEGE EEE QUESTION BANK UNIT I TRANSMISSION LINE PARAMETERSDocument20 pagesSVS COLLEGE EEE QUESTION BANK UNIT I TRANSMISSION LINE PARAMETERSFurqan WarisNo ratings yet

- Transmission Line MCQDocument3 pagesTransmission Line MCQkgopinath060201No ratings yet

- Prist University - Ece 2nd Year Detailed SyllabusDocument21 pagesPrist University - Ece 2nd Year Detailed SyllabusPrist UniversityNo ratings yet

- Percent ImpedanceDocument2 pagesPercent ImpedanceJohan TadlasNo ratings yet

- Lecture 5 Symmetrical FaultsDocument46 pagesLecture 5 Symmetrical FaultsJoshua Roberto GrutaNo ratings yet

- Power Systems RepresentationDocument23 pagesPower Systems RepresentationEnyewNo ratings yet

- ATP MCA Analysis Manual - 20190620Document81 pagesATP MCA Analysis Manual - 20190620jcpreditiva.solucoesNo ratings yet

- LA3220Document9 pagesLA3220Riyantooperator MudariNo ratings yet

- Lightning FMEADocument51 pagesLightning FMEASing Yew Lam100% (1)

- Cta RubricDocument58 pagesCta Rubricapi-313716520No ratings yet

- Capacitive ReactanceDocument6 pagesCapacitive ReactanceSureshraja9977No ratings yet

- Accuracy and Behaviour of Capacitive Voltage TransformersDocument75 pagesAccuracy and Behaviour of Capacitive Voltage TransformersJonathas KovaskiNo ratings yet

- 3-phase AC circuit analysisDocument50 pages3-phase AC circuit analysisAman PailwanNo ratings yet

- 4000kVA 23kV TPS 0056 7547 50Hz Dyn5 A1 Siemens NEO-datasheetDocument4 pages4000kVA 23kV TPS 0056 7547 50Hz Dyn5 A1 Siemens NEO-datasheetgusfabi1No ratings yet

- AC Circuit ConceptsDocument22 pagesAC Circuit ConceptsAmish ShahNo ratings yet

- Physics Questions Asked in Issb InterviewDocument5 pagesPhysics Questions Asked in Issb InterviewSaad Faheem100% (1)

- Per Unit SystemDocument37 pagesPer Unit SystemGopesh Nakra100% (1)

- Relay Setting Chart - CRP Panel - Shambhu - REVBDocument21 pagesRelay Setting Chart - CRP Panel - Shambhu - REVBmahesh100% (1)