Professional Documents

Culture Documents

High Concentration Slurry Density - Pem News Letter

Uploaded by

Girish BhagchandaniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High Concentration Slurry Density - Pem News Letter

Uploaded by

Girish BhagchandaniCopyright:

Available Formats

HIGH CONCENTRATION SLURRY DENSITY SYSTEM AN EFFICIENT AND ECONOMICAL WAY OF FLY ASH HANDLING

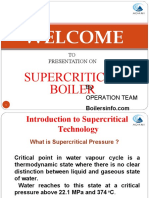

Coal fired power stations are main source of power generation in INDIA contributing almost 54 % of total power generating capacity of 1,32,300 MW as on date with 76,000 MW to be added by the end of 11th Plan. The bulk of this additional capacity shall be catered through coal based thermal power station, which means more ash to be handled as coal available in INDIA is of inferior quality having high ash content (in the range of 40-45%.). The coal combustion results in both bottom ash (20%) and fly ash (80%), which are disposed by various combinations of method. In majority of thermal plants ash is being disposed in wet slurry form which requires huge land for dumping ash & huge quantity of water to act as carrier and in turn danger of polluting soil due seepage of water. In recent past, fly ash has been found to be of usage and is being converted into useful products such as bricks, cement mix etc. However fly ash utilization as on date is only 43% and still huge quantity of fly ash is required to be stored in ash ponds. As a solution to this nagging problem of disposal of huge quantity of ash, High Concentration Slurry Density (HCSD) has come up as the efficient and economical disposal mode of handling fly ash. The Fly ash water slurry mixture is prepared at a high solid concentration (by weight) of 65-70% resulting in paste like homogeneous mixture, which is pumped using positive displacement pumps and this mixture is self-settling type. Mechanism: In conventional (lean) slurry disposal system, the concentration of solid in the slurry generally remains at 25-28% by weight. At low concentration of solids, slurry behaves like Newtonian fluid with pumping at high velocity to keep solids in suspension. As the concentration of solids increases, the viscosity also increases and slurry starts behaving more and more like a non-Newtonian fluid practically above concentration of 50% by weight. At this stage, velocity at which solid settles reduces considerably and slurry behaves as self limiting property at discharge point. System Description (Fig -1): The fly ash from silo/bin is fed to pre-mixing feeder (paddle feeder) through variable speed rotary vane feeder at controlled rate and mass flow meter to measure ash flow. The pre-mixing unit (ash conditioner) is provided to moisten the fly ash

Fig 1: Flow Scheme for High Concentration Slurry Density System before being lead to mixing tank for proper mixing. The moisten fly ash then drops into mixing tank where further mixing of ash water mixture takes place to attain the right rheology of slurry. A control loop with centrifugal pump is provided for recirculating the slurry back to mixing tank where water/fly ash is added as required. The control loop provided with density meter and pressure transmitter, continuously monitors the density of the slurry and pressure

drop for pumping thickened slurry and automatically provides for correction if required through the addition of water. Centrifugal booster pump is provided to feed main positive displacement pump through screens. The screens ensure any dried lumps of ash or trap material do not enter the mainline pump and pipeline. The slurry is transferred to the installed mainline Positive displacement (piston diaphragm) pumps. Pump design is such that pumped slurry does not come in contact with moving parts, such as piston and piston rods. This is accomplished by means of a rubber diaphragm, which provides a mechanical separation between the pumped liquid and the clean propelling liquid in which the moving parts are running. Slurry is pumped to ash dump area through seamless Mild Steel pipes and fittings with HDPE pipe over dyke. Emergency flushing pumps are provided to ensure flushing of line in case of any malfunctioning with main piston pumps. Special Features and Advantages of High Concentration Slurry Density System 1. Low water consumption: Water consumed is approximately half the weight of the ash transported. Since this water is not released at disposal, a water return/recirculation system is not required. 2. Self Limiting and self setting property: The slurry is self-limiting and in normal weather condition it dries up to a dense compact deposit hard enough to walk on within a day or two. No mechanical spreading or operational intervention is required as slurry spreads over area due to gravity. 3. Less requirement of area and versatile siting: HCSD uses less than half area required for lean phase slurry disposal and does not require any ash dyke development/retaining structure. Ash can be stacked up to height of 25-30 meters at an angle of 60 Deg to base. 4. Slurry pipeline diameter: For comparison sake, for an equivalent annual tonnage of ash, 300 Nb lean phase line would be equivalent to 100 Nb HCSD. 5. Specific Energy Consumption (SEC): HCSD requires much less specific power (Kwh per tonne km) than the conventional lean slurry disposal of boiler ash. Specific energy consumption for HCSD system is in the tune of 0.25 Kwh per tonne-km (at concentration of 55-60% by weight) compared to 0.75 Kwh per tonne-km for conventional slurry (at concentration of 28% by weight). Saving in power on ash pond recycle of water will be additional.

6. Permeability and Leaching: For an in-situ deposit density in the range of 1.3 1.4 t/cum (on dry basis), the ash permeability has been measured to 10-8 to 10-9 m/s. This prevents rainfall from accessing in the deposit and prevents leaching. 7. Material for Slurry pipeline: Slurry velocity in HCSD being very low (less than 1.5 m/s), wear is not problem in HCSD system. Mild Steel is a sufficient material for the slurry pipeline and life expectancy is high. 8. Generation of fugitive dust does not occur due to dense nature of deposit. 9. Significant cost saving in disposal area, liner and dyke construction of upto 60% (approximation, may vary from soil to soil condition) Some disadvantages of High Concentration Slurry Density system 1. High Capital cost due to special purpose pumps (imported) and instrumentation. However overall operational cost is less compared to conventional slurry pumping system, which will result into benefit in longer period. 2. Very strict quality control of all process parameters is required to ensure trouble free working of the system. 3. Experience with bottom and fly ash mixture (in Indian scenario) being pumped together is still not proven. Installations in INDIA 1. 2 x 250 MW CSES, Budge-Budge TPS (under operation) 2. 2 x 210 MW MPSEB, Khaparkheda TPS (under operation) 3. 4 x 135 MW BALCO TPS (under operation) 4. 2 x 210 MW APEGENCO- Rayalseema TPS (under execution) 5. 4 x 120 NALCO TPS (under execution) From the above, it is evident that the High Concentration Slurry Density system will provide efficient & economical solution to problem of disposing high volume of ash being generated in INDIA and an easy to operate and environment friendly system. Girish Bhagchandani Dy. Manager (MAUX)

You might also like

- Liquid Process Piping - Part 6 Ancillary Equipment & Corrosion Protection PDFDocument17 pagesLiquid Process Piping - Part 6 Ancillary Equipment & Corrosion Protection PDFnitin guptaNo ratings yet

- Application of Shell Reactor Internals in Huizhou RefineryDocument6 pagesApplication of Shell Reactor Internals in Huizhou RefineryapitbhuNo ratings yet

- Operating and Maintenance Manual - Air Conditioning DivisionDocument42 pagesOperating and Maintenance Manual - Air Conditioning DivisionmmNo ratings yet

- Cooling Water TreatmentDocument42 pagesCooling Water TreatmentMalay Raul100% (1)

- Demister Pads/ Mist EliminatorsDocument14 pagesDemister Pads/ Mist Eliminatorsaagarwal30No ratings yet

- Pro Ii User'S Guide Release 7.1Document388 pagesPro Ii User'S Guide Release 7.1karlaNo ratings yet

- 1.0 Chiller UnitDocument12 pages1.0 Chiller UnitfebousNo ratings yet

- Valve Selection EssentialsDocument8 pagesValve Selection EssentialsdigecaNo ratings yet

- 9 Types of Hydrogen Storage-1Document27 pages9 Types of Hydrogen Storage-1HosseinNo ratings yet

- Rotary FeederDocument6 pagesRotary Feedersham7523100% (1)

- Chemistry Assignment 1Document20 pagesChemistry Assignment 1Ahmed KamalNo ratings yet

- Water Requirement in Chemical Process IndustriesDocument145 pagesWater Requirement in Chemical Process IndustriesKAUSTAV ROYNo ratings yet

- Cellulose Fascinating Bio PolymerDocument36 pagesCellulose Fascinating Bio PolymerEunju Lee100% (1)

- Duplex Operating ManualDocument47 pagesDuplex Operating ManualalexfrizNo ratings yet

- H2 Supply Chain Evidence - Publication VersionDocument126 pagesH2 Supply Chain Evidence - Publication VersionNelly VanessaNo ratings yet

- Barclay, 2007 - SMR LNG ProcessDocument10 pagesBarclay, 2007 - SMR LNG ProcessfatimaludovicoNo ratings yet

- Current and Future Role of Haber-Bosch Ammonia in ADocument26 pagesCurrent and Future Role of Haber-Bosch Ammonia in ADung Phan Thị ThùyNo ratings yet

- Pce-II Unit-I & II 1Document84 pagesPce-II Unit-I & II 1Pavan SatishNo ratings yet

- Basic Design and Cost Data On MEA Treating UnitsDocument6 pagesBasic Design and Cost Data On MEA Treating UnitsTuesou MachereNo ratings yet

- Room Temperature Synthesis of Copper Oxide Nanoparticles Morphological Evaluation and Their Catalytic Applications For Degradation of Dyes and C-N Bond Formation Reaction PDFDocument11 pagesRoom Temperature Synthesis of Copper Oxide Nanoparticles Morphological Evaluation and Their Catalytic Applications For Degradation of Dyes and C-N Bond Formation Reaction PDFAshpavi ArunNo ratings yet

- Chiller - An OverviewDocument21 pagesChiller - An OverviewDtl SarozNo ratings yet

- Turbine GeneratorDocument3 pagesTurbine GeneratorNagamuthu Pandian100% (1)

- 18 Control PhilosophyDocument13 pages18 Control PhilosophyWael WaelNo ratings yet

- IE 2014 EP Levelized Cost of Electricity (LCOE) of Renewable Energies and Required Subsidies in ChinaDocument10 pagesIE 2014 EP Levelized Cost of Electricity (LCOE) of Renewable Energies and Required Subsidies in ChinabendermxjaggNo ratings yet

- RefrigerationDocument52 pagesRefrigerationSreejith VaneryNo ratings yet

- Super Critical BoilerDocument32 pagesSuper Critical BoilerNardo LlanosNo ratings yet

- 2501-General Instructions For Thermal DesignDocument12 pages2501-General Instructions For Thermal DesignfarooqkhanerNo ratings yet

- So Many Tuning Rules, So Little Time: Control Talk ColumnsDocument36 pagesSo Many Tuning Rules, So Little Time: Control Talk ColumnsIvan BevandaNo ratings yet

- PHD Thesis Naveen BhutaniDocument252 pagesPHD Thesis Naveen BhutaniSagar SrinivasNo ratings yet

- Hydro Processing Corrosion Wash WaterDocument9 pagesHydro Processing Corrosion Wash WaterNagendra H100% (1)

- 1.0 Specification of Equipment / Material and Installation Standards 1.1 Specifications For Water Cooled Centrifugal Chiller Performance ParametersDocument8 pages1.0 Specification of Equipment / Material and Installation Standards 1.1 Specifications For Water Cooled Centrifugal Chiller Performance Parametersعامر شیخNo ratings yet

- Presentation AirDocument19 pagesPresentation AirMohd JamalNo ratings yet

- 20-85-Performance Investigation of A Screw Turbine Operating Under Low Head and Less Flow Rate RequirementDocument5 pages20-85-Performance Investigation of A Screw Turbine Operating Under Low Head and Less Flow Rate RequirementMalik Haseeb AhmadNo ratings yet

- Titan HMXT 062007Document131 pagesTitan HMXT 062007Jhofran HidalgoNo ratings yet

- Ion Exchange Presentation - Team 18Document53 pagesIon Exchange Presentation - Team 18api-392769552No ratings yet

- Sustainable Cooling Technologies PDFDocument54 pagesSustainable Cooling Technologies PDFAyesha ParveenNo ratings yet

- Vapour Compression For Propane-Propylene SplittersDocument3 pagesVapour Compression For Propane-Propylene SplittersJohnNo ratings yet

- Ejectors Give Any Suction PressureDocument7 pagesEjectors Give Any Suction Pressurehappale2002No ratings yet

- 14 Exercises enDocument68 pages14 Exercises enRobertoNo ratings yet

- Ozone PDFDocument4 pagesOzone PDFShesharam ChouhanNo ratings yet

- Replacing A Corroded Column With Packing InternalsDocument4 pagesReplacing A Corroded Column With Packing InternalsPlutarco Chuquihuanga CórdovaNo ratings yet

- 62-69 Engineer's Notebook DudaDocument5 pages62-69 Engineer's Notebook DudaMichael LagundinoNo ratings yet

- Deionized For Cooling Tower PDFDocument8 pagesDeionized For Cooling Tower PDFThipsuree KornboonraksaNo ratings yet

- Chiller Water TemperatureDocument3 pagesChiller Water TemperatureMohamed Munaver100% (1)

- Designing Atmospheric Crude Distillation For Bitumen Service PDFDocument6 pagesDesigning Atmospheric Crude Distillation For Bitumen Service PDFfawmer61No ratings yet

- Reboiler: Types of ReboilersDocument5 pagesReboiler: Types of ReboilersMigueAngelPFNo ratings yet

- Proceco Eco-Smart MVRDocument2 pagesProceco Eco-Smart MVRZlatko Partlič100% (1)

- SafetyCases SuccessOrFailure PDFDocument11 pagesSafetyCases SuccessOrFailure PDFLesley Michael LiuNo ratings yet

- PTQ Enhancing Heat TransferDocument5 pagesPTQ Enhancing Heat TransferkulaspiroNo ratings yet

- Section 1 Chapter XII Safety Aspects & MSDS PrintedDocument86 pagesSection 1 Chapter XII Safety Aspects & MSDS PrintedrajuNo ratings yet

- Use Operator Training Simulators For FCC UnitsDocument3 pagesUse Operator Training Simulators For FCC Unitssaleh4060No ratings yet

- Sulfur Hy SealDocument6 pagesSulfur Hy SealodeinatusNo ratings yet

- Handout BOILER FEED WATERDocument9 pagesHandout BOILER FEED WATERMuhammad Omar AzadNo ratings yet

- Chemcad: Utility Processes John Edwards, P&I Design LTD January 2015Document19 pagesChemcad: Utility Processes John Edwards, P&I Design LTD January 2015Eng-MustafaHathalAl-SaraiNo ratings yet

- Chiller and Tower Sizing Formulas PDFDocument2 pagesChiller and Tower Sizing Formulas PDFnagarjuna reddy mNo ratings yet

- Tower Line Size Criteria PDFDocument1 pageTower Line Size Criteria PDFBurhanNo ratings yet

- 2136-Vol 3Document28 pages2136-Vol 3BSRNo ratings yet

- Oxy Enrich Process For Capacity Enhancement of Claus Based Sulfur Recovery UnitDocument22 pagesOxy Enrich Process For Capacity Enhancement of Claus Based Sulfur Recovery Unitsara25dec689288No ratings yet

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsFrom EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahNo ratings yet

- Contracts Act, 2010Document59 pagesContracts Act, 2010Sam KNo ratings yet

- El Condor1 Reporte ECP 070506Document2 pagesEl Condor1 Reporte ECP 070506pechan07No ratings yet

- Violence Against NursesDocument22 pagesViolence Against NursesQuality Assurance Officer Total Quality ManagementNo ratings yet

- Belimo Fire and Smoke Brochure en UsDocument8 pagesBelimo Fire and Smoke Brochure en UsAmr AbdelsayedNo ratings yet

- Cost Justifying HRIS InvestmentsDocument21 pagesCost Justifying HRIS InvestmentsNilesh MandlikNo ratings yet

- LabVIEW Core 3 2013 - Course ManualDocument135 pagesLabVIEW Core 3 2013 - Course Manualtalaindio100% (2)

- Job Schedule Sheet: 'Lead Time Monitoring GraphDocument48 pagesJob Schedule Sheet: 'Lead Time Monitoring GraphEndraNo ratings yet

- Annexure - IV (SLD)Document6 pagesAnnexure - IV (SLD)Gaurav SinghNo ratings yet

- 3H Case DigestsDocument296 pages3H Case DigestsMark Jorrel BautistaNo ratings yet

- Creating Website Banners With Photoshop PDFDocument18 pagesCreating Website Banners With Photoshop PDFLiza ZakhNo ratings yet

- ZIOIEXCELDocument4 pagesZIOIEXCELSunil GNo ratings yet

- Text-Book P3Document147 pagesText-Book P3Nat SuphattrachaiphisitNo ratings yet

- Mathswatch Student GuideDocument8 pagesMathswatch Student Guideolamideidowu021No ratings yet

- Exercise For AutoCADDocument3 pagesExercise For AutoCADnavri_nalhadNo ratings yet

- SEMIKRON DataSheet SK 30 GD 066 ET 24914960Document5 pagesSEMIKRON DataSheet SK 30 GD 066 ET 24914960prajwalNo ratings yet

- Ahi Evran Sunum enDocument26 pagesAhi Evran Sunum endenizakbayNo ratings yet

- LivePerson Chat ReportsDocument23 pagesLivePerson Chat ReportsEdenEtfNo ratings yet

- Environmental Life Cycle AssessmentDocument1 pageEnvironmental Life Cycle Assessmentkayyappan1957No ratings yet

- Profile 5930 Series Dispersoil. Viscosity Reducer RSKDocument1 pageProfile 5930 Series Dispersoil. Viscosity Reducer RSKIwan SetiawanNo ratings yet

- 24 Antiseizure DrugsDocument71 pages24 Antiseizure DrugsThea MallariNo ratings yet

- 1st Division Mancom MinutesDocument18 pages1st Division Mancom MinutesseiNo ratings yet

- Scope: Manufacture of High Precision and CloseDocument1 pageScope: Manufacture of High Precision and CloseAnuranjanNo ratings yet

- Review of Polyurea Coating ResearchesDocument12 pagesReview of Polyurea Coating ResearchesDineshNo ratings yet

- UPDATED CV-Neeraj KR - Sharma-2021.Document5 pagesUPDATED CV-Neeraj KR - Sharma-2021.supriyaNo ratings yet

- MyFlixer - Watch Movies and Series Online Free in Full HD On MyFlixerDocument1 pageMyFlixer - Watch Movies and Series Online Free in Full HD On MyFlixerGeanina OlteanuNo ratings yet

- How To Install Libpango-1.0-0 Ubuntu Package On Ubuntu 20.04 - Ubuntu 18.04 - Ubuntu 19.04 - Ubuntu 16.04Document2 pagesHow To Install Libpango-1.0-0 Ubuntu Package On Ubuntu 20.04 - Ubuntu 18.04 - Ubuntu 19.04 - Ubuntu 16.04ruslikennethNo ratings yet

- Indiabulls PILDocument64 pagesIndiabulls PILPGurus100% (1)

- Yesenia Acc SjournalsDocument7 pagesYesenia Acc SjournalsFileon ChiacNo ratings yet

- Quiz 1 - Domain Modeling With Answer KeyDocument5 pagesQuiz 1 - Domain Modeling With Answer Keyprincess100267% (3)

- Contribution of Science and Technology To National DevelopmentDocument2 pagesContribution of Science and Technology To National DevelopmentAllan James DaumarNo ratings yet