Professional Documents

Culture Documents

Spraying Techniques Polyurethane Paint Systems

Uploaded by

moses_cCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spraying Techniques Polyurethane Paint Systems

Uploaded by

moses_cCopyright:

Available Formats

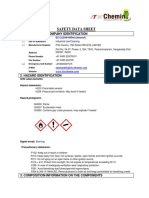

Spraying TechniquesPolyurethane Paint Systems All personnel assigned duties involving the mixing and applicationof polyurethane coatings

should receive a pre-placement and periodicmedical evaluation. The date and results of each medical evaluations h o u l d b e e n t e r e d o n t h e A d m i n i s t r a t i v e R e m a r k s p a g e o f t h e individuals service record and in the individuals training jacket. Thepolyurethane systems used on naval aircraft consist of two types. Thealiphatic type is used in polyurethane paints. The aromatic type isu s e d in rain erosion-resistant coatings. These materials generallyp r e s e n t n o s p e c i a l h a z a r d t o h e a l t h w h e n t h e y a r e c u r e d ( d r i e d ) . T h e y d o r e q u i r e s p e c i a l p r e c a u t i o n s d u r i n g t h e i r preparation, application, and curing because isocyanate vapors arep r o d u c e d . T h e u n t r e a t e d i s o c y a n a t e s r e l e a s e d c a n p r o d u c e si gn i f i c a nt i r r i t a t i o n t o the s ki n , e ye s , and r e s pi r a t or y t r ac t e ve n in v e r y s m a l l c o n c e n t r a t i o n s . T h e y m a y a l s o i n d u c e a l l e r g i c sensitization. aliphatic polyurethane is the standard g e n e r a l - purpose exterior protective coating for aircraft surfaces. Its uniquecombination of flexibility, gloss retention, and resistance to fuelsand lubricating oils make the coating extremely suitable for aircraftex t er i o r s u r f a ces . It i s s up p l i e d a s a t w o -c o mp o n e n t ki t of base andc a t a l y s t . Y o u s h o u l d u s e a l i p h a t i c p o l y u r e t h a n e over epoxy-polyamide primer and for touch up and insignia m a r k i n g o v e r polyurethane paint systems. All personnel using polyurethane touchup operations should wear protective clothing as described in NA 0 1 - 1 A -5 0 9 . U n p r o t e ct e d p e r s on n el s h o ul d n o t b e p e r mi t t e d cl o se r t h a n 1 5 f e e t t o t h e s p r a y z o n e d u r i n g p a i n t a p p l i c a t i o n w i t h a brush, roller, or spray equipment. They should be permitted no c l o s e r t h a n 4 0 f e e t d u r i n g a p p l i c a t i o n s w i t h c o m p r e s s e d - a i r spray. Unprotected personnel should not be permitted closer than 15f e e t to newly painted surfaces for 30 minutes after the p a i n t i n g operation is completed unless forced air exhaust ventilation is beingused. Aliphatic polyurethane paint is available in kits consisting of 1 part pigmented material and 1 part clear resin component. When youmix aliphatic polyurethane paint, the clear resin component shouldalways be added to the pigmented component. Only material from the same kit should be mixed together. However, two or more kits of thesame color and manufacturer may be mixed in the same vessel. You should not mix clear resin components and pigmented components fromd i f f e r e n t m a n u f a c t u r e r s . Y o u s h o u l d a l s o f o l l o w t h e p r e s c r i b e d mixing ratios to prevent long drying times, poor chemic al resistance,or loss of flexibility. You should use a mechanical shaker to agitatethe pigmented component for at least 20 minutes. Then add the clearresin slowly to the pigmented component while you are stirring thepigmented component. Ensure the pigmen ted component and clearresin are thoroughly mixed. You should mix only the amount of paintt h at yo u c an u s e i n t he 4 -h o u r p o t l i f e o f t h e mi x e d p a i nt . W he n painting with polyurethane paints, you should clean the paint gun at thee n d o f e a c h u s e o r e v e r y 4 h o u r s , w h i c h e v e r c o m e s f i r s t . T o s p r a y a l i p h at i c p ol yu r e t ha n e p ai n t , yo u s h o u l d t h i n i t w i t h thinnert o t h e d e s i r e d s p r a y v i s c o s i t y . T h e n s t i r t h e m i x t u r e , s t r a i n i t t h r o u g h cheesecloth, and allow it to stand for a minimum of 15minutes. If theviscosity of the mixed paint is too thick for spraying within 3 hoursafter mixing, it maybe thinned again by adding thinner. You shouldnot attempt to re-thin paint after 3 hours because it t ends to produceo r a n g e p e e l o r

d r y s p o t s . A l i p h a t i c p o l y u r e t h a n e p a i n t s h o u l d b e applied over a clean epoxypolyamide primer within 8 hours of primerapplication. For the best results, you should apply the topcoat as soon asthe primer is dry. You should apply the minimum thickness required tohide the primer. Apply two thin, wet coats about 30 minutes apart. Do not apply a mist coat because it may cause a low gloss. A primer ortopcoat that has aged longer than 24 hours should be scuff sanded andc l e a n e d b e f o r e i t i s p a i n t e d . Y o u s h o u l d a l l o w a p p r o x i m a t e l y 8 h o u r s f or p ai nt e d s u r f a c es t o dr y. A d d i t i o n al t i me , u s u a l l y 1 o r 2 h o u r s , wi l l b e r e qu i r e d i f t h e t e mp e r a t ur e is b el o w 7 0 F . During the a p p l i c a t i o n o f a n a l i p h a t i c p o l y u r e t h a n e t o p c o a t , c e r t a i n d i s c r e p a n c i e s m a y a p p e a r o n t h e f i n i s h b e c a u s e o f f a u l t y application methods.The most common defects, probable causes, andp r e ve n t i on s ar e l i s t e d i n N A 0 1 -1 A -5 0 9 . If a n y o f t h e s e de f e ct s a r e found, they should be corrected before you continue to paint.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Rotogravure Printing: Ntroduction Asis AND ResumptionsDocument4 pagesRotogravure Printing: Ntroduction Asis AND Resumptionsmoses_cNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- 5 Amazing Health Benefits of KambuDocument8 pages5 Amazing Health Benefits of Kambumoses_cNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Petroleum JellyDocument7 pagesPetroleum Jellymoses_c100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Sodium SilicateDocument12 pagesSodium Silicatemoses_cNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Soaps and Detergents PDFDocument16 pagesSoaps and Detergents PDFsachinsaboo3No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- EczemaDocument2 pagesEczemamoses_cNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Water Repellent CoatingDocument90 pagesWater Repellent Coatingmoses_cNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Coconut OilDocument4 pagesCoconut Oilmoses_cNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Builder Guideline Booklet (USA) - JAN 2022 - Website EditionDocument64 pagesBuilder Guideline Booklet (USA) - JAN 2022 - Website EditionTreyNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Literature Review of Glass FiberDocument7 pagesLiterature Review of Glass Fiberaflsjizaf100% (1)

- Proposed waiting shed in Lumbia, Cagayan de Oro CityDocument7 pagesProposed waiting shed in Lumbia, Cagayan de Oro CityMac KYNo ratings yet

- 5th Grade PlasmaDocument10 pages5th Grade PlasmaMonserrat Vasquez HernandezNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Forged Engineering DataDocument4 pagesForged Engineering DataretrogradesNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- T Printing 1Document19 pagesT Printing 1Amrinder DhimanNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Catalog: Flanged Safety Relief Valves Series 526 CCDocument12 pagesCatalog: Flanged Safety Relief Valves Series 526 CCSuelen SobrinhoNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- SM-5910 B Método de Adsorción UVDocument5 pagesSM-5910 B Método de Adsorción UVEdRo GarcíaNo ratings yet

- Study The Different Types of Pattern and Their CharacteristicsDocument5 pagesStudy The Different Types of Pattern and Their CharacteristicsUsman RazaNo ratings yet

- Htri Trial PDFDocument39 pagesHtri Trial PDFcroprobosNo ratings yet

- Solid and Liquid Silicone Rubber Product Selection GuideDocument16 pagesSolid and Liquid Silicone Rubber Product Selection GuideD.I. Pablo BoverioNo ratings yet

- Catalogo MartinDocument208 pagesCatalogo MartinFrancisco Garibaldi MarquezNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Chemical SensorsDocument70 pagesChemical SensorsRenu SamuelNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- FEM GHG Emission Factors FEM 2021Document13 pagesFEM GHG Emission Factors FEM 2021Emdad YusufNo ratings yet

- 1.2 Structure and PropertiesDocument15 pages1.2 Structure and PropertiesLuisa Fernanda Sanchez ZambranoNo ratings yet

- Understanding The Quenchant Report PDFDocument8 pagesUnderstanding The Quenchant Report PDFSandeep SarafNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- SSPC News Bulletin - July 2020Document26 pagesSSPC News Bulletin - July 2020JlkKumarNo ratings yet

- Sandwitched Fly Ash PanelDocument33 pagesSandwitched Fly Ash PanelEdeeksha Shekhawat100% (1)

- Biodiesel Production by A Continuous Process Using Hetergenous CatalystDocument3 pagesBiodiesel Production by A Continuous Process Using Hetergenous Catalystdstar13No ratings yet

- Chemkin PDFDocument44 pagesChemkin PDFmohamedIGCMONo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- PET Properties Recyclable ThermoplasticDocument2 pagesPET Properties Recyclable ThermoplasticsabbysamuraNo ratings yet

- Ec Clean - SdsDocument5 pagesEc Clean - SdsMary JosephineNo ratings yet

- Process Design for Coal Liquefaction and Exergy AnalysisDocument46 pagesProcess Design for Coal Liquefaction and Exergy AnalysisSukaran SinghNo ratings yet

- Forging a SwordDocument3 pagesForging a Swordglen biazonNo ratings yet

- Unit 1 Module 1 Forces of AttractionDocument9 pagesUnit 1 Module 1 Forces of AttractionRovina Narayan DiasNo ratings yet

- Factors Affecting Resistance in a Wire Multiple ChoiceDocument8 pagesFactors Affecting Resistance in a Wire Multiple ChoiceGeeja EdgerNo ratings yet

- UPVC Litaflex Conduit & FittingDocument10 pagesUPVC Litaflex Conduit & FittingSara NuonNo ratings yet

- Water Jet Reed Best Manufacturer & Supplier in Ahmedabad, IndiaDocument8 pagesWater Jet Reed Best Manufacturer & Supplier in Ahmedabad, IndiaVijay PanchalNo ratings yet

- Resistivity Log: Well Logging (Pe413)Document9 pagesResistivity Log: Well Logging (Pe413)Ramy MaamounNo ratings yet

- UH Materials Science and Engineering - Courses - 2016-03-23Document3 pagesUH Materials Science and Engineering - Courses - 2016-03-23Tabish KamranNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)