Professional Documents

Culture Documents

Cap

Uploaded by

Washimul AminOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cap

Uploaded by

Washimul AminCopyright:

Available Formats

*****************************************************************************

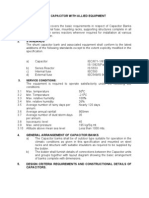

Annexure D TECHNICAL SPECIFICATION FOR 11KV CAPACITOR BANK: 1.0 Scope: This specification covers 11kV 50Hz pole-mounted automatically switched capacitor installations comprising of (i) 11kV automatic capacitor switches and (ii)12.65kV capacitor banks of 660KVAr rating. 2.0 Operating/service conditions: The equipment/material offered shall be entirely satisfactory for operation under the conditions indicated below:2.1 Service Conditions: a) b) c) d) e) f) g) h) i) j) 2.2 Maximum Ambient Temperature (Degree C) Minimum Ambient Temperature (Degree C) Relative Humidity (%) Maximum annual rain fall (mm) Maximum wind pressure (Kg/m sq) Maximum wind velocity Isoceraunic level (days/year) Maximum altitude above mean sea level (Meter) Seismic level (Horizontal acceleration) Moderately hot and humid tropical climate conducive to rust and fungus growth :50 :3.5 :10 to 100 :1450 :150 :45 :50 :1000 :0.3g :

Operating Conditions: a) Nominal system voltage b) Highest system voltage c) Normal frequency : 11 kV : 12 kV : 50 Hz

3.0

Applicable Standards: Unless otherwise stipulated in the specification, the 11kV pole mounted switched capacitors shall comply with the latest version of IS:2834(Shunt Capacitors for Power Systems).

4.0

Temperature Category: Unless otherwise specified, the capacitors shall be suitable for upper limit of temperature category 50 C as per IS-2834.

5.0

Rated Output: The standard rated output of a switched capacitor bank shall be 660KVAr at 12.65 kV rated voltage. The bank shall comprise of 3 single phase units of 220 KVAr each at 7.3kV phase to earth voltage connected in star with floating neutral.

6.0

Permissible Overloads: The maximum permissible overloads with regard to voltage, current and reactive output shall conform to IS:2834.

7.0

Power Loss: The power loss in capacitors shall not exceed 0.2 Watt/kVAr (Subject to a tolerance of plus 10%).

8.0

Discharge Device: Suitable discharge device shall be connected across the capacitor units in accordance with the provision of IS:2834. The discharge device shall reduce the residual voltage from the cross value of the rated voltage to 50V or less within 5 minutes after the capacitor is disconnected from the source of supply.

9.0

Earth Connection:

The container of each capacitor unit shall be provided with suitable earthing terminal clearly marked as (1). 10.0 Protective Fuses: The capacitors shall be provided with external fuses. It shall be possible to identify the blown off fuse from outside. The tolerance and the degree of unbalances shall also be indicated as per relevant IS. The manufacturer shall supply a set of external fuses together with fixing accessories and a set of three spare fuse links alongwith the capacitor bank. 11.0 11.1 11.2 11.3 General Requirements: The capacitors shall be of non-PCB type, using polypropylene film as the dielectric. The containers shall be made from sheet steel of thickness not less than 2mm.(14 SWG). The container shall be hermetically sealed by controlled arc welding process. The metal flanges of the bushing should be soldered/welded to the container and covered with epoxy compound providing a strong hermetical seal to the container. Suitable mounting brackets, as required by the purchaser shall be welded to the container. The outside of the container should have smooth and tidy look and should be coated with weather-proof and corrosion-resistant paint of white or light gray shade. The container/enclosure shall be painted with light gray colour, shade 631 as per IS: 5. The fuses and capacitors cells shall be interchangeable. The dielectric loss angle (tan delta) shall be less than as per IS 2834. Marking: The capacitor shall be provided with a rating plate and terminal markings as stipulated in IS:2834. Tests:

11.4 11.5

11.6 11.7 12.0

13.0

13.1 Routine Tests: All the individual capacitor units shall be subjected to following routine tests at the manufacturers works (at the cost of manufacturer) in accordance with IS:2834 with latest amendments. 1) 2) 3) 4) 5) 6) 7) Visual inspection Sealing Test Measurement of output and capacitance Insulation resistance between terminals and containers Capacitor loss tangent (tan delta) measurement Voltage test between terminals and containers Test of discharge device

The routine tests at 3 & 4 shall be carried out on the 600 kVAR bank also. 13.2 Type Tests: The tests indicated in the IS:2834 with latest amendments shall constitute the type tests. All the type tests as under shall be carried out at the laboratories accredited by National Accreditation Board of Testing and Calibration Laboratories (NABL) in accordance with IS:2834 with latest amendments. a) b) c) d) e) f) Voltage test between terminals Ac voltage test between terminals and containers Thermal stability test Capacitor loss tangent (tan delta) measurement Lightening impulse test between terminals and container Short circuit discharge test

13.3 Acceptance Tests: The inspecting officer will carry out the acceptance tests specified in the IS:2834 with latest amendments.

14.0

Type Test Reports: The tenderer shall furnish detailed type test reports of the offered Capacitor Banks for the tests as per relevant IS mentioned in this specification. All these Type Tests shall be carried out at

laboratories that are accredited by the National Accreditation Board of Testing and Calibration Laboratories (NABL) of Government of India. These tests should have been carried out within 5 years prior to the date of opening of this tender. However, the tenderers who have supplied the Capacitor Banks to this Distribution Co. / erstwhile Board against order from Purchaser of M.S.E.D.C.L. /erstwhile M.S.E.B. shall be exempted from submission of type test reports against this tender, provided offered Capacitor Banks are already fully type tested at Laboratories accredited by the National Accreditation Board of Testing and Calibration Laboratories (NABL) within five years prior to the date of opening of the tender and there is no change in the design of already type tested the Capacitor Banks and those offered against this tender. Such tenderers shall furnish an undertaking in the format scheduled F enclosed herewith. The detailed type test reports along with the relevant oscillograms/certified drawings, etc. or undertaking seeking exemption from their submission in the format schedule F, are to be submitted in sealed cover on or before 15.00 hrs. on the same date of the month one month after the date of tender opening ( e.g. if the tender is opened on 3rd June, the submission of the type test reports shall be on or before 3rd July) or the next working day in case the same day is a holiday, duly super-scribed on it following details: Type Test Reports of Capacitor Banks against Tender The purchaser reserve the right to demand repetition of some or all the Type Tests in presence of purchasers representative at purchasers cost. For this purpose, the tenderer shall quote unit rates for carrying out each Type Test. However, such unit rates will not be considered for evaluation of the offer. In case the unit fails in the type tests, the complete supply shall be rejected. The successful tenderer shall take approval/waiver of type tests from C.E. (Dist.), M.S.E.D.C.L. Prakashgad, Bandra, Mumbai, prior to commencement of supply. 15.0 Bill of Material enclosed alongwith the tender specification incorporating structure, Lightning Arresters, are only indicative and the scope of the supply is already mentioned in this specification.

16.0 17.0

The equipment offered by the manufacturer shall comply with the general safety regulations. Bill of Material: 1) 12.65KV Capacitor Bank (3 x 220 KVAR) 2) Expulsion type fuse assembly (3 nos.) 3) Structure for capacitor Bank mounting a) M.S.Channel 75x40x6 - 600mm. b) M.S.Channel 75x40x6 - 1400mm. 2 nos. 2 nos. 1 set

- 1 set

18.0

Physical Documents Submission i) Test Certificate as per Clause no.14.0 of technical specification in accordance to IS 2834 shall be submitted for approval to Chief Engineer (Distribution) Drawing and Catalogues Tender must accompany relevant catalogues and sectional drawing showing necessary details of the equipment offered. One copy of the dimensional drawing and internal construction drawing shall be submitted with the tender. As per the conditions of the tender these drawing shall be of A-3 (420 x 297) size only. iii) Past Experience in schedule L.

ii)

SCHEDULE - `L' SCHEDULE OF TENDERER'S EXPERIENCE Tenderer shall furnish here a list of similar orders executed /under execution by him to whom a reference may be made by Purchaser in case he considers such a reference necessary. ----------------------------------------------------------------------------------Sr. Name of the Value of Period of Name & address to No. client and order supply and whom reference Description Commissioning may be made of items ordered. ----------------------------------------------------------------------------------1 2 3 4 5 -----------------------------------------------------------------------------------

NAME OF FIRM ___________________________________

NAME & SIGNATURE OF THE TENDERER________________

DESIGNATION ____________________________________ DATE ___________________________________________

SCHEDULE - `F Proforma of Undertaking

We hereby confirm that Capacitor Banks have been supplied by us to M.S.E.D.C.L./erstwhile M.S.E.B. against earlier Order No._______________ Dated ___________ and the type test certificates thereof were approved by C.E.(Dist.) vide Letter No.____________________________ Dated __________ copy enclosed.

NAME OF FIRM ___________________________________

NAME & SIGNATURE OF THE TENDERER________________

DESIGNATION ____________________________________ DATE ___________________________________________

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- 66 KV Circuit BreakerDocument25 pages66 KV Circuit Breakershivender777No ratings yet

- 6-66 KV SF6 BKR R3 May12Document26 pages6-66 KV SF6 BKR R3 May12PB MehtaNo ratings yet

- Fewa SpecificationsDocument28 pagesFewa SpecificationsAnonymous GdZqtY88ZRNo ratings yet

- Tech - Spec. LA For WBSEDCL Sept.07, ArresterDocument6 pagesTech - Spec. LA For WBSEDCL Sept.07, ArresterThanh NguyenNo ratings yet

- Tech Spec of PTR 33 11 KVDocument34 pagesTech Spec of PTR 33 11 KVAnonymous sAmJfcVNo ratings yet

- 111 - 33KV Capacitor Bank .Document16 pages111 - 33KV Capacitor Bank .Aseem TandonNo ratings yet

- 6 400KV CB PirDocument36 pages6 400KV CB PirRAPRATSINNo ratings yet

- 33kv Capacitor With Allied EquipmentDocument9 pages33kv Capacitor With Allied EquipmentsbpathiNo ratings yet

- 04 400 KV 50 63 80 125 MVAr Shunt Reactor NGR SA R2 Jul 08Document66 pages04 400 KV 50 63 80 125 MVAr Shunt Reactor NGR SA R2 Jul 08anjes1No ratings yet

- 0 Line 13 Conductor Zebra Used in Transmission LinesDocument9 pages0 Line 13 Conductor Zebra Used in Transmission LinesPavithra ShivanNo ratings yet

- Cl. No.: Scope of ContractDocument11 pagesCl. No.: Scope of ContractEswar Kiran ReddyNo ratings yet

- HT Capacitor SpecDocument9 pagesHT Capacitor SpecsbpathiNo ratings yet

- LTX Lpe Cable RevDocument9 pagesLTX Lpe Cable RevRakesh ShinganeNo ratings yet

- 7 - 220 - 132 - 220 - KV - NCT - 2147Document20 pages7 - 220 - 132 - 220 - KV - NCT - 2147Sheraz azamNo ratings yet

- Terminal Connectors 66 132 220 400 KVDocument9 pagesTerminal Connectors 66 132 220 400 KVVishnu ShankerNo ratings yet

- 66 - KV - CT - PT - R5 - Metering - Jan - 10 GETCO PDFDocument33 pages66 - KV - CT - PT - R5 - Metering - Jan - 10 GETCO PDFRupesh ChowdaryNo ratings yet

- Three Phase Power Converter Distribution TransformersDocument19 pagesThree Phase Power Converter Distribution Transformersali hamzaNo ratings yet

- Spec Automatic Reactive Power CompensationDocument7 pagesSpec Automatic Reactive Power CompensationDolyNo ratings yet

- Substation Filter BankSpecsDocument7 pagesSubstation Filter BankSpecsTudor BostanNo ratings yet

- 66kv Lightning ArresterDocument9 pages66kv Lightning ArresterbinodeNo ratings yet

- Line Trap 132kv 0Document17 pagesLine Trap 132kv 0Neelakandan MasilamaniNo ratings yet

- Technical Specification of 10 Position Fully Automatic Meter Testing Equipment With Reference Meter of Class 0.02 1. ObjectiveDocument22 pagesTechnical Specification of 10 Position Fully Automatic Meter Testing Equipment With Reference Meter of Class 0.02 1. ObjectiveNikhil SinhaNo ratings yet

- CTOperated TOD Meters Specifications 04 03 08 PDFDocument24 pagesCTOperated TOD Meters Specifications 04 03 08 PDFRitesh JaiswalNo ratings yet

- Specification No. CSC-XX-R-III/DH/UH/P&D/2012-2013Document20 pagesSpecification No. CSC-XX-R-III/DH/UH/P&D/2012-2013Pradeep Kumar MaraptlaNo ratings yet

- 100 - 5A LT CT Operated TOD Meters With RS 232 Port 130608Document24 pages100 - 5A LT CT Operated TOD Meters With RS 232 Port 130608Ritesh JaiswalNo ratings yet

- Nigam 11 KV Shunt CapacitorDocument13 pagesNigam 11 KV Shunt CapacitorSandeep SharmaNo ratings yet

- Breaker SpecifiDocument27 pagesBreaker SpecifiankitrajNo ratings yet

- 1 11 and 66kV Cap Bank R2 Apr09Document26 pages1 11 and 66kV Cap Bank R2 Apr09Sakthi RajNo ratings yet

- Especificacion - ResistorDocument6 pagesEspecificacion - ResistorMARIANELA CASTILLONo ratings yet

- Battery Charger TS Rev-0-31.12.22Document29 pagesBattery Charger TS Rev-0-31.12.22DEVI PRASAD GREENSECURENo ratings yet

- HTXLPESPEC2006Document11 pagesHTXLPESPEC2006Faazil FairoozNo ratings yet

- Enquiry Cum Scope of Supply & Technical Specifications of Tender ITEM NO:-10 QUANTITY: - 1 EA (Each) Item DescriptionDocument5 pagesEnquiry Cum Scope of Supply & Technical Specifications of Tender ITEM NO:-10 QUANTITY: - 1 EA (Each) Item Descriptionpramodyad5810No ratings yet

- 6 - Linetrap - 400kv - 10mH - 3150 - A - R - 0Document17 pages6 - Linetrap - 400kv - 10mH - 3150 - A - R - 0Hassan KhaterNo ratings yet

- SpecificationsDocument5 pagesSpecificationsAnonymous mcHqIfbnV1No ratings yet

- 16 400 220 132KV C R PanelsDocument87 pages16 400 220 132KV C R PanelsShatrughna SamalNo ratings yet

- 3 Silicone Rubber InsulatorsDocument24 pages3 Silicone Rubber Insulatorsdecorindo2002100% (1)

- 33 KV Control Relay Spec PDFDocument75 pages33 KV Control Relay Spec PDFMohanta Amrit100% (2)

- 5 Clamps Connectors 220 400kv SsDocument12 pages5 Clamps Connectors 220 400kv SsJaswanth SaiNo ratings yet

- 14 A 66 KV CT PT R5 Metering Jan 10Document33 pages14 A 66 KV CT PT R5 Metering Jan 10Ramesh Ananthanarayanan100% (1)

- 33KV GTP WbsebDocument13 pages33KV GTP Wbsebmaniking1No ratings yet

- 11 - 11KV Outdoor Switches - Spec No 36Document40 pages11 - 11KV Outdoor Switches - Spec No 36diputhe diyaNo ratings yet

- 22 Control PLT Power CableDocument54 pages22 Control PLT Power CableSanthosh V RaajendiranNo ratings yet

- TST-08 - Insulator HardwareDocument8 pagesTST-08 - Insulator HardwarerinaldiafriyantoNo ratings yet

- Battery Charger SOWDocument4 pagesBattery Charger SOWzakalyNo ratings yet

- Bundle Spacer: Engineering DepartmentDocument4 pagesBundle Spacer: Engineering DepartmentpvenkyNo ratings yet

- Annexe Le 8170Document23 pagesAnnexe Le 8170AbhishekNo ratings yet

- Technical Specification OF HT Cables FOR Power Stations: InstalledDocument25 pagesTechnical Specification OF HT Cables FOR Power Stations: InstalledmonsNo ratings yet

- 5 MTR 24-10-2020Document162 pages5 MTR 24-10-2020rakeshkaydalwarNo ratings yet

- Getco 400KV - CT PDFDocument27 pagesGetco 400KV - CT PDFSunny RathNo ratings yet

- Trafo Differential & Distance Prot. RelaysDocument16 pagesTrafo Differential & Distance Prot. RelaysTheresa WestNo ratings yet

- 87meg 01Document6 pages87meg 01DEVI PRASAD GREENSECURENo ratings yet

- Gujarat Energy Transmission Corporation LTD.: 132 KV Instrument TransformersDocument33 pagesGujarat Energy Transmission Corporation LTD.: 132 KV Instrument TransformersEngr Zia UR RehmanNo ratings yet

- 23 - 220KV - CT - P - Metering - R - 5 - APR - 10 PDFDocument33 pages23 - 220KV - CT - P - Metering - R - 5 - APR - 10 PDFgaurang1111No ratings yet

- Static Meter-R1-For EPC & Turnkey ProjectDocument36 pagesStatic Meter-R1-For EPC & Turnkey ProjectVishnu ShankerNo ratings yet

- 01 29-7-13 VK VK Rs Clause 2.3 M) of Section-2 DeletedDocument30 pages01 29-7-13 VK VK Rs Clause 2.3 M) of Section-2 DeletedPritesh Patel50% (2)

- 33kV - Cap - Bank-SIKAP - Spec - FY 12-13 - 30.11.11-Cesc - 20 MVARDocument9 pages33kV - Cap - Bank-SIKAP - Spec - FY 12-13 - 30.11.11-Cesc - 20 MVARSatyajit RaiNo ratings yet

- Power TransformerDocument43 pagesPower TransformerSudhir SainiNo ratings yet

- AGECL AIIB Trafo SpecsDocument100 pagesAGECL AIIB Trafo SpecsBu ManNo ratings yet

- 16342-Metal Clad MV SWGRDocument14 pages16342-Metal Clad MV SWGRuddinnadeemNo ratings yet

- Transformer Fault Current CalculationDocument1 pageTransformer Fault Current CalculationNarasimha RaoNo ratings yet

- Mobile Battery Compatibility Chart Mobile Battery Compatibility ChartDocument1 pageMobile Battery Compatibility Chart Mobile Battery Compatibility ChartAnupam SrivasatavNo ratings yet

- Layout RevisedDocument1 pageLayout RevisedAnupam SrivasatavNo ratings yet

- Tnerc CodesDocument84 pagesTnerc CodesBala SubramanianNo ratings yet