Professional Documents

Culture Documents

Whirlpool SBS 2006 Collection Repair Manual

Uploaded by

Neil PoundOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Whirlpool SBS 2006 Collection Repair Manual

Uploaded by

Neil PoundCopyright:

Available Formats

Whirlpool SBS 2006 Collection Repair Manual Models

HOME

FRWW2VAF20/0; FRUU2VAF20/0; FRBB36AF20/2; FRUU36AF20/2; FRSS36AF20/2; FRSB36AF20/2; FTSB36AF20/3; FFII36AF20/3; FRSS36AF25/3

LCD version

Numeric display version Error Codes Error Code Numeric Display Version

Error Code LCD Version

Cause Freezer Sensor fault Refrigerator sensor fault Air Baffle fault Ambient Sensor fault Freezer too warm Appliance has been switched on for first time/ or after

SF on Freezer Display C on Freezer Display SF on Refrigerator Display AF on Refrigerator display C on Refrigerator Display

D Refrigerator display D Refrigerator display N/A

-- on Freezer display -- on Freezer display

complete defrost. Press OK Button to turn buzzer off.Wait for approx 6 hours for freezer to reach correct temperature. -9C or more on Freezer display Long-black out -9C or more on Freezer activated This display occurs after power failure. Communication fault between Main Control PCB and User PCB (control panel) Ensure that Ice maker function is switched ON Ensure that water tap is switched on and that water is coming through dispenser

CF on Freezer display CF on Freezer display

Appliance does not make ice

Appliance does not make ice

NTC Temperature resistances

Diagnostics for SF or C Error Code

Diagnostics for D Error Code

Diagnostics for CF Error Code

Explanation of Controls

Freezer Fast Freeze Compressor runs for 24hrs continuously Refrigerator Super Cool The Refrigerator runs 6 hours at the minimum temperature (which is 0) Freezer Party Mode Compressor runs for 30 minutes to enable a bottle of sparkling wine to be cooled faster. Wine to be placed anywhere in freezer Freezer Ice Mode Choice between crushed or cubed ice. Default is cubed ice Refrigerator Vacation Fridge compartment is cooled every 30 minutes to avoid bacteria growth

Sixth Sense Appliances Only Water Filter Indicator Shows the effectiveness of the water filter. It starts at F99% and counts down. Once the indicator F98% shows any percentage from F20% to F1% it is advisable to replace filter. The Filter Indicator can be reset by pressing the button for a period of 3 secs Sixth Sense Freezer Freezer compartment runs at a colder sense temperature automatically to counter act prolonged door opening Sixth Sense Refrigerator Refrigerator compartment runs at a sense colder temperature automatically to counter act prolonged door opening Numeric Display Appliances Numeric appliances have the same controls except Party Mode and Sixth Sense. The controls have the same functions a part from the Water Filter Indicator. This has a 3 level indicator that starts from Green (SIS team assumes that the next levels are Amber and Red). The Filter Indicator can be reset by pressing the button for 3 secs. Icemaker Diagnostic (Optical Indication) Accessing Diagnostic Mode: Fix the emitter flap in the closed position with a piece of tape Close the door Switch the Ice Maker on by pressing the relevant button Within 60 secs open the freezer door Hold the light switch in the closed position Switch the Ice Maker on by pressing the relevant button Listen to the receiver LED output code (Please note the manual that the above information was taken has been translated into English and therefore certain parts are not very

clear. If the following information is not exact then please contact your SIS team member so that it can be updated correctly.) LED Output Failure Indication: 2 flashesoff for 1 second2 flashes Fault - Optical Problem. Solution Change IR receiver 3 flashesoff for 1 second3 flashes Fault Ice Maker fault. Solution Change Ice Maker 4 flashesoff for 1 second4 flashes Fault Defective Relay. Solution Change IR receiver LED on for 5 seconds constantly Ice Maker is functioning correctly Note If there is more than one fault with the Ice Maker, the error code shown wil be the first one to occur. Therefore to ensure that only one fault is present, after fixing the fault shown complete the diagnostic test again. Test Points on Ice Maker

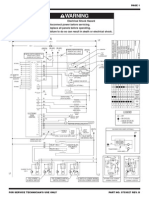

N = Neutral M = Motor Connection H = Heater Connection T = Thermostat Connection (BIMetal) L = Live (Manual states L1. Assumed to be Live) V = Water Valve Connection T-H = Bridge over to start/rotate the shut off arm

Power ON Test Points Test between points L + N Voltage check = 230V Test between points T + H motor and bimetal-thermostat check Test points T + H will verify an open/closed bimetal-thermostat. Place an insulated piece of wire across points T + H to run the motor: If the motor doesnt function it will need replaced If motor is functioning correctly; the temperature on the ice-mould is colder than -9C and the bimetal-thermostat is not closed replace the bimetal-thermostat Test between points T + H mould heater check

Place an insulated piece of wire across points T + H to run the motor After approx. rotation of the ejector heat can be felt in the mould. If this is not the case then the mould heater is defective and the complete mould will need replaced. Test between points L + V water valve check Place an insulated piece of wire across points L + V the water valve should energise and water should be seen flowing into the mould. Note A faulty mould heater will prevent the valve from energising. Test between points M + N ice maker motor check Place an insulated piece of wire across points M + N check too see if motor is running. Power OFF Test Points Test between points L+ H mould heater check a resistance reading of approx. 280 . Electronic PCB Connections

Wiring Colours

Troubleshooting

Fridge temperature too warm and meat/pan slider drawer iced

Fridge temperature too warm

Appliance does not cool down Cause: Thermal fuse open circuit. Procedure: When the appliance is powered up it will go immediately into a Defrost. If either the Thermal fuse or the Defrost Heater is open circuit then the appliance will remain in the Defrost condition. Ensure appliance is unplugged Gain access to Electronic Control PCB

Disconnect 12 Way connector block Using a multimeter: Place one probe on Pin 1 (blue wire) of the 12 Way connector. Place the other probe on Pin 1 (brown wire) of the 16 Way connector. Ensure that this is connected to the PCB. A resistance reading of between 83-94?, will confirm that the defrost heater and thermal fuse are ok. If an open circuit reading is returned then there is either an open circuit thermal fuse/defrost heater-OR- a wiring fault. Food on upper two shelves of the fridge starts to freeze (7 segment version) Cause: If customer has changed the position of the upper two shelves, this can inadvertently reduce the air circulation to the fridge sensor. This will cause the fridge sensor to continually ask for more cold air to be fed into the refrigerator compartment, which in turn will eventually freeze the food. Cure: Replace the air baffle cover and sensor support in the fridge compartment. The air baffle cover has been modified to help counter act the above problem.

New Air Baffle Cover incorporating 3 vents for better air circulation Temperature Alarm on Constantly Cause: Cause: Check for system leaks. Evaporator completely iced up Measure the pressure in the cooling cycle. Check for continuity of Bimetal between orange and white wires. Check for continuity of Thermal fuse between blue and brown wires. Check the resistance values of the heating element (84-94?)

If all the above are ok then replace Electronic Control PCB. User Interface black out Cause: The capacitor in the older Electronic PCB versions eventually start to loose their capacity to store a charge. Cure: Appliances produced before week 30 in 2004 will need both Main Control PCB and User Control PCB to be replaced. Appliances produced after week 30 in 2004 will need the Main Control PCB replaced. Mid trans bar too hot (this is the bar between the refrigerator and the freezer compartments) Cause: Compressor/Condenser fan is faulty Cure: Check wiring connections if OK then replace fan. Refrigerator compartment too warm & Freezer compartment completely frozen Cause: NTC Sensor wires are reversed in the connector block on the PCB i.e. Freezer Sensor wires are in the refrigerator sensor wires position. Cure: The correct wiring configuration is shown below. Pin 1 Freezer Probe Common (Signal) Pin 2 Fridge Probe Common (Signal) Pin 3 Freezer Probe (Signal) Pin 4 Fridge Probe (Signal)

4 Way Connector Main Control PCB

Refrigerator or Freezer Door Open Alarm On and Red LED Flashing Cause:

Refrigerator door switch faulty Freezer door switch faulty Cure: Check wiring connections at 16 Way connector, on the Main PCB, Pin 7 for the Refrigerator and Pin 6for the Freezer. If the wiring is OK then replace relevant door switch. Rattling Noise from the Appliance Cause: Capacitors on the Main Electronic PCB are not holding a charge. Cure: Replace Main Electronic PCB Ice Water all around the Ice Maker Cause: Check if water is dripping from the water tube in the ice maker Cure: If this is the case then the valve is not closing properly and is therefore faulty. The valve has to be replaced. Cause: Check if the appliance is taking in too much water into the ice maker. This process is timed and should run for 7.5 secs which will mean approx. 125 CubicCM of water. Cure: Use adjustment screw on Ice Maker timer to alter the amount taken in. When the small hole is centred in the larger hole then the water fill time is set to 7.5 secs (Normal fill capacity) Turning screw clockwise decreases water filling Turning screw anti-clockwise increases water filling A complete 360 rotation increases/decreases 40 Cubic CM of water or 2.4 secs A 180 half rotation increases/decreases 20 Cubic CM of water or 1.2 secs

Refrigerator compartment too warm (LCD Version only) Cause: Bimetal is positioned incorrectly If the sensing surface is placed face down on top of the evaporator it reduces the duration of the defrost cycle and therefore will eventually cause the evaporator to ice up completely which will in turn reduce the air flow between the compartments. Cure: Ensure that Bimetal is positioned correctly. See Diagrams

You might also like

- Service Data Sheet 240389646Document2 pagesService Data Sheet 240389646Arianna IsabelleNo ratings yet

- Fast Track Troubleshooting: Component Resistance Wattage VoltageDocument11 pagesFast Track Troubleshooting: Component Resistance Wattage Voltagediego rotpeNo ratings yet

- Amana Refrigerator Service ManualDocument72 pagesAmana Refrigerator Service ManualTom SenbergNo ratings yet

- GTF916PZPM ApzqeurDocument87 pagesGTF916PZPM ApzqeurMonete FlorinNo ratings yet

- FRS-25NC Manual ServicioDocument57 pagesFRS-25NC Manual ServicioCiclismo Sexta Región100% (2)

- W10444925 PDFDocument100 pagesW10444925 PDFRoberto Augusto Aristizabal MorenoNo ratings yet

- Maytag Amana Bottom Mount Refrigerator Service ManualDocument77 pagesMaytag Amana Bottom Mount Refrigerator Service ManualRich FosterNo ratings yet

- Coleman Mach 8 Ac ManualDocument12 pagesColeman Mach 8 Ac Manualgcannon3No ratings yet

- Service: Washing Machine Drum TypeDocument43 pagesService: Washing Machine Drum TypeRaul Alexandru CuldaNo ratings yet

- Samsung Service Bulletin Ice MakerDocument11 pagesSamsung Service Bulletin Ice Makerplumber1900No ratings yet

- NEC FR-358 Instruction ManualDocument12 pagesNEC FR-358 Instruction Manualekim444666No ratings yet

- Refrigerator Frs U20bci U21gaiDocument92 pagesRefrigerator Frs U20bci U21gaiJoão Pedro Almeida100% (1)

- Fast Track Troubleshooting: Model: WF461ABP/XAA WF461ABW/XAADocument9 pagesFast Track Troubleshooting: Model: WF461ABP/XAA WF461ABW/XAAMaugrys CastilloNo ratings yet

- یخچال Service ManualDocument19 pagesیخچال Service ManualMadjid RahmaniNo ratings yet

- Code Samsung 6thDocument207 pagesCode Samsung 6thLounes HADDADNo ratings yet

- Electrolux EW23BC71IS0 Refrigerator Tech SheetDocument2 pagesElectrolux EW23BC71IS0 Refrigerator Tech SheetEdison EspinalNo ratings yet

- Amana BTM MNT FRZR Tech Sheet 16023133Document4 pagesAmana BTM MNT FRZR Tech Sheet 16023133En VyNo ratings yet

- Royal Coffee Bar DiagramDocument6 pagesRoyal Coffee Bar DiagramservicerNo ratings yet

- 31-9153 ManualDocument66 pages31-9153 ManualTrish Pierce WhiteNo ratings yet

- Viking VCSB542 - 542D Refrigerator Service Manual SMR-0008Document84 pagesViking VCSB542 - 542D Refrigerator Service Manual SMR-0008MattNo ratings yet

- Refrigerator: Model: SR-L676EV SR-L678EV SR-L626EV SR-L628EVDocument59 pagesRefrigerator: Model: SR-L676EV SR-L678EV SR-L626EV SR-L628EVMiguel Alejandro RondonNo ratings yet

- Fisher-Paykel DD603 Drawer RemovalDocument1 pageFisher-Paykel DD603 Drawer RemovalSamurai Appliance Repair Man100% (3)

- LRSC26912xx Service ManualDocument142 pagesLRSC26912xx Service Manualstaish11No ratings yet

- Aqv 09 12 Uge Ewe Ugfeur 10uge Uwe Uwfeurgsm Sansung Inverter PlacaDocument167 pagesAqv 09 12 Uge Ewe Ugfeur 10uge Uwe Uwfeurgsm Sansung Inverter PlacaAdriano NascimentoNo ratings yet

- AIRE INVERTER HAIER-Tempo-Series-Service-ManualDocument79 pagesAIRE INVERTER HAIER-Tempo-Series-Service-ManualElkin FernandezNo ratings yet

- GE Refigerator PFSS9PKY-PFSS9SKY Rervice-ManualDocument88 pagesGE Refigerator PFSS9PKY-PFSS9SKY Rervice-Manualdan theman100% (1)

- Refrigerator: Service ManualDocument19 pagesRefrigerator: Service ManualCesar Calderon GrNo ratings yet

- Manual de Servicios Splits SamsungDocument86 pagesManual de Servicios Splits SamsungBelkys PaezNo ratings yet

- MSA VMW PP PresentationDocument65 pagesMSA VMW PP PresentationplasmapeteNo ratings yet

- Sharp Refrigerator sj44lwh1Document28 pagesSharp Refrigerator sj44lwh1Joseph AlbertNo ratings yet

- Technical Data Sheet 3RW33 Soft Starter For Carrier NGC Iv: DangerDocument9 pagesTechnical Data Sheet 3RW33 Soft Starter For Carrier NGC Iv: DangervickersNo ratings yet

- Samsung-Rt 31-2007 PDFDocument24 pagesSamsung-Rt 31-2007 PDFviveck.guptaNo ratings yet

- Manual de Servicio Daewoo, DWC-F0567FCLDocument16 pagesManual de Servicio Daewoo, DWC-F0567FCLWalter Ivan Peña FloresNo ratings yet

- Gree Service ManualDocument57 pagesGree Service Manualtheskyishigh33% (3)

- G7881 Fault CodDocument16 pagesG7881 Fault CodMai Doan Nhu ThuanNo ratings yet

- Service Manual w11169652 Reva 27in Front Load WashersDocument94 pagesService Manual w11169652 Reva 27in Front Load WashersSunny SonawaneNo ratings yet

- LG Lrg30 30 RangeDocument78 pagesLG Lrg30 30 Rangedan themanNo ratings yet

- Ice MakerDocument48 pagesIce Makermikec200100% (1)

- 31-9162 GE PFSS6NKW PFSF6NKW Refrigerator Service ManualDocument89 pages31-9162 GE PFSS6NKW PFSF6NKW Refrigerator Service ManualJim Harmke100% (1)

- Samsung Direct Cool Ice Maker Update KitDocument8 pagesSamsung Direct Cool Ice Maker Update Kitdan themanNo ratings yet

- Defrost Control SystemsDocument40 pagesDefrost Control Systemsdreamyson1983100% (1)

- Samsung Refrigerator RF4287HA ManualDocument56 pagesSamsung Refrigerator RF4287HA Manualujjval10No ratings yet

- Service Manual: RefrigeratorDocument98 pagesService Manual: RefrigeratoryatinthoratscrbNo ratings yet

- Service Manual Videocon Ff-Vz330l, 280l, 250lDocument39 pagesService Manual Videocon Ff-Vz330l, 280l, 250ljitendraNo ratings yet

- Dfe 29 JGDocument91 pagesDfe 29 JGKale ArbroughNo ratings yet

- Manual de Microondas FrigidaireDocument52 pagesManual de Microondas FrigidaireFreddy Enrique Luna MirabalNo ratings yet

- Rs68n SeriesDocument105 pagesRs68n SeriesMonete FlorinNo ratings yet

- Fisher & Paykel ACTIVE SMART Refrigerator/Freezer Ice and Water Models E522BRXFDU, E522BRXU, E522BLXFDU, E522BLXUDocument45 pagesFisher & Paykel ACTIVE SMART Refrigerator/Freezer Ice and Water Models E522BRXFDU, E522BRXU, E522BLXFDU, E522BLXUKevNo ratings yet

- Whirlpool Duet HTDocument96 pagesWhirlpool Duet HTdanny85901100% (2)

- KitchenAid Range KESC3008WH11 - Service ManualDocument6 pagesKitchenAid Range KESC3008WH11 - Service ManualplasmapeteNo ratings yet

- Wiring Diagrams For Maytag Heritage Gas & Electric Ranges Failure Codes andDocument124 pagesWiring Diagrams For Maytag Heritage Gas & Electric Ranges Failure Codes andAndre VPNo ratings yet

- Service Manual Frize - GBDocument56 pagesService Manual Frize - GBpol8331No ratings yet

- mfl53274410 LGDocument54 pagesmfl53274410 LGVidal VelasquezNo ratings yet

- RFG297AA Fast Track R1 PDFDocument6 pagesRFG297AA Fast Track R1 PDFRoberto Augusto Aristizabal MorenoNo ratings yet

- Rf265aa-Ab-Ac Fast Track r1Document5 pagesRf265aa-Ab-Ac Fast Track r1hinkxxNo ratings yet

- RF4287HA Updated Fast Track R4Document8 pagesRF4287HA Updated Fast Track R4gmanvbva100% (1)

- RM255 Fast Track R1 PDFDocument8 pagesRM255 Fast Track R1 PDFarjr51No ratings yet

- Samsung RefDocument40 pagesSamsung RefjessluquinNo ratings yet

- Aprilaire Dehumidifier Troubleshooting Manual Models 1710A, 1750A, 1770ADocument17 pagesAprilaire Dehumidifier Troubleshooting Manual Models 1710A, 1750A, 1770AReynaldo FloresNo ratings yet

- RF266AE Fast TrackDocument6 pagesRF266AE Fast Trackplvg2009No ratings yet

- Ice Maker Scotsman ManualDocument32 pagesIce Maker Scotsman ManualfrodoclNo ratings yet

- 600 2 Sub-Zero Built-In Series Refrigerator Service ManualDocument188 pages600 2 Sub-Zero Built-In Series Refrigerator Service Manual911servicetechNo ratings yet

- GE CustomStyle RefrigeratorDocument112 pagesGE CustomStyle RefrigeratorBlake NormanNo ratings yet

- Household Refrigerators and FreezersDocument12 pagesHousehold Refrigerators and FreezersLuis Carlos PardoNo ratings yet

- IMD Series Ins ManualDocument32 pagesIMD Series Ins ManualLidia RoblesNo ratings yet

- Manual KenmoreDocument19 pagesManual KenmoremianlogaiNo ratings yet

- Whirlpool Interactive Catalog Winter 2013-1 PDFDocument123 pagesWhirlpool Interactive Catalog Winter 2013-1 PDFUbaldo BritoNo ratings yet

- lfx31945st Owners ManualDocument63 pageslfx31945st Owners ManualTongyu WangNo ratings yet

- Ice Maker Kold Draft60.Series - Service.manual - Rev.04.2013Document86 pagesIce Maker Kold Draft60.Series - Service.manual - Rev.04.2013Cheohdez100% (1)

- ICe Cube Maker HoshizakiDocument68 pagesICe Cube Maker HoshizakiConcordeus Meyselva Setyaranto Nugroho100% (1)

- Koller Refrigeration ProfileDocument43 pagesKoller Refrigeration ProfileDahlan to100% (1)

- GE Pgss5pjxss ManualDocument74 pagesGE Pgss5pjxss ManualplasmapeteNo ratings yet

- Refrigerator User Manual For Samsung RSA1STMGDocument42 pagesRefrigerator User Manual For Samsung RSA1STMGcezarignat100% (2)

- Winnebago CatalogDocument241 pagesWinnebago Catalogchaput87No ratings yet

- Daewoo Refrgerador Frs-U201sm Manual TecnicoDocument92 pagesDaewoo Refrgerador Frs-U201sm Manual TecnicoJomasando100% (1)

- HZB-15S Service ManualDocument20 pagesHZB-15S Service ManualJason Cravy100% (1)

- Gss25qsta Ss ManualDocument112 pagesGss25qsta Ss ManualathapaNo ratings yet

- Cooling Brochure - September 2008Document16 pagesCooling Brochure - September 2008monique5617No ratings yet

- ManualServicio Refrig HaierDocument88 pagesManualServicio Refrig Haierantonio gaitanNo ratings yet

- Service Flash Freezer Ice Maker Fill Tube On French Door Models PDFDocument1 pageService Flash Freezer Ice Maker Fill Tube On French Door Models PDFMatt BoulayNo ratings yet

- Service Manual: Side by Side S20B RSB21-A/GDocument16 pagesService Manual: Side by Side S20B RSB21-A/GjicutuNo ratings yet

- KENWOOD American Style Fridge Freezer KSBSDIX16 ManualDocument16 pagesKENWOOD American Style Fridge Freezer KSBSDIX16 ManualAli AwanNo ratings yet

- Components of A RefrigeratorDocument8 pagesComponents of A RefrigeratorSihem CessiliaNo ratings yet

- Infection Control Audit Tool - July 2009Document50 pagesInfection Control Audit Tool - July 2009rachael_duff100% (6)

- Fisher & Paykel Quick ReferenceDocument28 pagesFisher & Paykel Quick ReferenceNeilJenkins100% (2)

- Mitsubishi Electric WX627Document4 pagesMitsubishi Electric WX627vincen4lamNo ratings yet

- Manitowoc IndigoDocument4 pagesManitowoc IndigoLuis Esteban Baquerizo OrtizNo ratings yet

- 49 60646 2 - HiresDocument41 pages49 60646 2 - HiresSehar KhanNo ratings yet

- FFSS2614QS0Document23 pagesFFSS2614QS0Josè Ramòn Silva AvilèsNo ratings yet

- Frigidiare PLHS69EESS2 Refrigerator Tech Sheet 241636601 PDFDocument2 pagesFrigidiare PLHS69EESS2 Refrigerator Tech Sheet 241636601 PDFjames leeNo ratings yet