Professional Documents

Culture Documents

Radiatino

Uploaded by

Jose BrightOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Radiatino

Uploaded by

Jose BrightCopyright:

Available Formats

Proceedings of PVP2007

2007 ASME Pressure Vessels and Piping Division Conference

July 22-26, 2007, San Antonio, Texas

Copyright 2007 by ASME

PVP2007-26242

CFD SIMULATIONS OF NATURAL CONVECTION/RADIATION HEAT TRANSFER WITHIN THE FUEL

REGIONS OF A TRUCK CASK FOR NORMAL TRANSPORT

Venkata V.R. Venigalla

Research Assistant

Mechanical Engineering Department

University of Nevada Reno

Reno, Nevada 89557

venigall@unr.nevada.edu

Miles Greiner

Professor of Mechanical Engineering

University of Nevada, Reno

Reno, NV 89557

Phone-(775) 784-4873

greiner@unr.edu

ABSTRACT

A two-dimensional finite volume mesh is constructed that

accurately represents the geometry of a legal weight truck cask,

including four PWR fuel assemblies inside. CFD simulations

calculate buoyancy driven gas motion as well as natural convection

and radiation heat transfer in the gas filled fuel regions. They also

calculate conduction within the cask solid components. The cask is

in a normal transportation environment. The fuel and cask

temperatures are calculated for ranges of fuel heat generation rate and

cladding emissivity, for both helium and nitrogen backfill gas. The

cask thermal capacity, which is the fuel heat generation rate that

brings the peak fuel cladding to its temperature limit, is also

determined. The results are compared to simulations in which the gas

speed is set to zero, to determine the effect of buoyancy induced

motion. The allowable heat generation rate is 23% higher for helium

than for nitrogen due to heliums higher thermal conductivity.

Increasing the cladding emissivity by 10% increases the allowed fuel

heating rate by 4% for nitrogen, but only 2% for helium. The higher

value for nitrogen is caused by the larger fraction of heat transported

by radiation when it is the backfill gas compared to helium. The

stagnant-gas calculations give only slightly higher cladding

temperatures than the gas-motion simulations. This is because

buoyancy induced gas motion does not greatly enhance heat transfer

compared to conduction and radiation for this configuration. The

cask thermal capacity from the stagnant-CFD calculation is therefore

essentially the same as that from the CFD simulation. This suggests

that future cask thermal calculations may not need to include gas

motion. These results must be experimentally benchmarked before

the CFD methods can be used with confidence for designing transport

casks. Basket surface temperatures calculated in this work can be

used as the basis for boundary condition in those experiments.

INTRODUCTION

Light water reactor nuclear fuel assemblies consist of fuel

rods held in square arrays by periodic spacer plates [1, 2]. The rods

themselves are stacks of UO

2

fuel pellets within zircaloy cladding.

Some spaces in the array contain hollow instrumentation or guide

thimble tubes instead of fuel rods. Different boiling water reactor

(BWR) assemblies consist of 66 to 99 arrays of rods surrounded

by a square-cross-section zircaloy channel. Pressurized water reactor

(PWR) assemblies generally consist of 9x9 to 17x17 rod arrays but

do not have surrounding channels. PWR rod diameters are generally

smaller than those of BWRs, but their total assembly cross sections

are larger.

Spent nuclear fuel (SNF) is placed in water pools after it is

removed from a reactor to allow its heat generation and radioactive

decay rates to decrease [3]. After an appropriate time SNF is placed

in casks for dry storage or offsite transport [4, 5]. In transportation

casks, individual SNF assemblies are supported horizontally within

square cross-section basket tubes inside the casks containment

region. That region is evacuated and backfilled with helium or

another non-oxidizing gas. Casks transported by truck or rail have

enough space for roughly 4 or 21 PWR assemblies, respectively [4,

5].

Heat generated by the SNF assemblies makes the cask and

fuel hotter than their surroundings [6, 7]. However, the zircaloy

cladding that encapsulates the fuel pellets provides an important

boundary and its temperature must not exceed its containment

integrity limit of 400C [8]. This can limit the cask thermal capacity,

which is the number and heat generation rate of assemblies that may

be safely loaded.

Finite element thermal simulations are used to predict cask

and fuel temperatures for a given fuel heat generation rate [4].

Multiple simulations are used to determine the maximum fuel heat

generation rate that does not cause the fuel cladding to exceed its

temperature limit [6]. The multiple fuel regions of a cask are

complex to model because each contains many fuel rods. In the past

computational resources were not available to perform multiple

calculations in finite element models that accurately represented the

fuel. To address this problem, the fuel assemblies and backfill gas

were replaced by fictitious but representative solid elements with

temperature-dependent effective thermal conductivities (ETC). [4, 9-

11]

Manteufel and Todreas [9] developed ETC models based

on a one-dimensional analytical model of radiation and conduction

heat transfer in a two-dimensional array of heated rod within a

stagnant gas. That model does not account for unheated tubes or

channels, or multi-dimensional effects. Bahney and Lotz [10]

performed two-dimensional finite element thermal simulations of

Proceedings of PVP2007

2007 ASME Pressure Vessels and Piping Division Conference

July 22-26, 2007, San Antonio, Texas

PVP2007-26242

1

Copyright 2007 by ASME

2

several different fuel assemblies, including unheated components,

within isothermal enclosures. They developed ETC models based on

conduction and radiation heat transfer. In some cases ETC models

are employed in analysis without stating their source or the methods

used to develop them [4, 11].

A shortcoming of conductivity models is that they

approximate heat flux at a location based only on the temperature and

its spatial gradient at that location. This is not universally

appropriate. Natural convection heat flux is dependent on local

velocity, which depends on temperatures at different locations.

Radiation heat transfer also depends on temperatures at a distance.

As a result, a conductivity model that is appropriate within fuel

basket openings near the center of a large rail cask, where the surface

is nearly isothermal, may not be accurate for tubes near its periphery.

Simulations have shown that the basket temperature near the

periphery of rail cask is highly non-uniform [7]. This is important

because the thermal resistance of the periphery cells strongly affect

the temperature of the center basket opening, which affects the

hottest cladding.

The simplifying assumptions employed in ETC models are

intended to cause them to over-predict the cladding temperature.

Finite element cask models that employ this methodology therefore

under-predict the cask thermal capacity. This can cause operators to

under-load cask compared to their true safe capacity. This increases

the required number of storage and transport casks, the number of

shipments, and the associated costs. More accurate (less

conservative) predictions of cask capacity can lead to lower system

costs. It can also reduce the number of shipments and therefore the

risk of transportation accidents.

Experiments that measure the temperature within mock fuel

assemblies inside isothermal enclosures have provided a good

understanding of the combined natural convection and radiation heat

transfer within the fuel assemble/backfill gas regions of casks [12-

14]. Computational fluid dynamics (CFD) simulations of those

experiments accurately reproduced that data [15-18] and hold

promise for developing improved fuel region heat transfer models.

Currently available computational resources are sufficient

to perform two-dimensional simulations in a full cask cross section

that employ CFD in the multiple fuel regions. This can lead to better

estimates of the cask thermal capacity for specific fuel and cask

designs, even for non-uniform fuel heat generation. It also provides

an opportunity to accurately determine the non-isothermal

temperature profiles of the periphery basket tubes [6].

In the current work two-dimensional models of a legal

weight truck (LWT) cask cross-section are developed. Four PWR

assemblies, each consisting of a 15x15 square array of heat

generating fuel rods, are placed within the basket tubes. Buoyancy

induced gas motion and Natural convective/radiation heat transfer

within the fuel regions, as well as conjugate conduction in the solid

regions, are modeled using the Fluent CFD package. The results are

compared to those from finite element models that employ ETC

models in the fuel regions.

The maximum allowed heat generation rate that causes the

cladding to reach its temperature limit is determined for atmospheric

pressure helium and nitrogen backfill gases. The sensitivity of the

allowable heat generation rate to the cladding emissivity is also

evaluated. The non-uniform temperature profiles of the basket tubes

are determined at the maximum allowed heat generation rate. These

profiles will be used in future benchmark experiments.

NOMENCLATURE

BWR Boiling water reactor

CFD Computational Fluid Dynamics

ETC Effective thermal conductivity

LWT Legal Weight Truck

PWR Pressurized Water Reactor

SNF Spent Nuclear Fuel

Q Heat generation rate within an individual fuel

assembly

Q

A

Maximum allowable heat generation rate at which the

cladding reaches the temperature of concern

S

max

Maximum flow speed

T

avg

Average of the temperature along the walls of fuel basket

NU

Maximum Temperature difference in a basket

C,L

Temperature of cladding concern

c

Cladding surface emissivity

FSS

Support Structure surface emissivity

SS

Liner surface emissivity

LEGAL WEIGHT TRUCK PACKAGE

Figure 1 shows the cross section of a generic Legal Weight

Truck (LWT) cask loaded with four spent PWR fuel assemblies.

This cask is similar but not identical to a currently licensed package

[4]. The model is developed using MSC/Patran. The cross section in

Fig. 1 is midway between cask ends. The dot-filled region represents

four 15x15 PWR fuel assemblies within backfill gas. All 225 fuel

rods of each assembly are identical. Each contains UO

2

pellets of

diameter 9.36 mm enclosed in zircaloy cladding of thickness 0.78

mm. No gap or contact resistance between the pellets and cladding

are modeled. The square tube array has center to center spacing of

14.5 mm, and the distance between the center of the outer most rod

and the basket wall is 9.82 mm. The fuel assembly is similar to a

Babcock & Wilcox 15x15 Mark B PWR [19], but the model does not

contain unheated components.

The cross-shaped component at the center of the package is

a 1.5 cm thick stainless steel support structure. Its surface emissivity

is

FSS

= 0.8. Borated carbon (B

4

C) pellets fill 1.1 cm-diameter holes

that are drilled radially in the legs of the structure. The sides of the

four square openings where the fuel is placed are H = 22.3 cm long.

The support structure and fuel are surrounded by a 0.96 cm

thick stainless steel liner. Its emissivity is

SS

= 0.2. The liner is

surrounded by a depleted uranium gamma shield. Its maximum

thickness is 6.7 cm and it has an outer radius of curvature of 11.4 cm

at its corners. A 3.8 cm thick stainless steel package body surrounds

the gamma shield.

An external, 12.4-cm-thick neutron shield encircles the

package. A single region is used to model several components.

These components are 12.1-cm-thick Polypropylene-1% boron, 24

aluminum radial fins of thickness 0.245 cm, and a 0.27 cm thick

stainless steel outer skin. The mixture thermal conductivity for this

composite structure was developed based on an equivalent

conduction model [20].

Heat generated within the fuel rods is transferred to the

surrounding surfaces by natural convection and radiation heat transfer

across the backfill gas, and conduction through the rod spacer plates.

In this work we neglect the spacer plates.

Copyright 2007 by ASME

3

COMPUTATIONAL METHODS

Cask Models

Figure 2a shows the computational meshes used in the

current work. Only one half of the cask cross section is modeled to

take advantage of the geometric and boundary condition symmetry.

The computational grid is constructed using MSC Patran software.

Mesh independence is evaluated using coarse and fine grids with

46,798 and 210,874 elements, respectively. Portions of the fuel

region of those meshes are shown in Figs. 2b and 2c. The majority of

simulations documented in this work are performed using the coarse

grid.

The current simulations calculate the cask and fuel

temperatures using three different fuel region models. One model

uses computational fluid dynamics (CFD) simulations that include

buoyancy-induced fluid motion. Another uses CFD but assumes the

gas speed is zero (Stagnant-CFD). Both these models include the

effects of radiation heat transfer. Comparison of these two results

shows the effect of gas motion. The last model employs the effective

thermal conductivity (ETC) developed by Manteufel and Todreas [9].

Different simulations are performed for each model using

helium or nitrogen backfill gases. Temperature dependent thermal

conductivities are applied to all solid and gas components. Those

properties were obtained from standard sources [4, 5]. The support

structure and stainless steel liner emissivities are

FSS

= 0.8 and

SS

=

0.2, respectively. The cladding emissivity used in the majority of

simulations is

c

= 0.8. Several different cladding emissivities are

presented in the literature [9, 11]. Simulations were performed for

the range

c

= 0.6 to 0.9 to determine its effect on the results.

For both the CFD and Stagnant-CFD models the meshes in

Fig. 2 are imported into the Fluent CFD package. That code utilizes

the finite volume method to solve the governing mass, momentum

and energy equations. A second order upwind discretization scheme

is used to solve the momentum and energy equations along with

SIMPLEC algorithm for pressure velocity coupling.

For the CFD simulations, Fluent calculates buoyancy

induced gas motion, convection and surface-to-surface radiation heat

transfer across the gas filled regions, and conduction in the solid

components. For the Stagnant-CFD simulations the gas speed is set

to zero. Those results were compared to determine the effect of gas

motion.

For all Fluent calculations a uniform volumetric heat

generation was applied to all the fuel pellets. It was determined by

dividing the total heat generation rate of each assembly by the total

volume of its fuel pellets (0.05 m

3

, based on a rod length of 3.601 m

[19]), multiplied by a peaking factor of 1.25 [6, 10]. That factor

accounts for the higher heat generation rate in the midsection of the

PWR assembly compared to its average.

The ETC simulations are performed using the Patran

P/thermal finite element code. The Manteufel and Todreas model [9]

is applied to the 15x15 PWR assembly used in the current work. In

that model the region inside each square opening of the fuel basket is

divided into a central square that represents the fuel assembly, and a

thin edge region that represents the gas filled gap between the

assembly and basket. For the current work the outer edge thickness

is 0.3 cm, which is the distance between the outermost rod center and

the wall, minus half the pin center-to-center pitch. The interior

square with side length 21.7 cm represents the fuel.

Neutron Shield

Package Body

Liner

Gamma Shield

Support Structure

PWR Fuel Assembly

Figure 1: Cross section of a Legal Weight Truck

(LWT) cask that transports four spent pressurized

water reactor fuel assemblies.

Figure 2: Computational domain of a LWT cask (a) Half

Coarse Grid (b) Detail of fine grid with 210874 elements

(c) Detail of Coarse grid with 46798 elements.

(a)

(b)

(c)

U

L

X

0.01

0.1

1

10

0 200 400 600

T [

o

C ]

k

[

W

/

m

o

C

] k

INT ,

He

k

EDGE ,

He

k

INT ,

N

2

k

EDGE ,

N

2

Figure 3: Effective thermal conductivity versus

Temperature for Helium and Nitrogen backfill gases.

Copyright 2007 by ASME

4

The Manteufel and Todreas model gives two different effective

thermal conductivities for the interior and edge regions k

INT

and

k

EDGE

. These conductivities are plotted versus temperature in Fig. 3

for both helium and nitrogen backfill gases. The interior and edge

conductivities were applied to the appropriate elements in Fig 2.

A uniform volumetric heat generation rate is applied to the

central square region. It is determined by dividing the total assembly

heat generation rate by the effective fuel volume (area of the square

region times its effective length), multiplied by a peaking factor.

Cask Boundary Conditions

For all simulations the cask exterior surfaces are exposed to

normal hot day conditions [21]. Those conditions are still air at an

environment temperature of T

E

= 38C, with a constant, solar heat

flux of 388 W/m

2

absorbed by the entire exterior package surface. In

this work, the solar absorptivity is unity and the package radiates to

the environment with a surface emissivity of 0.2 [4]. The natural

convection heat flux at each surface location is calculated as q = h (T

- T

E

). In this expression T is the local surface temperature, and h is

the heat transfer coefficient between the package surface and its

surroundings. It is determined based on a Nusselt number correlation

for a horizontal cylinder in stagnant air [22]:

2

27 / 8

16 / 9

6 / 1

Pr

559 . 0

1

* 387 . 0

6 . 0

|

|

|

|

|

|

|

\

|

+

+ =

Ra

d

k

h

(1)

In this equation the package diameter is d = 2.42 m, k is the thermal

conductivity of air, Pr = / is the air Prandtl number. The kinematic

viscosity of air is and its thermal diffusivity is . The Rayleigh

number is

v

d T T g

Ra

E

d

3

) (

= (2)

where g is the acceleration of gravity and is the isobaric expansion

coefficient of air.

SIMULATION RESULTS

Q = 800 W

Fuel and Cask Temperatures Figure 4 shows

temperature contours within the right side of the cask for a fuel heat

generation rate of Q

= 800 watts/assembly. The plots in Figs. 4a, 4b

and 4c are from the ETC, Stagnant-CFD and CFD simulations,

respectively. The temperatures in the left side of the cask are a

mirror image of those in the figure and are not shown.

Buoyancy-induced gas motion is not included in the ETC

or Stagnant-CFD simulations. As a result the temperature contours

exhibit the same symmetry as the cask geometry. The hottest fuel is

located on diagonal lines that are 45 above and below horizontal,

and the maximum temperatures in the upper and lower fuel regions

are the same. The walls that enclose the fuel are not isothermal. The

sides that are closer to the package outer surface are cooler than those

closer to the interior.

The ETC temperature contours in Fig. 4a exhibit

discontinuities at the lines between the interiors and edges of the fuel

regions. This is caused by the difference in effective conductivity in

those regions. The Stagnant-CFD and CFD temperature contours in

Figs. 4b and 4c exhibit discontinuities throughout their fuel regions.

This is because distinct regions are used for the fuel rods and the gas,

and the rod thermal conductivity is significantly higher than that of

the gas.

The CFD temperature contours do not exhibit the same

symmetries as the other simulations. That is because the CFD

simulations include buoyancy induced gas motion, which shifts the

hottest locations upward compared to the Stagnant-CFD calculations.

That motion also causes the upper surface of each basket opening to

be hotter, and the lower surface to be colder, than it is if the gas is

stagnant. This causes a net transfer of heat from the lower to the

upper fuel region, and makes the average temperature of the upper

fuel region hotter than that of the lower.

Buoyancy induced gas motion in each fuel region is

characterized by its Rayleigh number, which is the ratio of buoyancy

to viscous forces. The Rayleigh number is

v

H T g

Ra

MAX

MAX

3

) (

= (4)

The maximum gas temperature difference in the upper fuel region is

T

MAX

= T

CLAD,MAX

T

BASKET,MIN

, where T

CLAD,MAX

is the maximum

clad temperature and T

BASKET,MIN

is the minimum basket temperature.

The CFD simulation in Fig. 4c predicts T

MAX

= 96C. The

acceleration of gravity is g, and , and are, respectively, the gas

expansion coefficient, kinematic viscosity and thermal diffusivity of

the gas. These gas properties are evaluated at the film temperature

(T

CLAD,MAX

+ T

BASKET,MIN

)/2. For the results in Fig. 4c Ra

MAX

=

1.24*10

7

.

Canaan and Klein [13 and 16] experimentally and

computationally studied natural convection heat transfer for a

horizontal 8x8 BWR spent fuel assembly within an isothermal

enclosure. They considered nitrogen and helium gas. For Rayleigh

numbers less than 10

6

the Nusselt number was independent of

(a)

(b)

(c)

Figure 4: Normal hot day transport temperature

contours (in Kelvin) of a LWT cask with 800W/assembly

using (a) ETC model (b) Stagnant CFD (c) CFD model.

Copyright 2007 by ASME

5

Rayleigh number. This is considered the conduction regime because

buoyancy induced motion does not affect heat transfer. For Rayleigh

numbers greater than 10

7

, the Nusselt number increased proportional

to Ra

1/3

. This is the convection regime. Rayleigh numbers between

these values constitute the transition regime. The Rayleigh number

for the simulation in Fig. 4c is therefore in the convection regime.

The conditions of the current work are somewhat different from that

of Canaan and Klein because the enclosure temperature is not

isothermal and the rod temperatures are affected by radiation heat

transfer.

Figure 5 shows temperature versus radial distanced form

the cask center r from all three fuel models. Results are presented for

the upper (U) and lower (L) diagonal lines shown in Fig. 2. Figure 5a

and 5b show results for nitrogen and helium gas, respectively. We

note that for the ETC and stagnant-CFD simulations these diagonals

pass through the hottest fuel locations. For the CFD model the

hottest fuel in each assembly is above the diagonals.

For both gases and all three models, the temperature

profiles are nearly identical for r > 0.225 m, which is outside the

fuel/backfill gas region. The ETC simulations give higher

temperatures within the fuel than the other two models. The ETC

temperatures from the upper and lower diagonals are identical

because that simulation does not include buoyancy induced gas

motion. Its temperature gradient exhibits a discontinuity at the

interfaces between the interior and gap regions. This is because it

employs a much lower conductivity in the gap than in the interior.

The Stagnant-CFD simulation results are also identical

along the upper and lower diagonals. Its profile shape exhibits flat

regions in the relatively high conductivity rods, and larger gradients

in the lower conductivity gas. For nitrogen, the maximum cladding

temperature from the Stagnant-CFD simulation is 51C lower than

that predicted by the ETC model. For both the nitrogen and helium

simulations, the temperature gradient in the interior of the ETC

model is roughly the same as that of the Stagnant-CFD simulation.

However, the ETC gradients near the wall (in its gap region) are

significantly higher. This appears to be the primary contributor to the

different peak temperatures predicted by these two models.

For the nitrogen gas simulations, the CFD model does not

give the same results for the upper and lower diagonals. For r > 0.07

m the upper diagonal temperatures are hotter than those of the lower.

For the helium gas, the CFD temperatures along the upper and lower

diagonal are nearly identical, and they are nearly the same as the

Stagnant-CFD results. The conductivity of helium is sufficiently

high that gas motion does not significantly affect heat transfer.

(a)

(b)

-0.1

-0.08

-0.06

-0.04

-0.02

0

0.02

0.04

0 0.05 0.1 0.15 0.2 0.25

X [m]

V

y

[

m

/

s

]

Lower Basket

Upper Basket

Figure 6: (a) Exploded view of the velocity stream

functions in the basket. (b) Velocity profiles in Y direction

for Nitrogen backfill gas.

Gas Flow Field Figure 6a shows streamlines in the two

of fuel regions from the nitrogen gas CFD simulation with Q = 800

W. The streamlines in these two regions are similar but they are not

identical, especially on their left sides. The heated rods and the cool

walls cause the gas to move upward in the center of the regions and

downward at their sides. This develops two counter rotating vortices.

In both fuel regions the vortex closer to the cask periphery (the right)

is significantly larger than the one near the cask center. This

asymmetry is caused by the non-isothermal walls. In contrast,

simulations for BWR and PWR assemblies within uniform

temperature enclosures [17, 23] show symmetric vortices.

Figures 6b shows the vertical component of gas velocity

versus distance from the left side of the fuel region, X. The speeds

are for horizontal lines midway between the 7

th

and 8

th

row of rods

(b)

(a)

130

150

170

190

210

230

250

270

290

310

0 0.1 0.2 0.3 0.4

r [m]

T

[

o

C

]

ETC(U & L)

CFD - L

CFD - U

Stagnant CFD(U & L)

130

150

170

190

210

230

250

0 0.1 0.2 0.3 0.4

r [m]

T

[

o

C

]

ETC(U & L)

CFD & Stagnant CFD(U & L)

Figure 5: Normal conditions of transport temperature

profiles calculated along bold line U and L in Fig. 2

versus Radial Distance from the package center, for Q

= 800 watts/assembly and with (a) Nitrogen Backfill

gas (b) Helium Backfill gas.

Copyright 2007 by ASME

6

(counted from the bottom) in both the top and bottom fuel regions of

Fig. 6a. In both fuel regions the flow moves upward with fairly low

speed in a large portion of the interior. It moves downward with

significantly higher speed in thin regions near the side walls,

especially on the right (near the cask periphery). The maximum gas

speed in the upward and downward directions are S

MAX,UP

= 3.44 and

S

MAX,DOWN

= 10.92 cm/s, respectively.

The multi-peaked shape of the profile is caused by the

faster speeds above the regions between rods compared to that above

the rods themselves. The profile shapes for the helium (not shown) is

very similar to that of nitrogen but roughly ten times smaller. The

speed profiles for helium in the upper and lower regions are even

more nearly identical than they are for nitrogen. The Reynolds

number for this simulation is Re

H

= S

MAX

H/ = 691. It does not

appear that turbulence modeling is necessary for this simulation

because Re

H

< 1000.

Dependence on Q

Figure 7a is a plot of the maximum temperature difference

T

MAX

versus fuel heat generation rate Q. Nitrogen and helium gas

results are presented from both CFD and stagnant-CFD simulations.

T

MAX

is higher for nitrogen than it is for helium due to nitrogens

lower thermal conductivity.

For both gases, at low Q heat is transferred from the rods to

the enclosure primarily by conduction through the gas. This is

because the temperature difference in the gas is too small to initiate

buoyancy induced gas motion, and the surface temperatures are too

low for radiation to be significant. As Q increases the importance of

gas motion and radiation also increase. This causes the slope of the

T

MAX

versus Q data to decrease.

For both gases the stagnant-CFD temperatures are hotter

than the CFD results. This is because the stagnant simulations do not

include the effect of gas motion. However, Fig. 7a shows that the

effect of gas motion small. For nitrogen the difference reaches its

highest level (2.3

o

C) at 800 watts/assembly. The differences are even

smaller for helium.

Figure 7b shows the maximum Rayleigh number versus

heat generation rate for He and N

2

from the CFD and Stagnant CFD

simulations. Horizontal lines indicate the minimum Rayleigh number

for the convection regime and the maximum value for the conduction

regime [12].

The Rayleigh numbers for nitrogen are two orders of

magnitude higher than for helium. This indicates that buoyancy

forces are much more significant compared to viscosity for nitrogen

than for helium. At low heat generation rates the Rayleigh numbers

increase with the heating rate. This is because T

MAX

increases and

this increases buoyancy effects. At higher Q, the gas temperature

increases, and this changes its properties so that the ratio of buoyancy

to viscous forces decreases. As a result, even though T

MAX

continues to increase (Fig. 7a), Ra

MAX

reaches a peak and then

decreases (Fig. 7b).

For all heat generation rates considered in this work the

helium simulations are deep inside the conduction regime [12]. This

suggests that buoyancy induced gas motion has no effect on heat

transfer. This explains why the Stagnant-CFD and CFD results for

(b)

(a)

0

2

4

6

8

10

12

0 500 1000 1500 2000 2500 3000 3500

Heat Q [watts /as s embly]

S

m

a

x

[

c

m

/

s

]

N

2

-

Down

He - Down

N

2

-

Up

He - Up

1

10

100

1000

0 500 1000 1500 2000 2500 3000 3500

Q [watts/assembly]

R

e

H

=

S

m

a

x

H

/

N

2

He

Figure 8: (a) Maximum velocity magnitude versus heat

generation rate. (b) Reynolds number versus heat

generation rate.

(b)

(a)

0

50

100

150

200

250

0 500 1000 1500 2000 2500 3000 3500

Q [watts/assembly]

T

M

A

X

=

T

C

l

a

d

,

M

a

x

-

T

B

a

s

k

e

t

,

M

i

n

[

o

C

]

Stagnant CFD CFD

He

CFD and Stagnant CFD

N

2

1.E+04

1.E+05

1.E+06

1.E+07

1.E+08

1.E+09

200 700 1200 1700 2200 2700

Q [watts/assembly]

R

a

m

a

x

He

N

2

Conduction Regime < 10

6

Convection Regime > 10

7

Transition Regime

Figure 7: (a) Max. Temperature difference between

cladding and basket temperatures versus heat

generation rate for CFD and stagnant CFD (b) Rayleigh

number versus heat generation rate for helium and

nitrogen backfill gases for CFD and Stagnant CFD

simulations with heat transfer regimes predicted by

Canaan and Klein, 1998.

Copyright 2007 by ASME

7

helium are nearly identical in Fig. 7a. On the other hand, the nitrogen

simulations are in the lower portions of the convection regime for

heat generation rates between 250 to 1600 watts/assembly. This

suggests that gas motion will enhance heat transfer compared to

stagnant gas. However, the difference between the Stagnant-CFD

and CFD results in Fig. 7a for nitrogen is small. This suggest that,

even though gas motion does increase heat transfer compared to gas

conduction and radiation, radiation heat transfer which is included in

both simulations, dominates.

Gas Speeds

Figure 8a shows the magnitude of maximum upward and

downward gas speed in the fuel regions versus assembly heat

generation rate. Results for nitrogen and helium are presented. For

all heat generation rates and both gases, the speed in the down flow is

greater than that in the upward direction. Figure 6b shows that the

downward flow is concentrated in thin regions near the enclosure

walls and upward flow exists in a much larger portion of the domain

interior. The gas speeds are larger for nitrogen than they are for

helium, in agreement with the Rayleigh numbers presented in Fig. 7b.

The gas speeds increase with Q, reach a peak, and then

decrease. The highest downward speed in nitrogen is observed at Q

= 600 W. In Fig. 7b, the peak Rayleigh number for nitrogen is also

observed at this heating rate.

Figure 8b shows the Reynolds number versus assembly

heat generation rate. The Reynolds numbers are calculated using the

downward velocities to obtain the maximum value. The maximum

Reynolds numbers for helium and nitrogen are, 9.7 and 712

respectively.

Maximum Allowable Heat Generation

Figure 9a and 9b shows the peak (maximum) fuel

temperature versus heat generation rate predicted by the ETC,

stagnant-CFD and CFD models. Results for nitrogen and helium gas

are presented in Figs. 9a and 9b, respectively. The peak temperature

increases with the assembly heat generation rate for all three models

and both gases. The ETC model predicts higher cladding

temperatures than either CFD model. The stagnant-CFD and CFD

results are so close together they are indistinguishable on this plot.

Figure 9c show the difference between the peak cladding

temperatures predicted by different CFD models versus fuel heat

generation rate. Two of the lines show the difference between the

stagnant-CFD and CFD results for helium and nitrogen. The third

shows the difference between the refined and nominal grids results

for nitrogen between. The maximum difference between the refined

and nominal grid is 2.3C. This is 0.5% of the temperature difference

between the hottest and coolest portions of the cask, and indicates

that the current simulations are mesh-independent.

For nitrogen gas the peak cladding temperature predicted

by the Stagnant-CFD calculation is 1.2C hotter than the CFD value

at Q = 600 watts. The difference is smaller at all other heating rates.

For helium the difference is less than 0.5C. The random nature and

small size of this difference appears to be caused by numerical error

of the calculation technique.

The horizontal lines in Figs. 9a and 9b show the maximum

allowable clad temperature T

C,L

= 400C [5]. The allowable heat

generation rate Q

A

is the rate that causes the cladding to reach T

C,L

.

The allowable heat generation rate for both gases and all three

models are summarized in Table 1. The CFD and stagnant-CFD

models predict nearly identical maximum cladding temperatures and

they predict nearly the same value of Q

A

for both gases. This

indicates that it may not be necessary to expend the computational

resources required to calculate fluid motion when predicting the

allowable heat generation rate. Both CFD models predict higher heat

generation rates than those predicted by the ETC model.

(b)

(a)

(c)

-2.50

-2.00

-1.50

-1.00

-0.50

0.00

0.50

1.00

1.50

0 500 1000 1500 2000 2500 3000

Q [watts/assembly]

T

[

o

C

]

N

2

[Stagnant CFD - CFD]

N

2

[Refined - Nominal]

He [Stagnant CFD -CFD]

100

150

200

250

300

350

400

450

500

550

200 700 1200 1700 2200 2700

Heat Q [Watts /as s embly]

T

C

l

a

d

,

M

a

x

[

o

C

]

E TC

T

C , L

=

400

o

C

C F D and S tagnant C F D

100

150

200

250

300

350

400

450

500

200 700 1200 1700 2200 2700

Heat Q [watts /as s embly]

T

C

l

a

d

,

M

a

x

[

o

C

]

T

C , L

= 400

o

C

E TC

C F D and S tagnant C F D

Figure 9: Maximum fuel clad temperature versus Heat

generation rate and cladding long term temperature

limit (a) With Nitrogen as backfill. (b) With Helium as

backfill. (c) Max. Temperature difference between CFD

and Stagnant CFD simulations for different backfill

gases and Max. Temperature difference between

refined and nominal grid for nitrogen backfill gas.

Q

A

[watts/assembly]

Upper

Basket

Lower

Basket

Gas

CFD

Stagnant

CFD

ETC

T

avg

[

o

C]

T

NU

[

o

C ]

T

avg

[

o

C]

T

NU

[

o

C ]

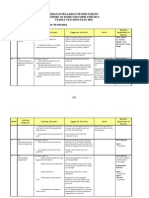

Nitrogen 2025 2025 1400 309.1 151.0 307.0 155.2

Helium 2500 2500 2000 317.7 140.0 317.5 140.2

Table 1: Average temperatures and Max. Temperature

differences along the walls of a SNF assembly.

Copyright 2007 by ASME

8

Effect of Cladding Emissivity

A number of different sources give different estimates of

cladding emissivity for spent fuel [9, 11]. The baseline simulations

presented in this work use

C

= 0.8. The CFD simulations were

repeated for a range of emissivities to determine how they affect the

allowable fuel heat generation rate. Figure 10 is a plot of the ratio of

Q

A

at different emissivities to the value using

C

= 0.8, Q

A,c=0.8

.

Results are plotted for

C

= 0.6 to 0.9 for both nitrogen and helium.

For both gases the ratio increases with

C

. A 10% increase

in

C

results in a 4% increase in Q

A

for nitrogen, but only a 2%

increase for helium. Helium has a higher thermal conductivity than

nitrogen. As a result, a smaller fraction of the total heat is transferred

by radiation for helium than for nitrogen and so its heat transfer rate

is less affected by uncertainty in cladding emissivity.

Basket Wall Temperatures

Figure 11 is a plot of the basket wall temperatures at the

allowable heat generation rate versus wall coordinate, s. Figs. 11a

and 11b show results for nitrogen with Q = Q

A

= 2025 W, and helium

with Q = Q

A

= 2500 W, respectively. The s-coordinate is the

distance in Fig. 2 along the basket surface starting from the basket

opening corner closest the package center and ending at the corner

farthest from that location. Results for four different cords are

presented, two from the upper basket opening and two from the

lower. The results from different cords are not distinguished in the

figure because they are close to each other.

The surfaces close to the cask center are hotter and exhibit

a larger temperature gradient than the surfaces near the package

periphery. The profiles exhibit small amplitude waves that are

caused by local heat transfer variations due to the nearby fuel rods.

For nitrogen (Fig. 11a) the wall temperature varies from 240 to

390C while the variation for helium (Fig. 11b) is 250 to 396C. For

nitrogen the temperature profiles along the four cords are not

identical due to the effects of natural convection. However, the

temperatures at each s-location are within 15C of each other. The

variation is much smaller for helium because the helium motion has a

much smaller effect on heat transfer.

The average and non-uniformity temperatures, T

AVG

and

T

NU

for the upper and lower openings are presented in Table 1. The

non-uniformity temperature is the difference between the maximum

and minimum wall temperatures. Results are given for both nitrogen

and helium at the allowable heat generation rate for that gas. The

average surface temperature is higher for helium that nitrogen. This

is because heliums higher conductivity makes the difference

between its surface temperature and the maximum cladding

temperature smaller than it is for nitrogen. Heliums higher thermal

conductivity makes its temperature non-uniformity smaller than that

of nitrogen. The differences between these results for the upper and

lower cells are smaller for helium than it is for nitrogen. This is

because the effects of natural convection are stronger for nitrogen

than for helium.

SUMMARY AND CONCLUSIONS

Highly radioactive spent nuclear fuel is transported in thick

walled casks. The fuel is placed in square cross-section openings of a

basket structure inside the cask containment volume. That volume is

evacuated and backfilled with a non-oxidizing gas. Heat generated

by the fuel is transferred through the gas and cask walls to the

environment. The walls must be thick enough to protect the public,

but conductive so the fuel cladding does not exceed its allowed

temperature. Finite element (FE) thermal models are used to

determine the cask thermal capacity, which is the maximum fuel heat

generation rate that does not cause the fuel cladding to exceed its

temperature limit.

Effective thermal conductivity (ETC) models are typically

employed in the fuel regions of the FE models to predict the cladding

temperature. They model conduction and radiation heat transfer from

the fuel rods to the basket but neglect some heat transfer effects. It is

difficult to develop conductivities that are accurate for different fuel

assembly designs, backfill gas compositions and pressures, and fuel

cladding emissivities. Conservative assumptions are therefore

employed so that the conductivities overestimate the cladding

temperature and FE models that employ the conductivities

underestimate the cask capacity.

Figure 10: Effect of Cladding Emissivity on Maximum

allowed heat generation rate QA.

0.92

0.94

0.96

0.98

1

1.02

1.04

1.06

0.5 0.6 0.7 0.8 0.9 1

Emissivity

c

Q

A

/

Q

A

=

0

.

8

He

N

2

(b)

(a)

200

220

240

260

280

300

320

340

360

380

400

0 0.1 0.2 0.3 0.4 0.5

T

[

o

C

]

S [m]

240

260

280

300

320

340

360

380

400

0 0.1 0.2 0.3 0.4 0.5

T

[

o

C

]

S [m]

Figure 11: Temperature profiles along the walls of PWR

basket for a) Nitrogen at Q = 2025 watts/assembly and

(b) Helium at Q = 2600 watts/assembly.

Copyright 2007 by ASME

9

Computational fluid dynamics (CFD) simulations offer an

opportunity to more completely model the fuel/backfill gas regions

than ETCs, but they require more computational resources. The

current work demonstrates the use of a cask CFD model and attempts

to determine which heat transfer effects are significant, and which

may be reasonably neglected in order to reduce the required

computational resources.

A two-dimensional finite volume mesh is constructed that

accurately represents the geometry of a legal weight truck cask,

including the fuel inside. CFD simulations are performed that

calculate buoyancy driven gas motion, as well as the natural

convection and radiation heat transfer in the gas filled fuel region.

They also calculate conduction within the cask solid components.

The cask is in a normal transportation environment. The fuel and

cask temperatures are calculated for ranges of fuel heat generation

rate and cladding emissivity, for both helium and nitrogen backfill

gas. The maximum allowed fuel heat generation rate, which brings

the peak fuel cladding to its temperature limit, is also determined.

The results are compared to stagnant-CFD simulations, in which the

gas speed is set to zero, to determine the effect of buoyancy induced

motion. The allowable heat generation rate is 23% higher for helium

than for nitrogen due to heliums higher thermal conductivity.

Increasing the cladding emissivity by 10% compared to the baseline

value increased the allowed fuel heating rate by 4% for nitrogen, but

only 2% for helium. It is higher for nitrogen because radiation

transports a larger fraction of the heat when it fills the containment

volume than when helium is present. The stagnant-CFD simulations

give only slightly higher cladding temperatures than the CFD

calculations. This is because buoyancy induced gas motion does not

greatly enhance heat transfer compared to conduction and radiation

for this configuration. The allowed heat generation rate from the

stagnant-CFD calculation is therefore essentially the same as that

from the CFD simulation. This suggests that future cask thermal

calculations may not need to include gas motion. These results must

be experimentally benchmarked before the CFD methods can be used

with confidence for designing transport casks. Basket surface

temperatures presented in this work can be used as the basis for

boundary condition for those experiments.

REFERENCES

[1] U.S Department of Energy, 1987, Characteristics of

Spent Nuclear Fuel, High-Level Waste, and Other

Radioactive Wastes Which May Require Long-Term

Isolation, U.S Department of Energy, Office of

Civilian Radioactive Waste Management, DOE/RW-

0184, December

[2] Bahney, R.H., and Lotz, T.L., 1996, Spent Nuclear

Fuel Effective Thermal Conductivity Report, Prepared

for the U.S. DOE, Yucca Mountain Site

Characterization Project Office by TRW

Environmental Safety Systems, Inc., July 11, D.I.:

BBA000000-01717-5705-00010 REV 00.

[3] Saling, J. H. and Fentiman, A. W., 2001, Radioactive

Waste Management, 2nd Edition, Taylor and Francis,

New York.

[4] General Atomics (GA), 1998, GA-4 Legal Weight

Truck From-Reactor Spent Fuel Shipping Cask, Safety

Analysis Report for Packaging (SARP), Prepared by

General Atomics, San Diego, California 92186-5608.

[5] Office of Civilian Radioactive Waste Management

(OCRWM), US Department of Energy, 1993, Multi-

Purpose Canister (MPC) Implementation Program

Conceptual Design Phase Report, DOC ID:

A20000000-00811.

[6] Greiner, M., Gangadharan, K.K., and Gudipati, M.,

"Use Of Fuel Assembly/Backfill Gas Effective

Thermal Conductivity Models to Predict Basket and

Fuel Cladding Temperatures within a Rail Package

during Normal Transport," PVP2006-ICPVT-11-

93742, Proceedings of PVP2006-ICPVT-11, 2006

ASME Pressure Vessels and Piping Division

Conference, July 23-27, 2006, Vancouver, BC, Canada,

2006.

[7] Gangadharan, K.K. 2006, Use Of Fuel

Assembly/Backfill Gas Effective Thermal Conductivity

Models to Predict Basket and Fuel Cladding

Temperatures within a Rail Package during Normal

Transport, Masters Thesis, Mechanical Engineering

Department, University of Nevada, Reno.

[8] Nuclear Regulatory Commission (NRC), 2005,

Cladding Considerations for the Transportation and

Storage of Spent Fuel, Interim Staff Guidance Report

for the Spent Fuel Project Office of the U.S., ISG-11

Rev. 3, available at www.nrc.gov

[9] Manteufel, R.D., and Todreas, N.E., 1994, Effective

thermal conductivity and edge conductance model for a

spent fuel assembly, Nuclear Technology, Vol. 105,

pp. 421-440.

[10] Bahney, R. H., and Lotz, T. L., 1996, Spent Nuclear

Fuel Effective Thermal Conductivity Report, Prepared

for the U.S. DOE, Yucca Mountain Site

Characterization Project Office by TRW

Environmental Safety Systems, Inc., July 11, D.I.:

BBA000000-01717-5705-00010 REV 00.

[11] Unterzuber, R., Milnes, R. D., Marinkovich, B. A. and

Kubancsek, G. M., 1982, Spent-Fuel Dry-Storage

Testing at EMAD (March 1978 through March 1982.)

Prepared for the US DOE Commercial Spent Fuel

Management Program Office at the Pacific Northwest

Laboratory, B-D3339-A-G. September.

[12] Lovett, P. M., 1991 An Experiment to Simulate the

Heat Transfer Properties of a Dry, Horizontal Spent

Nuclear Fuel Assembly. M.S. Thesis, Nuclear Eng.,

Massachusetts Institute of Technology

[13] Canaan, R. E. and Klein, D. E., 1996, An

Experimental Investigation of Natural Convection Heat

Transfer within Horizontal Spent Fuel Assemblies,

Nuclear Technology, Vol.116, pp. 306-318, December.

[14] Arya, M. S. and Keyhani, M., 1990, Convective Heat

Transfer in a Sealed Storage Cask Containing Spent

Fuel Canisters, Journal of Nuclear Science and

Engineering, Vol. 105, pp. 248-259.

[15] Wix, S.D. and Koski, J.A., 1993, Numerically

predicting horizontally oriented spent fuel rod surface

temperatures, High level radioactive waste

management: proceedings of the 4th annual

international conference, Las Vegas, Nevada, April 26-

30, pp. 1785-1789.

[16] Canaan, R. E. and Klein, D. E., 1998, A Numerical

Investigation of Natural Convection Heat Transfer

within Horizontal Spent-Fuel Assemblies, Nuclear

Technology, Vol. 123, August, pp. 193-208

[17] Gmez, P.E.A., and Greiner, M., "Benchmark Natural

Convection/Radiation Simulations Within An Enclosed

Array Of Horizontal Heated Rods," PVP2006-ICPVT-

11-94021, Proceedings of PVP2006-ICPVT-11, 2006

Copyright 2007 by ASME

10

ASME Pressure Vessels and Piping Division

Conference, July 23-27, 2006, Vancouver, BC, Canada,

2006.

[18] Chalasani, N.R., and Greiner, M., "Natural

Convection/Radiation Heat Transfer Simulations Of An

Enclosed Array Of Vertical Rods," PVP2006-ICPVT-

11-93734, Proceedings of PVP2006-ICPVT-11, 2006

ASME Pressure Vessels and Piping Division

Conference, July 23-27, 2006, Vancouver, BC, Canada,

2006.

[19] Office of Civilian Radioactive Waste Management,

1987, Characteristics of Spent Fuel, High-Level

Waste, and Other Radioactive Wastes Which May

Require Long-Term Isolation, Vol. 3, DOE/RW-0184,

December.

[20] Mallidi, N., Greiner, M., and Venigalla, V.R.V., "Fire

Durations of Concern for a Modern Legal Weight

Truck Cask," PVP2006-ICPVT-11-93748, Proceedings

of PVP2006-ICPVT-11, 2006 ASME Pressure Vessels

and Piping Division Conference, July 23-27, 2006,

Vancouver, BC, Canada, 2006.

[21] U.S. Nuclear Regulatory Commission, Packaging and

Transportation of Radioactive Material, Rules and

Regulations, Title 10, Part 71, Code of Federal

Regulations, April 1992.

[22] Incropera, F.P., and DeWitt, D.P., 1996, Introduction to

Heat Transfer, 3

rd

edition, J. Wiley and Sons, New

York.

[23] Gmez, P.E.A., and Greiner, M., "2d Natural

Convection And Radiation Heat Transfer Simulations

Of A Pwr Fuel Assembly Within A Constant

Temperature Support Structure," PVP2006-ICPVT-11-

93332, Proceedings of PVP2006-ICPVT-11, 2006

ASME Pressure Vessels and Piping Division

Conference, July 23-27, 2006, Vancouver, BC, Canada,

2006.

You might also like

- The Vocabulary Builder - The Practically Painless Way To A Larger VocabularyDocument163 pagesThe Vocabulary Builder - The Practically Painless Way To A Larger VocabularyMina Fawzy100% (5)

- The Vocabulary Builder Workbook - Magoosh-1Document502 pagesThe Vocabulary Builder Workbook - Magoosh-1Shubh Gandhi97% (67)

- 1Document1 page1Jose BrightNo ratings yet

- Motor Insurance - Private Car Liability Only PolicyDocument2 pagesMotor Insurance - Private Car Liability Only PolicyOm Prakash SharmaNo ratings yet

- (A History of Indian literature _ v. 10 _ Dravidian literature_ Fasc. 2)) George L Hart_ Jan Gonda (Editor) - A History of Indian Literature, Volume X_ Dravidian Literature, Part 2_ The Relation BetweDocument41 pages(A History of Indian literature _ v. 10 _ Dravidian literature_ Fasc. 2)) George L Hart_ Jan Gonda (Editor) - A History of Indian Literature, Volume X_ Dravidian Literature, Part 2_ The Relation BetweThomas JohnsonNo ratings yet

- Hack DietDocument338 pagesHack DietDartus100% (10)

- VarmakalaiDocument16 pagesVarmakalaikowsilaxNo ratings yet

- Application FormDocument5 pagesApplication Formrahul_r_dNo ratings yet

- Konstantinos Mylonas Dean Miller Dorothy Whitti B-Ok - Xyz CompressedDocument431 pagesKonstantinos Mylonas Dean Miller Dorothy Whitti B-Ok - Xyz Compressedrmpalmav100% (1)

- 2005 01 0971Document11 pages2005 01 0971Jose BrightNo ratings yet

- Numerical Heat Transfer and Fluid Flow PDFDocument107 pagesNumerical Heat Transfer and Fluid Flow PDFNeelkanth NirmalkarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- R&AC Lab ManualDocument29 pagesR&AC Lab ManualPARAMESHNo ratings yet

- ALU DELTA II T and T/PDocument23 pagesALU DELTA II T and T/PMax HeadroomNo ratings yet

- HM 289 Experiments With A Pelton Turbine Gunt 848 PDF 1 en GBDocument3 pagesHM 289 Experiments With A Pelton Turbine Gunt 848 PDF 1 en GBbeshirNo ratings yet

- Gas Pressure Regulators For Inlet Pressures Up To 100 Bar: British Standard Bs en 334:2005+A1:2009Document108 pagesGas Pressure Regulators For Inlet Pressures Up To 100 Bar: British Standard Bs en 334:2005+A1:2009vinay1999No ratings yet

- Coating of SuperalloysDocument4 pagesCoating of SuperalloysFaraj MohamedNo ratings yet

- Produced Water TreatmentDocument53 pagesProduced Water TreatmentMahathir Che Ap83% (6)

- Review of Fillet Weld Strength Parameters: For ShipbuildingDocument64 pagesReview of Fillet Weld Strength Parameters: For Shipbuildingcarlos ivan carvajal ortizNo ratings yet

- Physics Year 10 Assessment TestDocument16 pagesPhysics Year 10 Assessment TestJoyceNo ratings yet

- Bezinal XPDocument2 pagesBezinal XPHeca WahyuniNo ratings yet

- Sealeze APH Brush Seals BrochureDocument2 pagesSealeze APH Brush Seals BrochureMurilo Camisão SchwindenNo ratings yet

- Ch22 h3 Solutions PDFDocument4 pagesCh22 h3 Solutions PDFld393563No ratings yet

- Duct Design For "Super" SupermarketDocument47 pagesDuct Design For "Super" Supermarketkevin_thian_1100% (4)

- Garrison: Oceanography An Invitation To Marine Science, 8e FinalDocument22 pagesGarrison: Oceanography An Invitation To Marine Science, 8e FinalBagas IndiantoNo ratings yet

- Determining The Work of The Thermodynamic System in Polytropic Processes PV ConstDocument2 pagesDetermining The Work of The Thermodynamic System in Polytropic Processes PV ConstTHÀNH NGUYỄN PHÚNo ratings yet

- Sky Air Seasonal Classic Conductos Baja Silueta Serie DDocument1 pageSky Air Seasonal Classic Conductos Baja Silueta Serie DmiroNo ratings yet

- Heat Input Effects in WeldingDocument34 pagesHeat Input Effects in WeldingMohammed SulemanNo ratings yet

- Ashrae Revision 2005 To 2008Document7 pagesAshrae Revision 2005 To 2008Wilfredo Nool MadronioNo ratings yet

- Repol® C015Eg: Reliance Industries LimitedDocument2 pagesRepol® C015Eg: Reliance Industries LimitedCamilo ObandoNo ratings yet

- Carbon Fibre ReportDocument14 pagesCarbon Fibre ReportyoyotoyoNo ratings yet

- Ultra - Temp Installation and Maintenance Manual IOM 101.2Document16 pagesUltra - Temp Installation and Maintenance Manual IOM 101.2Abdiel Kadir Martinez MendozaNo ratings yet

- Assignment 1 and SolutionDocument5 pagesAssignment 1 and Solutionamin alzuraikiNo ratings yet

- Damped Free VibrationDocument9 pagesDamped Free VibrationAdeoti OladapoNo ratings yet

- Beam CalculationsDocument17 pagesBeam CalculationsFellaa Supazaein100% (1)

- Earth Science Honors, Grade 7 HMH Earth's Water & Atmosphere (Module E)Document21 pagesEarth Science Honors, Grade 7 HMH Earth's Water & Atmosphere (Module E)aveen rasulNo ratings yet

- Physics Form 4 Yearly Lesson Plan 2010Document26 pagesPhysics Form 4 Yearly Lesson Plan 2010Mohd Khairul AnuarNo ratings yet

- Series FV: Cantilever Sump PumpsDocument4 pagesSeries FV: Cantilever Sump PumpsFranciscoNo ratings yet

- Week - 09 - Pressure and Velocity MeasurementsDocument21 pagesWeek - 09 - Pressure and Velocity MeasurementsMohammad MohiuddinNo ratings yet

- 3D Blade Analysis v1.0Document12 pages3D Blade Analysis v1.0DUVAN FELIPE MUNOZ GARCIANo ratings yet

- (CGPR - 82) Nathaniel Bradley and Daniel R. VandenBerge-Beginners Guide For Geotechnical Finite Element Analyses-Center For Geotechnical Practice and Research (2015)Document102 pages(CGPR - 82) Nathaniel Bradley and Daniel R. VandenBerge-Beginners Guide For Geotechnical Finite Element Analyses-Center For Geotechnical Practice and Research (2015)hapsinte100% (1)

- M 236 ContentDocument103 pagesM 236 ContentgeetanandnNo ratings yet