Professional Documents

Culture Documents

Experiment 3

Uploaded by

Jc NicolasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experiment 3

Uploaded by

Jc NicolasCopyright:

Available Formats

Hardenability of Steel

Jared Christian B. Paz Department of Mining, Metallurgical, and Materials Engineering University of the Philippines Diliman MatE 113 WWX

Abstract

The Jominy End Quench Test is a common method used to measure the hardenability of steel. It is done by heating a steel sample to its austenitizing temperature and quenching one end of the sample with a given quenching medium. In this experiment, three types of steel were used: AISI 1020, 1045 and 4140.The specimens were mounted on a Jominy end quench fixture and one end was quenched using tap water. The microstructures and the Rockwell Hardness values of the specimens were determined. Then, the hardenability curve for each type of steel was obtained. It was observed that as the distance from the quenched end increased, the hardness and the martensite present in the region being measured decreased. Also, as the amount of martensite decreased, the amount of ferrite and pearlite in the microstructure increased. Alloying elements and factors such as austenitizing temperature and quenching medium are also significant in determining the hardenability of the steel samples.

1. Introduction:

Hardenability is a property that measures the metals ability to harden under a given heat treatment process. It measures the depth of hardness of a metal when subjected to the said heat treatment process. When steel is heated above its recrystallization or austenitizing temperature and then quenched, its hardness increases due to the formation of martensite (a hard, brittle and needle-like crystal structure). The rate of formation of martensite determines the steels hardenability. Each type of steel alloy has a unique relationship between the formation of martensite and cooling rate. A standard method to determine hardenability is the Jominy end quench test. It involves heating a round steel sample above its austenitizing temperature and quenching the sample with tap water at one end. For this experiment, the hardenability of different steel alloys was determined using the Jominy end quench test. Hardenability of Steel, JC B Paz, 2007-63299 2. Methodology: For this experiment, three types of steel were used; plain carbon steel AISI 1020 and AISI 1045, and low alloy steel AISI 4140. For each type of steel, a 4-inch specimen with a 1-inch diameter was used. The specimens were placed inside a furnace set to a temperature 100oF above the upper critical temperature. The specimens were kept at a constant temperature for one hour. Then the samples were immediately taken out of the furnace and placed firmly in the Jominy end quench fixture. The quenching water had a temperature at 75oF and issued out of a 0.5 inch orifice with a free height of 2.5 inches.

Page 1

Figure 1. 1020 Steel 1st Inch region

The specimen remained at the set-up for 20 minutes. The specimens were then cooled to room temperature. Two parallel shallow flats about 0.4mm deep and 1 cm wide were grinded along the specimen length (one flat was on the side opposite to the other flat). One flat was metallographically prepared by grinding, polishing and etching. For the grinding process, 8 grades of sandpaper were used; 80, 120, 220, 320, 400, 600, 800 and 1200. For the polishing process, coarse then fine polishing was performed until a mirror-like finish was achieved. The specimens were then etched using a 2% Nital solution to reveal the microstructures. A specimen was polished and etched again if the specimen was over-etched or under-etched. The photomicrographs at the 1st, 2nd and 3rd inch regions were taken. Then, the Rockwell Hardness readings were taken at 1/16 inch intervals for the first inch, 1/8 inch intervals for the second inch, and inch intervals for the remaining length.

Figure 2. 1020 Steel 2nd Inch Region

Figure 3. 1020 Steel 3rd Inch Region

3. Results: All photomicrographs presented, except for Figures 7 to 9, are at 200x magnification.

Hardenability of Steel, JC B Paz, 2007-63299

Page 2

Figure 4. 1045 Steel 1st Inch Region Figure 7. 4140 Steel 1st Inch Region (500x)

Figure 5. 1045 Steel 2nd Inch Region

Figure 8. 4140 Steel 2nd Inch Region (500x)

Figure 6. 1045 Steel 3rd Inch Region

Figure 9. 4140 Steel 3rd Inch Region (500x)

Hardenability of Steel, JC B Paz, 2007-63299

Page 3

Table 1. Rockwell Hardness Values for 1020 Steel. Region 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 Trial 1 30 26 29 30 30 29 29 29 28 28 25 24 24 24 26 22 23 23 22 23 21 21 22 21 21 20 20 20 21 23 Trial 2 Trial 3 First Inch 19 30 27 29 30 30 29 30 30 30 30 30 29 31 31 32 28 30 29 30 27 28 30 27 29 30 29 28 30 29 27 27 Second Inch 25 25 25 23 23 23 24 22 24 23 23 23 24 24 24 23 Third Inch 21 21 21 21 21 21 21 22 Fourth Inch 21 21 19 18 Average 26.33 27.33 29.67 29.67 29.67 30.00 29.67 29.67 30.67 28.67 29.00 26.67 27.00 27.67 27.00 28.33 25.33 24.33 23.67 22.67 23.00 22.67 22.33 23.33 22.67 21.00 20.67 20.67 21.00 21.00

5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

60 56 58 50 50 42 49 50 47.5 50.5 48 56

60 60 60 55.5 51 55 56 56 54 56 51.5 48 Second Inch 50.5 56 55 53 65 66 50 54 48.5 50 51 54 49.5 51 47 50 Third Inch 44 39 43 49 46 45.5 46 49 Fourth Inch 45 44 43.5 48 35 46 43 49

64 60 59 56 54 59 58 56 51.5 54 53 56 54 56 52 53.5 48.5 49.5 49.5 47 52 45 45.5 43 39.5 43 52 50

61.33 58.67 59.00 53.83 51.67 52.00 54.33 54.00 51.00 53.50 50.83 53.33 53.50 54.67 61.00 52.50 49.00 51.5 50.00 48.00 45.00 45.67 45.67 46.00 42.83 44.33 44.33 47.33

Table 3. Rockwell Hardness Values for 4140 Steel. Region 1 2 3 4 5 6 7 8 9 10 11 Trial 1 59 52 49 64 63 61 60 65 65 64 65 Trial 2 Trial 3 First Inch 59 61 63 62 66 63 62 65 67 65 68 65 67 67 66 67 66 64 67 60 63 63 Average 59.67 59.00 59.33 63.67 65.00 64.67 64.67 66.00 65.00 63.67 63.67 Page 4

Table 2. Rockwell Hardness Values for 1020 Steel. Region 1 2 3 4 Trial 1 Trial 2 Trial 3 First Inch 58 62 62 72 69.5 67 70 70 70 66.5 67.5 70 Average 60.67 69.50 70.00 68.00

Hardenability of Steel, JC B Paz, 2007-63299

12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

63 61 60 60 58 56 59 56 57 53 55 51 52 51 46 51 41 48 52 52 50

64 62 61 61 60 Second Inch 60 59 58 57 58 56 56 55 Third Inch 55 53 54 54 Fourth Inch 48 52 48 47

61 60 60 61 59 57 58 53 52 55 53 55 54 52 55 55 55 52 48 50 50

62.67 61.00 60.33 60.67 59.00 57.67 58.67 55.67 55.33 55.33 54.67 54.00 53.67 52.67 51.33 53.33 50.00 49.33 50.67 50.00 49.00

4. Discussion: Based from the photomicrographs obtained, it can be seen that for all samples, the quenched end had the most amount of martensite present and as the distance from the quenched end increases, the amount of martensite present in the microstructure decreases while the amount of ferrite and pearlite increases. Depending on the cooling rate, steel in its austenite phase can either transform to martensite or a mixture of pearlite and ferrite. Pearlite and ferrite formation involves diffusion of carbon atoms from the austenite phase, which takes time. The rate of change in temperature required for diffusion is called the critical cooling rate. If the specimens cooling rate is faster than its critical cooling rate, the carbon atoms will not be given enough time to diffuse out of the austenite phase. When cooled, the austenite phase, along with the trapped carbon atoms, transforms into martensite. From the Jominy end quench test, it can be seen that the cooling rate of certain regions of the specimens decreases as the distance from the quenched end increases thus, explaining the characteristics of the obtained microstructures. Since martensite is significantly harder than the ferrite-pearlite mixture, the hardness of a measured region is inversely proportional to the distance from the quenched end. The Rockwell Hardness values obtained also showed the same pattern that the amount of martensite in the microstructures showed. The Rockwell Hardness value is also inversely proportional to the distance from the quenched end. To determine the hardenability of steel, two parameters are needed: cooling rate and hardness. The Jominy End Quench Test is the most common method of determining the hardenability of steel because of its simplicity and ease of performance. Since only one end of the heated metal is being quenched, the cooling Page 5

Figure 10. Plot of Hardness (HRC) versus Distance from Quenched End (inch).

80 70 60 y = -4.242x + 63.89 (green) 50 y = -5.084x + 61.49 (blue) 40 30 20 10 0 0 1 2 3 4 5 y = -3.177x + 29.44 (red)

*blue = 1045 steel red = 1020 steel green = 4140 steel

Hardenability of Steel, JC B Paz, 2007-63299

rate differs at different parts of the steel sample. The hardness of the steel sample can be obtained by performing a hardness test. From Figure 10, it can be seen that the 1045 steel had the highest hardenability followed by 4140, then 1020 steel. Theoretically, 4140 steel has greater hardenability than 1045 steel since 4140 steel is made for hardenability and machinability [5] while 1045 steel is made for strength and hardness [6]. The discrepancies in the obtained data were due to experimental errors. In general, alloying elements improves the hardenability of steel by slowing down ferrite and pearlite formation which, in turn, making martensite formation easier and possible at lower temperatures. Lengthening the austenitizing time will produce more martensite, providing a more accurate hardenability curve while lowering the austenitizing temperature and using oil as a quenching medium will decrease the accuracy of the hardenability curve obtained.

7. References: [1] Callister, W. D., Materials Science and Engineering: An Introduction 7th Ed., John Wiley & Sons, Inc., New York, 2007. [2] McGraw-Hill Dictionary of Scientific & Technical Terms 6th Ed., The McGraw-Hill Companies, Inc., 2003. [3] Martensite. http://www.threeplanes.net/martensite.html, Accessed Mar 10, 2012. [4] Hardness and Hardenability - Part Two: A Discussion on Hardenability and Hardenability Testing. http://www.industrialheating.com/Articles/Colu mn/BNP_GUID_9-52006_A_10000000000000379772, Accessed Mar 10, 2012. [5] Atlas Specialty Metals. http://www.atlassteels.com.au/documents/Atlas4 140.pdf, Accessed Mar 13, 2012. [6] AISI 1045. http://www.efunda.com/materials/alloys/carbon_ steels/show_carbon.cfm?ID=AISI_1045&prop= all&Page_Title=AISI%201045, Accessed Mar 13, 2012. [7] Standard Specication for Carbon and Alloy Steel Bars Subject to End-Quench Hardenability Requirements, ASTM Designation A304, ASTM Annual Book of Standards, 2004.

5. Conclusions: The following conclusions were made: 1) the hardness values and amount of martensite present in the microstructure are inversely proportional to the distance from the quenched region; 2) Alloying improves the hardenability of steel; 3) Factors such as the austenitizing time and quenching medium have an effect on the hardenability curve obtained.

6. Recommendations: The next observers are recommended to do the following: 1) Make sure that the steel samples are properly placed in the Jominy end quench fixture to avoid uneven quenching.

Hardenability of Steel, JC B Paz, 2007-63299

Page 6

You might also like

- Heat-Treatment of High Carbon Steel Wire - PatentingDocument4 pagesHeat-Treatment of High Carbon Steel Wire - Patentingعزت عبد المنعم100% (1)

- Lab Material 3Document11 pagesLab Material 3Faiz AmeeriNo ratings yet

- Experiment No. 8 DoneDocument25 pagesExperiment No. 8 DoneshahNo ratings yet

- Annealing Test 1Document14 pagesAnnealing Test 1Andy Tan WXNo ratings yet

- Thermal Lab 1Document6 pagesThermal Lab 1Muhammad ZulhilmiNo ratings yet

- Jominy Experiment ReportDocument13 pagesJominy Experiment Reportsinabirecik0% (1)

- Your Name: Ulises Jose Corona Name of The Course: MAE2160 Materials Science Lab Date: Report DateDocument7 pagesYour Name: Ulises Jose Corona Name of The Course: MAE2160 Materials Science Lab Date: Report DateUlises Corona100% (4)

- Effect of Precipitation Hardening On Hardness and PDFDocument9 pagesEffect of Precipitation Hardening On Hardness and PDFirajfarjiNo ratings yet

- Unit 11394: Select and Specify Materials For Mechanical Engineering ApplicationsDocument4 pagesUnit 11394: Select and Specify Materials For Mechanical Engineering ApplicationsMehul BansalNo ratings yet

- SD Article 46Document8 pagesSD Article 46Mustafa MoussaouiNo ratings yet

- Quenching & TemperingDocument4 pagesQuenching & Temperingkgkganesh8116No ratings yet

- Metallographic Study of Type 304 Stainless Steel Long-Term Creep-Rupture Specimen Biss1981Document3 pagesMetallographic Study of Type 304 Stainless Steel Long-Term Creep-Rupture Specimen Biss1981Andrea CalderaNo ratings yet

- IntroDocument9 pagesIntroKeyshia KoishiNo ratings yet

- 4 Harden AbilityDocument12 pages4 Harden AbilityFadlin QisthiNo ratings yet

- Austentite Steel Thermal StabilizationDocument17 pagesAustentite Steel Thermal StabilizationArangamar KumaranNo ratings yet

- Metallurgy Lab 3Document4 pagesMetallurgy Lab 3api-280725686No ratings yet

- Cold WorkingDocument7 pagesCold WorkingShahir Afif IslamNo ratings yet

- Jominy End Quench Hardenability Test: Tejas AtyamDocument15 pagesJominy End Quench Hardenability Test: Tejas AtyamNaisarg ChauhanNo ratings yet

- Cooling Rate Effect: Lab ReportDocument4 pagesCooling Rate Effect: Lab ReportandyNo ratings yet

- Pan 2014Document5 pagesPan 2014vinayakNo ratings yet

- Velocity in MetalsDocument30 pagesVelocity in MetalsChegwe CorneliusNo ratings yet

- Formal Lab Report Two: Heat Treatment - Quenching & Tempering-Of Steel and PrecipitationDocument18 pagesFormal Lab Report Two: Heat Treatment - Quenching & Tempering-Of Steel and Precipitationapi-306927868100% (1)

- Jominy TestDocument5 pagesJominy TestAhmet Ozan Basar100% (1)

- Jominy Hardenability Test: ObjectivesDocument3 pagesJominy Hardenability Test: ObjectivesDoğukan CemaloğluNo ratings yet

- Ojay 1ST Publication PDFDocument16 pagesOjay 1ST Publication PDFvenkatrangan2003No ratings yet

- En8 CharpyDocument10 pagesEn8 CharpyfailureanalystNo ratings yet

- Comin Eli 2014Document12 pagesComin Eli 2014Dominic TanNo ratings yet

- 002 Hardness and Impact Toughness of Niobium Alloyed Austempered Ductile IronDocument5 pages002 Hardness and Impact Toughness of Niobium Alloyed Austempered Ductile IronWilson SCKUDLAREKNo ratings yet

- TP 1893 PDFDocument5 pagesTP 1893 PDFRohammed CastilloNo ratings yet

- Syifa Luthfiyah - Paper - ISAIME PDFDocument9 pagesSyifa Luthfiyah - Paper - ISAIME PDFSyifa LuthfiyahNo ratings yet

- Rheology and Metal Forming of Fire-Refined CopperDocument6 pagesRheology and Metal Forming of Fire-Refined CoppervitordeleteNo ratings yet

- Artigo ZucatoDocument5 pagesArtigo ZucatocaroleuzinhaNo ratings yet

- Effect of FoldingDocument13 pagesEffect of FoldingAbdul RehmanNo ratings yet

- Jominy Experiment ReportDocument13 pagesJominy Experiment ReportMohammedNo ratings yet

- Kim 2018Document26 pagesKim 2018Muhammad Rizki Gorbyandi NadiNo ratings yet

- Eddy Current MeasurementsDocument4 pagesEddy Current MeasurementsBassam AbdelazeemNo ratings yet

- Limitations of The Use of Grossman Quench Severity FactorsDocument12 pagesLimitations of The Use of Grossman Quench Severity FactorsPedro Polastri PatriotaNo ratings yet

- On The Mechanical and Wear Properties of Copper-Lead Bearing AlloysDocument11 pagesOn The Mechanical and Wear Properties of Copper-Lead Bearing AlloysAswar ATSNo ratings yet

- Rippling BoilerDocument10 pagesRippling BoilernewprintmNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Panduan BeasiswaDocument7 pagesPanduan BeasiswaAmalia Tri WNo ratings yet

- Effect of Tungsten On Mechanical Properties of High-Purity 60 mass%Cr-Fe AlloysDocument6 pagesEffect of Tungsten On Mechanical Properties of High-Purity 60 mass%Cr-Fe AlloysElMacheteDelHuesoNo ratings yet

- NDT Characterization of Decarburization of Steel After Long-Time AnnealingDocument9 pagesNDT Characterization of Decarburization of Steel After Long-Time AnnealingSHUBHNo ratings yet

- HardenabilityDocument7 pagesHardenabilityZaidee AliasNo ratings yet

- Jominy Hardness TessDocument3 pagesJominy Hardness TessIqbal BashiruNo ratings yet

- Hardenability of SteelDocument9 pagesHardenability of SteelUmitjan PirnepesowNo ratings yet

- Hardness Tests 2009Document6 pagesHardness Tests 2009Ariel Mark PilotinNo ratings yet

- Quenching Heat Treatment Effects On SteeDocument5 pagesQuenching Heat Treatment Effects On SteeYAKSEN 7No ratings yet

- Lab Material 3Document14 pagesLab Material 3neenoonaaNo ratings yet

- Pitting CorrosionDocument7 pagesPitting CorrosionAminNo ratings yet

- C2 JominyDocument5 pagesC2 Jominysujith 105No ratings yet

- Effect of Copper Content On The Mechanical and Sliding Wear Properties of Monotectoid-Based Zinc-Aluminium-copper AlloysDocument6 pagesEffect of Copper Content On The Mechanical and Sliding Wear Properties of Monotectoid-Based Zinc-Aluminium-copper AlloysuzairmetallurgistNo ratings yet

- Mill Scale 2Document7 pagesMill Scale 2viswaprasad005No ratings yet

- Tests of Centri Fug 00 BurgDocument28 pagesTests of Centri Fug 00 BurgnfcastingsNo ratings yet

- Characteristics of Oxide Scale Formed On Ferritic Stainless SteelDocument42 pagesCharacteristics of Oxide Scale Formed On Ferritic Stainless SteelSomnath PraharajNo ratings yet

- Introduction of Heat and Surface Treatment PDFDocument45 pagesIntroduction of Heat and Surface Treatment PDFScott BakerNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Rating: 5 out of 5 stars5/5 (1)

- Manhole SpecsDocument32 pagesManhole Specsscorpio1878No ratings yet

- Geopier Tech Paper No1Document15 pagesGeopier Tech Paper No1Maris AlexandruNo ratings yet

- Aluminum Pigments For Plastics Complete Jun 6 2011 - WebDocument20 pagesAluminum Pigments For Plastics Complete Jun 6 2011 - Webhuy.dicNo ratings yet

- BP 07 Roofing and Waterproofing Scope ofDocument6 pagesBP 07 Roofing and Waterproofing Scope ofjacksondcplNo ratings yet

- Specification For General Construction: A. Intent and Application of The Provision of This SectionDocument7 pagesSpecification For General Construction: A. Intent and Application of The Provision of This SectionJanice SubidoNo ratings yet

- 2.1. Design ParametersDocument2 pages2.1. Design ParametersFarly VergelNo ratings yet

- PhotoLitho and SputteringDocument2 pagesPhotoLitho and SputteringAndre KostroNo ratings yet

- Microwave Welding For Thermoplastics..Document4 pagesMicrowave Welding For Thermoplastics..Jessica GonzalezNo ratings yet

- Dme Unit I Mech 30.6.12Document22 pagesDme Unit I Mech 30.6.12PN MohankumarNo ratings yet

- Clamped Cover Plate DesignDocument7 pagesClamped Cover Plate DesignChiedu OkonduNo ratings yet

- LKP GI Ampel Monthly 10-2019 (Oktober 2019) R.1 LIMOSINDocument153 pagesLKP GI Ampel Monthly 10-2019 (Oktober 2019) R.1 LIMOSINindra squarefaceNo ratings yet

- QA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeDocument2 pagesQA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeNon Etabas GadnatamNo ratings yet

- Hydril CsDocument134 pagesHydril CsRicardo Calderón Herreño67% (3)

- Flare Piping Stress NalysisDocument7 pagesFlare Piping Stress Nalysisgpskumar22100% (1)

- Utilisation of Waste Plastic in Bituminous Mixes For Road ConstructionDocument34 pagesUtilisation of Waste Plastic in Bituminous Mixes For Road Constructionshiva5059100% (4)

- (1 Unread) - Umoosa@YahooDocument1 page(1 Unread) - Umoosa@YahooMuhammad Usman MoosaNo ratings yet

- Engineering Design Handbook - Hydraulic FluidsDocument166 pagesEngineering Design Handbook - Hydraulic Fluidsburreiro0% (1)

- 2D Nonlinear Analysis of Asphaltic Concrete - Core Embankment DamsDocument8 pages2D Nonlinear Analysis of Asphaltic Concrete - Core Embankment DamsLNo ratings yet

- Floating Ball ValveDocument36 pagesFloating Ball ValveSureshNo ratings yet

- Concrete FormsDocument11 pagesConcrete FormsmurdicksNo ratings yet

- Shunyam House, Jodhpur: Presented byDocument2 pagesShunyam House, Jodhpur: Presented byManasi Sonar100% (1)

- Everything You Need To Know About Flatteners and Levelers For Coil Processing-Part 2 - The FabricatorDocument7 pagesEverything You Need To Know About Flatteners and Levelers For Coil Processing-Part 2 - The FabricatorSIMONENo ratings yet

- Design of Lifting Hook: Earth Fill Load (Dl2)Document21 pagesDesign of Lifting Hook: Earth Fill Load (Dl2)Asaru DeenNo ratings yet

- Mixing: Aeration and Agitation in A Stirred Tank ReactorDocument15 pagesMixing: Aeration and Agitation in A Stirred Tank ReactorAixa BerchiNo ratings yet

- Horizontal Sidewall Sprinkler, Light HazardDocument8 pagesHorizontal Sidewall Sprinkler, Light HazardAhrian BenaNo ratings yet

- Anchor TechnicalGuide2003Document24 pagesAnchor TechnicalGuide2003grahambrasicNo ratings yet

- Portal Frame - Airport Hangar PDFDocument12 pagesPortal Frame - Airport Hangar PDFShinjini BhattacharjeeNo ratings yet

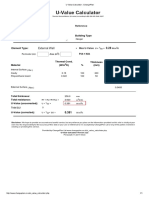

- U Value Calculator - With Liner Only1Document1 pageU Value Calculator - With Liner Only1muathNo ratings yet

- Guidance Note Installation of Preloaded Bolts No. 7.05: ScopeDocument6 pagesGuidance Note Installation of Preloaded Bolts No. 7.05: ScopeAli ZarkaNo ratings yet

- Types of Piles Load Tests: Proof-TestDocument13 pagesTypes of Piles Load Tests: Proof-Testkaranbir123No ratings yet