Professional Documents

Culture Documents

.. PDF DrySolidsBro

Uploaded by

Maxwell ToffahOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

.. PDF DrySolidsBro

Uploaded by

Maxwell ToffahCopyright:

Available Formats

D RY S O L I D S P R O C E S S I N G E Q U I P M E N T

BETTER BY DESIGN

FOR USE ON POWDERS PELLETS FLAKES CHIPS AGGLOMERATES

B I N A C T I VAT O R S

Standard Types

Diameters: 2-16 Features an exclusive dual baffle to prevent compaction of material. Construction Materials: Carbon steel, special coatings, 304SS, 316SS.

Posibins

Diameters: 21 models from 20 to 8 Capacity: 3 to 750 cu. ft. Bulk Density: to 200 lbs./cu. ft. Construction Materials: Carbon steel, 304 or 316 stainless, special coatings.

Sanitary Types

Diameters: 2-12 Features an exclusive dual baffle to prevent compaction of material. Construction Materials: 304 or 316 stainless, polished to a #4 finish. White neoprene food grade continuous sleeve. 3A Dairy Approved

Live Bins

Diameters: 20 to 60 Capacity: 3 to 100 cu. ft. Bulk Density: to 100 lbs./cu.ft. Construction Materials: Carbon steel, 304 or 316 stainless. Pressure designs to 14.9 PSIG positive. Sanitary Construction Available

Pre-Steamer/ Discharger

Diameters: 8-16 Features an exclusive dual baffle to prevent compaction of material. Special steam injection. Processing Temperature: 250F Construction Materials: 304 or 316 stainless only.

G R AV I M E T R I C F E E D E R S

Better-Weigh Feeders

Accuracy: 0.25% to 0.50% Screw Sizes: 1/2, 3/4, 1, 1-1/2, 2, 3, 4, 6 Feed Rates: 0.03 to 550 cu. ft./hr. Features: Platform and level balance scales, sealed tactile keyboard, 7 digit numerical keypad, automatic manual batching, 2 or 5 cu. ft. hopper. Sanitary construction available.

Sanitary Types

MTS For sanitary applications (foods, pharmaceuticals, etc.) Quick disassembly feature without the use of tools. Accuracy: 1 to 1-1/2% (one minute samples) Screw Sizes: 1/2 to 6 diameter Feed Rates: 0.03 to 550 cu. ft./hr. Construction Materials: Contact surfaces, 304 or 316 stainless polished to a #4 finish. Food grade white neoprene gasketing. External carbon steel parts painted white epoxy.

Better-Weigh Feeder Controls

For Gain, Loss or Continuous Weighing Applications Enclosure: NEMA 4X Display Type: 5.7 16 shades of grey (touch screen) Visual Display: 4.72 x 3.5 (touch screen) Features: Automatic batching or continuous feed rate control, automatic feed rate optimization for fast/ slow speed settings and dribble point determination, numerous other operating features

Combination Types

MTL Combination Screw Feeder/Conveyor Accuracy: 1 to 1-1/2% (one minute samples) Screw Sizes: 6 to 20 Inlet to Outlet: 3 to 12 Feed Rates: 55 to 18,000 cu. ft./hr. Construction Materials: Carbon steel, carbon steel epoxy coated, 304 and 316 stainless steel. Other materials available.

VOLUMETRIC SCREW FEEDERS C O M PA C T & M I N I AT U R E

Standard Types

MetaTech

VOLUMETRIC SCREW FEEDERS

Mini Feeders

MTM Accuracy: 1 to 1-1/2% (one minute samples) Screw Sizes: 1/2, 3/4, 1, 1-1/2, 2 Feed Rates: 0.03 to 20 cu. ft./hr. Requires only 12 x 16 foot print. Construction Materials: Carbon steel, carbon steel epoxy coated, 304 or 316 stainless steel. Other materials and sanitary construction available.

Accuracy: 1 to 1-1/2% (one minute samples) Screw Sizes: 1/2 to 6 diameter Feed Rates: 0.03 to 550 cu. ft./hr. With only two moving parts Construction Materials: Carbon steel, carbon steel epoxy coated, 304 or 316 stainless; other specified materials.

MTP For more difficult to feed materials; film scrap, wood chips, filter cake, asbestos powders, etc. Accuracy: 1 to 1-1/2% (one minute samples) Screw Sizes: 3, 4, 6 diameter; agitator/ conditioning screws 8 and 10 Feed Rates: 3 to 550 cu. ft./hr. Construction Materials: Carbon steel, carbon steel with special coatings, 304 or 316 stainless

BULK BAG UNLOADER

CONTINUOUS MIXER

Handles: Lined and unlined bulk bags up to 3,300 lbs. Materials: Powders and difficult to handle dry bulk materials. Construction Materials: Carbon steel or stainless; available with or without frame. Features: Complete and positive discharge regardless of bag contents. Dust-free operation. Requires only one person. Unique design eliminates spillage or waste.

MODEL CB1 Blends two or more materials into one. Sizes: 6, 8, 10, 12, 16 Feed Rates: As high as 2500 cu. ft./hr. Construction Materials: Carbon steel, carbon steel with special coatings, 304 or 316 stainless; other specified materials. Features: A/C constant speed drive standard; other drives available.

CONVEYORS

V O L U M E T R I C B E LT F E E D E R S

MODEL Convey-All/ FSC Flexible Screw Conveyors Handles: Powders, pellets, flakes, and other dry solids. Sizes: Two models in configurations from 10-20 ft. lengths. Screw Sizes/Conveying Notes: 3 dia. helix screw for up to 150 cu. ft./hr. and 4 dia. helix screw for up to 450 cu. ft./hr. Construction Materials: 304 stainless steel helix screw and contact parts with 2B mill type finish. White UHMW tube at 30-60 inclination. Optional sanitary design. Features: Only one moving part. Top and bottom cleanout parts. Dust-free connections.

MODEL APB Accuracy: 1 to 2% (one minute samples) Belt Widths: 12, 24, 36, 48 Belt Lengths: 36, 72, 108, 144 respectively Feed Rates: to 5,000 cu. ft./hr. Construction Materials: Carbon steel, 304 or 316 stainless steel, belts standard neoprene or HYCAR, Nordel, Viton, and special coatings.

MODEL Convey-All/ VTC Vibratory Tube Conveyors Handles: High rates of difficult flowing or friable dry solids. Sizes: Nine models in 4-10 ft. lengths. Conveying Notes: 6, 8 & 10 dia. tubes convey up to 400 cu. ft./hr. Construction Materials: 304 stainless steel with 2B mill type finish. Features: Only two moving parts. Clamp on vibrating tube. Choice of top or bottom mounted conveyor and/or drive. Easily accessible cleanout ports. For literature and complete information on any of these dependable, quality-built dry bulk solids processing products, contact your Metalfab representative, or call or write:

Convey-All is a trademark of Metalfab, Inc. Better-Weigh is a registered trademark of Metalfab, Inc. Posibin is a trademark of Metalfab, Inc. HYCAR is a registered trademark of Noveon, Inc. Nordel and Viton are registered tradmarks of DuPont Copyright, Metalfab, Inc., 2003, Rev. 3/07 Printed in USA

Dry Solids Processing Equipment P Box 9, Prices Switch Rd., .O. Vernon, NJ 07462 Tel: (973) 764-2000 FAX: (973)764-0272 www.metalfabinc.com E-mail: sales@metalfabinc.com

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Interview BookDocument21 pagesThe Interview BookTariq Guroo67% (3)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Take Up Your Cross DailyDocument3 pagesTake Up Your Cross DailyMaxwell ToffahNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- ISO 9001 2015 AwarenessDocument23 pagesISO 9001 2015 AwarenessSeni Oke0% (1)

- Maintenance PlannerDocument20 pagesMaintenance PlannerMaxwell ToffahNo ratings yet

- Human EpigenomicsDocument234 pagesHuman EpigenomicsHeron HilárioNo ratings yet

- Hydro Cyclone: Centripetal Force Fluid ResistanceDocument10 pagesHydro Cyclone: Centripetal Force Fluid ResistanceMaxwell ToffahNo ratings yet

- Design and Fabrication of Mini Ball MillDocument16 pagesDesign and Fabrication of Mini Ball MillAbhinav100% (2)

- Service Manual: SV01-NHX40AX03-01E NHX4000 MSX-853 Axis Adjustment Procedure of Z-Axis Zero Return PositionDocument5 pagesService Manual: SV01-NHX40AX03-01E NHX4000 MSX-853 Axis Adjustment Procedure of Z-Axis Zero Return Positionmahdi elmay100% (3)

- Hey Friends B TBDocument152 pagesHey Friends B TBTizianoCiro CarrizoNo ratings yet

- Log Building News - Issue No. 76Document32 pagesLog Building News - Issue No. 76ursindNo ratings yet

- PMP Question BankDocument3 pagesPMP Question BankOmerZiaNo ratings yet

- Maintenance PolicyDocument15 pagesMaintenance PolicyMaxwell Toffah100% (2)

- Group 2 Energy AuditDocument5 pagesGroup 2 Energy AuditMaxwell ToffahNo ratings yet

- Five Factors That Can Affect Your Weighing System's AccuracyDocument12 pagesFive Factors That Can Affect Your Weighing System's AccuracyMaxwell ToffahNo ratings yet

- Seaspark Ltd-Project C1047 - Floating Wharf ConceptDocument1 pageSeaspark Ltd-Project C1047 - Floating Wharf ConceptMaxwell ToffahNo ratings yet

- LEIA Home Lifts Guide FNLDocument5 pagesLEIA Home Lifts Guide FNLTejinder SinghNo ratings yet

- Partes de La Fascia Opteva Y MODULOSDocument182 pagesPartes de La Fascia Opteva Y MODULOSJuan De la RivaNo ratings yet

- Snapdragon 435 Processor Product Brief PDFDocument2 pagesSnapdragon 435 Processor Product Brief PDFrichardtao89No ratings yet

- The Indonesia National Clean Development Mechanism Strategy StudyDocument223 pagesThe Indonesia National Clean Development Mechanism Strategy StudyGedeBudiSuprayogaNo ratings yet

- Lithuania DalinaDocument16 pagesLithuania DalinaStunt BackNo ratings yet

- AnticyclonesDocument5 pagesAnticyclonescicileanaNo ratings yet

- The Magic DrumDocument185 pagesThe Magic Drumtanishgiri2012No ratings yet

- Mastertop 1230 Plus PDFDocument3 pagesMastertop 1230 Plus PDFFrancois-No ratings yet

- Impact of Advertising On Consumers' Buying Behavior Through Persuasiveness, Brand Image, and Celebrity EndorsementDocument10 pagesImpact of Advertising On Consumers' Buying Behavior Through Persuasiveness, Brand Image, and Celebrity Endorsementvikram singhNo ratings yet

- 5c3f1a8b262ec7a Ek PDFDocument5 pages5c3f1a8b262ec7a Ek PDFIsmet HizyoluNo ratings yet

- All You Need To Know About Egg YolkDocument7 pagesAll You Need To Know About Egg YolkGolden Era BookwormNo ratings yet

- Gemini Dollar WhitepaperDocument7 pagesGemini Dollar WhitepaperdazeeeNo ratings yet

- Assembler Pass 2Document5 pagesAssembler Pass 2AnuNo ratings yet

- Bana LingaDocument9 pagesBana LingaNimai Pandita Raja DasaNo ratings yet

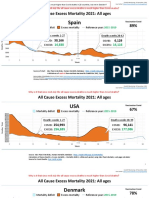

- Countries EXCESS DEATHS All Ages - 15nov2021Document21 pagesCountries EXCESS DEATHS All Ages - 15nov2021robaksNo ratings yet

- WL-80 FTCDocument5 pagesWL-80 FTCMr.Thawatchai hansuwanNo ratings yet

- Android Developer PDFDocument2 pagesAndroid Developer PDFDarshan ChakrasaliNo ratings yet

- PR KehumasanDocument14 pagesPR KehumasanImamNo ratings yet

- Functions in C++Document23 pagesFunctions in C++Abhishek ModiNo ratings yet

- Chapter 1 To 5 For Printing.2Document86 pagesChapter 1 To 5 For Printing.2Senku ishigamiNo ratings yet

- Chemistry Test 1Document2 pagesChemistry Test 1shashankNo ratings yet

- HirePro Video Proctored Online-Instruction Sheet - Bain IndiaDocument1 pageHirePro Video Proctored Online-Instruction Sheet - Bain Indiaapoorv sharmaNo ratings yet

- Working With Difficult People Online WorksheetDocument4 pagesWorking With Difficult People Online WorksheetHugh Fox IIINo ratings yet

- 3 ALCE Insulators 12R03.1Document12 pages3 ALCE Insulators 12R03.1Amílcar Duarte100% (1)