Professional Documents

Culture Documents

Finite Element Solution For Plain Stress Problem Using SAP2000

Uploaded by

Jemo NoxOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Finite Element Solution For Plain Stress Problem Using SAP2000

Uploaded by

Jemo NoxCopyright:

Available Formats

License #

Finite element solution for plain stress problem

SAP2000 Analysis Report

Prepared by

Kamal Hassan Model Name: Finite Element Analysis.SDB

15 May 2010

Finite Element Analysis.SDB 1. Model geometry

SAP2000 v14.0.0 - License # 15 May 2010

1. Model geometry

This section provides model geometry information, including items such as joint coordinates, joint restraints, and element connectivity.

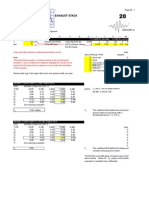

Figure 1: Finite element model

1.1. Joint coordinates

Table 1: Joint Coordinates

Joint 1 2 3 4 CoordSys GLOBAL GLOBAL GLOBAL GLOBAL Table 1: Joint Coordinates CoordType GlobalX in Cartesian 0.000 Cartesian 20.000 Cartesian 0.000 Cartesian 20.000 GlobalY in 0.000 0.000 0.000 0.000 GlobalZ in 10.000 10.000 0.000 0.000

Kamal Hassan

Page 2 of 9

Finite Element Analysis.SDB 2. Material properties

SAP2000 v14.0.0 - License # 15 May 2010

1.2. Joint restraints

Table 2: Joint Restraint Assignments

Joint 1 3 U1 Yes Yes Table 2: Joint Restraint Assignments U2 U3 R1 Yes Yes Yes Yes No No R2 No No R3 No No

1.3. Element connectivity

Table 3: Connectivity - Area

Area 1 2 Table 3: Connectivity - Area Joint1 Joint2 Joint3 1 2 3 3 2 4 Joint4

Table 4: Area Section Assignments

Table 4: Area Section Assignments Area Section MatProp 1 2 kk kk Default Default

2. Material properties

This section provides material property information for materials used in the model.

Table 5: Material Properties 02 - Basic Mechanical Properties

Material 4000Psi A992Fy50 MAT Table 5: Material Properties 02 - Basic Mechanical Properties UnitWeight UnitMass E1 G12 U12 Kip/in3 Kip-s2/in4 Kip/in2 Kip/in2 8.6806E-02 2.2483E-04 3.6E+06 1.5E+06 0.200000 2.8356E-01 7.3446E-04 2.9E+07 1.1E+07 0.300000 2.8356E-01 7.3446E-04 3.0E+10 1.2E+10 0.300000 A1 1/F 5.5000E-06 6.5000E-06 6.5000E-06

Kamal Hassan

Page 3 of 9

Finite Element Analysis.SDB 3. Section properties

SAP2000 v14.0.0 - License # 15 May 2010

Table 6: Material Properties 03a - Steel Data

Table 6: Material Properties 03a - Steel Data Material Fy Fu FinalSlope Kip/in2 Kip/in2 A992Fy50 50000.000 65000.000 -0.100000

Table 7: Material Properties 03b - Concrete Data

Table 7: Material Properties 03b - Concrete Data Material Fc FinalSlope Kip/in2 4000Psi 4000.000 -0.100000

3. Section properties

This section provides section property information for objects used in the model.

3.1. Areas

Table 8: Area Section Properties, Part 1 of 2

Section kk Material MAT Table 8: Area Section Properties, Part 1 of 2 AreaType Type Thickness BendThick in in Plane Plane-Stress 1.0000 F11Mod 1.000000 F22Mod 1.000000

Table 8: Area Section Properties, Part 2 of 2

Section kk F12Mod 1.000000 Table 8: Area Section Properties, Part 2 of 2 M11Mod M22Mod M12Mod V13Mod 1.000000 1.000000 1.000000 1.000000 V23Mod 1.000000 MMod 1.000000 WMod 1.000000

4. Load patterns

This section provides loading information as applied to the model.

4.1. Definitions

Kamal Hassan

Page 4 of 9

Finite Element Analysis.SDB 5. Load cases

SAP2000 v14.0.0 - License # 15 May 2010

Table 9: Load Pattern Definitions

LoadPat DEAD Table 9: Load Pattern Definitions DesignType SelfWtMult DEAD 0.000000 AutoLoad

5. Load cases

This section provides load case information.

5.1. Definitions

Table 10: Load Case Definitions

Case DEAD Table 10: Load Case Definitions Type InitialCond ModalCase LinStatic Zero BaseCase

5.2. Static case load assignments

Table 11: Case - Static 1 - Load Assignments

Case DEAD Table 11: Case - Static 1 - Load Assignments LoadType LoadName LoadSF Load pattern DEAD 1.000

5.3. Response spectrum case load assignments

Table 12: Function - Response Spectrum - User

Table 12: Function - Response Spectrum - User Name Period Accel FuncDamp Sec UNIFRS 0.000 1.000 0.050 UNIFRS 1.000 1.000

6. Structure results

This section provides structure results, including items such as structural periods and base reactions.

Kamal Hassan

Page 5 of 9

Finite Element Analysis.SDB 6. Structure results

SAP2000 v14.0.0 - License # 15 May 2010

Figure 2: Deformed shape

6.1. Mass summary

Table 13: Assembled Joint Masses

Joint 1 2 3 4 U1 Kip-s2/in 0.0245 0.0490 0.0490 0.0245 Table 13: Assembled Joint Masses U2 U3 R1 Kip-s2/in Kip-s2/in Kip-in-s2 0.0245 0.0245 0.000 0.0490 0.0490 0.000 0.0490 0.0490 0.000 0.0245 0.0245 0.000 R2 Kip-in-s2 0.000 0.000 0.000 0.000 R3 Kip-in-s2 0.000 0.000 0.000 0.000

6.2. Base reactions

Kamal Hassan

Page 6 of 9

Finite Element Analysis.SDB 7. Joint results

SAP2000 v14.0.0 - License # 15 May 2010

Table 14: Base Reactions

OutputCase DEAD GlobalFX Kip -10000.00 Table 14: Base Reactions GlobalFY GlobalFZ GlobalMX Kip Kip Kip-in 0.000 1.554E-12 0.000 GlobalMY Kip-in -50000.0 GlobalMZ Kip-in 0.000

7. Joint results

This section provides joint results, including items such as displacements and reactions.

Table 15: Joint Displacements

Joint 1 2 3 4 OutputCase DEAD DEAD DEAD DEAD U1 in 0.000 6.096E-07 0.000 6.637E-07 Table 15: Joint Displacements U2 U3 in in 0.000 0.000 0.000 4.163E-09 0.000 0.000 0.000 1.041E-07 R1 Radians 0.000 0.000 0.000 0.000 R2 Radians 0.000 0.000 0.000 0.000 R3 Radians 0.000 0.000 0.000 0.000

Table 16: Joint Reactions

Joint 1 3 OutputCase DEAD DEAD F1 Kip -5000.000 -5000.000 Table 16: Joint Reactions F2 F3 Kip Kip 0.000 3002.400 0.000 -3002.400 M1 Kip-in 0.000 0.000 M2 Kip-in 0.000 0.000 M3 Kip-in 0.000 0.000

8. Area results

This section provides area results, including items such as forces and stresses.

Table 17: Element Stresses - Area Planes

Area 1 1 1 2 2 2 AreaElem 1 1 1 2 2 2 Joint 1 3 2 2 3 4 Table 17: Element Stresses - Area Planes OutputCase S11 S22 Kip/in2 Kip/in2 DEAD 1004.800 301.440 DEAD 1004.800 301.440 DEAD 1004.800 301.440 DEAD 995.200 -1.200 DEAD 995.200 -1.200 DEAD 995.200 -1.200 S33 Kip/in2 0.000 0.000 0.000 0.000 0.000 0.000 S12 Kip/in2 2.400 2.400 2.400 -2.400 -2.400 -2.400

Kamal Hassan

Page 7 of 9

Finite Element Analysis.SDB 9. Material take-off

SAP2000 v14.0.0 - License # 15 May 2010

9. Material take-off

This section provides a material take-off.

Table 18: Material List 2 - By Section Property

Section kk Table 18: Material List 2 - By Section Property ObjectType NumPieces TotalLength in Area TotalWeight Kip 56.710

10. Design preferences

This section provides the design preferences for each type of design, which typically include material reduction factors, framing type, stress ratio limit, deflection limits, and other code specific items.

10.1. Steel design

Table 19: Preferences - Steel Design - AISC-LRFD93, Part 1 of 2

FrameType Moment Frame Table 19: Preferences - Steel Design - AISC-LRFD93, Part 1 of 2 PatLLF SRatioLimit PhiB PhiC PhiT 0.750 0.950 0.900 0.850 0.900 PhiV 0.900 PhiCA 0.900

Table 19: Preferences - Steel Design - AISC-LRFD93, Part 2 of 2

Table 19: Preferences - Steel Design - AISC-LRFD93, Part 2 of 2 DLRat SDLAndLLRat LLRat TotalRat NetRat 120.000 120.000 360.000 240.000 240.000

10.2. Concrete design

Table 20: Preferences - Concrete Design - ACI 318-05/IBC2003, Part 1 of 2

Table 20: Preferences - Concrete Design - ACI 318-05/IBC2003, Part 1 of 2 MinEccen PatLLF UFLimit SeisCat PhiT No 0.750 0.950 D 0.900

Kamal Hassan

Page 8 of 9

Finite Element Analysis.SDB 10. Design preferences

SAP2000 v14.0.0 - License # 15 May 2010

Table 20: Preferences - Concrete Design - ACI 318-05/IBC2003, Part 2 of 2

Table 20: Preferences - Concrete Design - ACI 318-05/IBC2003, Part 2 of 2 PhiVSeismi PhiCTied PhiCSpiral PhiV PhiVJoint c 0.650 0.700 0.750 0.600 0.850

10.3. Aluminum design

Table 21: Preferences - Aluminum Design - AA-ASD 2000

Table 21: Preferences - Aluminum Design - AA-ASD 2000 FrameType SRatioLimit LatFact UseLatFact Moment Frame 1.000 1.333 No

10.4. Cold formed design

Table 22: Preferences - Cold Formed Design - AISI-ASD96

FrameType SRatioLim it 1.000 Table 22: Preferences - Cold Formed Design - AISI-ASD96 OmegaBL OmegaBS OmegaBU OmegaVS OmegaVN S TB S 1.670 1.670 1.670 1.670 1.500 OmegaT OmegaC

Braced Frame

1.670

1.800

Kamal Hassan

Page 9 of 9

You might also like

- SAFE Analysis & Design Report: License #Document15 pagesSAFE Analysis & Design Report: License #PinapaSrikanthNo ratings yet

- Design Report - Raft of OhwtDocument163 pagesDesign Report - Raft of Ohwtvaibhav dahiwalkarNo ratings yet

- SAP2000 analysis of reinforced concrete frame structureDocument17 pagesSAP2000 analysis of reinforced concrete frame structureDarley MauricioNo ratings yet

- SAP2000 Analysis Report: License #2010 1KU4BH288P9NHNJDocument8 pagesSAP2000 Analysis Report: License #2010 1KU4BH288P9NHNJmauriciotrochesaNo ratings yet

- Table: Active Degrees of Freedom: Portal Beton SAP2000 v14.0.0 - License # 26 June 2012Document8 pagesTable: Active Degrees of Freedom: Portal Beton SAP2000 v14.0.0 - License # 26 June 2012RamaNo ratings yet

- Report SAP 2000Document33 pagesReport SAP 2000Anonymous tBhJoH5wgMNo ratings yet

- (Untitled) .SDB SAP2000 v14.0.0 - License # 06 October 2016Document3 pages(Untitled) .SDB SAP2000 v14.0.0 - License # 06 October 2016fransNo ratings yet

- Gaus GableDocument20 pagesGaus GableWayan SuwestraNo ratings yet

- SAP2000 v15.1.0 Analysis Report for SVC-132kv-Steel Support StructureDocument18 pagesSAP2000 v15.1.0 Analysis Report for SVC-132kv-Steel Support StructureMian M KhurramNo ratings yet

- Finite Element Model DefinitionDocument26 pagesFinite Element Model DefinitionUcok DedyNo ratings yet

- Curtain Wall With HZ & VL Louvers Structural Calculation For Building a-PART (6) at AXIS (34-42) - A'Document59 pagesCurtain Wall With HZ & VL Louvers Structural Calculation For Building a-PART (6) at AXIS (34-42) - A'نصر عبدالسلامNo ratings yet

- SAFE ReportDocument11 pagesSAFE ReportAmmar AbusalehNo ratings yet

- Friction and Wear Behavior of ABS - 2014, INDIADocument5 pagesFriction and Wear Behavior of ABS - 2014, INDIAvaxevNo ratings yet

- Lifting Beam Deign Staad 82187560 Design Calc 10T Spreader BeamDocument20 pagesLifting Beam Deign Staad 82187560 Design Calc 10T Spreader BeamJurie_sk360888% (8)

- 20 SeismicDocument16 pages20 SeismicNash GoldManNo ratings yet

- ASTM-B90-B90M-13 Standard Specification For Magnesium-Alloy Sheet and PlateDocument8 pagesASTM-B90-B90M-13 Standard Specification For Magnesium-Alloy Sheet and Plateatishr100% (1)

- J336-ST-DOC-RPT-001 - Analysis of CSC Tank Frame - Rev 0Document21 pagesJ336-ST-DOC-RPT-001 - Analysis of CSC Tank Frame - Rev 0Thomas StephenNo ratings yet

- Exhaust Stack: Engineering With The SpreadsheetDocument16 pagesExhaust Stack: Engineering With The SpreadsheetMakanjuola Ronald OlaitanNo ratings yet

- Seismic Performance Evaluation of Reinforced ConcreteDocument3 pagesSeismic Performance Evaluation of Reinforced ConcreteRezviNo ratings yet

- IBC 2006 Static MethodDocument22 pagesIBC 2006 Static MethodfaridhassaniNo ratings yet

- Genta Permata Putra 2001022018 Tugas Portal Sap 2000 Kelas 2A.Sdb SAP2000 v14.0.0 - License # 15 December 2021Document3 pagesGenta Permata Putra 2001022018 Tugas Portal Sap 2000 Kelas 2A.Sdb SAP2000 v14.0.0 - License # 15 December 2021Genta PermataNo ratings yet

- Steel BS Parameter PDFDocument8 pagesSteel BS Parameter PDFdpkNo ratings yet

- Report SPeaDer BarDocument24 pagesReport SPeaDer BarMochammad Shokeh100% (2)

- Table: Beam Properties 01 - General: RAFT1.fdb SAFE v12.2.0 - License # 20 August 2011Document332 pagesTable: Beam Properties 01 - General: RAFT1.fdb SAFE v12.2.0 - License # 20 August 2011Anonymous YDwBCtsNo ratings yet

- Angleflexseat - Xls (Revision 1.2)Document4 pagesAngleflexseat - Xls (Revision 1.2)cataiceNo ratings yet

- Exhaust Stack: Engineering With The SpreadsheetDocument8 pagesExhaust Stack: Engineering With The SpreadsheetZain Saeed0% (1)

- Rcc95 Continuous Beams (Tables)Document8 pagesRcc95 Continuous Beams (Tables)Steve JsobNo ratings yet

- Seismic Analysis and Design of Shear Walls in Multi-Storey BuildingsDocument18 pagesSeismic Analysis and Design of Shear Walls in Multi-Storey BuildingsRam IngalkarNo ratings yet

- Fe Analysis of Rotor Assembly: Document No: Ch/Report/Drm/109/2016-17Document37 pagesFe Analysis of Rotor Assembly: Document No: Ch/Report/Drm/109/2016-17Nishit KhuntNo ratings yet

- SAP2000 material properties tablesDocument3 pagesSAP2000 material properties tablesrafaelNo ratings yet

- Exhaust Stack: Engineering With The SpreadsheetDocument16 pagesExhaust Stack: Engineering With The SpreadsheetAie Bantugan100% (1)

- Asce7 05 Earthquake F 7310 Sand Surge HopperDocument1 pageAsce7 05 Earthquake F 7310 Sand Surge HopperDeepmalaJayeshNo ratings yet

- Offshore sign board frame design and analysisDocument14 pagesOffshore sign board frame design and analysisgery_No ratings yet

- Informative Annex 2 - Surface FinishDocument10 pagesInformative Annex 2 - Surface FinishzaheerNo ratings yet

- TRE - Pavement Design - GRP 5Document25 pagesTRE - Pavement Design - GRP 5Ayush TripathiNo ratings yet

- Formulae and Design Rules To Ec2Document45 pagesFormulae and Design Rules To Ec2moodoo100% (4)

- Beban AnginDocument11 pagesBeban AnginKevin NathanielNo ratings yet

- Structural Design and Calculation: Proposed Health Center BuildingDocument58 pagesStructural Design and Calculation: Proposed Health Center BuildingDominic DatuinNo ratings yet

- Design Calculations For Light MastDocument23 pagesDesign Calculations For Light Mastjobees7850No ratings yet

- Sample21 SpreadsheetDocument20 pagesSample21 SpreadsheetSivateja NallamothuNo ratings yet

- Design Calculations For Light MastDocument24 pagesDesign Calculations For Light Mastjobees7850100% (17)

- RCsolver 2012 - Concrete Column DesignDocument12 pagesRCsolver 2012 - Concrete Column DesignAmelaLjNo ratings yet

- Calculation Report For Monorail and Hatch Cover REV.0Document15 pagesCalculation Report For Monorail and Hatch Cover REV.0Tran Van DaiNo ratings yet

- Appendix BDocument15 pagesAppendix Bapi-287564533No ratings yet

- SAP2000 Analysis Report: License #2010 1KU4BH288P9NHNJDocument7 pagesSAP2000 Analysis Report: License #2010 1KU4BH288P9NHNJmauriciotrochesaNo ratings yet

- Znd522 A 1way Slab Rev ADocument9 pagesZnd522 A 1way Slab Rev AFelixander FalguiNo ratings yet

- Analysis and Design of Frame-1: 1 Roll No:39 Reuben JacobDocument22 pagesAnalysis and Design of Frame-1: 1 Roll No:39 Reuben JacobReubenNo ratings yet

- SAP2000 Analysis ReportDocument20 pagesSAP2000 Analysis Reportroan sthaNo ratings yet

- Manual and Software Deflection Calculations for Manila Office SlabDocument9 pagesManual and Software Deflection Calculations for Manila Office SlabklynchelleNo ratings yet

- Easy Guide On How To Design Columns To Eurocode 2Document10 pagesEasy Guide On How To Design Columns To Eurocode 2tim_lim12No ratings yet

- Calculation Notes of Sign Board of JoulzeDocument17 pagesCalculation Notes of Sign Board of Joulzeنصر عبدالسلامNo ratings yet

- Embedded Plate Connection Calculations ReviewDocument176 pagesEmbedded Plate Connection Calculations ReviewErnest NavarroNo ratings yet

- What Is New & Changed in STAAD - ProDocument52 pagesWhat Is New & Changed in STAAD - Proanon_441948462No ratings yet

- Simplified ANSYS Model Concrete CrackDocument10 pagesSimplified ANSYS Model Concrete CrackMohamadreza Seraji100% (3)

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- Flat Panel Display ManufacturingFrom EverandFlat Panel Display ManufacturingJun SoukNo ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo ratings yet

- Computer Processing of Remotely-Sensed Images: An IntroductionFrom EverandComputer Processing of Remotely-Sensed Images: An IntroductionNo ratings yet

- Proofs of ConspiracyDocument412 pagesProofs of Conspiracyironmercury50% (2)

- Preparing Your Tracks For Mixing - SoundBetterDocument5 pagesPreparing Your Tracks For Mixing - SoundBetterEmmanuel TuffetNo ratings yet

- Prepositional Phrases in SentencesDocument2 pagesPrepositional Phrases in SentencesDianaNo ratings yet

- spm2 ExamDocument7 pagesspm2 ExamFikruNo ratings yet

- Today's Court Decision on Land Registration AppealDocument6 pagesToday's Court Decision on Land Registration AppealJohn Lester TanNo ratings yet

- HIlbro SurgicalDocument70 pagesHIlbro Surgicalshazay_7733% (3)

- Caterpillar Oil Filter Pehj0068-02Document2 pagesCaterpillar Oil Filter Pehj0068-02Parinpa Ketar100% (1)

- Assignment IDocument4 pagesAssignment IDylan HsiehNo ratings yet

- Residency Programs in The USADocument28 pagesResidency Programs in The USAAnastasiafynnNo ratings yet

- Fake News Detection PPT 1Document13 pagesFake News Detection PPT 1Sri VarshanNo ratings yet

- Economic Impact of Food Culture and History of West Bengal On TouristDocument17 pagesEconomic Impact of Food Culture and History of West Bengal On Touristhitesh mendirattaNo ratings yet

- Katipunan and KartilyaDocument70 pagesKatipunan and KartilyaNINA ROSE CUDIANo ratings yet

- Fault Code: 352 Sensor Supply 1 Circuit - Voltage Below Normal or Shorted To Low SourceDocument3 pagesFault Code: 352 Sensor Supply 1 Circuit - Voltage Below Normal or Shorted To Low SourceFernando AguilarNo ratings yet

- DKK1413 - Chapter 04-1Document37 pagesDKK1413 - Chapter 04-1Salini ShaNo ratings yet

- (Template) ELCT Question Paper - Summer - 2021Document2 pages(Template) ELCT Question Paper - Summer - 2021Md.AshikuzzamanNo ratings yet

- MeasurIT Flexim WaveInjector 1003Document3 pagesMeasurIT Flexim WaveInjector 1003cwiejkowskaNo ratings yet

- Tropical Fruit CHAPTER-3Document32 pagesTropical Fruit CHAPTER-3Jeylan FekiNo ratings yet

- Contact DetailsDocument2 pagesContact DetailsSunil KumarNo ratings yet

- Bilge Oily Water SeparatorDocument25 pagesBilge Oily Water Separatornguyenvanhai19031981100% (2)

- 2015 - Product Keys For Autodesk ProductsDocument7 pages2015 - Product Keys For Autodesk ProductsmonkeyDivanNo ratings yet

- Manual Videoporteiro Tuya Painel de Chamada 84218Document6 pagesManual Videoporteiro Tuya Painel de Chamada 84218JGC CoimbraNo ratings yet

- Planning Manual: LCT SystemDocument40 pagesPlanning Manual: LCT System唐鹏飞No ratings yet

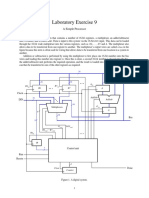

- Laboratory Exercise 9: A Simple ProcessorDocument8 pagesLaboratory Exercise 9: A Simple ProcessorhxchNo ratings yet

- AP School Education Rules SummaryDocument17 pagesAP School Education Rules SummaryThirupathaiahNo ratings yet

- Assignment: New Product Development PROJECT TITLE: Safety Alarm For Construction WorkerDocument21 pagesAssignment: New Product Development PROJECT TITLE: Safety Alarm For Construction WorkerHazim ZakiNo ratings yet

- Keyin MaterialsDocument17 pagesKeyin MaterialsH.GorenNo ratings yet

- Summary of Jordan Peterson's Biblical LecturesDocument25 pagesSummary of Jordan Peterson's Biblical LecturesRufus_DinaricusNo ratings yet

- Bells and WhistlesDocument2 pagesBells and Whistlesapi-265536295No ratings yet

- Songs For The Deaf: Parental Advisory EdDocument5 pagesSongs For The Deaf: Parental Advisory EdTinta CafeNo ratings yet

- Cost Estimation and Cost Allocation 3Document55 pagesCost Estimation and Cost Allocation 3Uday PandeyNo ratings yet