Professional Documents

Culture Documents

CPM Poster

Uploaded by

David M CroninCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CPM Poster

Uploaded by

David M CroninCopyright:

Available Formats

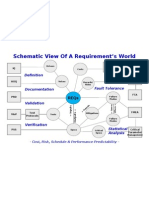

Enabling an Active Design Desktop with

Critical Parameter Management

Executive Overview

What is Critical Parameter Management? Motivation for CPM

• A disciplined methodology for managing, analyzing, and reporting technical product performance

• Enables a lean approach to to optimize product cost, performance, schedule, and manufacturability

• A process for mathematically linking parameters for sensitivity analysis and optimization of requirements

• CPM means PREDICTING product performance and design characteristics before a system is actually built

• An “Active Design Management” system providing real time collaborative feedback of system performance behavior

• Provide complete history of design intent, rationale, input/output, thereby easing compliance requirements

• A strategic tool for improving product development by integrating systems, software, and hardware engineering

• Leverage statistical design methods to allow for performance to be modeled in a PROBABLISTIC manner

CPM Primary Program Benefits • Re use of technical knowledge, capture of corporate TRIBAL KNOWLEDGE and intellectual capital

Improve Collaboration • Trace each design parameter to its corresponding Voice of the Customer

-Share technical analysis and knowledge ←Collaborate

-Link ownership to parameters • Connect performance based design decisions with their COST IMPACTS early in the development process

-Mathematically connect parameters to understand requirement flow-down

-Capture and leverage invested intellectual capital for future business reuse • Connect design teams and encourage COLLABORATION between all disciplines around performance

Facilitate Analysis •Connect various geographical sites

-Statistical modeling & optimization of the performance – cost trade space

-Real-time System-level sensitivity analysis •Connect large numbers of engineers from various disciplines

-Connect analyses between system, subsystem and component levels

•Provide a real time portal for managers to track the development process

Streamline Reporting ←Analyze*

-Design margins are statistically tracked over product lifecycle

-Automated, real-time requirements data gathering / report generation

Optimize Cost v. Performance

-Reconciliation of requirement allocation and engineering design capability CPM helps designs meet both cost and performance goals with predictive,

Performance repeatable results based on analytical input. CPM also helps development

teams make informed decisions that optimize both cost and performance

←Report

€¥$

throughout the development process. CPM lets teams answer important

questions such as: “If this requirement is being met, just how much

margin is there? Is it over-designed? Are there cost reduction

opportunities in this design?

Is CPM Just Like Requirements Management? Domains in Product Development

NO - CPM and Requirements Management are NOT the Same Process! System Requirements Management

Product Definition

Requirements

Management Voice of the SRM CPM, like these other product development domains,

Customer CPM has significant advantages over traditional requirements provides a key repository for product knowledge and

“The System SHALL …” management. A robust CPM process includes requirements becomes the “go to” location for all performance and

management as one piece but CPM allows requirements to be Critical Product functional data for a system.

System Parameter

connected to parameters in an analytical way Data

A-Spec

Management CPM PDM

Management

Performance Configuration

B- Spec Traditional requirements management is a text based approach to Definition Definition

B1- SS interaction with customer needs and regulatory compliance. CPM, PCM

through its dynamic relationships between requirements and

B2-HRD

parameters, provides real time feedback and notification throughout Product Cost Management

Requirements Management is used to track, the system about requirement or parameter changes as well as the Affordability Definition

manage, and control requirements flow-down in sensitivities of individual parameters on the overall system.

a text based environment

CPM helps the product or process development team trace the

Critical Parameter connection between each key design decision and it associated

CPM Creates the Dynamic

Management Voices of the

Customers Relationships to Monitor all

VOC (Voice Of the Customer). This helps ensure that the

Performance/ Design Aspects of a Process or System development team works on the most important design elements

“The System CAN …” Capability

System and lets the corporation re use product knowledge in future

System Cpk/PNC/Notifications

TPM / Req Requirements Parameters generations of design.

System Subsystem Cpk/PNC/Notifications Subsystem

Parameters f(x)

Requirements

Sub-System

Subassembly … Subassembly

Parameters f(x)

Sub-Assembly

Component

Requirements

Component

Requirements

… Component

Specifications

f(x)

The Active Design Desktop

CPM is a mathematically interconnected hierarchy

of requirements and parameters allowing flow Mfg. Process Mfg. Process

The CPM process creates an Active Design Desktop

… f(x)

down AND flow up of design sensitivities Requirements Specifications which allows engineers and management to:

CPM captures corporate “tribal knowledge” along with best • Query and access parameter information and relationships

practices and analytical reasoning, and provides complete

historical tracing for any process, system, or system of systems. • Create real time, dynamic program status reports

• Manage the many-to-many relationships of parameters

Critical Parameter Management (CPM)

CPM is a Disciplined Methodology to Capture the • Navigate/browse through the parameter function tree Real time feedback on design

Product Performance into a Structured Repository • Manage all transfer functions , Y=F(x) and total system capabilities

• Control access & ownership for design control

Marketing MFG

Critical The CPM Active Design Desktop is a Single Point of

Parameter

Systems Control for Product Data and Knowledge:

Engineering Management Suppliers

(CPM) • Launch -> Load -> Retrieve Parameters with Applications

This parameter can now answer

the famous question: • Manage Application Files, Engineering Models, and Capabilities

Subject

Matter Partners • Repository for Supporting Design Artifacts and Documents

Who am I? Experts

Why am I Design Standards

here?

The CPM Active Design Desktop is a process and Where do I have design margin

tool set that enables the improvement of product and where am I at risk?

design and reduction of program costs by:

• Providing a single go-to repository for all users to interact with

Methodology: CPM Process Overview requirements and parameters in a real time collaborative

environment across the organization

Given a System Level Requirement and/or a Voice of the Customer…

• Reducing late-design firefighting due to inefficient collaboration

Ex: Range, Cost, Comfort, Force, Tone, Weight, Ease, etc. • Exposing and managing risks in product design and

manufacturing capability

• Allocate top-level requirements into sub-system/process and • Identifying cost savings opportunities due to over-design

component/raw material requirements that are given to designers to meet

• Eliminating inefficiencies in program reporting

• Each designer or team works independently to assess itself on how well it

is going to meet its allocation by building a model that predicts anticipated

design characteristics

Design Convergence reports track

• Teams identify which parameters are most sensitive to their requirements current parameter values v. their targets

CPM Enables the Active Design

and allocate appropriate resources for analysis Desktop through analytical

interactions between

• Statistical parameters are added to provide confidence to the model and

requirements and parameters

predict top-level capability probablistically. “Can I meet the cost target”, v.

“Can I meet the cost target with 99% statistical confidence?” The Active Design Desktop is

a Global Positioning System

• These parameters are rolled up from each designer or team using for Product Development

transfer functions to provide a system-level prediction

• Where necessary, sensitivity analysis is conducted to focus efforts where

they have the most significant impact on system requirements.

This poster is copyright 2007 by Cognition Corporation. All rights reserved. www.cognition.us *The Excel, Crystal Ball, Minitab, and Matlab symbols are trademarks of their respective owners: Microsoft, Decisioneering, Minitab, and MathWorks.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cognition Risk ManagementDocument21 pagesCognition Risk ManagementDavid M Cronin100% (1)

- Cognition Requirements ManagementDocument71 pagesCognition Requirements ManagementDavid M CroninNo ratings yet

- Cockpit For Requirements ManagementDocument58 pagesCockpit For Requirements ManagementDavid M Cronin100% (1)

- Balancing Cost and PerformanceDocument31 pagesBalancing Cost and PerformanceDavid M CroninNo ratings yet

- Cognition Cockpit OverviewDocument29 pagesCognition Cockpit OverviewDavid M CroninNo ratings yet

- World of RequirementDocument1 pageWorld of RequirementDavid M CroninNo ratings yet

- AT89C52 Is An 8Document3 pagesAT89C52 Is An 8amishra_771992No ratings yet

- CMDB2.0.1 DevelopersReferenceGuideDocument386 pagesCMDB2.0.1 DevelopersReferenceGuidemarkiitotNo ratings yet

- RDBMS Full ProgramsDocument2 pagesRDBMS Full ProgramsSulbha GathNo ratings yet

- Video For Linux 2 V 4 L 2: by Rahul C Alphaics CorpDocument15 pagesVideo For Linux 2 V 4 L 2: by Rahul C Alphaics CorpRahul CNo ratings yet

- Iee PaperDocument3 pagesIee PaperAmrutha SeshadriNo ratings yet

- Java Notes For ECEDocument42 pagesJava Notes For ECEDhiman1001No ratings yet

- Computer Chess PioneersDocument87 pagesComputer Chess PioneersKartik ShroffNo ratings yet

- Miskath Hossain (211002602)Document17 pagesMiskath Hossain (211002602)Ahsan KHANNo ratings yet

- System Administrator - Co-Operative Societies - Dt. 28.04.2019 Quesstion Code - ADocument3 pagesSystem Administrator - Co-Operative Societies - Dt. 28.04.2019 Quesstion Code - AShafat91No ratings yet

- STD OutDocument2 pagesSTD OutpeterNo ratings yet

- Predicate TestingDocument23 pagesPredicate TestingKartheek 577No ratings yet

- Microprogram ControlDocument30 pagesMicroprogram ControlMit BhaiyaNo ratings yet

- Java ProgrammingDocument48 pagesJava ProgrammingAbhishekNo ratings yet

- Studio RM PDFDocument27 pagesStudio RM PDFMohammed JemlaNo ratings yet

- NERD TreeDocument63 pagesNERD TreesebexNo ratings yet

- Arduino Based Boiling Milk Using Ultrasonic Sensor Block DiagramDocument7 pagesArduino Based Boiling Milk Using Ultrasonic Sensor Block DiagramAnonymous qh5UUGTNo ratings yet

- Web Technology Theory and Practice CompressDocument392 pagesWeb Technology Theory and Practice CompressshiNo ratings yet

- FSai 300 00279-Comparison of Sievers 900 Series and Sievers M-Series TOC AnalyzersDocument2 pagesFSai 300 00279-Comparison of Sievers 900 Series and Sievers M-Series TOC AnalyzersAndy RojasNo ratings yet

- M334AB ManualDocument81 pagesM334AB Manualsamel abreNo ratings yet

- Key StretchingDocument2 pagesKey StretchingAbinaya Thulasirajan100% (1)

- Loop-V4200-9: Muxmaster/Wideband Iad Csu/Dsu, E1/T1 Converter, DacsDocument6 pagesLoop-V4200-9: Muxmaster/Wideband Iad Csu/Dsu, E1/T1 Converter, DacsSay Hong Jeffrey TanNo ratings yet

- Group No.33. IDEA Plagiarism PDFDocument38 pagesGroup No.33. IDEA Plagiarism PDFbishal sarmaNo ratings yet

- Ch8 Programming Challenges SolutionDocument5 pagesCh8 Programming Challenges SolutionAmmar Ahmed KhanNo ratings yet

- User Manual DigiBunai PDFDocument53 pagesUser Manual DigiBunai PDFDinesh Bhathela100% (1)

- NSG 9000-40G Hectoqam: Scalable Universal EdgeqamDocument4 pagesNSG 9000-40G Hectoqam: Scalable Universal EdgeqamJacob WilkersonNo ratings yet

- Editing Worksheets: With Polaris Office, You Can Create New .Xls and .XLSX Sheets or Edit Your Worksheets With EaseDocument10 pagesEditing Worksheets: With Polaris Office, You Can Create New .Xls and .XLSX Sheets or Edit Your Worksheets With EaseSaim HussainNo ratings yet

- v1.0 IWM-LR3 LR4 UM ENDocument21 pagesv1.0 IWM-LR3 LR4 UM ENCarlos LeyvaNo ratings yet

- JSP ArchitectureDocument2 pagesJSP ArchitectureNigam PatelNo ratings yet

- Unit 7 & 8 - Working With XML & Web Service SBDocument34 pagesUnit 7 & 8 - Working With XML & Web Service SBdhruv shahNo ratings yet

- C++ CaseStudyDocument14 pagesC++ CaseStudyalhussainraad0No ratings yet