Professional Documents

Culture Documents

Agitation and Mixing

Uploaded by

Faraj Al-TaherOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Agitation and Mixing

Uploaded by

Faraj Al-TaherCopyright:

Available Formats

~ -'= , Sirte University

~--)- -- Faculty of Engineering

--'----- ~--)- ;~- Chemical Engineering Department

Fluid Mechanics II F. Al-Taher, 01.06.2010 Spring 2009-2010

Agitation and Agitation and Agitation and Agitation and Mixing Mixing Mixing Mixing of liquids in tanks of liquids in tanks of liquids in tanks of liquids in tanks

Mixing: Intermingling of two or more dissimilar portions of a material, resulting in the attainment

of a desired level of uniformity, either physical or chemical, in the final product.

Agitation: Creation of a state of activity such as flow or turbulence, apart from any mixing

accomplished.

Classification of agitators:

In general, agitators can be classified into the following two groups.

1. Agitators with a small blade area which rotate at high speeds. These includes:

(a) Turbines propellers (Fig.5-1).

(b) Marine propellers (Fig.5-2).

2. Agitators with a large blade area which rotate at low speeds. This is more effective than the

first in the mixing of high viscosity liquids. These includes:

(a) Anchors. ('--' .--)

(b) Paddles. ( ', )

(c) Helical screws. (-',')

The mean shear rate produced by an agitator in a mixing tank (

.

m

) is proportional to the rotational

speed of the agitator (N). Thus

kN

m

=

.

--------------------- (5-1)

k: Dimensionless proportionality constant for a particular system.

~ -'= , Sirte University

~--)- -- Faculty of Engineering

--'----- ~--)- ;~- Chemical Engineering Department

Fluid Mechanics II F. Al-Taher, 01.06.2010 Spring 2009-2010

For a liquid mixed in a tank with a rotating agitator, the shear rate is greatest in the immediate

vicinity of the agitator.

1. Small blade high speed agitators:

Small blade high speed agitators are used to mix low to medium viscosity liquids (10-50 Pa.s).

Since they are high shear agitators they are useful for mixing pseudoplastic liquids.

Flat blade turbines used to mix liquids in baffled tanks produce radial flow patterns primarily

perpendicular to the vessel wall as shown in Figure 5.3.

In contrast, marine type propellers used to mix liquids in baffled tanks produce axial flow

patterns primarily parallel to the vessel wall as shown in Figure 5.4.

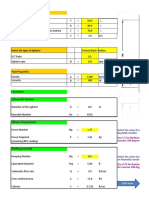

Figure 5.5 shows a turbine agitator of diameter D

A

in a cylindrical tank of diameter D

T

filled

with liquid to a height H

L

. The agitator is located at a height H

A

from the bottom of the tank and the

baffles which are located immediately adjacent to the wall have a width b. The agitator has a blade

width a and blade length r and the blades are mounted on a central disc of diameter s. A typical

turbine mixing system is the standard configuration defined by the following geometrical

relationships:

~ -'= , Sirte University

~--)- -- Faculty of Engineering

--'----- ~--)- ;~- Chemical Engineering Department

Fluid Mechanics II F. Al-Taher, 01.06.2010 Spring 2009-2010

Six-blade flat blade turbine agitator

D

A

= D

T

/3

H

A

= D

T

/3

a = D

T

/5

r = D

T

/4

H

L

= D

T

4 symmetrical baffles

b = D

T

/10

Agitator tip speeds are commonly used as a measure of the degree of agitation in a liquid mixing

system. It is given by

N D u

A t

. . = ----------------------- (5-2)

Tip speed ranges for turbine agitators are recommended as follows:

For low agitation: u

t

= 2.5 3.3 m/s

For medium agitation: u

t

= 3.3 4.1 m/s

For high agitation: u

t

= 4.1 5.6 m/s

If turbine or marine propeller agitators are used to mix relatively low viscosity liquids in unbaffled

tanks, vortexing develops. In this case the liquid level falls in the immediate vicinity of the agitator

shaft. Vortexing increases with rotational speed N until eventually the vortex passes through the

agitator. As the liquid viscosity increases, the need for baffles to reduce vortexing decreases.

Volumetric circulating capacity: A marine propeller can be considered as a ceaseless pump. In this

case its volumetric circulating capacity Q

A

is:

4

3

A

A

ND

Q

= ----------------------- (5-3)

Where: : Dimensionless efficiency factor (approximately 0.6)

~ -'= , Sirte University

~--)- -- Faculty of Engineering

--'----- ~--)- ;~- Chemical Engineering Department

Fluid Mechanics II F. Al-Taher, 01.06.2010 Spring 2009-2010

The best mixing: To get the best mixing process the tank turnover rate (I

T

) should be at a

maximum, where (I

T

) is the ratio of volumetric circulating capacity to the tank volume (I

T

= Q

A

/V).

For a given tank volume V, this means that the circulating capacity Q

A

should have the highest

possible value for the minimum consumption of power.

2. Large blade low speed agitators:

Large blade low speed agitators are used to mix relatively high viscosity liquids and depend on

a large blade area to produce liquid movement throughout a tank. Since they are low shear agitators

they are useful for mixing dilatant liquids. A gate type anchor agitator is shown in Figure 5.6.

The flow pattern in a baffled helical screw system is shown in Figure 5.7. Baffles are not

required if the helical screw is placed in an off-centred position since in this case the system

becomes self-baffling. However, off-centred helical screws require more power to produce a

comparable mixing result.

~ -'= , Sirte University

~--)- -- Faculty of Engineering

--'----- ~--)- ;~- Chemical Engineering Department

Fluid Mechanics II F. Al-Taher, 01.06.2010 Spring 2009-2010

Dimensionless groups for mixing:

In the design of liquid mixing systems the following dimensionless groups are of

importance:

1. Power Number:

5 3 0

A

A

D N

P

P

=

2. Reynolds Number for mixing:

It represents the ratio of the applied to the opposing viscous drag forces.

2

Re

A

M

ND

=

3. Froude Number for mixing:

It represents the ratio of the applied to the opposing gravitational forces.

g

D N

Fr

A

M

2

=

4. Weber Number for mixing:

It represents the ratio of the applied to the opposing surface tension forces.

3 2

A

M

D N

We =

Weber number is only important when separate physical phases are present in the liquid mixing

system as in liquid-liquid extraction.

Where:

: Liquid density (kg/m

3

) : Liquid viscosity (Pa.s), : Liquid surface tension (N/m)

A

P : Agitator power consumption (Watt) N : Agitator rotational speed (rev/s)

A

D : Agitator diameter (m)

By dimensional analysis, it can be shown that the power number

0

P can be related to the Reynolds

number for mixing

M

Re and the Froude number for mixing

M

Fr by the equation

x

M y

M

C

Fr

P

Re .

0

= = ----------------------- (5-4)

~ -'= , Sirte University

~--)- -- Faculty of Engineering

--'----- ~--)- ;~- Chemical Engineering Department

Fluid Mechanics II F. Al-Taher, 01.06.2010 Spring 2009-2010

Where:

C: Overall dimensionless shape factor which represents the geometry of the system.

: Dimensionless power function.

In liquid mixing systems, baffles are used to suppress vortexing. Since vortexing is a gravitational

effect, the Froude number is not required to describe baffled liquid mixing systems. In this case the

exponent "y" in equation (5-4) is zero, that is " 1 =

y

M

Fr ".

Thus for non-vortexing systems equation (5-4) can be written as

x

M

C P Re .

0

= =

Or as

M

xLog LogC LogP Re

0

+ = ----------------------- (5-5)

Power curves:

A power curve is a plot of the power function (or the power number P

0

) against the

Reynolds number for mixing

M

Re on log-log coordinates. Each geometrical configuration has its

own power curve and since the plot involves dimensionless groups it is independent of tank size.

1. For baffled non-vortexing system:

Figure (5-8) shows the power curve for this system configuration. It can be distinguish three

flow regions:

Laminar flow region (AB): [ ] <10 Re

M

x = -1 and C = 71 of eq.(5-5)

Transition flow region (BCD): [ ] < < 10000 Re 10

M

x and C are vary continuously.

Turbulent flow region (DE): [ ] >10000 Re

M

x = 0 and 3 . 6

0

= = = P C

Calculation procedure:

1. Calculate Re

M

from equation of Reynolds number.

2. Read P

0

(or ) from figure (5-8).

3. Calculate the agitation power from equation of power number as follow

5 3

0 A A

D N P P =

~ -'= , Sirte University

~--)- -- Faculty of Engineering

--'----- ~--)- ;~- Chemical Engineering Department

Fluid Mechanics II F. Al-Taher, 01.06.2010 Spring 2009-2010

2. For unbaffled vortexing system:

Figure (5-9) shows the power curve for this system configuration. Up to point "C", Fig.(5-9) is

identical with Fig.(5-8), as the Reynolds number for mixing increases beyond point "C" in the

unbaffled system, vortexing increases and the power falls sharply.

Calculation procedure:

1. Calculate Re

M

from equation of Reynolds number.

2. Read P

0

(or ) from figure (5-9).

3. Calculate the agitation power from the following equation

y

A

A A

g

D N

D N P

=

2

5 3

Where,

( )

M

Log

y

Re

=

For six-blade flat blade turbine agitators of D

A

= 0.1 m:

= 1 and = 40

The power curves given in Fig.(5-8) and Fig.(5-9) were obtained for experiments using Newtonian

liquids. It is possible to calculate the apparent viscosities of non-Newtonian liquids in agitated

tanks from the appropriate power curves for Newtonian liquids.

~ -'= , Sirte University

~--)- -- Faculty of Engineering

--'----- ~--)- ;~- Chemical Engineering Department

Fluid Mechanics II F. Al-Taher, 01.06.2010 Spring 2009-2010

~ -'= , Sirte University

~--)- -- Faculty of Engineering

--'----- ~--)- ;~- Chemical Engineering Department

Fluid Mechanics II F. Al-Taher, 01.06.2010 Spring 2009-2010

Example #1:

Calculate the theoretical power for a six-blade flat blade turbine agitator with diameter D

A

= 3 m

running at a speed of N = 0.2 rev/s in a tank system conforming to the standard tank configuration

illustrated in Figure 5.5. The liquid in the tank has a dynamic viscosity = 1 Pa.s and a density of

= 1000 kg/m3.

Solution:

The Reynolds # for mixing is

( )

1800

1

3 2 . 0 1000

Re

2 2

=

= =

A

M

ND

From Fig.(5-8),

5 . 4

0

= = P

The theoretical power for mixing is

( ) ( )

5 3 5 3

0

3 2 . 0 1000 5 . 4 = =

A A

D N P P 8748 =

A

P Watts Ans.

------------------------------------------------------------------------------------------------------------------------

Example #2:

Calculate the theoretical power for a six-blade flat blade turbine agitator with diameter D

A

= 0.1 m

running at N = 16 rev/s in a tank system without baffles but otherwise conforming to the standard

tank configuration illustrated in Figure 5.5. The liquid in the tank has a dynamic viscosity = 0.08

Pa.s and a density of = 900 kg/m3. For this configuration = 1 and = 40.

Solution:

The Reynolds # for mixing is,

( )

1800

1

1 . 0 16 900

Re

2 2

=

= =

A

M

ND

From Fig.(5-9),

2 . 2 =

Calculating y,

( )

05638 . 0

40

) 1800 ( 1 Re

=

=

Log Log

y

M

The theoretical power for mixing is:

( ) ( )

( )

=

05638 . 0

2

5 3

2

5 3

81 . 9

1 . 0 16

1 . 0 16 900 2 . 2

y

A

A A

g

D N

D N P =

A

P 76.83 Watts Ans.

You might also like

- 0132368692-Ch10 IsmDocument38 pages0132368692-Ch10 IsmOnline Review Specialists100% (4)

- Atec Manual ElectronicDocument73 pagesAtec Manual ElectronicMinaSaeed67% (3)

- 343 400Document58 pages343 400MakaraSoyNo ratings yet

- Agitator Design 11 PDF FreeDocument9 pagesAgitator Design 11 PDF FreeMeisam MomeniNo ratings yet

- Lightnin Impeller Technology PDFDocument8 pagesLightnin Impeller Technology PDFNaila TheExplore HorisonNo ratings yet

- Agitator Full Design PDFDocument8 pagesAgitator Full Design PDFRajesh KumarNo ratings yet

- ServiceKitsForSPAndAgitators E10046 PDFDocument8 pagesServiceKitsForSPAndAgitators E10046 PDFgilbertogatoNo ratings yet

- Agitator Design CalcDocument5 pagesAgitator Design Calcranjit34380% (5)

- Design and Calculation AgitationDocument18 pagesDesign and Calculation AgitationDavid Lambert67% (3)

- Jacket and Coils of Agitated Vessels PDFDocument2 pagesJacket and Coils of Agitated Vessels PDFlolofm25No ratings yet

- Designing a Horizontal Reflux DrumDocument15 pagesDesigning a Horizontal Reflux DrumArfel Marie FuentesNo ratings yet

- Lab Report 3Document4 pagesLab Report 3api-340581896No ratings yet

- 25 Clicker QuestionsDocument20 pages25 Clicker QuestionsFuentesBrisbaneNo ratings yet

- Froude Number in Mixing PDFDocument4 pagesFroude Number in Mixing PDFrinuakNo ratings yet

- Agitated VesselsDocument12 pagesAgitated VesselsFren2008100% (11)

- Reactor Geometry and Agitator SelectionDocument26 pagesReactor Geometry and Agitator SelectionChemical Engineering100% (2)

- Agitator DesignDocument2 pagesAgitator Designnaruto256100% (1)

- Agitation & Mixing of FluidsDocument20 pagesAgitation & Mixing of Fluidsmarkbene69No ratings yet

- Chapter 6-Agitated LiquidDocument48 pagesChapter 6-Agitated LiquidAhmad SiddiqNo ratings yet

- Agitaionandmixing 160117143824 PDFDocument30 pagesAgitaionandmixing 160117143824 PDFMESCIA EngineersNo ratings yet

- Inquiry - Sitemap - E-Mail: Dispersing, Suspending, Emulsifying & Homogenizing Technik For Liquid and PasteDocument5 pagesInquiry - Sitemap - E-Mail: Dispersing, Suspending, Emulsifying & Homogenizing Technik For Liquid and PasteCik MinnNo ratings yet

- Agitator Design: HP CalculationDocument32 pagesAgitator Design: HP CalculationJose Heli Vallejos CoronadoNo ratings yet

- Mixing With Helical Ribbon AgitatorsDocument9 pagesMixing With Helical Ribbon AgitatorsWilson Agudelo CatañoNo ratings yet

- Solid-liquid mixing techniques for mass transfer optimizationDocument9 pagesSolid-liquid mixing techniques for mass transfer optimizationDiana M P100% (1)

- Agitated Liquids GuideDocument33 pagesAgitated Liquids GuideNurtasha Atikah100% (1)

- Agitation: Introduction To Principles and PracticeDocument44 pagesAgitation: Introduction To Principles and Practicearun89000100% (9)

- HT AgitatorsDocument12 pagesHT AgitatorsSantoshkota123No ratings yet

- Calculos DemisterDocument2 pagesCalculos DemistermoviedohNo ratings yet

- Agitiation and Mixing Liquids To StudentsDocument30 pagesAgitiation and Mixing Liquids To StudentsAkshay dev100% (1)

- Design Calculations of Pitch Blade TurbineDocument6 pagesDesign Calculations of Pitch Blade TurbineAyaz_HasanjiNo ratings yet

- Apply these principles of power-law fluid behavior to scale up mixing processes from the laboratory to the production plantDocument9 pagesApply these principles of power-law fluid behavior to scale up mixing processes from the laboratory to the production plantOdst Ovac100% (1)

- Purpose of Agitation VesselDocument6 pagesPurpose of Agitation VesselMAHAD ZahidNo ratings yet

- Stirred Tank CFD SimulationDocument49 pagesStirred Tank CFD SimulationAdhe ParamitaNo ratings yet

- MixingandAgitation93851 10Document18 pagesMixingandAgitation93851 10Eugenio Díaz HenríquezNo ratings yet

- Alcohol DistillationDocument4 pagesAlcohol DistillationprocesspipingdesignNo ratings yet

- Maximizing Wet Scrubber PerformanceDocument7 pagesMaximizing Wet Scrubber PerformanceHESuarez100% (1)

- B635 Tank Mixing Eductors PDFDocument12 pagesB635 Tank Mixing Eductors PDFivanmatijevicNo ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument28 pagesAgitator Power Requirement and Mixing Intensity Calculationcandra100% (3)

- Thermascrew: Advanced FeaturesDocument3 pagesThermascrew: Advanced FeaturesFLIRIDIR1678No ratings yet

- Agitators: Robert L. Bates, President Chemineer, IncDocument24 pagesAgitators: Robert L. Bates, President Chemineer, InctenshinomiyukiNo ratings yet

- Agitator DesignDocument9 pagesAgitator DesignDeepika100% (1)

- Mesh & Vane Mist EliminatorsDocument16 pagesMesh & Vane Mist EliminatorsstressesNo ratings yet

- Batch Reactive DistillationDocument7 pagesBatch Reactive DistillationChalmer BelaroNo ratings yet

- Multistage Agitated ReactorsDocument9 pagesMultistage Agitated ReactorsArunkumarNo ratings yet

- The Unexpected Benefits of Testing Custom Mixers and BlendersDocument4 pagesThe Unexpected Benefits of Testing Custom Mixers and BlendersJoshua JohnsonNo ratings yet

- Power Requirement (Agitator and High-Torque Stirrer)Document8 pagesPower Requirement (Agitator and High-Torque Stirrer)DozdiNo ratings yet

- Hi-Fab Engineers Pvt. Ltd. drawing and design property documentDocument18 pagesHi-Fab Engineers Pvt. Ltd. drawing and design property documentuttam prabhuNo ratings yet

- CHAPTER 5 AGITATATION and MIXING PDFDocument42 pagesCHAPTER 5 AGITATATION and MIXING PDFProfessionalNo ratings yet

- Chapter 6 Solid Liquid SeparationDocument51 pagesChapter 6 Solid Liquid SeparationbrounietaNo ratings yet

- MASTERING MIXING FUNDAMENTALSDocument82 pagesMASTERING MIXING FUNDAMENTALSArturo K. Cabras Jr.No ratings yet

- FMX Static MixerDocument6 pagesFMX Static MixerTint LwinNo ratings yet

- Agitation and Mixing FlowDocument9 pagesAgitation and Mixing FlowSasitharan MNo ratings yet

- Mixing VarietiesDocument64 pagesMixing VarietiesManojkumarNo ratings yet

- Stirred Tank Reactor MixingDocument15 pagesStirred Tank Reactor MixingAixa BerchiNo ratings yet

- Semester No: 4: Name of The Discipline: Chemical EngineeringDocument18 pagesSemester No: 4: Name of The Discipline: Chemical EngineeringSk jahidul IslamNo ratings yet

- Cabeq 2006 1 3Document16 pagesCabeq 2006 1 3altealodNo ratings yet

- Understanding CSTR Dynamics with a Step Change Input ExperimentDocument16 pagesUnderstanding CSTR Dynamics with a Step Change Input ExperimentAhmadAzriMohamad50% (2)

- Study of The Discharge Stream From A Standard Rushton Turbine ImpellerDocument9 pagesStudy of The Discharge Stream From A Standard Rushton Turbine ImpellerCarlos PerezNo ratings yet

- Experiment 4-Unit OpsDocument5 pagesExperiment 4-Unit OpsZeny NaranjoNo ratings yet

- Impeller Design For Mixing of SuspensionsDocument16 pagesImpeller Design For Mixing of SuspensionsFaycel OuerdienNo ratings yet

- 909design of High Efficiency Pelton Turbine For Micro-HydropowerDocument13 pages909design of High Efficiency Pelton Turbine For Micro-HydropowerrachidtuNo ratings yet

- Tank Rapid MixDocument5 pagesTank Rapid MixvicdejoNo ratings yet

- Umping Capacity of Pitched Blade Multi Stage Impellers: Tomáš JiroutDocument7 pagesUmping Capacity of Pitched Blade Multi Stage Impellers: Tomáš Jiroutthomas_v501925No ratings yet

- Flow Equalization Tank DesignDocument9 pagesFlow Equalization Tank DesignhaymedeleonNo ratings yet

- Fluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984From EverandFluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984No ratings yet

- Influence of Size Ion On The Stability of Chloroplumbates PDFDocument7 pagesInfluence of Size Ion On The Stability of Chloroplumbates PDFUriel VázquezNo ratings yet

- Flexural Strength Tests of Ceramics (SubsTech)Document3 pagesFlexural Strength Tests of Ceramics (SubsTech)mypenta2008No ratings yet

- CHEMICAL ENGINEERING LICENSURE EXAM REVIEWDocument3 pagesCHEMICAL ENGINEERING LICENSURE EXAM REVIEWJayson Ordinaria100% (1)

- AC Circuit Problems and SolutionsDocument4 pagesAC Circuit Problems and SolutionsGarlapati Srinivasa RaoNo ratings yet

- Candy Veš M.model Cj433tDocument19 pagesCandy Veš M.model Cj433tpedjavaljarevicNo ratings yet

- Chem127 Chapter IV NMRDocument13 pagesChem127 Chapter IV NMRMark Ryan TripoleNo ratings yet

- 2008 HKCEE Physics P2 SolDocument24 pages2008 HKCEE Physics P2 SolAlex KongNo ratings yet

- Cswip 3.1 Difficul - Multichoice QuesDocument11 pagesCswip 3.1 Difficul - Multichoice QuesLuan Nguyen0% (1)

- Pipe Fitting LossesDocument5 pagesPipe Fitting LossesVrushiket PatilNo ratings yet

- Structural Analysis of DomesDocument10 pagesStructural Analysis of DomesThotho Kennedy100% (2)

- Solubility of S-Block CompoundsDocument4 pagesSolubility of S-Block CompoundsNkemzi Elias NzetengenleNo ratings yet

- BiophysicsandMolecularBiology PDFDocument101 pagesBiophysicsandMolecularBiology PDFRisikrrishna DasNo ratings yet

- Machine Elements 2 (Introduction)Document12 pagesMachine Elements 2 (Introduction)Melinda100% (2)

- Homework 14 Solutions Spring 2001Document2 pagesHomework 14 Solutions Spring 2001Ikhwan Wf Miscellaneous AveroesNo ratings yet

- Photoelectric Effect: Jump To Navigation Jump To SearchDocument10 pagesPhotoelectric Effect: Jump To Navigation Jump To SearchSrynnENo ratings yet

- Projectile Motion: Understanding the Physics of Thrown ObjectsDocument32 pagesProjectile Motion: Understanding the Physics of Thrown ObjectsJoyce EstrevencionNo ratings yet

- Bab 1 Ee201Document29 pagesBab 1 Ee201Noor Hanisah AbdullahNo ratings yet

- Split Up Syllabus Class Xii Physics 22-23Document1 pageSplit Up Syllabus Class Xii Physics 22-23ROHIT SIHRANo ratings yet

- Nucleophilic Substitution Reactions of Alkyl HalidesDocument36 pagesNucleophilic Substitution Reactions of Alkyl HalidesmaulidyaNo ratings yet

- UntitledDocument3 pagesUntitledFarah EssidNo ratings yet

- Partial Differential Equation MCQ For M.Sc. From T. AmaranatjDocument10 pagesPartial Differential Equation MCQ For M.Sc. From T. AmaranatjSanket K Mohare100% (5)

- 5-1 13 3/8" Surface Casing DesignDocument10 pages5-1 13 3/8" Surface Casing Designeng20072007No ratings yet

- Vacuum, General Relativity: PHY100 The Nature of The Physical WorldDocument21 pagesVacuum, General Relativity: PHY100 The Nature of The Physical WorldJacecosmozNo ratings yet

- Question Bank: Ee 1403 - Design of Electrical ApparatusDocument11 pagesQuestion Bank: Ee 1403 - Design of Electrical ApparatussuriyasureshNo ratings yet

- Impact of A JetDocument14 pagesImpact of A JetKamarul Yusri100% (4)