Professional Documents

Culture Documents

Crude Oil Distillation System According To ASTM Standards

Uploaded by

motphanbayOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crude Oil Distillation System According To ASTM Standards

Uploaded by

motphanbayCopyright:

Available Formats

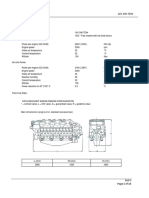

DIST D-2892/5236 CC

Computer Controlled-Combined Distillation System according to ASTM D-2892 (TBP) ASTM D-5236 (Potstill)

The i-Fischer Dist D-2892 / 5236 CC is a fully computer controlled unit of turn-key design, and ready for use after installation and commissioning. The system is fully housed and equipped with doors in the front and rear to satisfy safety requirements and to facilitate service aspects. The automatic fraction collector (in the system section TBP: with 20 receivers) includes a built-in internal balance for the determination of the fraction weight, while the separate volume follower system is used for discharging the fractions into the final recei-

vers and the determination of the fraction volume as well as for the direct distillation rate control. The automatic fraction collector (in the system section Potstill: with 12 receivers) includes a built-in internal balance and volume follower system, which is used for the simultaneous determination of the fraction weight, volume and for the direct distillation rate control. The vacuum equipment and the control system are used for alternative operation of both distillation processes.

expect essentials

Technical Data Operation Temperature: IBP ... 575C AET (depending on product) Operation Pressure: 0.1 ... 760 mmHg (Torr) Fraction collector: 20 receivers (TBP) 12 receivers, heated by IR-radiators (Potstill) Design Essentials operation through PC and flow chart (process parameters are indicated digitally and are presented in coloured curves as a diagram "parameter vs. time") easy unit management also by less experienced operators user-software application operated under WINDOWSXP "log-book with permanent data report and data storage reported history of distillation processes storage of distillation processes with parameters and data, limited by OS ("operator system) only pre-selectable heating modes, e.g. indirect/direct distillation rate control fully automatic fraction discharge into final receivers without any disturbance of the column equilibrium

automatic closing of the final receivers (TBP section only) automatic fraction/receiver changes according to pre-selected cut temperatures and/or receiver volume determination of fraction volumes and weights by built-in volume follower system and internal balance "supervisory-mode for manual overruling of automatic control mode with indication of every manual intervention in the flow chart => manual/semi-automatic operation of the unit (in emergency cases or for maintenance etc.) => manual receiver change automatic debutanisation procedure automatic continuation of the TBPprocess, e.g. with the next vacuum run to be effected automatic cooling down procedure after a distillation run programmable washing/cleaning runs for different solvents evaluation of final data and TBP-curve electrical lifts for heating jackets integrated UPS-system for PC, control system for data storage up to 10 minutes during a power failure

sophisticated vacuum control with dynamic vacuum reduction procedure sophisticated safety and product cracking checks media supply check (nitrogen, instrumentation air, cooling water) all alarms & safety checks with attended/unattended mode various options available: e.g. "water removal/dehydration, "density measurement, "safety devices, "calibration devices, "high vacuum extension (final cut range up to 620650C AET), "software extension 2x 20 receivers for collecting narrow cuts

You might also like

- Preliminary Specifications: Programmed Data Processor Model Three (PDP-3) October, 1960From EverandPreliminary Specifications: Programmed Data Processor Model Three (PDP-3) October, 1960No ratings yet

- DIST D-2892/5236 CC: Computer Controlled-Combined Distillation System According ToDocument2 pagesDIST D-2892/5236 CC: Computer Controlled-Combined Distillation System According ToMiguelNo ratings yet

- Apparatus eDocument12 pagesApparatus eck19654840No ratings yet

- Pilodist: Petrodist 400 CCDocument7 pagesPilodist: Petrodist 400 CCWaheed ZebNo ratings yet

- 2013petrodist 100CC1Document3 pages2013petrodist 100CC1Arun RaoNo ratings yet

- Controls For Lewa Odorizing SystemsDocument4 pagesControls For Lewa Odorizing SystemsDayo Idowu0% (1)

- Item Reference Description Qty.: Heating Module (5 Cai + Cal) Ref: 0940/5SDocument3 pagesItem Reference Description Qty.: Heating Module (5 Cai + Cal) Ref: 0940/5SA94leo14hsetmaNo ratings yet

- UCP Computer Controlled Process Control System: (With Electronic Control Valve)Document6 pagesUCP Computer Controlled Process Control System: (With Electronic Control Valve)Wilmark R. CahiligNo ratings yet

- 633LS ProdspecDocument14 pages633LS ProdspecAdrian AbellaNo ratings yet

- Product Specification: Model RefDocument6 pagesProduct Specification: Model RefHermawan HerryNo ratings yet

- Item Reference Description Qty.: Refrigeration. Medium Module (20 Cai + Cal) Ref: 0911/20SDocument6 pagesItem Reference Description Qty.: Refrigeration. Medium Module (20 Cai + Cal) Ref: 0911/20SA94leo14hsetmaNo ratings yet

- Item Reference Description Qty.: Heating Module Ref: 0940Document3 pagesItem Reference Description Qty.: Heating Module Ref: 0940A94leo14hsetmaNo ratings yet

- Item Reference Description Qty.: Refrigeration. Medium Module (5 Cai + Cal) Ref: 0911/5SDocument6 pagesItem Reference Description Qty.: Refrigeration. Medium Module (5 Cai + Cal) Ref: 0911/5SA94leo14hsetmaNo ratings yet

- TBMC12Document10 pagesTBMC12Joel E ValenciaNo ratings yet

- Item Reference Description Qty.: Air Conditioning - Basic Module Ref: 0930Document4 pagesItem Reference Description Qty.: Air Conditioning - Basic Module Ref: 0930A94leo14hsetmaNo ratings yet

- Item Reference Description Qty.: Air Conditioning Automobile Module Ref: 0933Document3 pagesItem Reference Description Qty.: Air Conditioning Automobile Module Ref: 0933A94leo14hsetmaNo ratings yet

- Item Reference Description Qty.: Air Conditioning Automobile Module (5 Cai + Cal) Ref: 0933/5SDocument3 pagesItem Reference Description Qty.: Air Conditioning Automobile Module (5 Cai + Cal) Ref: 0933/5SA94leo14hsetmaNo ratings yet

- N3150 Rmu7..b enDocument17 pagesN3150 Rmu7..b enknele555No ratings yet

- Item Reference Description Qty.: Air Conditioning Automobile Module (10 Cai + Cal) Ref: 0933/10SDocument3 pagesItem Reference Description Qty.: Air Conditioning Automobile Module (10 Cai + Cal) Ref: 0933/10SA94leo14hsetmaNo ratings yet

- 30RB 039-160/30RQ 039-160: Air-Cooled Liquid Chillers Reversible Air-to-Water Heat PumpsDocument28 pages30RB 039-160/30RQ 039-160: Air-Cooled Liquid Chillers Reversible Air-to-Water Heat Pumpsdimkost2No ratings yet

- Air To Water Heat Pumps 30RH040 240Document16 pagesAir To Water Heat Pumps 30RH040 240konstantinosNo ratings yet

- Flow Measurement: Sitrans F CDocument9 pagesFlow Measurement: Sitrans F CknchnNo ratings yet

- Dosing ControlDocument288 pagesDosing ControlSüleymanŞentürkNo ratings yet

- 0-System PhilosopyDocument4 pages0-System PhilosopydazcornishNo ratings yet

- Vega T: Electronic Counter For Tank Trucks andDocument6 pagesVega T: Electronic Counter For Tank Trucks andRudin Fahrudin RahmanNo ratings yet

- Item Reference Description Qty.: Refrigeration. Advanced Module Ref: 0912Document7 pagesItem Reference Description Qty.: Refrigeration. Advanced Module Ref: 0912A94leo14hsetmaNo ratings yet

- Automation and Process Control CRT - Temperature Control and Regulation Study UnitDocument4 pagesAutomation and Process Control CRT - Temperature Control and Regulation Study Unitjoao0honoratoNo ratings yet

- D Woodward Integrated Compressor Control Afjfkjfj FJFJFJFDocument5 pagesD Woodward Integrated Compressor Control Afjfkjfj FJFJFJFDiego PareschiNo ratings yet

- MIS DescriptionDocument8 pagesMIS Descriptionmalmoosawi_1No ratings yet

- Transformer Monitoring Systems - MRDocument4 pagesTransformer Monitoring Systems - MRKelly chatingNo ratings yet

- Computer Controlled Process Control System With SCADA and PID ControlDocument12 pagesComputer Controlled Process Control System With SCADA and PID Controldwi meyNo ratings yet

- Item Reference Description Qty.: Refrigeration. Advanced Module (5 Cai + Cal) Ref: 0912/5SDocument8 pagesItem Reference Description Qty.: Refrigeration. Advanced Module (5 Cai + Cal) Ref: 0912/5SA94leo14hsetmaNo ratings yet

- Confort SystemDocument6 pagesConfort Systemjpedro.costa8323No ratings yet

- Metering System OverviewDocument83 pagesMetering System Overviewtubagus syarief100% (1)

- Petrodist 400 CCDocument6 pagesPetrodist 400 CCJoao FernándezNo ratings yet

- Bharat Heavy Electricals LTD - Station C & I and MMI-DASDocument5 pagesBharat Heavy Electricals LTD - Station C & I and MMI-DASmandar_paradkarNo ratings yet

- P6..W..EV-BAC 1 0 enDocument10 pagesP6..W..EV-BAC 1 0 enZoran DanilovNo ratings yet

- Centrifugal, Field-Erected - Tech Guide - PanelDocument12 pagesCentrifugal, Field-Erected - Tech Guide - PanelPawan BhattaNo ratings yet

- Bms System-Basic PDFDocument59 pagesBms System-Basic PDFWaelBou95% (21)

- Building Management SystemsDocument27 pagesBuilding Management Systemsped376100% (2)

- MTUDocument16 pagesMTUWira Karya Diesel50% (6)

- 30HXC - 50 H: Water-Cooled Screw Compressor Liquid ChillersDocument8 pages30HXC - 50 H: Water-Cooled Screw Compressor Liquid ChillersvickersNo ratings yet

- Ds Ve 0024 En1390976235020390783Document10 pagesDs Ve 0024 En1390976235020390783Dusko ArsenovskiNo ratings yet

- TAC-404 Electronic Control Family SpecificationsDocument111 pagesTAC-404 Electronic Control Family SpecificationsJosé Lopes100% (1)

- 11101174-0 MTF1500-320editionS PDFDocument11 pages11101174-0 MTF1500-320editionS PDFAnonymous f3LUQEdFNo ratings yet

- Closed-Loop Control Toolbox APP-RTT-E-GBDocument11 pagesClosed-Loop Control Toolbox APP-RTT-E-GBLuis Enrique PariapazaNo ratings yet

- 08-80.2 E MicroCal PDocument4 pages08-80.2 E MicroCal PctmtectrolNo ratings yet

- Edibon SCADADocument37 pagesEdibon SCADAMusa MohammadNo ratings yet

- Technical Data 30RH040-240Document16 pagesTechnical Data 30RH040-240Jhair Diaz AranaNo ratings yet

- Microgel - RCD/RCM: Microgel For Injection MoldingDocument12 pagesMicrogel - RCD/RCM: Microgel For Injection Moldingraulmoscoso3No ratings yet

- D EhcDocument12 pagesD Ehcmsalem73100% (2)

- Computer Controlled Absorption Refrigeration Unit, With SCADADocument19 pagesComputer Controlled Absorption Refrigeration Unit, With SCADAAhmed AzadNo ratings yet

- Boiler Control Standard Proposal - 1Document3 pagesBoiler Control Standard Proposal - 1Hery PrabowoNo ratings yet

- Scanner 2000 Technical Data SheetDocument4 pagesScanner 2000 Technical Data SheetDennis Espinoza Rospigliosi100% (1)

- Boiling Pointce t108 9d C eDocument2 pagesBoiling Pointce t108 9d C eMøąđ ĄllibýNo ratings yet

- Trane Rooftop PDFDocument76 pagesTrane Rooftop PDFriz333No ratings yet

- Humboldt Triaxial Equipment GuideDocument38 pagesHumboldt Triaxial Equipment GuideElizabeth Gronerth TipaNo ratings yet

- 90.15 Ipc11550 Brochure ArmstrongDocument4 pages90.15 Ipc11550 Brochure Armstrongtomaz_filhoNo ratings yet

- Introduction to the simulation of power plants for EBSILON®Professional Version 15From EverandIntroduction to the simulation of power plants for EBSILON®Professional Version 15No ratings yet

- Assignment 1 Fluid Mechanics 1Document3 pagesAssignment 1 Fluid Mechanics 1Right LuckNo ratings yet

- Mitochondria IsolationDocument4 pagesMitochondria IsolationRuan JinglinNo ratings yet

- Inox Dgel Super PlusDocument6 pagesInox Dgel Super PlusZoran DanilovNo ratings yet

- Cryogenic Engine in Rocket PropulsionDocument29 pagesCryogenic Engine in Rocket PropulsionSai NandanNo ratings yet

- List of Periodic Table Elements Sorted by Atomic NumberDocument3 pagesList of Periodic Table Elements Sorted by Atomic NumberKrishnaMehta100% (2)

- Reaction RateDocument96 pagesReaction RateSoh Ming LunNo ratings yet

- A Beginners Guide To Flow Cytometry PDFDocument8 pagesA Beginners Guide To Flow Cytometry PDFBrahmananda Chakraborty100% (1)

- Flame Test Laboratory ReportDocument4 pagesFlame Test Laboratory ReportJohn Carlo Almero0% (1)

- CHEM 1031 Final Exam Study GuideDocument43 pagesCHEM 1031 Final Exam Study GuidePranava MalluNo ratings yet

- UV Drip Off: CharacteristicDocument3 pagesUV Drip Off: Characteristicpro6339No ratings yet

- Plastic Bearings IGUSDocument532 pagesPlastic Bearings IGUSGuillermo LMNo ratings yet

- Syllabus of Neet 2020 Drill Test Series: Physics Chemistry BiologyDocument1 pageSyllabus of Neet 2020 Drill Test Series: Physics Chemistry BiologyRakesh RakiNo ratings yet

- Preparationofpotassiumtrisoxalateferrateiitrihydrate 140328134711 Phpapp02Document15 pagesPreparationofpotassiumtrisoxalateferrateiitrihydrate 140328134711 Phpapp02Guru P MNo ratings yet

- AASHTO T 217 SpeedyDocument6 pagesAASHTO T 217 SpeedyDaniel RodasNo ratings yet

- Chemical Reactions Chapter 6Document31 pagesChemical Reactions Chapter 6R.S.HNo ratings yet

- Lec 1Document12 pagesLec 1Kainat MusawarNo ratings yet

- Galvanic CorrosionDocument22 pagesGalvanic CorrosionDiego1980bNo ratings yet

- Chemistry The Molecular Science 5th Edition Moore Solutions Manual 1Document36 pagesChemistry The Molecular Science 5th Edition Moore Solutions Manual 1josephandersonxqwbynfjzk100% (27)

- AIRVO v2.5 Disinfection Manual UI-185048125 - DDocument14 pagesAIRVO v2.5 Disinfection Manual UI-185048125 - DpaionenseNo ratings yet

- Rock Forming MineralsDocument2 pagesRock Forming Mineralsrao_gsv7598No ratings yet

- Detection and Isolation of Mutants By: Replica-Plating TechniqueDocument23 pagesDetection and Isolation of Mutants By: Replica-Plating TechniquePUSHPALATHA.TNo ratings yet

- XII-C Chemistry Projects ListDocument2 pagesXII-C Chemistry Projects ListSarthak VermaNo ratings yet

- Steam Table For Compressed Liquid & Superheated Steam PDFDocument60 pagesSteam Table For Compressed Liquid & Superheated Steam PDFm sajjadNo ratings yet

- FORMULAS XNXNDocument23 pagesFORMULAS XNXNRaymart Layson0% (1)

- Production of Ethanol From Corn Using Yeast (Saccharomyces Cerevisiae)Document7 pagesProduction of Ethanol From Corn Using Yeast (Saccharomyces Cerevisiae)Erlia NovriyantiNo ratings yet

- Science Class X Sample Paper Test 12 For Board Exam 2024Document7 pagesScience Class X Sample Paper Test 12 For Board Exam 2024ag17ayushgNo ratings yet

- Group 3: Micropumps and MicrovalvesDocument20 pagesGroup 3: Micropumps and MicrovalvesPhenias ManyashaNo ratings yet

- SOP For Calibration of Conductivity TDS MeterDocument6 pagesSOP For Calibration of Conductivity TDS MeterSolomon Gamanuel100% (1)

- GE07 - Fire Prevention (Workbook)Document21 pagesGE07 - Fire Prevention (Workbook)Samo BenNo ratings yet

- Appendix A13: List of China's Natural Gas Chemical BasesDocument2 pagesAppendix A13: List of China's Natural Gas Chemical BasesarapublicationNo ratings yet