Professional Documents

Culture Documents

Determining Clearance and Interference Fits for Couplings

Uploaded by

vilaschinke1230 ratings0% found this document useful (0 votes)

548 views4 pagesCouplings Ior connecting shaIts can be placed in two categories: keyed and keyless. A keyless coupling arrangement will always have an interIerence Iit. The lower the power rating, the greater the probability oI using a clearance fit.

Original Description:

Original Title

Clearance and Interference Coupling Fits

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCouplings Ior connecting shaIts can be placed in two categories: keyed and keyless. A keyless coupling arrangement will always have an interIerence Iit. The lower the power rating, the greater the probability oI using a clearance fit.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

548 views4 pagesDetermining Clearance and Interference Fits for Couplings

Uploaded by

vilaschinke123Couplings Ior connecting shaIts can be placed in two categories: keyed and keyless. A keyless coupling arrangement will always have an interIerence Iit. The lower the power rating, the greater the probability oI using a clearance fit.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

, Print ,

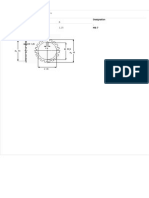

Fig. 1. A typical gear-tooth-style steel coupling

Clearance And InterIerence Coupling Fits

Written bv Tom Bishop, P.E., Electrical Apparatus Service Association (EASA)

Wednesdav, 12 Mav 2010 10.31

Check out these tips on when to use and how to determine tolerances with your coupling arrangements.

Couplings Ior connecting shaIts (shown in Fig. 1) can be placed in two categories: keyed

and keyless. Similarly, the Iits oI couplings to shaIts can be categorized as clearance or

interIerence. A keyless coupling arrangement will always have an interIerence Iit, while a

keyed arrangement may have either a clearance or an interIerence Iit. This article will

Iocus on determining when to use a clearance or an interIerence Iit, and how to obtain the

tolerances Ior the resulting Iit. Since we are dealing with existing shaIts and couplings, the

category oI keyed or keyless has already been established and will not be considered.

Clearance versus interference fits

The lower the power rating (actually the lower the transmitted torque), the greater the

probability oI using a clearance Iit between coupling and shaIt. Conversely, higher power

and torque usually requires an interIerence Iit. Further, as the power and torque

requirements become very high, it is more common to Iind that keyless Iits are required.

Note that the terms "lower," "higher" and "very high" are all relative, with no guideline

levels associated with them.

The questions that oIten arise are on when to use a clearance Iit versus an interIerence Iit,

and what tolerance range to use Ior the applicable clearance or interIerence. We'll proceed

Irom applications where a clearance Iit can be used, to those requiring progressively

greater interIerence Iits. A general rule oI thumb: There's little risk with having more interIerence than necessary, while there's more risk in

having less.

Clearance fit (keys and setscrews)

Keyed clearance Iit couplings are most Irequently used on lower-power applications with shaIts under about 2.5 in (about 65 mm). A visual

indicator that the Iit is clearance rather than interIerence is that set screws are usually provided over the key when a clearance Iit is used (see

Fig. 2). The set-screw location "A" oI Fig. 2 is more common, but some manuIacturers use location "B." Be sure to remove set screws beIore

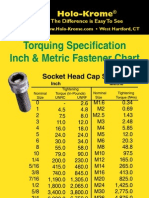

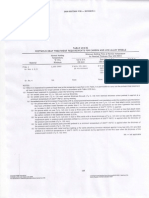

trying to remove a coupling. Table I reIlects clearance Iits used Ior NEMA-Irame-size motor shaIts.

The design principle oI the clearance Iit is that the torque is transmitted through the key, minimizing any sliding oI the coupling on the shaIt.

Whether a clearance Iit is acceptable depends on the torque to be transmitted, the coeIIicient oI Iriction used, the dimensions oI the hub and

operating speed. II the torque Iorces or misalignment are excessive, the coupling hub may rock and become loose, leading to Iretting. Evidence

oI this condition will be a Iine rust-colored powder at the ends oI the coupling Iits, oIten with visible wear to one side oI the key and/or

keyway.

+f10f2012 Clearance And !nterference Coupling .

mt-online.comf.f1505-clearance-and. 1f+

Interference fit (keys)

Keyed interIerence Iit couplings are commonly used Ior applications up to a Iew thousand horsepower/kW, and speeds up to or slightly above

10,000 rpm. The interIerence Iit standard Ior most couplings made oI medium-carbon steel are 0.00050-0.00075 in/in (mm/mm) interIerence up

to 1800 rpm and 0.00075-0.00100 in/in (mm/mm) over 1800 rpm. Table II reIlects interIerence Iits used Ior NEMA-Irame-size motor shaIts.

The purpose oI the interIerence Iit with a keyed shaIt is to axially locate the coupling hub and resist Iorces associated with unbalance and

misalignment. A Irequently used reIerence Ior keyed-coupling interIerence Iits is ANSI/AGMA 9002-B04.

Interference fit (keyless)

For high-horsepower/kW and high-speed applications, ANSI/AGMA 9003-B08 or equivalent Iits (straight and tapered) are commonly used.

The interIerence Ior keyless Iits needs to be adequate to withstand expected normal and transient loads. Common keyless interIerence Iits range

Irom 0.0015 in/in (mm/mm) to 0.0020 in/in (mm/mm). The Brinell hardness oI the hub material is a signiIicant Iactor in keyless coupling Iit.

Typical Iits Ior various Brinell hardness (BH) steels are: 0.00175 in/in (mm/mm) Ior 250 BH, 0.0025 in/in (mm/mm) Ior 300 BH and 0.0030

in/in (mm/mm) Ior 330 BH.

+f10f2012 Clearance And !nterference Coupling .

mt-online.comf.f1505-clearance-and. 2f+

Coupling bore and key

The key is a critical element in successIul transmission oI torque. The bore and keyway in a coupling hub should be checked beIore installation.

Bores should have surIace Iinishes oI 63 to 125 microinches (1.6 to 3.2 micrometers) and must not be eccentric or skewed. II a bore is machined

eccentric to the hub axis, the coupling eccentricity may cause vibration. A coupling bore machined askew to the centerline axis will increase the

misalignment Ior which the coupling, shaIt and bearings must compensate. The keyway should be cut square and centered to the shaIt.

The Iit oI the key is critical in assuring suIIicient capacity oI the shaIt-to-coupling hub interIace. Be sure to check that the key Iits tightly in

the shaIt keyway; that the key has a sliding Iit (but not be too loose) in the coupling hub keyway; and that the key has a clearance oI 0.003 to

0.020 in (0.08 to 0.51 mm) with the hub keyway at the top oI the key.

The key should have chamIered corners so that it Iits in the keyway without riding on the keyway radii. A loosely Iitted key can roll or shear

when heavily loaded and provide a path Irom which coupling lubricant can leak. Conversely, too tight a Iit will make assembly diIIicult and

increase residual stresses, possibly resulting in premature Iailure oI the coupling hub and/or shaIt. A key that is too high in the keyway also

could cause the coupling hub to Iracture.

Coupling heating

Steel coupling hubs require an increase oI 160 F degrees (90 C) Ior every mil (0.001 in or 0.025 mm) oI interIerence divided by the hub inside

diameter. For example, a steel hub with a 2.125 in-bore with an interIerence oI 0.0015 in will require an increase oI 1.5/2.125 x 160 113 F

degrees (63 C). Thus, iI the shaIt temperature is 70 F (21 C), the hub temperature must be at least 183 F (84 C). This does not account Ior

potential cooling due to handling time, so as a general rule add about 60 F degrees (33 C) to the calculated expansion temperature to account Ior

these Iactors. In this example the target temperature would be 243 F (117 C). II the calculated target temperature exceeds 350 F (177 C), check

with the coupling manuIacturer to be certain the required temperature will not aIIect the coupling hub integrity.

The hub should be heated on an induction-type bearing heater or in an oven; a torch should not be used. Use oI a torch or open Ilame could

cause distortion or a reduction in hardness and strength oI the hub material. BeIore installing the coupling hub, make certain that the inboard

and outboard ends have been identiIied. Removal and reinstallation oI an incorrectly installed coupling hub will be diIIicult or impossible at the

installation location. Also, make certain that the grease seals are in place and not damaged beIore installing the coupling covers.

Dynamic balance

Don't simply assume that a new coupling is dynamically balanced. Not all couplings are pre-balanced by the manuIacturerand some are not

designed to be balanced. Check with the coupling manuIacturer or supplier to determine iI a new coupling has been Iactory balanced. A good

practice is to measure vibration levels aIter replacing a coupling (whether or not it has been balanced) to conIirm that the levels are within

acceptable limits. The length oI the key will aIIect the balance. To determine the correct key length, add the length oI the shaIt keyway to the

length oI the coupling-hub keyway and divide by two.

Lubrication

The grease used Ior couplings is not the same as that used in electric motors. Be sure to use a coupling grease equivalent to that speciIied by the

coupling manuIacturer. Lubricant should be replenished when the motor alignment is periodically checked, and the customer should typically

replenish the coupling grease on an annual basis. MT

Tom Bishop is a technical support specialist Ior EASA, headquartered in St. Louis, MO. Telephone: (314) 993-2220.

+f10f2012 Clearance And !nterference Coupling .

mt-online.comf.f1505-clearance-and. 3f+

For more info, enter 01 at www.MT-freeinfo.com

+f10f2012 Clearance And !nterference Coupling .

mt-online.comf.f1505-clearance-and. +f+

You might also like

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Fastener Torque Table SAE Grade - Engineers Edge PDFDocument1 pageFastener Torque Table SAE Grade - Engineers Edge PDFnate anantathatNo ratings yet

- Inch Socket Head Cap Screws Dimensions and SpecificationsDocument16 pagesInch Socket Head Cap Screws Dimensions and SpecificationsyauctionNo ratings yet

- Carbon Hollow Bar ST 52Document2 pagesCarbon Hollow Bar ST 52JeganeswaranNo ratings yet

- ARPCatalog PDFDocument128 pagesARPCatalog PDFAnonymous wpUyixsjNo ratings yet

- Metric Washer FlatDocument4 pagesMetric Washer Flatjontylee87No ratings yet

- Hollow Bar ChartDocument1 pageHollow Bar Charthornet121No ratings yet

- Angle Section DimensionsDocument4 pagesAngle Section DimensionsAnonymous q0irDXlWAmNo ratings yet

- NPT Thread ChartDocument1 pageNPT Thread ChartFredy Alvarez LucasNo ratings yet

- SOUTHLAND PIPE, Steel Pipe General Data Size Chart, Steel Pipe Sales, NationwideDocument3 pagesSOUTHLAND PIPE, Steel Pipe General Data Size Chart, Steel Pipe Sales, Nationwidea769No ratings yet

- Prevailing Torque Locknut Technical SpecificationsDocument3 pagesPrevailing Torque Locknut Technical SpecificationsLiu YangtzeNo ratings yet

- External Threads For Machine Screws and SEMSDocument2 pagesExternal Threads For Machine Screws and SEMSez1010No ratings yet

- Acople Nara CatalogDocument48 pagesAcople Nara Catalogmarcelo castillo100% (1)

- Flat Washers Standard MetricDocument4 pagesFlat Washers Standard MetricsivaNo ratings yet

- Pipe Sizes ThreadsDocument2 pagesPipe Sizes ThreadsSumner TingNo ratings yet

- 13 Symbols DrawingsDocument13 pages13 Symbols DrawingsAlie AlbantaniNo ratings yet

- BSPT and NPT tapered pipe thread characteristicsDocument2 pagesBSPT and NPT tapered pipe thread characteristicsainul yakinNo ratings yet

- Nylstop Self Locking Nut - Vibration Resistant Nut Prevents LooseningDocument2 pagesNylstop Self Locking Nut - Vibration Resistant Nut Prevents Looseningaiyubi2No ratings yet

- Section Q: Splined Hubs, Drive KitsDocument8 pagesSection Q: Splined Hubs, Drive KitshaggNo ratings yet

- Thread TolerancesDocument8 pagesThread TolerancesLê Xuân HiệpNo ratings yet

- 250 KW Soalr SparesDocument1 page250 KW Soalr SparesRAJENDRA PRASADNo ratings yet

- Standard Series Limits Size-Unified and American Screw Threads PDFDocument19 pagesStandard Series Limits Size-Unified and American Screw Threads PDFrefaeNo ratings yet

- Unifai Screw INCHDocument21 pagesUnifai Screw INCHAnonymous RgGtg29No ratings yet

- Torque Data ChartDocument2 pagesTorque Data CharttnchsgNo ratings yet

- Metric BoltsDocument52 pagesMetric BoltsDGW100% (1)

- Tapping Torque Values PDFDocument1 pageTapping Torque Values PDFNitin AggarwalNo ratings yet

- Measurements, Sizes, Shafts, KeywaysDocument91 pagesMeasurements, Sizes, Shafts, KeywaysVenkat DoraNo ratings yet

- INA CatalogueDocument110 pagesINA CatalogueStroia Constantin MariusNo ratings yet

- TorqueDocument2 pagesTorquestaedtlerpNo ratings yet

- Selection of Valve Operators: Standard Practice ForDocument3 pagesSelection of Valve Operators: Standard Practice ForAhmad Zubair RasulyNo ratings yet

- Drawing Guide Weld SymbolsDocument3 pagesDrawing Guide Weld SymbolsspaljeniNo ratings yet

- Gear Coupling 2014Document4 pagesGear Coupling 2014Dado Maja ArseninNo ratings yet

- Price List - 2013Document11 pagesPrice List - 2013John MaNo ratings yet

- Whitworth BSW BSF PDFDocument2 pagesWhitworth BSW BSF PDFLaural MarshallNo ratings yet

- DE1000 GBD LP Derick CentrifugeDocument4 pagesDE1000 GBD LP Derick CentrifugePETROPATH FLUIDS INDIA PVT. LTD.No ratings yet

- Screw SelectionDocument1 pageScrew Selectionamarr1No ratings yet

- Nut Bolt HeightDocument8 pagesNut Bolt HeightMian M KhurramNo ratings yet

- SAE 100 R2AT Hose Data SheetDocument1 pageSAE 100 R2AT Hose Data SheetNagarjunSHNo ratings yet

- Ball Screw CalculatorDocument60 pagesBall Screw Calculatorمنير بوزيدNo ratings yet

- Automotive & HSLA Steel SpecsDocument1 pageAutomotive & HSLA Steel SpecsBudi HermanaNo ratings yet

- Thread Identification and Drill Chart: MetricDocument1 pageThread Identification and Drill Chart: MetricMOHANNo ratings yet

- PipeDocument2 pagesPipeAmandeep SinghNo ratings yet

- PBL Series K CatalougeDocument117 pagesPBL Series K CatalougeankitkanujiyaNo ratings yet

- SwingClamp BottomFlangeDocument4 pagesSwingClamp BottomFlangePeter CusimanoNo ratings yet

- Unf ThreadDocument1 pageUnf Threadhisaj4uNo ratings yet

- AG Quick Release ENProDocument4 pagesAG Quick Release ENProNatalia WinataNo ratings yet

- EHP Series Piston Accumulators CatalogueDocument32 pagesEHP Series Piston Accumulators CatalogueMichael Akhramovich100% (1)

- Standard Torque Values - Metric SystemDocument1 pageStandard Torque Values - Metric SystemHassan Sleem100% (1)

- MeasurementDocument3 pagesMeasurementstormyhsNo ratings yet

- Dimensions of Heavy Hex Nuts ASME B18.2.2 Used With Stud Bolts ASME B16.5Document3 pagesDimensions of Heavy Hex Nuts ASME B18.2.2 Used With Stud Bolts ASME B16.5dino ricoNo ratings yet

- C DodgeDocument42 pagesC DodgeDaniel BolivarNo ratings yet

- Semi-Topping Shaper CuttersDocument4 pagesSemi-Topping Shaper CuttersalemarlonstosNo ratings yet

- Worm and Worm Wheel NomenclatureDocument1 pageWorm and Worm Wheel NomenclaturemuhdqasimNo ratings yet

- Seal Types & Gland Design: Major ClassificationsDocument6 pagesSeal Types & Gland Design: Major ClassificationsvinothNo ratings yet

- Torques Con Lubricante y UpgradeDocument17 pagesTorques Con Lubricante y UpgradeJed MayNo ratings yet

- SN757 2005-05 eDocument4 pagesSN757 2005-05 ehasan_676489616No ratings yet

- Cardan Shaft Catalog From STDocument6 pagesCardan Shaft Catalog From STAHMAD SAIFULLAH100% (1)

- CuñaDocument20 pagesCuñaJulian Granados RicoNo ratings yet

- Catalogo de Conectores Hidraulicos PARKER PDFDocument86 pagesCatalogo de Conectores Hidraulicos PARKER PDFgbobadillaNo ratings yet

- Hydraulic Cylinder Parker 3lDocument48 pagesHydraulic Cylinder Parker 3lDian Pramadi100% (2)

- MB (L) Lock Washers - MB 7Document1 pageMB (L) Lock Washers - MB 7vilaschinke123No ratings yet

- Coppusrla - Manual Manual de Turbina Coppus RlaDocument232 pagesCoppusrla - Manual Manual de Turbina Coppus Rlacristobal_tl2277No ratings yet

- STEAM TURBINE 3 Design and MaterialsDocument19 pagesSTEAM TURBINE 3 Design and MaterialsHandayani Kesumadewi100% (2)

- Sample LetterDocument1 pageSample Lettervilaschinke123No ratings yet

- Stress Relieving For SA516 GR 70Document1 pageStress Relieving For SA516 GR 70vilaschinke123No ratings yet

- Concept of EnergyDocument3 pagesConcept of EnergyJimseng100% (1)

- Calculation of Working Pressure of CylinderDocument6 pagesCalculation of Working Pressure of Cylindervilaschinke123No ratings yet

- PeeningDocument8 pagesPeeningvilaschinke123No ratings yet

- Press Fit PDFDocument9 pagesPress Fit PDFMohd Hilmi IzaanNo ratings yet

- EN8 Steel 080M40Document2 pagesEN8 Steel 080M40vilaschinke123No ratings yet

- Thermo Compressor CalculatorDocument6 pagesThermo Compressor CalculatorVilas m ChinkeNo ratings yet

- Pipe Fittings DimensionDocument5 pagesPipe Fittings Dimensionvilaschinke123No ratings yet

- Orifice Plate Flow MetersDocument4 pagesOrifice Plate Flow Metersvilaschinke123100% (2)

- Rupture DiskDocument9 pagesRupture Diskvilaschinke123No ratings yet

- Veh Des ChasDocument30 pagesVeh Des Chasvilaschinke123No ratings yet

- HTTP - WWW - Aphref.aph - Gov.au - House - Committee - Pjcis - nsl2012 - Additional - Discussion Paper PDFDocument61 pagesHTTP - WWW - Aphref.aph - Gov.au - House - Committee - Pjcis - nsl2012 - Additional - Discussion Paper PDFZainul Fikri ZulfikarNo ratings yet

- NX569J User ManualDocument61 pagesNX569J User ManualHenry Orozco EscobarNo ratings yet

- Páginas Desdeingles - Sep2008Document1 pagePáginas Desdeingles - Sep2008anayourteacher100% (1)

- Introduction to Corporate Communication ObjectivesDocument26 pagesIntroduction to Corporate Communication ObjectivesKali MuthuNo ratings yet

- How To Prepare Squash Specimen Samples For Microscopic ObservationDocument3 pagesHow To Prepare Squash Specimen Samples For Microscopic ObservationSAMMYNo ratings yet

- Process Validation Statistical ConfidenceDocument31 pagesProcess Validation Statistical ConfidenceSally PujaNo ratings yet

- MBA Study On Organisational Culture and Its Impact On Employees Behaviour - 237652089Document64 pagesMBA Study On Organisational Culture and Its Impact On Employees Behaviour - 237652089sunitha kada55% (20)

- MC145031 Encoder Manchester PDFDocument10 pagesMC145031 Encoder Manchester PDFson_gotenNo ratings yet

- CV Raman's Discovery of the Raman EffectDocument10 pagesCV Raman's Discovery of the Raman EffectjaarthiNo ratings yet

- Navier-Stokes EquationsDocument395 pagesNavier-Stokes EquationsBouhadjar Meguenni100% (7)

- Fault Tree AnalysisDocument5 pagesFault Tree AnalysisKrishna Kumar0% (1)

- Sample Statement of Purpose.42120706Document8 pagesSample Statement of Purpose.42120706Ata Ullah Mukhlis0% (2)

- Energy Efficient Solar-Powered Street Lights Using Sun-Tracking Solar Panel With Traffic Density Monitoring and Wireless Control SystemDocument9 pagesEnergy Efficient Solar-Powered Street Lights Using Sun-Tracking Solar Panel With Traffic Density Monitoring and Wireless Control SystemIJRASETPublicationsNo ratings yet

- The History of American School Libraries: Presented By: Jacob Noodwang, Mary Othic and Noelle NightingaleDocument21 pagesThe History of American School Libraries: Presented By: Jacob Noodwang, Mary Othic and Noelle Nightingaleapi-166902455No ratings yet

- The Stolen Bacillus - HG WellsDocument6 pagesThe Stolen Bacillus - HG Wells1mad.cheshire.cat1No ratings yet

- Corporate Strategic Planning AssignmentDocument10 pagesCorporate Strategic Planning AssignmentSumit DuttaNo ratings yet

- Laser Plasma Accelerators PDFDocument12 pagesLaser Plasma Accelerators PDFAjit UpadhyayNo ratings yet

- Light Body ActivationsDocument2 pagesLight Body ActivationsNaresh Muttavarapu100% (4)

- Getting BetterDocument3 pagesGetting BetterIngrid MedinaNo ratings yet

- Agricultural Typology Concept and MethodDocument13 pagesAgricultural Typology Concept and MethodAre GalvánNo ratings yet

- 4idealism Realism and Pragmatigsm in EducationDocument41 pages4idealism Realism and Pragmatigsm in EducationGaiLe Ann100% (1)

- Failure Reporting, Analysis, and Corrective Action SystemDocument46 pagesFailure Reporting, Analysis, and Corrective Action Systemjwpaprk1100% (1)

- COS1512 202 - 2015 - 1 - BDocument33 pagesCOS1512 202 - 2015 - 1 - BLina Slabbert-van Der Walt100% (1)

- Watershed Management A Case Study of Madgyal Village IJERTV2IS70558Document5 pagesWatershed Management A Case Study of Madgyal Village IJERTV2IS70558SharadNo ratings yet

- Google Fusion Tables: A Case StudyDocument4 pagesGoogle Fusion Tables: A Case StudySeanNo ratings yet

- Significance of Vaiseshika's PragabhavaDocument5 pagesSignificance of Vaiseshika's Pragabhavavskanchi0% (1)

- Print Application FormDocument4 pagesPrint Application Formarjun guptaNo ratings yet

- Growing Up Psychic by Chip Coffey - ExcerptDocument48 pagesGrowing Up Psychic by Chip Coffey - ExcerptCrown Publishing Group100% (1)

- Discourse Community 2Document7 pagesDiscourse Community 2api-272763663No ratings yet

- IS BIOCLIMATIC ARCHITECTURE A NEW STYLE OF DESIGNDocument5 pagesIS BIOCLIMATIC ARCHITECTURE A NEW STYLE OF DESIGNJorge DávilaNo ratings yet