Professional Documents

Culture Documents

Bourke (2001)

Uploaded by

anon_413169311Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bourke (2001)

Uploaded by

anon_413169311Copyright:

Available Formats

This article was downloaded by: [COMIMSA] On: 09 April 2012, At: 14:18 Publisher: Taylor & Francis

Informa Ltd Registered in England and Wales Registered Number: 1072954 Registered office: Mortimer House, 37-41 Mortimer Street, London W1T 3JH, UK

Journal of Applied Statistics

Publication details, including instructions for authors and subscription information: http://www.tandfonline.com/loi/cjas20

The geometric CUSUM chart with sampling inspection for monitoring fraction defective

Patrick D. Bourke Available online: 02 Aug 2010

To cite this article: Patrick D. Bourke (2001): The geometric CUSUM chart with sampling inspection for monitoring fraction defective, Journal of Applied Statistics, 28:8, 951-972 To link to this article: http://dx.doi.org/10.1080/02664760120076643

PLEASE SCROLL DOWN FOR ARTICLE Full terms and conditions of use: http://www.tandfonline.com/page/ terms-and-conditions This article may be used for research, teaching, and private study purposes. Any substantial or systematic reproduction, redistribution, reselling, loan, sub-licensing, systematic supply, or distribution in any form to anyone is expressly forbidden. The publisher does not give any warranty express or implied or make any representation that the contents will be complete or accurate or up to date. The accuracy of any instructions, formulae, and drug doses should be independently verified with primary sources. The publisher shall not be liable for any loss, actions, claims, proceedings, demand, or costs or damages whatsoever or howsoever caused arising directly or indirectly in connection with or arising out of the use of this material.

Journal of Applied Statistics, Vol. 28, No. 8, 2001, 951- 972

The geometric CUSUM chart with sampling inspection for monitoring fraction defective

PATRICK D. BOURKE, University College, Cork, Ireland

Downloaded by [COMIMSA] at 14:18 09 April 2012

abstract The detection of an upward shift in the fraction defective of a repetitive process is considered using the geometric CUSUM. This CUSUM makes use of the information provided by the run-lengths of non-defective items between successive defective items, and was initially developed for the case of 100% inspection. This paper considers the geometric CUSUM under sampling inspection, and emphasizes that the pattern of sampling inspection can be quite haphazard without causing any di culty for the operation of the CUSUM. Two separate mechanisms for the occurrence of a shift are considered. Methods for evaluating zero-state and steady-state ARL are presented for both 100% inspection and sampling inspection. Parameter choice is also considered, and recommendations made. Comparisons with some np-charts are provided. 1 Introduction The use of attributes data for monitoring the value of a proportion, such as the fraction defective of a repetitive process, continues to be of interest to both practitioners and researchers in the area of Statistical Process Control (SPC). The main applications are, of course, in industry and commerce, but there are also important applications in medicine and environmental science. A comprehensive review of the development of Control Charts using attributes data is provided in Woodall (1997), while excellent introductions are provided in textbooks such as Duncan (1986) and Montgomery (2001). Cumulative Sum (CUSUM) charts that utilize attributes data were proposed at an early stage in the development of SPC, and are referred to in the fundamental paper by Page (1954), followed by important development work on the Binomial CUSUM by Kemp (1962). Hawkins & Olwell (1998) provides a comprehensive review of CUSUM developments, while an earlier review may be found in Van Dobben de Bruyn (1968). The Binomial CUSUM is used to monitor the fraction

Correspondence: Department of Statistics, University College, Cork, Ireland. ISSN 0266-4763 print; 1360-0532 online/01/080951-22 DOI: 10.1080/02664760120076643 2001 Taylor & Francis Ltd

952

P. D. Bourke

Downloaded by [COMIMSA] at 14:18 09 April 2012

defective ( p) of a process, by forming a CUSUM of the number (X ) of defectives found in successive samples of size n. A paper in this journal (Gan, 1993) has focused on the optimal choice of the parameters of the Binomial CUSUM, and also considers the choice of the sample size (n) to be used. The Binomial CUSUM has also been considered in Reynolds & Stoumbos (1998, 1999), and in Bourke (2001), all recommending that the choice n 5 1 be made, so that this CUSUM would be termed the Bernoulli CUSUM. The proposal for the use of a geometric CUSUM to monitor the fraction defective of a process was made in Bourke (1991) for the case of 100% inspection, and the CUSUM was referred to as a Run-Length CUSUM. In that paper, comparisons were made with alternative schemes for monitoring the fraction defective, such as the p-chart, the RL2 chart (based on the negative binomial distribution) and also Kemps binomial CUSUM. Evaluations of the relative performance of these alternative control charts were made using what has come to be known as zero-state Average Run Length (ARL), but there may be pitfalls in relying solely on zero-state ARL comparisons, and this will be discussed later. In this paper, the geometric CUSUM is considered again, in the context of the recent development of the Bernoulli CUSUM, and of developments with regard to more appropriate ARL evaluations of CUSUM performance. The relationship between the Bernoulli CUSUM and the geometric CUSUM is explored, the use of the geometric CUSUM in sampling situations is considered, and a method for evaluating its ARL performance under sampling inspection is presented. It is assumed throughout this paper that the process being monitored is repetitively producing items under uniform conditions, so that it may be viewed as producing a stream of items according to a Bernoulli process. The fraction defective (or other proportion of interest) of the process is normally at the acceptable level pa , but may shift to an unacceptable higher level pr . We shall consider two separate cases, with regard to the way this shift may occur: Case 1. The shift occurs at a defective item. The shift occurs at an instant corresponding to the production of a defective item, and the number of defective items until this shift occurs follows a geometric distribution. Thus, up to and including the defective item at which a shift occurs, the fraction defective of the process remains at pa . This case corresponds to a situation where the production of a defective item may itself trigger the shift. Case 2. The shift occurs at any item. The shift occurs at an instant corresponding to the production of any item (defective or non-defective), and the number of items produced up until this shift occurs follows a geometric distribution. This type of shift process has been termed a random shock process by some researchers. In the next section, there is a discussion of various patterns of sampling inspection, emphasizing the point that the geometric CUSUM is applicable to either sporadic sampling inspection with varying sample sizes or systematic sampling inspection with a constant fraction inspected. In Section 3, the geometric CUSUM and the Bernoulli CUSUM and their parameters are reviewed, and the connections between these two CUSUMs are considered. In Section 4, consideration is given to performance measures such as Average Run Length (ARL), Average Number Inspection (ANI), Average Number of Defectives Observed (ANDO), and to methods for their evaluation. A procedure for evaluation of steady-state

Geometric CUSUM chart with sampling inspection

953

ANDO for 100% inspection is presented in Section 5, while in Section 6 sampling inspection is dealt with. The evaluation of zero-state ANDO is considered in Section 7, and comparisons with corresponding steady-state values are presented in Section 8. The choice of parameters for a geometric CUSUM is considered in Section 9. Some comparisons with np-charts are presented in Section 10. 2 Patterns of sampling inspection The monitoring of any process obviously requires some level of inspection of the items produced by the process, ranging from complete inspection of all items to a minimal level of sampling inspection. If the costs of inspection are low and/or the penalties arising from the non-detection of a faulty item are su ciently high, then it will be worthwhile to inspect every item produced. There will also be situations where considerations of costs and possibly the practical di culties of complete inspection, will lead to various levels of sampling inspection. In some circumstances it will be appropriate to have periods of inspection of n contiguous items, alternating with periods of non-inspection, with an overall sampling fraction at some level. This, of course, gives rise to the classic type of data for SPC charts such as the pchart or np-chart, and indeed for early versions of the binomial CUSUM (Kemp, 1962). In other circumstances, however, a non-stable work-situation may be such as to cause inspection to be carried out on a sporadic or haphazard basis, with both the contiguous sample-size and also the sampling fraction varying widely, as local circumstances permit. This latter situation has not been well-catered for by the tool-box of control charts available up to now. Both the geometric CUSUM and the Bernoulli CUSUM are very suitable for making full use of the data from such haphazard sampling inspection patterns, in addition to their applicability to more regular data-structures. But there is another important feature shared by both the Bernoulli CUSUM and the geometric CUSUM: in the case of either CUSUM, it may be quite feasible to inspect each item in the sample as it is being produced or shortly afterwards, updating the CUSUM appropriately. Thus, a signal may be triggered almost immediately following the production and inspection of a defective item, rather than having to wait for the full observation of a speci ed sample size as before. In this sense then, both CUSUMs may be thought of as `online control charts. 3 CUSUMs for monitoring the fraction defective A number of CUSUM schemes have been proposed for monitoring a proportion such as a fraction defective, based on such distributions as the binomial, Bernoulli and geometric. We begin with the long-established binomial CUSUM, and its more-recently developed o -shoot, the Bernoulli CUSUM. 3.1 The binomial and Bernoulli CUSUMs In the case of the binomial CUSUM, the observations consist of a sample of n (usually contiguous) items from the process and, following the inspection of each sample, the number (Xi ) of defective items is recorded, and we compute the CUSUM value (B i ) as follows: B i 5 Max [0, (B i 2

1

Downloaded by [COMIMSA] at 14:18 09 April 2012

+ Xi 2

kB )]

for i 5 1, 2, . . .

(1)

954

P. D. Bourke

where kB is the chosen reference value of the CUSUM scheme, and B 0 is the initial value of the CUSUM. The choice of kB may be based on the SPRT analysis of the CUSUM, and this has been investigated computationally by Gan (1993). The work of Moustakides (1986) has shown that the SPRT-based choice of the reference value is optimal in a certain sense. Once the CUSUM value B i reaches or exceeds a chosen level (hB ), termed the decision interval, this is interpreted as a signal from the monitoring scheme. The three parameters of a binomial CUSUM are kB , hB , and the sample size n. Kemp (1962) uses the Poisson approximation to the binomial in the development of useful tables, also presented in Duncan (1986), for making a choice of these parameters. The best choice of sample size for the Binomial CUSUM has been explicitly investigated in Reynolds & Stoumbos (1998, 1999), and in Bourke (2001), and it is recommended that n 5 1 be used, the resulting CUSUM being labelled the Bernoulli CUSUM. The magnitudes of the advantage in using n 5 1 are reported in Bourke (2001) for a range of situations.

Downloaded by [COMIMSA] at 14:18 09 April 2012

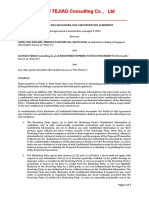

3.2 The geometric CUSUM The geometric CUSUM for monitoring fraction defective was proposed in Bourke (1991), which deals only with shift-processes of type 1 (i.e. shift occurs at a defective item) for the case of 100% inspection. Here, both sampling inspection and complete inspection are considered. A sequence of items from the process is inspected, and we record the run-length (Yi ) between successive defective items, ignoring periods of non-observation. Figure 1 illustrates the concept of run-length

Fig. 1. Illustration of run-length data for the geometric CUSUM.

Geometric CUSUM chart with sampling inspection

955

for both 100% inspection and sampling inspection. We can form a CUSUM {Gi } of these run-length values as follows: Gi 5 Max[0, (Gi 2

1

+ kG 2

Yi )]

for i 5 1, 2, . . .

(2)

where kG is a chosen parameter (the reference value) of the CUSUM scheme, and G0 is the initial value of the CUSUM (often taken as zero, but may be a non-zero value if it is desired to give the CUSUM a head-start, as discussed in Lucas & Crosier, 1982). The SPRT analysis of this CUSUM leads to the following expression for kG . kG 5 ln(pr /pa ) ln[(1 2 pa )/(1 2 pr )] (3)

Downloaded by [COMIMSA] at 14:18 09 April 2012

and it is noted that kG 5 (1/kB ) 2 1, where kB is the value arising from the expression for k in Gan (1993), using n 5 1. The relationship between the geometric and Bernoulli CUSUMs is considered later. The in uence of the chosen value for kG on the performance of the CUSUM is considered in Section 9. If the fraction defective increases toward pr , the values of Y will tend to be less than kG , so that the CUSUM value Gi begins to increase. As soon as Gi reaches or exceeds a chosen value hG , the decision interval, this is interpreted as a signal from the monitoring scheme that the fraction defective may have increased.

3.3 Relationship between the Bernoulli and geometric CUSUMs In Reynolds & Stoumbos (1999, p. 99), it is stated that the geometric CUSUM is equivalent to the Bernoulli CUSUM if the Bernoulli CUSUM is used with a headstart, and relationships between the parameters of equivalent schemes are given. In order to illustrate the relationship, we consider an example. Suppose we wish to monitor, with 100% inspection, a process for which pa 5 0.2, and pr 5 0.3. The following schemes will be used in the illustration: Bernoulli CUSUM kB 5 0.25; hB 5 2.5 Geometric CUSUM kG 5 3; hG 5 7

The value of kG was arrived at using equation (3), and the corresponding equation from Gan (1993) was used to choose the value for kB . We shall consider a method for choosing values for hG later. To begin with, let us use the value zero as the initial value of each CUSUM. In Table 1, these CUSUMs are applied to simulated data from a process with fraction defective 5 0.3. One can see that the geometric CUSUM is updated only at the occurrence of defective items (each of which marks the completion of a run of non-defective items). The geometric CUSUM signals rst, but there is an explanation for this: the rst run-length value is taken as 2, which implies that there was a defective directly before the observations began, and this confers an advantage on the geometric CUSUM. If there had been a defective immediately prior to the rst observation, then the initial Bernoulli CUSUM value (B 0 ) should be at least 0.75. With a head-start value of 0.75, both CUSUMs signal on item 13. Another way of correcting for the initial `advantage for the geometric CUSUM (in making comparisons with the Bernoulli CUSUM) is to use an appropriate value for Initial Run-Length (IRL). An IRL value of at least kG will properly correct for the apparent

956

P. D. Bourke

Table 1. Illustration of Bernoulli CUSUM and geometric CUSUM for simulated data from a process with fraction defective p 5 0.3 Bernoulli CUSUM (B 0 5 0) 0 0 0.75 1.5 1.25 1 1.75 1.5 1.25 2 1.75 1.5 2.25 2 2.75 Signal Geometric CUSUM (G0 5 0) Bernoulli CUSUM (B 0 5 0.75) 0.5 0.25 1 1.75 1.5 1.25 2 1.75 1.5 2.25 2 1.75 2.5 Signal Geometric CUSUM (G0 5 0) IRL* 5 3

Item No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Item Status (X ) 0 0 1 1 0 0 1 0 0 1 0 0 1 0 1 0

Run-length (Y )

2 0

1 4

0 3

Downloaded by [COMIMSA] at 14:18 09 April 2012

2 1

7 Signal

6 7 Signal

*IRL 5 Initial Run Length

`advantage of the geometric CUSUM. This is illustrated in Table 1, which shows that with this IRL feature the two CUSUMs signal on item 15. The following are the pairs of equivalent CUSUMs for this illustration: Bernoulli CUSUM (k 5 0.25, h 5 2.5) Geometric CUSUM (k is equivalent to B0 5 0 G0 5 0, IRL > is equivalent to B 0 5 0.25 G0 5 0, IRL 5 is equivalent to B 0 5 0.5 G0 5 0, IRL 5 is equivalent to B 0 5 0.75 G0 5 0, IRL 5 is equivalent to B0 5 1 G0 5 1, IRL 5 is equivalent to B 0 5 1.25 G0 5 2, IRL 5 is equivalent to B 0 5 1.5 G0 5 3, IRL 5 is equivalent to B 0 5 1.75 G0 5 4, IRL 5 is equivalent to B0 5 2 G0 5 5, IRL 5 is equivalent to B 0 5 2.25 G0 5 6, IRL 5

5

3, h 5 7) 3 2 1 0 0 0 0 0 0 0

It should be noted that for each possible head-start value for the Bernoulli CUSUM, there is a corresponding geometric CUSUM. However, if the kB value is of the form r/s where both r,s are integers, and r > 2, it does not appear possible to identify equivalent pairs of CUSUMS. 4 Average run lengths and related statistics for CUSUM schemes The performance of a monitoring scheme is usually quanti ed using Average Run Length (ARL), which is often taken as the average number of samples until the scheme produces a signal, although there are other interpretations. Here, the term ARL will be used to refer in a general way to the average value of some count-

Geometric CUSUM chart with sampling inspection

957

statistic (such as number inspected or number of defectives) until a signal is produced. A commonly-used approach to the choice of the parameter-values of a monitoring scheme is to nd values so that: ARL(pa ) is close to some acceptably large value (so that false alarms by the monitoring scheme are rare), and also so that ARL(pr ) is as small as possible (so that real alarms are detected as quickly as possible). There are, of course, economic approaches to parameter choice in which costs are associated with inspection levels and also with levels of defectives in the total output from the process, but consideration of such approaches is a matter for a separate investigation. Such economic approaches will also require evaluation of various types of ARL. One of the most convenient ways of computing ARL values for CUSUM schemes is through the use of the Markov chain approach due to Brook & Evans (1972). In the case of the binomial CUSUM, information on this approach is provided in Lucas (1985), Gan (1993), and in Reynolds & Stoumbos (1999), while Bourke (1991) provides corresponding information for the geometric CUSUM. Reynolds & Stoumbos (1999) also provide information on other methods for computing ARL values, as do Hawkins & Olwell (1998), and Vardemann & Ray (1985). Simulation is, of course, another alternative, and has been used extensively by the author in checking the various ARL values reported here. However, there are a number of di erent ARL concepts to be considered. In particular, it is important to distinguish between zero-state ARL and steady-state ARL. Zero-state ARL, denoted here as ARL0( p), is the ARL assuming that the initial value of the CUSUM (at the time of a shift) is zero, and most of the evaluations of ARL in various comparison-work reported in the older literature on CUSUMs, are of zero-state ARLs. However, it is often more appropriate to base comparisons of performance on steady-state ARLs, de ned as follows: ARLss ( p) 5 Average value of the relevant count-statistic, following the occurrence of a shift from pa to p, assuming that the CUSUM has been maintained for a considerable time prior to the shift. (4)

Downloaded by [COMIMSA] at 14:18 09 April 2012

The term steady-state is used because the possible CUSUM values are viewed as having reached a steady-state distribution prior to the occurrence of the shift in fraction defective. For a discussion of these ARL concepts, refer to Taylor (1968), Crosier (1986), Lucas & Saccucci (1990), Hawkins & Olwell (1998), and Zimmer et al. (2000). There is a further re nement of the steady-state ARL concept into conditional steady-state ARL and cyclical steady-state ARL, but the di erence is considered to be minor. Here, only cyclical steady-state ARL is considered, and it is referred to simply as steady-state ARL. Comparisons of alternative monitoring schemes can yield somewhat misleading results if one bases the comparisons solely on zero-state ARL evaluations, and this is illustrated in Bourke (2001) for a comparison of Bernoulli and binomial CUSUMs. Hawkins & Olwell (1998, p. 34) note that the relative rankings of di erent CUSUMs are generally not greatly a ected by whether one uses zero-state ARL or steady-state ARL. It is certainly of interest to investigate both types of ARL for the geometric CUSUM, and this is presented later. A speci c ARL-type performance-measure is the Average Number Inspected

958

P. D. Bourke

(ANI). Again, there is a steady-state version and a zero-state version of ANI, de ned as follows: ANI0 ( p) 5 Average number of items inspected, until the CUSUM produces a signal, given that the fraction defective is at level p, and that the (5) CUSUM value is initially zero at the time the shift from pa to p occurs. The de nition of ANIss( p) parallels that of ARLss(p) in an obvious way. The third measure of performance needed here is ANDO, the average number of defectives observed from the moment of shift until a signal is generated, and there are both zero-state and steady-state versions of ANDO. Referring to Bourke (1991), it may be seen that for the geometric CUSUM the application of the Brook- Evans (1972) method leads directly to ANDO values. It is noted that ANDO 5 p(ANI) where p is the value of fraction defective following the shift. (6)

Downloaded by [COMIMSA] at 14:18 09 April 2012

5 Evaluation of steady-state ANDO for 100% inspection Following Bourke (1991), one may view successive values of the geometric CUSUM as forming a Markov chain, with the states of the Markov chain corresponding to the possible CUSUM values. Thus, the CUSUM undergoes a transition at the completion of each run-length. The transition matrix describing transitions among states, following Brook & Evans (1972), has the following structure P5

R 0T

(I 2 R)1 1

(7)

where R is the transition matrix for the transient states, 1 is a column vector of ones, and 0 is a column vector of zeros. The form of the matrix R is given in Bourke (1991). Following Brook & Evans (1972), one is led to evaluate l 5 (I 2 R) 2 11 (8)

The rst element of this vector yields the zero-state ANDO value for 100% inspection for a type 1 shift-process, which we denote by ANDO0[pr , 1, 100%] for later reference, while the other elements of l yield ANDO values arising from various levels of head-start value for the CUSUM. The evaluation of zero-state ANDO for either a type 2 shift process with 100% inspection, or either shift process with sampling inspection, will require consideration of a cross-over runlength arising from the two levels for fraction defective pa and pr . It is considered preferable to defer consideration of such zero-state ANDO evaluations until Section 7, following treatment of the more important matter of steady-state evaluations of ANDO. We consider rst a type 1 shift in p, i.e. a shift occurring at an instant corresponding to the production of a defective item. Crosier (1986) has proposed a convenient method for evaluating steady-state ARL, and presents the details of a method for determining the steady-state distribution (pss , say) of the CUSUM when the process is in-control. Following the Lucas & Saccucci (1990) development

Geometric CUSUM chart with sampling inspection

959

of this method, one computes a modi ed form (P*) of the transition matrix as follows: P* 5

R 100 . . . 0

(I 2 R)1 0

(9)

and this modi cation ensures that the CUSUM is reset to zero whenever a signal is produced (prior to the shift). The value of fraction defective to be used in constructing this matrix is of course pa . Next, it is necessary to nd the steadystate distribution associated with P*, and this is found by solving p 5 P*Tp (10)

subject to pT1 5 1. Finally, after deleting the element in p corresponding to the absorbing state, we re-scale the other elements so that they sum to 1. We denote the resulting steady-state distribution by pss . The value of ANDOss( p) is then given (for type 1 shifts, with 100% inspection) by

Downloaded by [COMIMSA] at 14:18 09 April 2012

ANDOss ( pr , 1, 100%) 5 pT l ss

(11)

where fraction defective at level pr is used in (8) to evaluate l . This method for evaluating ANDOss (p) is not applicable to the case where the shift in p occurs at an instant corresponding to the production of a non-defective item (a type 2 shift): this case will be dealt with once sampling inspection has been considered in the next section. 6 Evaluation of steady-state ANDO for sampling inspection It is necessary to consider separately the two types of shift process. The rst type is where the shift can only occur at an instant corresponding to the production of a defective item. We shall refer to the defective item produced at the moment when the shift in fraction defective occurs as the shift-item. Under sampling inspection, it is possible that the shift-item may occur during one of the phases of observation of items from the process. In this case, the statistical performance of the geometric CUSUM is the same as when 100% inspection is used, and the method given in Section 5 for computing ANDOss (p) is applicable. The latter ANDO has been denoted as ANDOss [pr , 1, 100%], the `1 indicating the shift-process. However, if the shift in fraction defective occurs during one of the phases of non-observation of items from the process, then this gives rise to what is termed a cross-over run-length in the sequence of run-lengths that is being monitored, and this is illustrated in Fig. 1. This cross-over run-length is the sum of two geometric random variables arising from the fraction defective rates pa and pr . Thus, the observed run-length data, prior to and after a shift, will consist of either of the following forms (a) a series of run-lengths produced by a process with p 5 pa, followed immediately by a series of run-lengths produced by a process with p 5 pr, or (b) a series of run-lengths produced by a process with p 5 pa, followed immediately by a cross-over run-length, and then a series of run-lengths produced by a process with p 5 pr. The probability of occurrence of each of these two forms is given by f and (1 2 f ), where f is the sampling fraction. The presence of the cross-over run-length causes

960

P. D. Bourke

a slower initial build-up of the geometric CUSUM following the occurrence of a shift, so that the value of ANDOss(pr ) will be larger than it would be for the 100% inspection case. Let us denote this value by ANDOss[pr , cross-over]. Appendix 1 describes how the Markov chain approach to computing ANDOss (p) may be modi ed to accommodate the presence of a cross-over run-length. Thus, for type 1 shifts in fraction defective, the value of ANDOss( pr ) for the geometric CUSUM under sampling inspection is given by: ANDOss [pr , 1, sampling] 5 ( f )ANDOss [pr , 1, 100%] (12)

+ (1 2

f )ANDOss [pr , cross-over]

Downloaded by [COMIMSA] at 14:18 09 April 2012

The corresponding value of ANI may be found from ANDO 5 ( pr )ANI. Next, we consider the case where the shift in fraction defective may occur at an instant corresponding to the production of any item (the type 2 shift, mentioned in Section 1). In Section 5, we deferred the treatment of this case for the important circumstance of 100% inspection, and it will be dealt with now. For complete inspection of all items from the process, the observed run-length data will consist of either of the two forms described earlier, and the relative frequencies will be pa and (1 2 pa ), so that ANDOss [pr , 2, 100%] 5 ( pa )ANDOss [pr , 1, 100%] (13)

+ (1 2

pa )ANDOss [pr , cross-over]

We now return to consider sampling inspection, for which both the sampling fraction f and pa are relevant in determining the relative frequencies of the two forms of run-length data. These relative frequencies are fpa and (1 2 fp a ). Thus ANDOss [pr , 2, sampling] 5 ( fpa )ANDOss [pr , 1, 100%] (14)

+ (1 2

fp a )ANDOss[pr , cross-over]

The values of ANI may be found from ANDO 5 (pr )ANI. It is clear from equations (13) and (14) that the second term will dominate the rst, so that it is the `crossover evaluation that matters most.

7 Evaluation of zero-state ANDO As in the case of the steady-state evaluations in Sections 5 and 6, it is necessary to consider three separate situations in evaluating zero-state ANDO: (a) A type 1 shift process, with 100% inspection. (b) A type 1 shift process, with sampling inspection. (c) A type 2 shift process, with either 100% inspection or sampling inspection. Case (a) was considered in Bourke (1991), and was brie y reviewed in Section 5. For cases (b) and (c), the evaluation of zero-state ANDO is complicated by the fact that there is a possibility of a cross-over run-length associated with the occurrence of a shift, arising either because the shift-item may occur between samples, or because the shift-item may be a non-defective. The essential point of zero-state ARL evaluations is that the CUSUM is taken as zero at the moment of shift, and if there is a cross-over run-length, the initial Markov chain transition

Geometric CUSUM chart with sampling inspection

961

matrix must accommodate this. All subsequent CUSUM-state transitions are made according to transition matrix R of equation (7), with p 5 pr. The details of the evaluation of zero-state ANDO in the presence of a cross-over run-length are provided in Appendix 2. Following the rationale for steady-state evaluations in Section 6, it may be seen that, for a type 1 shift with sampling inspection, the evaluation of zero-state ANDO is given by: ANDO0[pr, 1, sampling] 5 ( f )ANDO 0[pr, 1, 100%] (15)

+ (1 2

f )ANDO 0[pr , cross-over]

while for a type 2 shift with 100% inspection, zero-state ANDO is given by ANDO0[pr , 2, 100%] 5 (pa )ANDO 0[pr , 1, 100%] (16)

+ (1 2

Downloaded by [COMIMSA] at 14:18 09 April 2012

pa )ANDO0[pr , cross-over]

Finally, for a type 2 shift with sampling inspection, zero-state ANDO is given by ANDO0 [pr , 2, sampling] 5 ( fpa )ANDO0 [pr , 1, 100%] (17)

+ (1 2

fpa )ANDO0 [pr , cross-over]

It is clear that it is the `cross-over evaluation that is most in uential, except in the case of a type 1 shift under sampling inspection with a sizeable sampling fraction f.

8 Comparisons of zero-state and steady-state evaluations of ANDO Inevitably, one may wonder whether there is much of a di erence between zerostate and steady-state evaluations of ANDO. This is considered for each of the following situations: type 1 shifts with 100% inspection, and the `cross-over runlength scenario. Inspection of equations (12) to (17) reveals that all the steadystate ANDO evaluations are expressed in terms of ANDOss [pr , 1, 100%] and ANDOss [pr , cross-over], while all the zero-state ANDO evaluations are expressed in terms of ANDO0[pr , 1, 100%] and ANDO0[pr , cross-over]. Thus, one can assess the di erences between zero-state evaluations and steady-state evaluations by making comparisons between ANDO0[pr , 1, 100%] and ANDOss [pr , 1, 100%], and between ANDO0[pr , cross-over] and ANDOss [pr , cross-over]. The geometric CUSUM scheme (k 5 66, h 5 188) is suitable for detecting a shift from pa 5 0.01 to pr 5 0.025, and has an ANDO value of about 50 when no shift from pa occurs. For values of p in the range 0.01 to 0.10, the percentage di erences between ANDO0[p, 1, 100%] and ANDOss [p, 1, 100%] were computed, and are presented in Fig. 2, which also contains the percentage di erences between ANDO0[p, cross-over] and ANDOss [p, cross-over]. At the in-control level of p (i.e. 0.01), the zero-state and steady-state values of ANDO, for a type 1 shift with 100% inspection, di er by about 9%, but this di erence rises quickly to about 21% for p 5 0.025. This is a substantial di erence. At the in-control level of p (i.e. 0.01), the zero-state and steady-state values of ANDO, for the cross-over runlength situation, di er by only 3%, but this di erence rises to about 9% for p 5 0.025, and this is considered sizeable. Bearing in mind that it is the ANDO value from the cross-over evaluation that will dominate overall evaluation of ANDO

962

P. D. Bourke

Downloaded by [COMIMSA] at 14:18 09 April 2012

Fig. 2. Percentage di erence between zero-state and steady-state evaluations of ANDO for a type 1 shift with 100% inspection, and for the case of a cross-over run-length.

from type 1 shifts with sampling inspection, and from type 2 shifts for both sampling and 100% inspection, one must conclude that the di erences in zero-state and steady-state evaluations are sizeable enough so that one cannot recommend that the zero-state evaluations be used as an approximation for the steady-state evaluations. For type 1 shifts with 100% inspection these di erences are clearly quite substantial. Further investigations indicate that: (i) these percentage di erences are smaller if one has chosen a k value for detection of a larger shift (say from 0.01 to 0.03, for which the corresponding percentage di erences are 19% for the type 1 shift with 100% inspection, and 7% for the cross-over situation); (ii) these percentage di erences decrease slightly if one wishes to use a larger value for in-control ANDO (say, 100 rather than the value of 50 used in the example in Fig. 2). 9 The choice of parameters This has been considered in Bourke (1991) for 100% inspection, but the comparisons of alternative schemes that were presented there were based on the use of zerostate ANIs for type 1 shifts. The choice of the reference value will be considered initially, and at this point it is appropriate to specify how comparisons of alternative schemes will be made. In making comparisons, the competing schemes will be

Geometric CUSUM chart with sampling inspection

963

matched by choosing their parameters as follows: the parameters are chosen so that (for schemes A and B, say), ANIA(pa ) is as close as possible to ANIB(pa ) at some large speci ed level (or equivalently, ANDOA( pa ) is as close as possible to ANDOB(pa )). Noting that pr 5 mp a is the shift above pa that we wish to detect by either scheme, it may be seen that the values of ANIA(mp a ) and ANIB(mp a ) provide performance-measures for each scheme, which may then be compared. This procedure has been used below in investigating alternative choices for the reference value.

9.1 The choice of k Gan (1993) investigated the choice of kB for the binomial CUSUM and demonstrated, for the case of zero-state ARLs, that the SPRT-based value for kB was optimal, which is consistent with the result in Moustakides (1986). Here, investigations have been conducted on the choice of k for the geometric CUSUM, and these con rm that the value for k arising from equation (3) is optimal if one is using zero-state ARLs. However, as we shall see, it appears better to use a value about 10% higher than this, if one is using steady-state ARLs. For the latter case, the dependence of ANI(pr ) on various values of k in the neighbourhood of k0 (the value arising from equation (3)) is illustrated in Fig. 3, which indicates that the minimum is rather at. In constructing Fig. 3, we considered the detection of a shift from 0.01 to 0.02, for a type 2 shift, and for a range of values of k in the neighbourhood of k0 , we identi ed corresponding values of h for which ANI is quite close to 5000. For each of these CUSUM schemes, we evaluated ANI(pr ). This exercise was repeated for the detection of a shift from pa 5 0.01 to pr 5 0.04. In a further investigation of the in uence of k, three CUSUM schemes, with

Downloaded by [COMIMSA] at 14:18 09 April 2012

Fig. 3. Percentage di erence of ANI( pr , k) from the minimum value of ANI(pr ) plotted against percentage deviation of the k value from k0 , for ANI(pa ) 5 5000, and two separate shift-sizes.

964

P. D. Bourke

Downloaded by [COMIMSA] at 14:18 09 April 2012

Fig. 4. Relative di erences in ANI(p) values for three pairs of geometric CUSUMs matched at p 5 0.002, plotted against fraction defective, p.

ANDO(pa ) 5 50, for detection of shifts above pa 5 0.002 were compared. The three shift sizes were pr 5 3pa , pr 5 6pa , and pr 5 9pa, and the schemes are as follows: Scheme 1: k 5 301, h 5 754, which is the best of the three for 0.002 < p < 0.009, Scheme 2: k 5 196, h 5 327, which is the best of the three for 0.009 < p < 0.015, Scheme 3: k 5 149, h 5 203, which is the best of the three for 0.015 < p. The relative performances of these schemes are presented in Fig. 4 by means of three pairwise comparisons, and Fig. 4 indicates that the greatest di erences in the relative performance of these schemes occur for lower values of p. A number of conclusions may be drawn from Figs 3 and 4. (i) One should use a value for k that is about 10% above the value given by equation (3). (ii) The minimum is atter for detection of larger shifts, and a particular choice for k should work quite well for a moderate range of shift-sizes. (iii) If one expects that process-shifts are likely to be in a particular range, then it appears advisable to take the mid-point of this range (or slightly below this) as the pr value to use in equation (3). 9.2 The choice of h The search for an appropriate value of the decision interval h may be carried out using the Markov-chain methods presented in Sections 5, 6 and 7. Bourke (1991) contains rather limited tables, and these relate to zero-state ANI values. Gan (1994) presents convenient charts for designing exponential CUSUMs using zero-

Geometric CUSUM chart with sampling inspection

965

Downloaded by [COMIMSA] at 14:18 09 April 2012

state ARL, and these may be adapted to the design of geometric CUSUMs for detection of type 1 shifts. To illustrate this: Suppose we wish to design a geometric CUSUM for which pa 5 0.005, pr 5 0.015 with ANDO(pa ) 5 100 (which is equivalent to ANI(pa ) 5 20 000). This corresponds to detecting a downward shift in the mean of an exponential distribution from 199 to 65.7. Using Gans work, one can see that the value of k (from Gans equation (1)) is 0.5493. Looking up Fig. 1 of Gan (1994) one sees that the corresponding value of h required to achieve an ANDO value of 100 is approximately 1.56. One then multiplies these values (k 5 0.5493, h 5 1.56) by 199, the in-control mean for run-lengths, to get the parameter-values of the geometric CUSUM. The resulting values are k 5 109.3 and h 5 310.44, which are rounded to 109 and 310. As a check on the accuracy of this approximating method, one can evaluate the true value of the zero-state ANDO for this CUSUM, and it turns out to be 100.2. This example is somewhat `lucky in the degree of accuracy: other examples indicate that the method using Gans exponential CUSUM charts are usually within 10% of the true value of ANDO. Accuracy appears to be better for smaller values of pa . Charts to aid the choice of h for a geometric CUSUM when one wishes to use steady-state ARL have not yet been developed, and would seem to pose di culties. If one wishes to achieve some speci ed level for ANDOss (pa ), then it is necessary to use some search method incorporating the evaluation of steady-state ANDO, as presented in Sections 5 and 6.

10 Comparisons with the np-chart The p-chart and the closely-related np-chart have, for a long time, been the most familiar control charts for monitoring fraction defective. Consequently, it seems appropriate to provide information on the performance of any newly proposed procedure for monitoring fraction defective in terms of comparisons with one or other of these standard methods. In Bourke (1991) comparisons with the np-chart were presented, but these were rather limited, in that only type 1 shifts were considered, zero-state ANI rather than steady-state ANI evaluations were used and, of course, 100% inspection was assumed. Here, a series of comparisons are presented for the second type of shift-process, with sampling inspection. The np-chart has two parameters: the sample size n and the acceptance number c. If the number of defectives found in any sample exceeds c, this is taken as a signal that the fraction defective may have shifted upward. In making comparisons, for either type 1 shifts or type 2 shifts, it is necessary to take account of the fact that the shift may occur within a sample (which we term the shift-sample) in which case the distribution of the number of defectives for the shift-sample will be a convolution of two binomials. For type 2 shifts, the parameters of these two binomials will be (n1 , pa ) and ((n 2 n1 ), pr ) where n1 is the order of the item within the shift-sample at which the shift occurs. It seems reasonable to assume that the value of n1 is uniformly distributed on the values 1, 2, 3, . . . n. If the shift occurs between samples, the analysis is much simpler because there is no shift-sample. The chances of a shift occurring within a sample may be taken as the sampling fraction ( f ). For an np-chart, the value of ANI (average number inspected up to a signal) is given by the following ANI[p, sampling] 5 ( f )ANI[p, within)]

+ (1 2

f )ANI[p, between]

(18)

966 where

P. D. Bourke

ANI[p, between] 5 (n) /P ANI[ p, within] 5 1 + n n1 5

n

(19) (20) (21)

ANI[p,n1 ]

1

ANI[p,n1 ] 5 (n 2 n1 ) +

(1 2 P1 ) n P

and P is the probability of a signal from a sample (of size n) following the shift, while P1 is the probability of a signal from the shift-sample, assuming that the shiftsample consists of n1 items produced before the shift, and (n 2 n1 ) items produced after the shift. Two separate sets of comparisons will be presented. In the rst set of comparisons, the relevant information is as follows: pa 5 0.01, and ANI( pa ) 5 5000, and the sampling fraction is 0.1.

Downloaded by [COMIMSA] at 14:18 09 April 2012

All of the evaluations of ANI are steady-state evaluations. The following matched schemes were found: scheme 1 scheme 2 scheme 3 Geometric CUSUM scheme np-Charts: n5 n5 n5 k5 5, c 5 1, for which ANI( pa ) 5 5101. 41, c 5 2, for which ANI( pa ) 5 5104. 103, c 5 3, for which ANI(pa ) 5 5083. 49, h 5 101, for which ANI( pa ) 5 5060.

Many researchers will be aware that for each of these np-chart schemes there will be a range of values for pr for which that scheme will be optimal (in the sense that with ANI(pa ) xed, that scheme has a smaller level for ANI(p) than any other npchart scheme. These ranges are as follows: scheme 1 (n 5 5, c 5 1) scheme 2 (n 5 41, c 5 2) scheme 3 (n 5 103, c 5 3) range: pr > 0.1164 range: 0.1164 > pr > 0.0433 range: 0.0433 > pr > 0.0277

The latter value here (0.0277) marks the pr value below which yet another np-chart (n 5 179, c 5 4) becomes more e cient than the scheme with c 5 3. There are very many geometric CUSUM schemes that would also have ANI(pa ) 5 5000: the k value for the scheme used here was chosen as suitable for detecting a shift from pa 5 0.01 to pr 5 0.04. Plots of the values of ANI(p) versus p are presented in Fig. 5, for values in the range 0.01 to 0.15. The shape of these ANI curves makes it somewhat di cult to see the relative performance of the schemes, hence the presentation in Fig. 6. Figure 6 shows the percentage increase in ANI(p) for each of the np-charts in comparison with that of the geometric CUSUM scheme, plotted against p. In the second set of comparisons, the relevant information is as follows: pa 5 0.002 and ANI(pa ) 5 25 000, and the sampling fraction is again 0.1. The following matched schemes were found: scheme 1 scheme 2 scheme 3 Geometric CUSUM scheme np-Charts: n5 n5 n5 k5 21, c 5 1, for which ANI( pa ) 5 25 640. 202, c 5 2, for which ANI( pa ) 5 25 065. 513, c 5 3, for which ANI( pa ) 5 25 003. 220, h 5 400, for which ANI( pa ) 5 25 010.

Geometric CUSUM chart with sampling inspection

967

Downloaded by [COMIMSA] at 14:18 09 April 2012

Fig. 5. Average number inspected plotted against fraction defective (p) for three np-charts, and a geometric CUSUM, with pa 5 0.01.

The ranges of pr values for which each of these np-chart schemes is optimal (in the sense speci ed in the rst set of comparisons above) are as follows: scheme 1 scheme 2 scheme 3 (n 5 21, c 5 1) (n 5 202, c 5 2) (n 5 513, c 5 3) range: pr > 0.0235 range: 0.0235 > pr > 0.00867 range: 0.00867 > pr > 0.00553

The latter value here (0.00553) marks the pr value below which yet another np-chart (n 5 896, c 5 4) becomes more e cient than the schemes with c 5 3. There are very many geometric CUSUM schemes that would also have ANI(pa ) 5 25 000: the k value for the scheme used here was chosen as suitable for detecting a shift from pa 5 0.002 to pr 5 0.01. Plots of the values of ANI(p) versus (p) are presented in Fig. 7, for values in the range 0.002 to 0.032. Figure 8 shows the percentage increase in ANI(p) for each of the np-charts in comparison with that of the geometric CUSUM scheme, plotted against p. These comparisons illustrate the e ciency of the geometric CUSUM, and also show that a CUSUM designed for detecting a shift of a particular size is also quite e ective for a neighbouring range of shift-sizes. 11 Conclusions In this paper, the use of the geometric CUSUM under sampling inspection has been considered, and earlier work on this CUSUM for 100% inspection has been

968

P. D. Bourke

Downloaded by [COMIMSA] at 14:18 09 April 2012

Fig. 6. Percentage increase in ANI(p) for three np-charts over that for a matched geometric CUSUM, plotted against fraction defective (p), for pa 5 0.01.

Fig. 7. Average number inspected plotted against fraction defective (p) for three np-charts, and a geometric CUSUM, with pa 5 0.002.

Geometric CUSUM chart with sampling inspection

969

Downloaded by [COMIMSA] at 14:18 09 April 2012

Fig. 8. Percentage increase in ANI(p) for three np-charts over that for a matched geometric CUSUM, plotted against fraction defective (p), for pa 5 0.002.

extended. Two mechanisms for the manner of occurrence of shift in fraction defective have been considered, and methods for the evaluation of both zero-state and steady-state ARL-type performance measures, such as Average Number of Defectives Observed until a signal occurs, have been presented. The results reported on in this paper indicate that the geometric CUSUM provides an e cient monitoring scheme for detection of upward shifts in fraction defective, for sampling inspection. There is a view held by some practitioners of SPC that `CUSUMs are good for detecting small shifts, but p-charts are better for large shifts. The comparisons reported here show that the geometric CUSUM is better for detecting both small and large shifts, and that a geometric CUSUM designed for detecting a speci ed shift can work quite well for a moderate range of neighbouring shift-sizes. The geometric CUSUM is equivalent in statistical terms to the Bernoulli CUSUM, but there are likely to be practical advantages in particular circumstances that will lead to the choice of one of these schemes over the other. The geometric CUSUM has the advantage that the updating of the CUSUM value is carried out only when a defective item is encountered, whereas the Bernoulli CUSUM must be updated after every observed item. There are also advantages for the Bernoulli CUSUM, which are discussed in Reynolds & Stoumbos (1999). Both CUSUM schemes share the signi cant advantage that they may be operated easily with either systematic sampling or any sporadic pattern of sampling inspection. A drawback in popularizing the use of geometric CUSUMs has been the computational burden associated with the choice of the parameter h. A method for dealing with this using ARL charts for the exponential CUSUM has been described.

970

P. D. Bourke

Further development work in this area is continuing. Another area that requires investigation is an adaptive version of the geometric CUSUM, in which a switch from sampling inspection toward 100% inspection could be triggered by rising CUSUM values, but this would increase the number of scheme parameters, adding to the complexity of the CUSUM.

REFERENCES

Bourke, P. (1991) Detecting a shift in fraction nonconforming using run-length control charts with 100% inspection, Journal of Quality Technology, 23, pp. 225- 238. Bourke, P. (2001) Sample size and the binomial CUSUM control chart: the case of 100% inspection, Metrika, 53, pp. 51- 70. Brook, D. & Evans, D. A. (1972) An approach to the probability distribution of CUSUM run-length, Biometrika, 59, pp. 539- 549. Crosier, R. B. (1986) A new two-sided cumulative sum quality control scheme, Technometrics, 28, pp. 187- 194. Duncan, A. J. (1986) Quality Control and Industrial Statistics, 5th edn (Homewood, IL, Richard D. Irwin). Gan, F. F. (1993) An optimal design of CUSUM control charts for binomial counts, Journal of Applied Statistics, 20(4), pp. 445- 460. Gan, F. F. (1994) Design of optimal exponential CUSUM control charts, Journal of Quality Technology, 26, pp. 109- 124. Hawkins, D. M. & Olwell, D. H. (1998) Cumulative Sum Charts and Charting for Quality Improvement (New York, Springer). Kemp, K. W. (1962) The use of cumulative sums for sampling inspection schemes, Applied Statistics, 11, pp. 16- 31. Lucas, J. M. (1985) Counted data CUSUMs, Technometrics, 27, pp. 129- 144. Lucas, J. M. & Crosier, R. B. (1982) Fast initial response for CUSUM quality control schemes: give your CUSUM a head start, Technometrics, 24, pp. 199- 205. Lucas, J. M. & Saccucci, M. S. (1990) Exponentially weighted moving average control schemes: properties and enhancements, Technometrics, 32, pp. 1- 12. Montgomery, D. C. (2001) Introduction to Statistical Quality Control, 4th edn (New York, Wiley). Moustakides, G. V. (1986) Optimal stopping times for detecting changes in distributions, The Annals of Statistics, 14(4), pp. 1379- 1387. Page, E. S. (1954) Continuous inspection schemes, Biometrika, 41, pp. 100- 114. Reynolds, M. R., Jr. & Stoumbos, Z. G. (1998) The SPRT chart for monitoring a proportion. IIE Transactions on Quality and Reliability, 30, pp. 545- 561. Reynolds, M. R., Jr. & Stoumbos, Z. G. (1999) A CUSUM chart for monitoring a proportion when inspecting continuously, Journal of Quality Technology, 31, pp. 87- 108. Taylor, H. M. (1968) The economic design of cumulative sum control charts, Technometrics, 10, pp. 479- 488. Van Dobben de Bruyn, C. S. (1968) Cumulative Sum Tests: Theory and Practice (London, Gri n). Vardeman, S. & Ray, D. (1985) Average run lengths for CUSUM schemes when observations are exponentially distributed, Technometrics, 27, pp. 145- 150. Woodall, W. H. (1997) Control charts based on attribute data: bibliography and review, Journal of Quality Technology, 29, pp. 172- 183. Zimmer, L. S., Montgomery, D. C. & Runger, G. C. (2000) Guidelines for the application of adaptive control charts, International Journal of Production Research, 38(9), pp. 1977- 1992.

Downloaded by [COMIMSA] at 14:18 09 April 2012

Appendix 1. Evaluation of ANDOss [p, cross-over] Crosier (1986) describes how to compute the steady-state ARL for a CUSUM. This method can be adapted to deal with the presence of a cross-over run-length associated with the occurrence of a shift in fraction defective. (1) The steady-state distribution (pss ) of CUSUM values is rst determined,

Downloaded by [COMIMSA] at 14:18 09 April 2012

Table A1. The transition matrix for the in-control states of a geometric CUSUM for the cross-over run length P(C 5 0) P(C 5 1) P(C 5 2) . 0 P(C 5 0) P(C 5 1) . 0 P(C 5 0) . . 0 0 ... ... ... .

k) k + 1) k + 2)

P(C 5 k 2 1) P(C 5 k) P(C 5 k + 1) .

P(C 5 k 2 2) P(C 5 k 2 1) P(C 5 k) .

... ... ... .

0) 1) 2) . ... . .

P(C > P(C > P(C > . . . . . . P(C > . P(C 5 h 2 1) . P(C 5 h 2 2) . ...

k + h 2 1)

. P(C 5 k + h 2 2)

. ...

0 0 0 . P(C 5 P(C 5 P(C 5 . . P(C 5

k)

Geometric CUSUM chart with sampling inspection 971

In Table A1, P(C 5 i) denotes the probability that a cross-over run length C equals the value i. The case of k < (h 2 1) is presented in this table: when k > (h 2 1) the triangular array of zeros in the top right-hand corner will not appear.

972

P. D. Bourke

and this may be thought of as being the distribution just prior to the crossover run-length. (2) The next step is to revise this distribution using the transition matrix K associated with the cross-over run-length, and the revised steady-state distribution is given by rss 5 pss K (A1.1)

The structure of K is given in Table A1. (3) The value of 1-R (rss )i gives the probability (likely to be quite small) that a signal will be generated by the cross-over run-length. We can then nd the average number of defectives observed until a signal occurs (ANDO) from ANDOss (cross-over) 5 1(1 2 R (rss)i ) + (rss )T(1 where l 5 (I 2 R) 2 11

+l

(A1.2) (A1.3)

Downloaded by [COMIMSA] at 14:18 09 April 2012

and R is the transition matrix for run-length values following the shift (i.e. with fraction defective given by pr ). The sructure of R is given in Bourke (1991). The presence of 1 in the term (1 + l ) of equation (A1.2) is explained by the need to count the defective that completes the cross-over run-length. Appendix 2: Evaluation of ANDO0[p, cross-over] Unlike the steady-state case considered in Appendix 1, we take the value of the CUSUM at the moment of shift to be zero. (1) This may be thought of as the `zero-state distribution : p0 5 (1, 0, 0, 0, 0, . . . , 0)T and represents the distribution of CUSUM values just prior to the crossover run-length. (2) The next step is to revise this distribution using the transition matrix K associated with the cross-over run-length, and the revised distribution is given by r0 5 p0K (A2.1)

The structure of K is given in Table A1. (3) The value of 1 2 R (r0 )i gives the probability (likely to be quite small) that a signal will be generated by the cross-over run-length. We can then nd the average number of defectives observed until a signal occurs (ANDO) from ANDO0(cross-over) 5 1(1 2 R (r0 )i ) + (r0 )T(1 + l ) where l 5 (I 2 R) 2 11 (A2.2) (A2.3)

and R is the transition matrix for run-length values following the shift (i.e. with fraction defective given by pr ). The presence of 1 in the term (1 + l ) of equation (A2.2) is explained by the need to count the defective item that completes the cross-over run-length.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- QuickTransit SSLI Release Notes 1.1Document12 pagesQuickTransit SSLI Release Notes 1.1subhrajitm47No ratings yet

- SEG Newsletter 65 2006 AprilDocument48 pagesSEG Newsletter 65 2006 AprilMilton Agustin GonzagaNo ratings yet

- HenyaDocument6 pagesHenyaKunnithi Sameunjai100% (1)

- Moor, The - Nature - Importance - and - Difficulty - of - Machine - EthicsDocument4 pagesMoor, The - Nature - Importance - and - Difficulty - of - Machine - EthicsIrene IturraldeNo ratings yet

- MBO, Management by Objectives, Pooja Godiyal, Assistant ProfessorDocument20 pagesMBO, Management by Objectives, Pooja Godiyal, Assistant ProfessorPooja GodiyalNo ratings yet

- Archlinux 之 之 之 之 Lmap 攻 略 ( 攻 略 ( 攻 略 ( 攻 略 ( 1 、 环 境 准 备 ) 、 环 境 准 备 ) 、 环 境 准 备 ) 、 环 境 准 备 )Document16 pagesArchlinux 之 之 之 之 Lmap 攻 略 ( 攻 略 ( 攻 略 ( 攻 略 ( 1 、 环 境 准 备 ) 、 环 境 准 备 ) 、 环 境 准 备 ) 、 环 境 准 备 )Goh Ka WeeNo ratings yet

- DLP in Health 4Document15 pagesDLP in Health 4Nina Claire Bustamante100% (1)

- 621F Ap4405ccgbDocument8 pages621F Ap4405ccgbAlwinNo ratings yet

- Numerical Methods Chapter 10 SummaryDocument8 pagesNumerical Methods Chapter 10 SummarynedumpillilNo ratings yet

- 1.each of The Solids Shown in The Diagram Has The Same MassDocument12 pages1.each of The Solids Shown in The Diagram Has The Same MassrehanNo ratings yet

- 4 Wheel ThunderDocument9 pages4 Wheel ThunderOlga Lucia Zapata SavaresseNo ratings yet

- The Impact of School Facilities On The Learning EnvironmentDocument174 pagesThe Impact of School Facilities On The Learning EnvironmentEnrry Sebastian71% (31)

- Theory of Linear Programming: Standard Form and HistoryDocument42 pagesTheory of Linear Programming: Standard Form and HistoryJayakumarNo ratings yet

- Phys101 CS Mid Sem 16 - 17Document1 pagePhys101 CS Mid Sem 16 - 17Nicole EchezonaNo ratings yet

- Do You Agree With Aguinaldo That The Assassination of Antonio Luna Is Beneficial For The Philippines' Struggle For Independence?Document1 pageDo You Agree With Aguinaldo That The Assassination of Antonio Luna Is Beneficial For The Philippines' Struggle For Independence?Mary Rose BaluranNo ratings yet

- National Standard Examination in Astronomy 2018-19 (NSEA) : Question Paper Code: A423Document1 pageNational Standard Examination in Astronomy 2018-19 (NSEA) : Question Paper Code: A423VASU JAINNo ratings yet

- New Education Policy 2019Document55 pagesNew Education Policy 2019Aakarshanam VenturesNo ratings yet

- If V2 would/wouldn't V1Document2 pagesIf V2 would/wouldn't V1Honey ThinNo ratings yet

- Steam Turbine Theory and Practice by Kearton PDF 35Document4 pagesSteam Turbine Theory and Practice by Kearton PDF 35KKDhNo ratings yet

- Non Circumvention Non Disclosure Agreement (TERENCE) SGDocument7 pagesNon Circumvention Non Disclosure Agreement (TERENCE) SGLin ChrisNo ratings yet

- Antenna VisualizationDocument4 pagesAntenna Visualizationashok_patil_1No ratings yet

- Budgetary ControlsDocument2 pagesBudgetary Controlssiva_lordNo ratings yet

- Merchandising Calender: By: Harsha Siddham Sanghamitra Kalita Sayantani SahaDocument29 pagesMerchandising Calender: By: Harsha Siddham Sanghamitra Kalita Sayantani SahaSanghamitra KalitaNo ratings yet

- Rishte ki baat SMS messages collectionDocument108 pagesRishte ki baat SMS messages collectionTushar AggarwalNo ratings yet

- PRODUCTDocument82 pagesPRODUCTSrishti AggarwalNo ratings yet

- Lifespan Development Canadian 6th Edition Boyd Test BankDocument57 pagesLifespan Development Canadian 6th Edition Boyd Test Bankshamekascoles2528zNo ratings yet

- Hindustan Motors Case StudyDocument50 pagesHindustan Motors Case Studyashitshekhar100% (4)

- Difference Between Text and Discourse: The Agent FactorDocument4 pagesDifference Between Text and Discourse: The Agent FactorBenjamin Paner100% (1)

- FSRH Ukmec Summary September 2019Document11 pagesFSRH Ukmec Summary September 2019Kiran JayaprakashNo ratings yet

- "Behind The Times: A Look at America's Favorite Crossword," by Helene HovanecDocument5 pages"Behind The Times: A Look at America's Favorite Crossword," by Helene HovanecpspuzzlesNo ratings yet