Professional Documents

Culture Documents

Q09

Uploaded by

James K. KirahukaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Q09

Uploaded by

James K. KirahukaCopyright:

Available Formats

Hydraulics Tutorial Sheet 9 Basic hydraulics of ow in pipes

1. A horizontal 50 mm pipeline leaves a water tank with a square-edged entrance at H = 6 m below the water surface and discharges into the atmosphere. Calculate the ow rate, assuming a friction factor = 0.025 and = 1.2 for four cases, with and without entrance loss K = 0.5, and for a pipe length L of 4.5 m and 45 m. (Ans: 0.012 m3 s1 , 0.011 m3 s1 , 0.0044 m3 s1 , 0.0043 m3 s1 ). 2. In Q1 you have examined the sensitivity to different losses. This does the same but mathematically. Now generalising, to estimate the relative importance of the velocity correction factor , a local loss K , and friction : a horizontal pipeline of diameter D a depth H below the surface leaves a water tank with entrance loss coefcient K and discharges into the atmosphere. The pipe has length L and friction factor . Calculate the ow rate in terms of these quantities and using the total differential explore the sensitivity of the discharge Q to , K , and by considering realistic values and uncertainties in those quantities for pipeline length/diameter ratios of 100 and 1000. Consider in the range 1 1.3, K might be, say, 0.5 0.15, and the value of from the Moody diagram might be 0.02 0.005, corresponding to uncertainties of 100% in the relative roughness. 3. Do Example 16 on page 74 of the lecture notes for yourself, paying attention to the plotting of the piezometric head line and the total head line. It might be easiest to do all calculations and plotting using a spreadsheet. 4. Repeat, but where instead of a nozzle, the pipe discharges into a tank where the water surface is 1 m above the pipe. Include the exit loss in your calculations, and again, carefully plot the lines mentioned in Question 1. (Ans: Q = 0.0766 m3 s1 , ...) 5. An irrigation siphon placed over a canal bank is a pipe with a diameter of 100 mm and the dimensions shown. Estimate the owrate for a head of 0.3 m. Assume a re-entrant loss of K = 0.8; the full kinetic energy loss at the exit, but where = 1 because the ow distribution in the pipe has not had time to develop; a friction factor of = 0.02 and bend loss coefcients of K = 0.2.. (Ans: 0.0107 m3 s1 ).

6. A town water supply has a reservoir whose surface is 100 m higher than that in the water tower in the town which acts as a distribution reservoir, which stores enough to average out ows between times of high and low demand. This means that when we design the pipeline joining the two we can consider mean demand, which is 250L per head per day. The town is estimated to have a population of 4, 000 people at the end of the 20 year design life. The reservoir and the tower are 5 km apart so that we can ignore local losses. The pipes to be used are concrete, with an equivalent roughness of 1 mm. Design the pipe that is, determine its minimum diameter so that the mean ow can be carried. Of course, in practice, the next larger commercial pipe size would be used. (Ans: a required diameter of at least 0.115 m). 7. Now generalising, to estimate the relative importance of the velocity correction factor , a local loss K , and friction : a horizontal pipeline of diameter D a depth H below the surface leaves a water tank with entrance loss coefcient K and discharges into the atmosphere. The pipe has length L 13

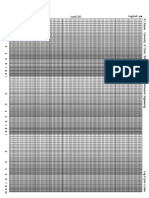

and friction factor . Calculate the ow rate in terms of these quantities (you could use the solution from the previous question) and using the total differential explore the sensitivity of the discharge Q to , K , and by considering realistic values and uncertainties in those quantities for pipeline length/diameter ratios of 100 and 1000. Consider in the range 11.3, K might be, say, 0.50.15, and the value of from the Moody diagram might be 0.02 0.005, corresponding to uncertainties of 100% in the relative roughness.

14

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Full Report A Flow Pass Circular CylinderDocument21 pagesFull Report A Flow Pass Circular CylinderHaziq Pazli67% (3)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Udoeyo Structural AnalysisDocument391 pagesUdoeyo Structural Analysisjucar fernandez100% (4)

- HYDROLOGICAL FREQUENCY ANALYSIS GUIDEDocument71 pagesHYDROLOGICAL FREQUENCY ANALYSIS GUIDEEdi Setiawan100% (1)

- HYDROLOGICAL FREQUENCY ANALYSIS GUIDEDocument71 pagesHYDROLOGICAL FREQUENCY ANALYSIS GUIDEEdi Setiawan100% (1)

- Water Softener 223100Document7 pagesWater Softener 223100ΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- 1044 Vol I 72dpiDocument248 pages1044 Vol I 72dpiJames K. KirahukaNo ratings yet

- Engineering Hydrology Book InsightsDocument33 pagesEngineering Hydrology Book InsightspewdspendellNo ratings yet

- 00 Tidyverse WebinarDocument57 pages00 Tidyverse WebinarJames K. KirahukaNo ratings yet

- Graph Semi LogDocument1 pageGraph Semi LogJames K. KirahukaNo ratings yet

- 00 Tidyverse WebinarDocument57 pages00 Tidyverse WebinarJames K. KirahukaNo ratings yet

- Import Data RDocument17 pagesImport Data RJames K. KirahukaNo ratings yet

- Aquacrop CourseDocument3 pagesAquacrop CourseJames K. KirahukaNo ratings yet

- Engineering Hydrology Book InsightsDocument33 pagesEngineering Hydrology Book InsightspewdspendellNo ratings yet

- Engineering Hydrology Book InsightsDocument33 pagesEngineering Hydrology Book InsightspewdspendellNo ratings yet

- Design of Square Base Shallow FoundationDocument2 pagesDesign of Square Base Shallow FoundationWaqas AnjumNo ratings yet

- Semi - Log GraphDocument1 pageSemi - Log GraphJames K. KirahukaNo ratings yet

- HYDR Tutorial6Document4 pagesHYDR Tutorial6James K. Kirahuka100% (1)

- Rigorous Derivation of Hooghoudt's Equation For Drainage Spacing PDFDocument41 pagesRigorous Derivation of Hooghoudt's Equation For Drainage Spacing PDFJames K. KirahukaNo ratings yet

- IISc Stochastic Hydrology Lecture Provides Insight into Bivariate DistributionsDocument52 pagesIISc Stochastic Hydrology Lecture Provides Insight into Bivariate DistributionsJames K. KirahukaNo ratings yet

- Rigorous Derivation of Hooghoudt's Equation For Drainage SpacingDocument41 pagesRigorous Derivation of Hooghoudt's Equation For Drainage SpacingJames K. KirahukaNo ratings yet

- Groundwater Hydrology Tutorial PDFDocument20 pagesGroundwater Hydrology Tutorial PDFJames K. KirahukaNo ratings yet

- ES322 Introduction To Watershed MorphometryDocument6 pagesES322 Introduction To Watershed MorphometryJames K. KirahukaNo ratings yet

- Watershed DelineationDocument1 pageWatershed DelineationJames K. KirahukaNo ratings yet

- Quickly calculate sum of numbers in RDocument12 pagesQuickly calculate sum of numbers in RGlobalStrategyNo ratings yet

- Vegetative Management and Water YieldDocument33 pagesVegetative Management and Water YieldJames K. KirahukaNo ratings yet

- River Discharge MeasurementDocument1 pageRiver Discharge MeasurementJames K. KirahukaNo ratings yet

- Water 08 00588Document16 pagesWater 08 00588James K. KirahukaNo ratings yet

- 12 How To Analyse Rainfall DataDocument40 pages12 How To Analyse Rainfall DataSagar Jss100% (1)

- Water 08 00588Document16 pagesWater 08 00588James K. KirahukaNo ratings yet

- Paper JEC PDFDocument11 pagesPaper JEC PDFJames K. KirahukaNo ratings yet

- WWW - Efm.leeds - Ac.uk CIVE CIVE2400 OpenChannelHydraulics2Document39 pagesWWW - Efm.leeds - Ac.uk CIVE CIVE2400 OpenChannelHydraulics2Prabu Rengarajan100% (1)

- Rebar order lists for D' Ace Plaza construction projectDocument4 pagesRebar order lists for D' Ace Plaza construction projectggsarneNo ratings yet

- Arindam Dey, RSS, Qip-Stc Gepd 2014Document147 pagesArindam Dey, RSS, Qip-Stc Gepd 2014AnNo ratings yet

- TMT RebarsDocument5 pagesTMT RebarsEktaNo ratings yet

- Retrofitting Design of Concrete Members Using Carbon Fiber-Reinforced Polymers (CFRP)Document12 pagesRetrofitting Design of Concrete Members Using Carbon Fiber-Reinforced Polymers (CFRP)gcsblue stacksNo ratings yet

- Worksheet On Marshal Mix DesignDocument1 pageWorksheet On Marshal Mix DesignHordofa ZekeriaNo ratings yet

- Strap Beam FootingDocument4 pagesStrap Beam Footingrukesh104No ratings yet

- BankofChina PDFDocument32 pagesBankofChina PDFyenyasNo ratings yet

- Ms DrainagesDocument3 pagesMs DrainagesdeanicoNo ratings yet

- Is 883 1994 PDFDocument21 pagesIs 883 1994 PDFkrishnanunniNo ratings yet

- EzyBrace 2011 Technical BookDocument32 pagesEzyBrace 2011 Technical BookHaisheng YinNo ratings yet

- CGN 3501 Lab 4 (Instructions & Data Sheets)Document11 pagesCGN 3501 Lab 4 (Instructions & Data Sheets)Stanley SibandaNo ratings yet

- Competency Based Learning Material: Prepare Pipe For Installation Preparing Pipe For InstallationDocument78 pagesCompetency Based Learning Material: Prepare Pipe For Installation Preparing Pipe For Installationmico alilayaNo ratings yet

- 2012 San Diego Regional Supplement To GreenbookDocument83 pages2012 San Diego Regional Supplement To GreenbookridlasNo ratings yet

- Detailed Estimation Report - High Rise at GurgaonDocument15 pagesDetailed Estimation Report - High Rise at GurgaonJackson ChristianNo ratings yet

- Fluids Study MaterialDocument34 pagesFluids Study MaterialLiza KimNo ratings yet

- Soil CharacteristicsDocument2 pagesSoil CharacteristicsCassandra DunnNo ratings yet

- Ultra-High Performance Concrete - From Fundamental To Applications - ScienceDirectDocument23 pagesUltra-High Performance Concrete - From Fundamental To Applications - ScienceDirectShabbir LokhandwalaNo ratings yet

- Soil ReinforcementDocument16 pagesSoil ReinforcementFITSUM BerheNo ratings yet

- Topic1 3 Foundations Footings 13Document19 pagesTopic1 3 Foundations Footings 13Hussein JaberNo ratings yet

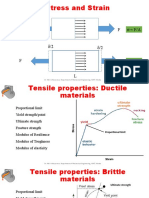

- Stress and Strain: σ = F/A F FDocument11 pagesStress and Strain: σ = F/A F FMd Arifuzzaman ArifNo ratings yet

- Beam Deflection Tables - MechaniCalcDocument9 pagesBeam Deflection Tables - MechaniCalcDave TruongNo ratings yet

- Laboratory Test Shows Neltex Sewer Pipes Meet StandardsDocument2 pagesLaboratory Test Shows Neltex Sewer Pipes Meet StandardsJose Fermin SantiagoNo ratings yet

- ITA-AITES Main Glossary of TermsDocument50 pagesITA-AITES Main Glossary of TermsswhuntNo ratings yet

- Chapter 3Document34 pagesChapter 3Jeric EliveraNo ratings yet

- Astm D2899Document6 pagesAstm D2899btwilliNo ratings yet

- Aashto CatalogDocument43 pagesAashto Catalograkesh singh officialNo ratings yet