Professional Documents

Culture Documents

Eurowater Pressure No Address)

Uploaded by

shalabyahmedOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eurowater Pressure No Address)

Uploaded by

shalabyahmedCopyright:

Available Formats

Mn++

NH4+ Fe++

CO2

Fe++

CO2

As As ++ NH4+ Mn++ Fe Fe++ CO2 ++ Fe

+++

Fe++

CO2

As+++

As+++

Filtration of water

DK

REN VANDBEHANDLING

INT., BE, NL, SK, CZ

P U R E WAT E R T R E AT M E N T

Pressure filters for treatment of water

For more than 70 years, EUROWATER has developed, manufactured, and marketed complete water treatment plants employing air and water backwashed pressure filters.

Water treatment No matter if you need drinking water or water for commercial or industrial use, the water must undergo some kind of treatment before the water has the required quality. The complexity of the treatment clearly depends on the state of the water supply, groundwater and surface water, and on the final application. The below model gives you an idea of the different water treatment steps needed to change the water from groundwater to ultra-pure water. From groundwater to drinking water One of the most important uses for water is drinking water. The required water quality is obtained in a pressure filter with individually composed layers of filter media for example for neutralization of aggressive carbon dioxide or for collection of iron, manganese, ammonium, and mechanical impurities. In order to dimension a filtration plant, the quality of the inlet water must be known. EUROWATER offers to make the necessary water analysis free of charge. From drinking water to "pure water" Probably every manufactured product uses water during some part of the production process. Industrial water use includes water for such purposes as fabricating, processing, washing, diluting, cooling, heating, or transporting a product, incorporating water into a product, or for sanitation needs within the manufacturing facility. EUROWATER is in a position to carry out projects within any industry and field of application. Visit eurowater.com to learn more about EUROWATER and our products.

The impurities of water

Inorganic salts/common ions Iron, manganese, ammonium, calcium, magnesium, sodium, bicarbonate, chloride, sulphate, fluoride, and nitrate Dissolved organic compounds Naturally occuring: humic acid Contaminating: pesticides, phenols, solvents, oil, and petrol Particles Sand, rust, and colloids Microorganisms Bacteria, viruses, algae, and fungi Gases Carbon dioxide, oxygen, methane, and hydrogen sulphide

From groundwater to pure water

Conductivity app. 30-800 S/cm

GROUNDWATER

Conductivity app. 30-800 S/cm

DRINKING WATER

Conductivity app. 30-800 S/cm

SOFTENED WATER

DEMINERALIZED WATER

Conductivity app. 5-30 S/cm

Conductivity app. 0.06-0.2 S/cm

ULTRA-PURE WATER

Removed elements Iron (Fe++) Manganese (Mn++) Ammonium (NH4+) Nitrite (NO2-) Aggressive carbon dioxide (CO2) Phosphorus (P) Arsenic (As+++) Hydrogen sulphide (H2S) Methane (CH4)

Removed elements Calcium (Ca++) Magnesium (Mg++)

Removed elements 98 % salts Potassium (K+) Sodium (Na+) Chloride (CI-) Nitrate (NO3-) Sulphate (SO4-- ) Silicic acid (SIO4-) Alkalinity (HCO3-)

Demineralization by ion exchange or EDI Removed elements Sodium (Na+) Chloride (CI-) Nitrate (NO3-) Sulphate (SO4-- ) Silicic acid (SIO4-) Alkalinity (HCO3-)

Reverse osmosis

Oxydation and filtration

Softening by ion exchange

What can be filtered and how?

The below table gives a survey of problems caused by selected impurities in the water, proven solutions, and the type of filter medium known to solve the problem in the best possible way. The table does not illustrate the complexity of the real world. If you encounter problems with the water, you are welcome to contact us for advice and guidance. EUROWATER has the necessary know-how of correct water treatment and guarantees quality and performance.

Impurities Aggressive CO2

Problems

Aggressive carbon dioxide corrodes concrete, piping, and hotwater tanks of black steel. The corrosion products make the water turbid and the water becomes red with rust and ochre. The carbon dioxide is often present in raw water in earth strata decient in calcium. Often, the worst problems of waterworks are iron and manganese because of discolouration of washing and sanitary appliances in buildings. Typical signs of elevated contents or iron and manganese in water are that the water becomes ochre-coloured or black with a metallic taste. The presence of ammonium indicates microbiological activity in the water, possibly resulting from fertilization, contamination, or from geology. Nitrite in raw water is often present as a residual product of an incomplete ammonium conversion. Nitrite also indicates contamination and microbiological activity. Contamination from pesticides is primarily a result of the use of the herbicides Caseron G and Prex G for weed control. The decomposition product 2.6 dichlorobenzamide BAM comes from dichlorobenil and chlorthiamid, which are the active substances of Caseron and Prex.

Solutions

Aggressive carbon dioxide can be neutralized in a pressure lter employing a calcium-containing lter medium. In special cases, aggressive carbon dioxide can be removed by degassing.

Filter media

Magno-Dol

Iron and manganese

After oxidation, iron and manganese can be ltered o in a pressure lter. The lter medium can be quartz sand, Nevtraco , or Hydrolit-MN.

Gravel

Ammonium and nitrite

Ammonium is converted into nitrite and afterwards nitrate through biological nitrication. Nitrication requires much oxygen and sucient lter medium.

Nevtraco

Pesticides and chlorine

BAM can be reduced in a pressure lter with a lter medium of activated carbon. Activated carbon is a natural product made from pit coal, wood, or coconut shells. Among other things, an activated carbon lter can remove free chlorine, pesticides, and organic solvents. Arsenic combines with iron and can be removed through co-precipitation with iron. If insucient iron is available in the raw water for this process, the iron content in the water can be increased by addition of iron chloride. Another approach is to remove arsenic by adsorption in a pressure lter with a special lter medium containing iron hydroxide. A recarbonation lter with various calciumcontaining lter media is employed for hardening of the water hardness, for example minerals have to be added to demineralized water before use.

Activated carbon

Arsenic

Arsenic is a natural element and related to certain geochemical environments. Arsenic is found in two forms, As(III) and As(V) of which As(III) is more poisonous and harder to remove from the water. According to WHO, arsenic poses serious health hazards when ingested and has been associated with skin cancer and various organ diseases.

Iron granulate

Adjustment of hardness

Calcium and magnesium mainly determine the total hardness in the water. A large content results in hard water, a small content in soft water. The hardness of the water is measured in German degrees of Hardness (GH).

Hydrolit CA

Suspended solids

If the water contains much suspended matter (high turbidity) such as surface water, there will be an increased need for frequent lter washing when traditional sand lters are employed.

A depth lter is also known as a multimedia lter because the solution combines surface and depth ltration in one pressure lter. The advantage is that a large volume of suspended matter and particles can be removed in one lter. The lter media quartz sand and hydro-anthracite are used for this purpose.

Hydro-anthracite

One plant many applications

EUROWATER has great expertise in developing reliable pressure filters with a long life and minimum need of maintenance and the applications are many.

Drinking water Waterworks and companies/households with own water boring needing drinking water quality use filtration in pressure filters to reduce contents of aggressive carbon dioxide, iron, manganese, ammonium, pesticides, and arsenic. Test samples are taken at the waterworks and at the consumers to check the water quality. The water must be clear and without colour, smell, or taste. If the water does not comply with the drinking water standards, filtration will often be the solution. Process water Industries are large consumers of clean water. Pressure filtration is often used as pretreatment before other water treatment, such as softening and demineralization. Reuse of process water is another example of application within industrial water treatment. Other applications Our filters are also applied to solve other problems such as: dechlorination filtration of seawater particle filtration recarbonation of demineralized water percolate filtration final filtration of wastewater

Arsenic removal by means of adsorption in waterworks. The solution comprises an automatic pressure lter type NSB 170 installed after open lters. Flow rate: 12 m/h.

Removal of iron, manganese, and ammonium in waterworks. Flow rate: 2 x 35 m/h. Solution: Pressure lters 4 x TFB 35 (primary and secondary lter) Oxidation equipment comprising compressor and aeration and control air system Blower and rinse pump for backwash Frequency-controlled discharge Complete plants with choice of external connection of maintenance personnel and watchmen via the internet Likewise alarming via SMS and generation of daily, weekly, monthly, quarterly, and yearly reports

The optimum solution

Selection of pressure filters depends on application, water quality, and water consumption. We are at your disposal for information and know-how about the right solution.

Our dimensioning of an individual plant is based on a water analysis combined with several other parameters that all influence the right solution: water quality, operational requirements, flow rate, filtration rate, and rinse frequency. Add to this: choice of materials, surface coating, and individually composed filter media. Flow rates up to 100 m/h In our standard programme, the flow rates of pressure filters range between 1-100 m/h per filter. These plants can solve filtration problems even in water with extreme pH-values and temperatures. The product programme covers a wide range of plant sizes making it possible to adapt the solution and thus your investment to the individual requirements for filtered water. If the pressure filter is used as a two-media filter or as a sand filter, the flow rate can be increased to 200 m/h. Own production We manufacture our own filters and that gives us the unique advantage of being able to control the entire production process from selection of supplier and welding of vessels and pipe system to assembly, pressure testing, and dispatch of the plant from our factory in Denmark. In this way, the plant complies with the high performance criteria of the industry. Pressure filter configuration The composition of the filter is individual based on the problem to be solved. The three most frequent configurations are: single filter, parallel filter, and primary and secondary filters. In single and parallel filters, the raw water is oxidized and filtered once. The advantages of parallel filters are enlarged capacity and the possibility of backwashing one filter while the other is in operation. In primary and secondary filters, the water is oxidized twice and also filtered twice. This method is used when single filtration is insufficient to reach the required water quality.

A great many consumers are situated so that connection to a large, municipal waterworks is not practical or desirable. The technical solution will of course be based on the same principles as the large water supplies. A pressure lter type NSB is ideal for small and medium drinking water supplies.

Manueltpressure filter type NS Manual trykfilter NS Ydelse fra 1 til 12 m3/time Flow rates from 1 to 12 m/h

Automatisk trykfilter NSB type NSB Automatic pressure filter Ydelse fra 1 til 12 m3/time m/h Flow rates from 1 to 12

Manuel/automatisk trykfilter TF/TFB TF/TFB Manual/automatic pressure filter type Ydelse op til 1001 to/timem/h Flow rates from m3 100

Efficient and reliable plants

Pressure filters are long-term investments and the requirements of EUROWATER for the best possible materials are a matter of course. Our time horizon will often be 25 years. Our filters have some significant advantages: easy to use, completely safe operation, and low wash water consumption.

Oxidation and aeration In our standard programme, the raw water is oxidized with atmospheric air to aid the precipitation processes and to oxidize the water to the regulations in force. The water is oxidized inside the pressure filter so that precipitations are not formed in the inlet piping. An integrated aeration and spraying system ensures optimum oxidation at the right place in the filtration process. External aeration can be supplied on request. Nozzle plate - optimum operation In the lower part of our pressure filters, there is a nozzle plate which brings some significant advantages. First of all, it ensures even distribution of load for optimum utilization of the filter medium. Furthermore, stagnant water is avoided - both during operation and during backwash, which is important in order to limit bacterial growth. Efficient backwash with air and water The special design with the nozzle plate also results in an efficient and even backwashing. The filter media is cleaned through backwashing at even intervals dependent on the quality of the raw water and the water consumption. To clean the filter, a strong air flow is blown upward through the filter to loosen embedded particles that afterwards are removed through backwashing with water. In special cases, it is necessary to use a combination washing with air and water. After backwash, the filter is again ready for use. Reuse of rinse water To save water, the rinse water can often be reused as raw water after filtration and UV disinfection. Compact pipe system The pipe system for manual and automatic pressure filters is either surface coated, hot-dip galvanized, of black steel, or alternatively of stainless steel or PE (polyethylene). The result from the water analysis is decisive for the selection of corrosionresistant materials. Our automatic pipe systems are constructed with one actuator for four valves, thereby minimizing the risk of incorrect valve positioning. Pressure filters with monitoring of operation and backwash have a pipe system equipped with monitoring of the valve positioning.

Oxidation and aeration of water Automatic air discharger

Spraying system

Type plate with serial number

Pressure gauge

Test cock

Pressure gauge

Test cock

Pneumatic actuator

Nozzle plate

Complete water treatment solution comprising a pressure lter and technical equipment for oxidation and backwashing.

Degassing of dissolved gases such as aggressive carbon dioxide, methane, and hydrogen sulphide is a precondition of optimum ltration. Photo: degassing and pressure ltration in brewery.

Surface coating The filter vessels are of steel and therefore extremely robust and less sensitive to changes in pressure. The composition of the water and the temperature determine the selection of surface coating. We offer a wide range of options with which we have great experience. Surface coating is classified as inside and outside surface coating. Normally, outside surface coating will be sand blasting and efficient priming followed by synthetic enamel in an optional RAL colour. Inside, the filter vessels can either be without coating or with coa-

tings suitable for different applications. Specific requirements for hygiene and drinking water approval can often be met. In most countries, such an approval is indispensable in order that the pressure filter can be used within water supply and food production. Several of the filter vessels are surface treated with polyethylene (PPA) both inside and outside. Thus, the filter vessels acquire the strength of steel combined with the strong corrosion resistance of a synthetic material. Hot-dip galvanizing or stainless steel are other options.

The Pressure Equipment Directive (PED)

All our pressure filter plants comply with the pressure equipment directive of the EU. This directive sets out common standards for the design and manufacture of pressure equipment.

User-friendly control All control solutions are custom-fitted to the requirements of the individual waterworks or industry. We offer a wide range of controls from simple programmers to PLC controls, solutions combining control, regulation and monitoring, web-based systems, and systems based on GSM communication.

SE10 and SE20 controls.

Control box.

After sales service

EUROWATER has an international sales and service organization. Our service cars are equipped with a broad range of spare parts, often enabling us to solve problems at site and in this way ensuring reliable operation of your water treatment plant. We offer service contracts and aroundthe-clock service. Pure water treatment since 1936 EUROWATER is an international group with subsidiary companies in 14 countries servicing our customers through 21 local offices. Moreover, we are represented in most of the other European countries through dealers that all are water treatment specialists.

DK

REN VANDBEHANDLING

INT., BE, NL, SK, CZ

P U R E WAT E R T R E AT M E N T

B40B-UKver1.0

Reduction of iron, manganese, aggressive carbon dioxide, and ammonium in waterworks. The solution comprises 5 x TFB 75 connected in parallel, blower, and rinse pump. Flow rate: 265 m/h. The colour of the tanks is custom-made.

You might also like

- Water Quality FaqDocument2 pagesWater Quality FaqMINETEKNo ratings yet

- Pre TreatmentDocument65 pagesPre TreatmentSagar SewlaniNo ratings yet

- Innovative Water & Waste Water Treatment Solutions ProviderDocument16 pagesInnovative Water & Waste Water Treatment Solutions ProviderA3S ENVIRONo ratings yet

- Wasseraufbereitung enDocument16 pagesWasseraufbereitung enVera VeroniqueNo ratings yet

- Water Treatment Plant Residue Management ModificationDocument33 pagesWater Treatment Plant Residue Management ModificationNitisha Rathore50% (2)

- MTPCL - WTP O&m ManualDocument62 pagesMTPCL - WTP O&m Manualm_ganesh1983100% (4)

- Drinking Water Treatment138 28742Document7 pagesDrinking Water Treatment138 28742vaglohrdNo ratings yet

- Aura Vitra Dennisa Antoni - Literasi Minggu Ke 11Document12 pagesAura Vitra Dennisa Antoni - Literasi Minggu Ke 11Aura DennisaNo ratings yet

- About Vasudev Water SolutionDocument12 pagesAbout Vasudev Water SolutionVasudev Water SolutionNo ratings yet

- Envicare - Product - Water Softner ADocument2 pagesEnvicare - Product - Water Softner AshaileshvcNo ratings yet

- Water Treatment Processes & ApplicationsDocument12 pagesWater Treatment Processes & ApplicationsSaravanan DayalanNo ratings yet

- Water management solutions for the pharmaceutical industryDocument44 pagesWater management solutions for the pharmaceutical industrySaurabh VijNo ratings yet

- Boilers - Water Treating 0Document26 pagesBoilers - Water Treating 0Mohammad RawoofNo ratings yet

- Advanced Waste Water TreatmentDocument1 pageAdvanced Waste Water TreatmentMoises FriasNo ratings yet

- EN - Water For Upstream Oil & Gas Industry - Degrémont IndustryDocument6 pagesEN - Water For Upstream Oil & Gas Industry - Degrémont IndustryDegrémont IndustryNo ratings yet

- Water For Injection-By AnamDocument20 pagesWater For Injection-By AnamMuhammad Bilal TahirNo ratings yet

- Water Tech GuideDocument43 pagesWater Tech GuideDevyani Gosavi100% (1)

- Water Conditioning- CPI-R RDocument25 pagesWater Conditioning- CPI-R Rdiwash ghimireNo ratings yet

- Basics Water Treatment For Hydrogen Mini Leaflet EUROWATERDocument20 pagesBasics Water Treatment For Hydrogen Mini Leaflet EUROWATERhayamalhareeshaNo ratings yet

- Waterland Water Treatment Environmental TechnologiesDocument36 pagesWaterland Water Treatment Environmental TechnologiesSiraj AL sharifNo ratings yet

- Water 2Document5 pagesWater 2Mayur SableNo ratings yet

- Industrial Water and Waste Water ManagementDocument15 pagesIndustrial Water and Waste Water ManagementsagarNo ratings yet

- 2000 LPH Reverse Osmosis Plant FRPDocument20 pages2000 LPH Reverse Osmosis Plant FRPt m murshedNo ratings yet

- Wastewater TreatmentDocument8 pagesWastewater TreatmentbekkuNo ratings yet

- Water Treatment - WikipediaDocument8 pagesWater Treatment - Wikipediaramthecharm_46098467No ratings yet

- Water Treatment Facilities and Processes Group IIIDocument24 pagesWater Treatment Facilities and Processes Group IIIJackie BeltranNo ratings yet

- Absolute Technology Company ProfileDocument4 pagesAbsolute Technology Company ProfilejbkrayanNo ratings yet

- Summary Statement - OLDDocument40 pagesSummary Statement - OLDankit7588No ratings yet

- Introduction To Industrial Wastewater Treatment SystemsDocument50 pagesIntroduction To Industrial Wastewater Treatment SystemsKaladorNo ratings yet

- Demineralization (DM) Water Treatment PlantsDocument5 pagesDemineralization (DM) Water Treatment PlantsmaniNo ratings yet

- Water DescalerDocument6 pagesWater DescalerAkshay AggarwalNo ratings yet

- Industrial Waste Water TreatmentDocument14 pagesIndustrial Waste Water Treatmentsijikarthik0% (1)

- WTP ManualDocument248 pagesWTP ManualAldren Delina Rivera89% (9)

- Drinking Water SolutionsDocument16 pagesDrinking Water SolutionsLiviu SomesanNo ratings yet

- Demineralization PlantsDocument7 pagesDemineralization PlantsPraveen KhatriNo ratings yet

- Proposed Water Refilling Station Engineering ReportDocument12 pagesProposed Water Refilling Station Engineering ReportJack MonterNo ratings yet

- ChE 517 Water PollutionDocument50 pagesChE 517 Water PollutionPrecious James100% (1)

- Question Bank For 1st IADocument9 pagesQuestion Bank For 1st IASubbu RajaNo ratings yet

- HA Tech - BrochureDocument20 pagesHA Tech - BrochureSunil KumarNo ratings yet

- Boiler Water TreatmentDocument22 pagesBoiler Water TreatmentTarun Patel100% (1)

- Osiris BrochureDocument4 pagesOsiris BrochureJoy Das MahapatraNo ratings yet

- PPTDocument45 pagesPPTThirumal ThirandasNo ratings yet

- QADocument7 pagesQAMiguel Magat JovesNo ratings yet

- Overview of Drinking Water and Wastewater Treatment ProcessesDocument33 pagesOverview of Drinking Water and Wastewater Treatment Processesyovanny familianNo ratings yet

- Water and Wastewater Treatment in The Alcoholic BeverageDocument33 pagesWater and Wastewater Treatment in The Alcoholic BeverageJeanne Kamille Evangelista PiniliNo ratings yet

- Components and Treatments of Oilfield Produced WaterDocument7 pagesComponents and Treatments of Oilfield Produced WatermoheauNo ratings yet

- Bgmea University of Fashion & TechnologyDocument37 pagesBgmea University of Fashion & TechnologyHassan Al MamunNo ratings yet

- Riva Appliances Pvt. LTD.: Deal In: Water & Waste Water ManagementDocument29 pagesRiva Appliances Pvt. LTD.: Deal In: Water & Waste Water ManagementVikrant ShelarNo ratings yet

- Utilizing Advanced Technologies to Revitalize Water ResourcesDocument12 pagesUtilizing Advanced Technologies to Revitalize Water ResourcesTong ChaipanyakulNo ratings yet

- Treatment of Water: 4 Process Will Be Used To Treat Waste Water in Steel IndustryDocument19 pagesTreatment of Water: 4 Process Will Be Used To Treat Waste Water in Steel IndustryReshab SahooNo ratings yet

- RESIDUALS PROCESSING AND DISPOSALDocument30 pagesRESIDUALS PROCESSING AND DISPOSALHeba YousifNo ratings yet

- Analysis System: SteamDocument22 pagesAnalysis System: SteamGaurav KumarNo ratings yet

- Water & Wastewater EngineeringDocument12 pagesWater & Wastewater EngineeringJan-Louis Reynders50% (2)

- 20140721gtpfactsheet PDFDocument3 pages20140721gtpfactsheet PDFMohit RajaiNo ratings yet

- Water Quality LectureDocument118 pagesWater Quality Lectureasabei084No ratings yet

- IGNTU EContent 673390684976 B.SC EnvironmentalSciences 2 PallaviDas EnvironmentalPollutionandHumanHealth 3Document34 pagesIGNTU EContent 673390684976 B.SC EnvironmentalSciences 2 PallaviDas EnvironmentalPollutionandHumanHealth 3Riyasath ahamedNo ratings yet

- DWGB 2 11 PDFDocument4 pagesDWGB 2 11 PDFmugunth.jcNo ratings yet

- Company ProfileDocument10 pagesCompany ProfilesamirNo ratings yet

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisFrom EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisRating: 5 out of 5 stars5/5 (1)

- Lifeline 1Document4 pagesLifeline 1shalabyahmedNo ratings yet

- 009 32 - Fy15 CH2Document89 pages009 32 - Fy15 CH2shalabyahmed100% (1)

- Surface Preparation Standards Comparison ChartDocument2 pagesSurface Preparation Standards Comparison ChartajuhaseenNo ratings yet

- Brief Profile Project New PDFDocument16 pagesBrief Profile Project New PDFshalabyahmedNo ratings yet

- Tds - Hydrogal 1133Document5 pagesTds - Hydrogal 1133shalabyahmedNo ratings yet

- Biocide BrochureDocument24 pagesBiocide BrochureshalabyahmedNo ratings yet

- Introduction To FAN SELECTION: Model DesignationDocument5 pagesIntroduction To FAN SELECTION: Model Designationradreamer14No ratings yet

- USDOD Protective Coatings and PaintsDocument249 pagesUSDOD Protective Coatings and PaintsSpace_Hulker100% (4)

- Wire Arc Additive ManufacturingDocument8 pagesWire Arc Additive ManufacturingshalabyahmedNo ratings yet

- Chemical CleaningDocument32 pagesChemical Cleaningkae kae100% (2)

- DICOM Viewer V3.1 User GuideDocument24 pagesDICOM Viewer V3.1 User GuideshalabyahmedNo ratings yet

- TD107 USCG Certification PDFDocument4 pagesTD107 USCG Certification PDFshalabyahmedNo ratings yet

- Tds - Hydrogal 1133Document5 pagesTds - Hydrogal 1133shalabyahmedNo ratings yet

- 2817Document7 pages2817shalabyahmedNo ratings yet

- Introduction To FAN SELECTION: Model DesignationDocument5 pagesIntroduction To FAN SELECTION: Model Designationradreamer14No ratings yet

- Fire DampersDocument1 pageFire DampersshalabyahmedNo ratings yet

- Ac Compressor OperationDocument3 pagesAc Compressor OperationshalabyahmedNo ratings yet

- TD107 Operation Manual PDFDocument42 pagesTD107 Operation Manual PDFshalabyahmedNo ratings yet

- QRAEII DatasheetDocument2 pagesQRAEII DatasheetshalabyahmedNo ratings yet

- Marine DeionizationDocument2 pagesMarine DeionizationshalabyahmedNo ratings yet

- RKI Eagle 2Document272 pagesRKI Eagle 2shalabyahmedNo ratings yet

- QRAEII DatasheetDocument2 pagesQRAEII DatasheetshalabyahmedNo ratings yet

- C816Document2 pagesC816shalabyahmedNo ratings yet

- ConfinedDocument2 pagesConfinedshalabyahmedNo ratings yet

- QRAE II - Pump or DiffusionDocument2 pagesQRAE II - Pump or DiffusionshalabyahmedNo ratings yet

- FlashDocument15 pagesFlashshalabyahmedNo ratings yet

- Classes of Biomaterials: Ceramics, Glasses and Glass-CeramicsDocument47 pagesClasses of Biomaterials: Ceramics, Glasses and Glass-CeramicsZeynu KulizeynNo ratings yet

- Course Plan BHP YearDocument15 pagesCourse Plan BHP YearZara GL -Escritora-Ensayista. Asesora MarketingNo ratings yet

- NEET OBJECTIVE EXAMINATION on ElecrostaticsDocument8 pagesNEET OBJECTIVE EXAMINATION on ElecrostaticsAlfiya ShereefNo ratings yet

- Era Pro-72hc 575wDocument1 pageEra Pro-72hc 575wjonatasrbassessoriaNo ratings yet

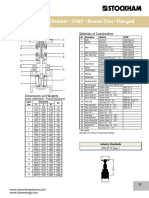

- 3882 StockhamDocument1 page3882 StockhamMitra Karya SejahteraNo ratings yet

- ALUMINIUMTECHNOLOGIES Week3Document84 pagesALUMINIUMTECHNOLOGIES Week3HaiLuuNo ratings yet

- Seminar Report 2Document23 pagesSeminar Report 2Mayank S.H88% (8)

- Phys HSSC 2 Model PaperDocument7 pagesPhys HSSC 2 Model PaperArooNo ratings yet

- Darshan Ranganathan - A Tribute: Personal NewsDocument3 pagesDarshan Ranganathan - A Tribute: Personal NewsDeepak House Videos collectionNo ratings yet

- PoteniometryDocument85 pagesPoteniometrymalyaaNo ratings yet

- Libro 4 PDFDocument8 pagesLibro 4 PDFCynthia Jazmin Flores CisnerosNo ratings yet

- Specimen-Paper-4 PhysicsDocument19 pagesSpecimen-Paper-4 PhysicsBenaDea LubbeNo ratings yet

- EPOM F OBE ASSIGNMENT Shuvro Sankar Sen 18-37524-1Document7 pagesEPOM F OBE ASSIGNMENT Shuvro Sankar Sen 18-37524-1Shuvro Sankar SenNo ratings yet

- Final - Chemical ISFETDocument23 pagesFinal - Chemical ISFETarnabianNo ratings yet

- Separating The Components of Panacetin PrelabDocument5 pagesSeparating The Components of Panacetin PrelabAmy LaPointe100% (2)

- CHEMISTRY Form 4 CHAPTER 4-The Periodic TableDocument47 pagesCHEMISTRY Form 4 CHAPTER 4-The Periodic TableAngie Kong Su MeiNo ratings yet

- 4.1 Laboratory Report Ideal Gas LawDocument5 pages4.1 Laboratory Report Ideal Gas Lawalejandro pederioNo ratings yet

- Momento Linear e Centro de Massa: Resolução de Problemas de MecânicaDocument4 pagesMomento Linear e Centro de Massa: Resolução de Problemas de MecânicaThales FreireNo ratings yet

- Astm D2434 PDFDocument6 pagesAstm D2434 PDFRoy Franco Velasco100% (2)

- Earth Science: Physical SettingDocument24 pagesEarth Science: Physical SettingKris TineNo ratings yet

- Chemistry: New 21st CenturyDocument9 pagesChemistry: New 21st CenturyAnson Ka Kin ChanNo ratings yet

- Engineering Dynamics Problem Set 9Document4 pagesEngineering Dynamics Problem Set 9700tyNo ratings yet

- Leaching Copper Sulfide OreDocument3 pagesLeaching Copper Sulfide OreJHPNo ratings yet

- Comets Asteroids and MeteorsDocument44 pagesComets Asteroids and Meteorsapi-275797426No ratings yet

- Bond Energy - Wikipedia, The Free EncyclopediaDocument2 pagesBond Energy - Wikipedia, The Free EncyclopediaSatyendra Nath PandeyNo ratings yet

- Shaik CVDocument7 pagesShaik CVaazshaik5861No ratings yet

- Laporan Pasca Kulit Kecil Dan Kulit Besar Up Glazz UpholsteryDocument18 pagesLaporan Pasca Kulit Kecil Dan Kulit Besar Up Glazz UpholsteryKhusnul KhotimahNo ratings yet

- CSIR-CFTRI Mysuru M.Sc Food Tech Entrance SyllabusDocument3 pagesCSIR-CFTRI Mysuru M.Sc Food Tech Entrance SyllabusBarnali DuttaNo ratings yet

- N.pip - GSP.001 - 3B Piping General SpecificationDocument145 pagesN.pip - GSP.001 - 3B Piping General SpecificationAiskel PazNo ratings yet

- Sdarticle 30Document165 pagesSdarticle 30Corina EsanuNo ratings yet