Professional Documents

Culture Documents

Dry Transformer Manual

Uploaded by

bacuoc.nguyen356Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dry Transformer Manual

Uploaded by

bacuoc.nguyen356Copyright:

Available Formats

Dry transformer

Operation instruction

Zhejiang Jiangshan Transformer Co.,Ltd (Zhejiang Jiangshan Transformer factory)

This Installation and Operation Instruction applies to on-load/off-load tap changer epoxy resin casting thin-insulation dry transformer with 5000KVA ,35KV and below.

Characteristic and purposes

The resin casting, thin-insulation, dry transformer manufactured by our factory have adopted advanced foreign technique, workmanship and equipments. The technical performance index completely reach the similar product standard of Italian MARNATE company, totally in accordance with GB6450-86GB/T10228-1997 and relevant IEC standards. The product features high energy-efficiency, small volume, lightness, anti-humidity,anti-impulse, inflaming retarding, small partial-discharge, high overload capacity, automatic temperature-regulating and so on. Its widely be used in power transportation and transformation system, hotels and restaurants, high-rises, commercial center, stadium, petro-chemical works, subway, railway, airport, oil derrick at sea and so on, especially installed on the limit-space, nearness to load center and areas which have special fire-proof requirements. This fully demonstrate its superiority in volume and inflammation retarding.

Usage condition and installation

1 Cooling methods could be divided into two classes: air-cooling(AN), Fan cooling(AF) 2 Shielding Level: IP00, IP20(outside) and so on 3 Ambient temperate: no more than 40. Altitude no more than 1000m. if the ambient temperature exceeds 40, or altitude 1000m, some adjustment must be done according to GB6450-86 and relevant regulations. 4 The insulating level of produce is F. 5 The product ,commonly, is installed indoors. The installation place should be clean , ventilated, enjoying proper atmosphere. If the transformer is installed underground or any other area which has limited space, ventilation must be guaranteed. For 1 KW loss of our product, there must be 4 m3 ventilation volume each minute. 6 when installing, there should be 300mm gap between the product and walls or other barrier, the gas between transformers 300mm. But for the electric switch box and other place with limited space, that distance could be adjusted. 7 In general, the transformer could be placed directly in the usage field, after checkup, it could be put into operation. For the filed with proof-earthquake requirements and other special conditions, the base for transformer installation should have bolts, when installing, disassemble the wheel of carriage, fix the transformer through bolts.

Shipment

1 The weather factory must be taken into account when shipping. The bad weather should be avoided. If shipping meets storm, necessary measures should be taken to prevent snow or rain from the transformer. Shipment cannot be done when ambient temperature is -5 and below. 2 When shipping, the slant angle should be no more than 30.

3 The product commonly is shipped totally. No disassembly for parts. If some accessories indeed need to be disassemble owing to weather factor, after the shipment, the customer should check the items in light of the accessories list, and install the items accordingly. For the acceleration , should be 1.0g horizontally, 1.5g vertically. 4 For the transformer with carriage, the wheel could be turned at 90. In order to prevent the motion of transformer in the shipment, commonly, the wheel was fixed on the wheel carrier reversely. 5 when lifting the transformer with packing case., the wire rope should be bound on the four padding blocks of the case, the angle between the wire rope and the horizon should be no more than 60. If no packing case , or the transformer is lifted directly from the case, all the lifting plate on the core&windings assembly should be put into use. If owing to lifting height limit, the beam could be used to hoist the transformer.

checkup and Inspection

when the transformer arrive at the final destination, the following checkup items should be done: 1 whether the nameplate is in accordance with the requirements, for example, designation, rated voltage, connection symbol, short circuit impedance and so on. 2 pads(if have ) should be cleaned up. Check whether there is any damage, displacement for all parts. Whether Joints are rickety, ruptured. Make sure no other object, dirty things. 3 whether the accessories ,parts are in accordance with packing list. 4 After the checkup, if no operation at once, the transformer should be re-packed, placed in the clean, ventilated inside area to prevent theft and any damage.

Checkup before operation

Following checks must be done before operation of the transformer. 1 check all the fasteners, joints, etalons, screw each one. 2 check whether the parts disassembled before is fixed correctly, make sure no other objects in the core&windings assembly 3 please read the instructions about motor fan, devices about temperatures and so on, make sure all this equipments and its accessory should be operated normally. 4 Check whether the cover ,iron core of the transformer is earthed permanently.

Tests before operation

Following tests should be made before operation: 1 Measure the winding D.C. resistance 2 Check whether the iron core is earthed reliably. 3 Test on insulating resistance, the value should meet as follows: High voltage -----Low Voltage, earth300M

Low voltage ------ earth 100M When in dry condition, its easy to reach the value of insulating resistance, but when in humid condition, the value could be drop. In general, if insulating resistance value of each rated voltage 100V could be bigger than 2 M(reading for one minute 25 ), it could meet the operation requirements. If the condensed dew come to the transformer due to great humidity, It must be dry up before voltage withstand test or operation.

4. for dry type power transformers with OLTC, test and examine OLTC before operation starts. 5. the voltage of external working frequency pressure-bearing experiment should be 85% of the delivery test voltage, duration is 5 minutes.

Put into operation

1. voltage regulation taps should be adjusted properly before operation, use temperature controll and temperature displaying instruments in a correct way. Taking operating reliability and observation convenience into consideration, temeperature icontroller is advised to be installed on screen counter, hung and fixed on the wall or on the isolated barrier block to ensure reading accuracy and personnel safety. Please see details in temperature controller instructions. (1). For no-load voltage regulation, end connectors of on-load voltage regulation taps should be connected to corresponding positions as per nameplate. (2). For on-load voltage regulation, see OLTC manual. (3). For power transformers with temperature controll panel and temperature displaying instrument, see their manuals respectively. 2. when operating, load should be increased step by step, sudden high load is forbidden. 3. generally speaking, the power transformer can restart without any extra measure after the operation. But in the case of condensation phenomena, need a dry processing before restart.

Maintenance

Regular examination and maintenance is necessary for normal operation: 1. if power transformer site is dry and clean, examination and maintenance should be done once a year or a bit longer. But if the dustiness index at site goes beyond the environmental protection range or polluted by photochemical smog, examination must be done every three to six months. 2. during examination process, clean it if too much dust collect to keep ventilation and avoid insulation breakdown. Especially clean the insulators, top and bottom

4

part of windings, clean dust in vent airway by vacuum cleaner. 3. check tightness of fastener and connecting fittings, rustiness and corrosion of conductive parts and other parts. Observe if there is creepage trace and carbonization phenomena on the surface of insulation pieces, and take measure when necessary.

Safety tips

1. before putting into operation of assembled power transformer, if its uncovered, a isolated barrier block is a must to avoid accidents. 2. after the power transformer is put into operation, no touch to the main body to avoid accidents. 3. the shortest distance between resin molded windings and house walls, see as below supplement: power transformers being over-load temporarily. Over-load capacity of power transformers has some relationship with winding time constant, initial load and circumstance temperature. See over-load graph of this product as below:

Note: for dry type power transformer with both self-cooling and air-cooling methods, if its load goes beyond self-cooling rated value and winding temperature goes higher than control value, temperature controller will make the fan work, supply the heat delivery surface with wind, strengthen the cooling effect and then lower the winding temperature, it can increase the capacity of power transformer for a short time. It is the operation in air-cooling way. But the power transformer is no good being operated this way continuously for a long time.

Zhejiang Jiangshan Transformer Co.,Ltd

Address84 , Hushan ROAD, JIANGSHAN ZHEJAING

Telephone: 0086-570 4231722 4231723 4231686 Fax 0086-5704231142 4221362 Website//www.jsbtransformer.com Post code324100

You might also like

- Corrosive Sulphur in Large Transformers Impact, Quantification and Detection 腐蚀性硫 论文 好Document143 pagesCorrosive Sulphur in Large Transformers Impact, Quantification and Detection 腐蚀性硫 论文 好Jicheng PiaoNo ratings yet

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsFrom EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsNo ratings yet

- Corrosive Sulfur Effects in Transformer Oils and Remedial ProceduresDocument9 pagesCorrosive Sulfur Effects in Transformer Oils and Remedial Proceduresandres100% (1)

- Auto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenFrom EverandAuto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenRating: 4 out of 5 stars4/5 (2)

- Transformer CastingDocument10 pagesTransformer CastingJanmejaya MishraNo ratings yet

- Arc Control in Circuit Breakers: Low Contact Velocity 2nd EditionFrom EverandArc Control in Circuit Breakers: Low Contact Velocity 2nd EditionNo ratings yet

- Doble Laboratory TestingDocument2 pagesDoble Laboratory TestingSimon KoutouaNo ratings yet

- Oil Preservation System, Dehydrating Breather: PTAP-ADB934 IZUA 4674-210 Installation GuideDocument8 pagesOil Preservation System, Dehydrating Breather: PTAP-ADB934 IZUA 4674-210 Installation GuidemersiumNo ratings yet

- Transformer ReportDocument39 pagesTransformer ReportSHAROON SARDAR GHULAMNo ratings yet

- Inverter Transformers For Photovoltaic (PV) Power Plants: Generic GuidelinesDocument9 pagesInverter Transformers For Photovoltaic (PV) Power Plants: Generic GuidelinesChandu GowdaNo ratings yet

- Guide To Low Resistance TestingDocument19 pagesGuide To Low Resistance TestingManish KhakhraNo ratings yet

- Sverker 760Document6 pagesSverker 760Junior Ramirez ReyesNo ratings yet

- Application of Epoxy Resins in Electrical ApparatusDocument8 pagesApplication of Epoxy Resins in Electrical ApparatusDulon22No ratings yet

- Phase Displacement Between HV and LV WindingsDocument8 pagesPhase Displacement Between HV and LV WindingspawannhpcNo ratings yet

- Ferroresonance Explained - Incident Prevention Article - 100212Document2 pagesFerroresonance Explained - Incident Prevention Article - 100212Anonymous 980dmQfwmiNo ratings yet

- How The Efficiency of Radiator For Transformer Cooling Is MeasuredDocument4 pagesHow The Efficiency of Radiator For Transformer Cooling Is MeasuredAbdulyunus AmirNo ratings yet

- Actom High Voltage Outdoor DisconnectorsDocument8 pagesActom High Voltage Outdoor Disconnectorsjoydeep_d3232No ratings yet

- CCVT Test Guide May 2010Document7 pagesCCVT Test Guide May 2010Shahid IqbalNo ratings yet

- Interpretation of Sweep Frequency Response AnalysiDocument8 pagesInterpretation of Sweep Frequency Response AnalysiRyan JohnNo ratings yet

- Operacion Recloser RoclwillDocument54 pagesOperacion Recloser RoclwillChristian Vasquez MedranoNo ratings yet

- Breaker ManualDocument4 pagesBreaker ManualamsaveniNo ratings yet

- Problems in Overall Differential Protection of Generator and GTDocument4 pagesProblems in Overall Differential Protection of Generator and GTsirsa11100% (1)

- Power Factor - Calculation and Power Factor Improvement - Electrical4uDocument6 pagesPower Factor - Calculation and Power Factor Improvement - Electrical4uANo ratings yet

- Constant Voltage Transformer and StabilizerDocument5 pagesConstant Voltage Transformer and StabilizerABDUL HAMEEDNo ratings yet

- Cigre 1-2015 PDFDocument11 pagesCigre 1-2015 PDFbenlahnecheNo ratings yet

- Technical Information CabelsDocument126 pagesTechnical Information CabelsZvonko BogdanNo ratings yet

- 15 Transformer Voltage Control and Tap Changing: Booster Transformer Booster TransformerDocument9 pages15 Transformer Voltage Control and Tap Changing: Booster Transformer Booster TransformerFaizan 'Fezar' RabbaniNo ratings yet

- Definition of Basic Insulation Level BILDocument7 pagesDefinition of Basic Insulation Level BILPierre Enrique Carrasco FuentesNo ratings yet

- ALSTOM Reverse Power Relay CCUM 21 High ResDocument4 pagesALSTOM Reverse Power Relay CCUM 21 High ResArun KumarNo ratings yet

- Transformer DesignDocument26 pagesTransformer DesignVinay KumarNo ratings yet

- RewindingDocument9 pagesRewindingBlack StarNo ratings yet

- Siemens Timer CatalogDocument4 pagesSiemens Timer Catalogshamim93146No ratings yet

- Distribution Transformers SiemensDocument148 pagesDistribution Transformers SiemensCu TíNo ratings yet

- On Load Tap ChangerDocument2 pagesOn Load Tap Changerashish_patel111No ratings yet

- GW4-72.5/126/145D (W) Outdoor HV Disconnect Switch: Item Unit CJ6B Motor CS17 ManualDocument3 pagesGW4-72.5/126/145D (W) Outdoor HV Disconnect Switch: Item Unit CJ6B Motor CS17 ManualTerry HerreNo ratings yet

- On-Load Tap-Changers: Selection GuideDocument8 pagesOn-Load Tap-Changers: Selection GuideRey ArthurNo ratings yet

- A 62-Transformers For Photovoltaic Solar Projects - Part 1 - LinkedInDocument13 pagesA 62-Transformers For Photovoltaic Solar Projects - Part 1 - LinkedInanuragpugaliaNo ratings yet

- Chargers Technical ManualDocument12 pagesChargers Technical Manualpriyanka236100% (1)

- Book 22Document35 pagesBook 22Mohd SalehNo ratings yet

- Sri RamachandranDocument7 pagesSri RamachandranNavaneethakrishnan MurugesanNo ratings yet

- Introduction To Instrument TransformersDocument20 pagesIntroduction To Instrument TransformersAbdul'Azeez Stanley IgweNo ratings yet

- Auto Transformer StarterDocument13 pagesAuto Transformer StarterarunNo ratings yet

- Indent No. Annexure - 1 Technical Specification of Alstom / Areva/ Make Protection Relay With Case. 1. CDG31 As Below Specs 4 NosDocument7 pagesIndent No. Annexure - 1 Technical Specification of Alstom / Areva/ Make Protection Relay With Case. 1. CDG31 As Below Specs 4 NosYaseen SagarNo ratings yet

- Partial Discharge TestDocument9 pagesPartial Discharge Testsadeeskumar.dNo ratings yet

- Electrostatic Shield, Earth Screen Usefulness in Transformer (Bet'n HV-LV)Document6 pagesElectrostatic Shield, Earth Screen Usefulness in Transformer (Bet'n HV-LV)aocalayNo ratings yet

- Power Factor Dry Type Transformer TestingDocument12 pagesPower Factor Dry Type Transformer TestingNADEEM KHANNo ratings yet

- Tap ChangerDocument10 pagesTap ChangerusefiNo ratings yet

- Automatic Voltage Regulating Relay EE 301-M: Instruction ManualDocument22 pagesAutomatic Voltage Regulating Relay EE 301-M: Instruction ManualnarendragahlotNo ratings yet

- Working Principle of A TransformerDocument4 pagesWorking Principle of A TransformerGyan BshnNo ratings yet

- Huaming OnLoadTapChanger ManufacturerDocument64 pagesHuaming OnLoadTapChanger ManufacturermuzaffererNo ratings yet

- SS-4 HV TestingDocument1 pageSS-4 HV TestingSoumya BhowmickNo ratings yet

- CA VD4-50kA (EN) Y 1VCP000001Document144 pagesCA VD4-50kA (EN) Y 1VCP000001linh tran100% (1)

- Transformer PD OnlineDocument12 pagesTransformer PD Onlinesumpeno enoNo ratings yet

- CP TD1 Reference ManualDocument158 pagesCP TD1 Reference Manualjon1224No ratings yet

- CB Timing 1234Document1 pageCB Timing 1234Akshay Gatkal100% (2)

- Disconnector Contact Condition PDFDocument130 pagesDisconnector Contact Condition PDFipraoNo ratings yet

- Vagm 22Document4 pagesVagm 22AONLANo ratings yet

- Dry Type MiniSub Manual With NGRDocument12 pagesDry Type MiniSub Manual With NGRroni pardamean sijabatNo ratings yet

- Power Transformer MaintenanceDocument27 pagesPower Transformer MaintenanceBIKASH SAHNo ratings yet

- I. I NtroductionDocument10 pagesI. I Ntroductionbacuoc.nguyen356No ratings yet

- Modelling and Regulation of Dual-Output LCLC Resonant ConvertersDocument6 pagesModelling and Regulation of Dual-Output LCLC Resonant Convertersbacuoc.nguyen356No ratings yet

- Chen ChienLiang D 2011 PDFDocument152 pagesChen ChienLiang D 2011 PDFbacuoc.nguyen356No ratings yet

- Cavalcante PESC05 PDFDocument7 pagesCavalcante PESC05 PDFbacuoc.nguyen356No ratings yet

- L44 5807 PDFDocument27 pagesL44 5807 PDFbacuoc.nguyen356No ratings yet

- DPR Solar PDFDocument5 pagesDPR Solar PDFbacuoc.nguyen356No ratings yet

- 1672 6340 (2012) 01 0007 08 PDFDocument6 pages1672 6340 (2012) 01 0007 08 PDFbacuoc.nguyen356No ratings yet

- 5 Section V SJVN Technical Specification Rev 1 PDFDocument195 pages5 Section V SJVN Technical Specification Rev 1 PDFbacuoc.nguyen356No ratings yet

- String Monitoring Unit For Megawatt Solar Power PlantsDocument6 pagesString Monitoring Unit For Megawatt Solar Power Plantsbacuoc.nguyen356No ratings yet

- 012 PRC Tacr PDFDocument474 pages012 PRC Tacr PDFbacuoc.nguyen356No ratings yet

- ABB Scheda - Tecnica - PVS980 - 0 - INVERTER 2MW PDFDocument6 pagesABB Scheda - Tecnica - PVS980 - 0 - INVERTER 2MW PDFbacuoc.nguyen356No ratings yet

- Solar Inverters and Inverter Solutions For Power Generation Brochure 3AXD50000039235 RevB Lowres PDFDocument44 pagesSolar Inverters and Inverter Solutions For Power Generation Brochure 3AXD50000039235 RevB Lowres PDFbacuoc.nguyen356No ratings yet

- Surface CareDocument18 pagesSurface CareChristi ThomasNo ratings yet

- Case Notes All Cases Family II TermDocument20 pagesCase Notes All Cases Family II TermRishi Aneja100% (1)

- Application of ARIMAX ModelDocument5 pagesApplication of ARIMAX ModelAgus Setiansyah Idris ShalehNo ratings yet

- Awais Inspector-PaintingDocument6 pagesAwais Inspector-PaintingMohammed GaniNo ratings yet

- Business Testimony 3Document14 pagesBusiness Testimony 3Sapan BanerjeeNo ratings yet

- Ramp Footing "RF" Wall Footing-1 Detail: Blow-Up Detail "B"Document2 pagesRamp Footing "RF" Wall Footing-1 Detail: Blow-Up Detail "B"Genevieve GayosoNo ratings yet

- Algorithm - WikipediaDocument34 pagesAlgorithm - WikipediaGilbertNo ratings yet

- Interest Rates and Bond Valuation: All Rights ReservedDocument22 pagesInterest Rates and Bond Valuation: All Rights ReservedAnonymous f7wV1lQKRNo ratings yet

- Residential BuildingDocument5 pagesResidential Buildingkamaldeep singhNo ratings yet

- Hitt PPT 12e ch08-SMDocument32 pagesHitt PPT 12e ch08-SMHananie NanieNo ratings yet

- Introduction To Wireless and Mobile Systems 4th Edition Agrawal Solutions ManualDocument12 pagesIntroduction To Wireless and Mobile Systems 4th Edition Agrawal Solutions Manualethelbertsangffz100% (34)

- CNG Fabrication Certificate16217Document1 pageCNG Fabrication Certificate16217pune2019officeNo ratings yet

- Kompetensi Sumber Daya Manusia SDM Dalam Meningkatkan Kinerja Tenaga Kependidika PDFDocument13 pagesKompetensi Sumber Daya Manusia SDM Dalam Meningkatkan Kinerja Tenaga Kependidika PDFEka IdrisNo ratings yet

- Stock Prediction SynopsisDocument3 pagesStock Prediction SynopsisPiyushPurohitNo ratings yet

- COGELSA Food Industry Catalogue LDDocument9 pagesCOGELSA Food Industry Catalogue LDandriyanto.wisnuNo ratings yet

- A Comparison of Pharmaceutical Promotional Tactics Between HK & ChinaDocument10 pagesA Comparison of Pharmaceutical Promotional Tactics Between HK & ChinaAlfred LeungNo ratings yet

- IEEE Conference Template ExampleDocument14 pagesIEEE Conference Template ExampleEmilyNo ratings yet

- Practical GAD (1-32) Roll No.20IF227Document97 pagesPractical GAD (1-32) Roll No.20IF22720IF135 Anant PatilNo ratings yet

- Dynamics of Interest Rate and Equity VolatilityDocument9 pagesDynamics of Interest Rate and Equity VolatilityZhenhuan SongNo ratings yet

- Hierarchy of The Inchoate Crimes: Conspiracy Substantive CrimeDocument18 pagesHierarchy of The Inchoate Crimes: Conspiracy Substantive CrimeEmely AlmonteNo ratings yet

- Agreement Deed BangladeshDocument8 pagesAgreement Deed BangladeshVabna EnterpriseNo ratings yet

- BreezeAIR 8000 Data SheetDocument2 pagesBreezeAIR 8000 Data Sheetalfasukarno100% (1)

- Amazon Case StudyDocument22 pagesAmazon Case StudySaad Memon50% (6)

- Quality in CRDocument10 pagesQuality in CRkaushikcrNo ratings yet

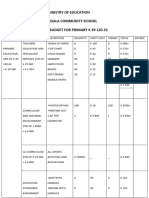

- Ministry of Education Musala SCHDocument5 pagesMinistry of Education Musala SCHlaonimosesNo ratings yet

- (ENG) Visual Logic Robot ProgrammingDocument261 pages(ENG) Visual Logic Robot ProgrammingAbel Chaiña Gonzales100% (1)

- Outage Analysis of Wireless CommunicationDocument28 pagesOutage Analysis of Wireless CommunicationTarunav SahaNo ratings yet

- Aman 5Document1 pageAman 5HamidNo ratings yet

- Reference: Digital Image Processing Rafael C. Gonzalez Richard E. WoodsDocument43 pagesReference: Digital Image Processing Rafael C. Gonzalez Richard E. WoodsNisha JosephNo ratings yet

- Electrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EFrom EverandElectrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70ERating: 3 out of 5 stars3/5 (6)

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemFrom EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo ratings yet

- Workbook to Accompany Maintenance & Reliability Best PracticesFrom EverandWorkbook to Accompany Maintenance & Reliability Best PracticesRating: 3.5 out of 5 stars3.5/5 (3)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesFrom EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesNo ratings yet

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- Fire Fighting Pumping Systems at Industrial FacilitiesFrom EverandFire Fighting Pumping Systems at Industrial FacilitiesRating: 4.5 out of 5 stars4.5/5 (3)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- An Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsFrom EverandAn Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsNo ratings yet

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- Casing and Liners for Drilling and Completion: Design and ApplicationFrom EverandCasing and Liners for Drilling and Completion: Design and ApplicationRating: 5 out of 5 stars5/5 (3)

- Healthy Buildings: How Indoor Spaces Drive Performance and ProductivityFrom EverandHealthy Buildings: How Indoor Spaces Drive Performance and ProductivityRating: 5 out of 5 stars5/5 (2)

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)