Professional Documents

Culture Documents

Ouzine

Uploaded by

Nima ArvinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ouzine

Uploaded by

Nima ArvinCopyright:

Available Formats

Full name Date and place of birth Nationality Marital status Phone E-mail 1981-1982 1982-1983 1984-1985 1985-1987

1998-1999

: Ahmad OUZINE : 1961 in Errachidia -MORROCO : Moroccan : Married father of 4 children : 00 212 6 68.96 34 10 (cell) : ouzine2999@yahoo.fr

EDUCATION

t Baccalaureate at applied science from Mohamed V High School in Goulmima. Morocco t First year of a BSc at Physics and chemistry. t Second year of a BSc at Physics and chemistry. t Preparing a university certificate of technology: industrial chemistry specialty at Mines Institute of Marrakech. Morocco t Preparing a specialized superior study certificate specialized at Valorisation of underground resources Polytechnic National Institute of the Lorraine, (INPL-Nancy France). t An Applied Science Baccalaureate, Mohamed V High School in Goulmima. Morocco t A university superior studies certificate in physics and chemistry specialty from School of Sciences, Moulay Ismail University in Mekns. Morocco t A university degree in technology Industrial chemistry specialty, with distinction. The mines Institute. Marrakech, Morocco t A postgraduate degree specialised at the valorisation of underground resources with distinction. Polytechnic National Institute of the Lorraine. t Diploma of expert in valorisation of underground resources. Mines Institute of Nancy - France.

DIPLOMAS

1982 1984 1987 1999

VOCATIONAL TRAINING

Within the context of my technical training: various training course at company are carried 1985 1986 1987 t Worker's training course at the manganeses mine company (Ouarzazate). t Technical training course at Morocco phosphorus II at Office Chrifien de Phosphate, Morocco t Study-end training course at the copper mine of Managem- mining holding of ONA Pilot-study of the copper leaching process: copper leaching parameters:- sulphuric acid consumption Dilution-pH- Leaching time /copper cementation parameters: pH-iron consumption) Subject of oxides copper project in 1988 t Study of the Imiter silver cementation parameters with zinc dust (problems of silver grade decrease in the cement)

Tests of the silver cementation in the cyanide environment- Analysis of the industrial data characterization of cement samples.

1999

Improvement obtained per utilization of the lead nitrate at the cementation reaction (Element of the reaction activation) 1988.1999 t Head foreman at Silver plant of SMI Metallurgic company of Imiter (company of BRPM then MANAGEM (mining holding of ONA) Silver valuing / cyanide leaching and cementation per Merrill Crow process. Primary and secondary crusher grinding- gravity separation- flotation-cyanide leaching-solid and liquid separation on the thickening clarification of the solutioncementation of the silver on the zinc dust acid leach of the gravity Concentrates-calcinations of the products and silver melting. t Head foreman of the plant Number 1 project created in 1969 - 85.000 t /year t Head foreman of the plant Number 2 project created in 1987 -: extension in 1984. Capacity 200.000 ton/year 500.000 ton/year. t Responsible of study and treatment test unit: tests and studies of the processs improvements: Optimization of the processing parameters of the Silver with cyanide: Free cyanide, leaching time stay, grinding size ,pH, pulp density. Test of Silver flotation of the cyanidation tailing : Optimization of the processing parameters: reagent consumption, time conditioning. Selection tests of zinc dust in the silver cementation Merrill Crow process Optimization of liquid-solid separation in the thickener : parameters of the separation and selection of the flocculants Test of the tailing pulp filtration subject of minimization of the soluble silver in the tailing pulp Parameters of filtration, calculating of the filter, selection of the pressing filter (Test with TECNICAS filter and CHOQUENET filter). Test of the tailing flotation to minimize the silver solid Studies of valorisation parameters of mixed shake table: Grinding, gravity separation subject of the extension project at 1997 Selection of cotton cloth used in the clarification of the silver loaded solution Utilization of the lead nitrate at the silver cementation on the zinc dust. Studies of the acid leaching parameters of the gravity concentrate. Optimization of the solid concentration, nitric acid concentration- leaching time stay and reactional temperature. Test of silver flotation before cyanidation subject of the extension project at 1998 Quality control of laboratory analysis . Organizer of the quality club created at 1994. Responsible Quality Security and Environment (QSE) : o Piloting of the quality improvement plan o Organizer of safety meeting : sensitization of the staff and analysis of the industrial accident

o o

o o

2000-2001

Constitution of safety club (anomaly clearance) Measure of the nuisances Detoxication of the cyanide in the waste dump. Environment protection. Safety visits

t Participation at installation and starting of AKKA GOLD MINING plant-Morocco. Project composed of: Primary and secondary Crushing-Grinding (SAG Mill and Ball Mill) Gravity separation (Falcon concentrator and shaking tables)- Flotation and cyanide leaching of flotation concentrate Vacuum filter of leaching discharge and Adsorption of Gold Carbon in column(CIC)- Elution of loaded carbon Electro winning - Nitric treatment of the gravity concentrate -Gold smelting Gold bars t Participation at project study of SEMAFO GUINEE plant in Kiniero- Republic of the GUINEA. t Supervisor of the Kinieros plant installation. t Plant manager of Kineros Gold plant - SEMAFO GUINEE - Republic of GUINEA: Procurement of the plant personnel. Training of the plant personnel at the Safety strategic axis of the company inculcation of the safety soul and Gold processing (classical and metallurgic processing: CIL Process). Review of the time stay in the CIL tanks (subject of the extension at 2003). Successful starting of the plant April 2002. Production management of the Gold Management of maintenance, geology and mining interfaces Optimization of the process parameters (Free cyanide -pH, oxygenation per Peroxides added, leaching time stay). Optimization of the elution parameters. Improvement of the plant capacity- 330.000 ton/year to 440.000 ton/year. Review of stand time in the tanks per implantation of the eighth tank increase of the stand time by factor of 1,6 subject of the plant extension in 2003 Review of the grinding size from 106 m to 75 m. improvement of the Gold recovery 93,3 % instead of 87%; Control of the specific reagent consumption and operating cost

2001-2002

2002-2004

August 04- 2005

t Plant manager of SAMIRA HILL plant - SML - Republic of NIGER : Plant of 1.800.000 tons of ore capacity 120.000 oz Gold Participation in the finalization of the plant installation Procurement of the plant personnel. Training of the plant personnel Safety strategic axis of the company inculcation of the safety soul and Gold processing (classical and metallurgic processing: CIL Process). Responsible of the plant start until the gold bar - Successful starting of the plant at September 2004 Smelting of the first bar of the Niger Republic history by ones hand. Production management Management of maintenance, geology and mining interfaces Optimization of the process parameters (free cyanide -pH, oxygenation per Peroxides added, leaching time stay). Optimization of the elution parameters.. Control of the specific reagent consumption and operating costs.

Oct. 2006- April 2008 t Responsible of the reconditioning project of the oxide cooper plant of SOMIFER Bleida mining south-east of Morocco. Managem- mining holding of ONA t Plant manager Plant built at 1989 base of Pilot-studies of the copper leaching per sulphuric acid process Subject of my end studies in 1987. Plant of 90.000 ton ore/year 1.440 tons of Cooper precipitate at 76% Cu. Including: Ore Crushing to 10 mm (ore from the open pit). Static leaching in the PUTCHUCAs tanks. Solid and liquid separation on the vibrator screen and thickener Copper cementation on the old iron. Capital budget of 14.millons MDH or 1,7 millions US $. Constitution of the project shift. Maintenance and installation of the existing equipments Reconditioning of the Jaw crusher DRAGON SE 45 gyratory crusher SYMONS 3 SVEDALA screen conveyors .reducers Metallic building and covering resin of the tanks rubberizing. Specification and order of the equipments (vibrator screen-pumps (water-acid and slurry) motors steel and HDPE pipes valves- weight meter- spare part of the existing equipments and various items of the project. Engineering of waste dam (23.000 m2 of HDPE liner 1 mm thick)-Installation of 3.000 meters linear of pipe. Procurement of the plant personnel

May -July 2008

Training of the plant personnel safety Cooper processing (classical and metallurgic processing). Successful starting of the plant August 2007. Production management

t Responsible of the process improvement in the Cobalt plant including: Classical process: crushing - gravity separation and flotation of the cobalt (production of cobalt concentrate) Hydrometallurgical process: acid leaching purification of the solutions and precipitation of cobalt hydroxide CTT Bouazzer - Managem- mining holding of ONA Morocco

Sept . 2008- 2009 t Element of technical management team. Representative of the technical management in Bouazzer and Bleidas mining

Bleidas gold mining at 60 km far from Bouazzer site:

Project studies of the gold ore treatment (ore from Far west pit) for production of carbon loaded in sight of treatment in the gold room (ZEDRA unit) of the industrial complex of CTT in Marrakech. CIL process including: : Crusher Grinding Leach CIL Balancing carbon: Loaded carbon output for gold elution out of the site. Establishment of process plan Material balance (data base) Concept of the plant implantation with keeping the existing equipments Calculate of equipments dimensions. Tanks of reagents preparation (cyanide- solid lime into the ball mill- milk lime iron sulphate solution). Pumps- pipes and valves-interstage screens-vibratory screens- fixed crane- waterproof dam Calculating of the capital budget 10 Millions MDH or 1,23 Millions US$ - within of 8 months. Constitution of the project shift. Reconditioning and installation of the existing equipments Excavation and civil engineering area of the mill and reagent tanks Metallic building and framework of the mill and reagents and lixiviation areas piping rack Installation of the ball mill agitators of the leaching tanks (CIL). Construction of the waste dam Installation of the piping-and equipments (pumps-vibratory screen-interstage screen-samplers weight meter-flow meters. Electricity supplying Stating test and first full with water and waste ore carbon addition for grading at the end of 2009 August. Successful starting of the plant with the average then rich grade since 2009 September 05 Training of the plant personnel and accompaniment of the team. Performance tests.

Bouazzer site Cobalt treatment : 1- Mini project studies of press filter (filtration of the flotation concentrate per replacement of the drum filter:

minimization target of the humidity to 15 %). Establishment of process plan Material balance (data base) Design of the plant implantation with keeping the existing equipments Calculate of equipments dimensions: Pumps-piping-valves - filtrate tanks- diaphragm pump. Calculating of the capital budget: Mini project 4 Millions MDH or 0, 5 Millions US$ - within of 2 months. Excavation and civil engineering area of the press filter mill and reagent tanks Recuperation of the press filter CTT Marrakech site and thickener from Bleida mining. Installation of the equipments Successful starting of the unit at 2009, April, 10

2- Project studies of decanters of the tables shake concentrates Excavation and civil engineering area of the decanters Metallic building and framework Stating at the end of 2009 July.

3- Installation of vibrator screen to classification of gravity products in sight of grinding and spirals feed. 4- Project studies of the cobalt tailing Gold grade between 1 and 2 ppm. Treatment of the gold by CIL process. Samples point for the laboratory test in the researches and valorisation centre at CTT complex Marrakech. Establishment of pilot plan LANGUAGES (WRITING AND SPEAKING) Tamazight Arabic French Mother Tongue writing and speaking good level. writing and speaking good level.

English

writing and speaking average level.

You might also like

- KMMLDocument35 pagesKMMLAJITH SNo ratings yet

- Processing Nickel Ore and Cobalt RecoveryDocument12 pagesProcessing Nickel Ore and Cobalt RecoveryAhmad Suryantoko100% (1)

- 03 - Heap Leaching Technique in Mining Within The Context of Best Available Techniques PDFDocument33 pages03 - Heap Leaching Technique in Mining Within The Context of Best Available Techniques PDFUlfa RianiNo ratings yet

- 46-Processing Gold OreDocument12 pages46-Processing Gold OrePaolo VelcichNo ratings yet

- Designing The Optimal Flotation Circuit - The Prominent Hill Case - Barns - DD - From Mill Ops 2010 PDFDocument10 pagesDesigning The Optimal Flotation Circuit - The Prominent Hill Case - Barns - DD - From Mill Ops 2010 PDFkennedysupNo ratings yet

- Bateman Com NickelDocument12 pagesBateman Com Nickelreky100% (1)

- CV English Jun 2021Document2 pagesCV English Jun 2021ricardov2009No ratings yet

- Lecture Notes: Introduction To Mining and Mineral Processing EngineeringDocument91 pagesLecture Notes: Introduction To Mining and Mineral Processing Engineeringfaizalamri2013No ratings yet

- Combined Ion Exchange - Solvent Extraction Process 1Document18 pagesCombined Ion Exchange - Solvent Extraction Process 1Georgi SavovNo ratings yet

- Tecnologia de Tratamiento de Efluentes de Minas de UranioDocument20 pagesTecnologia de Tratamiento de Efluentes de Minas de Uranioignacio.toriggiaNo ratings yet

- ALS Metallurgy - Iron Ore Process DevelopmentDocument8 pagesALS Metallurgy - Iron Ore Process DevelopmentDeepakKumarGoraiNo ratings yet

- Mineral Processing and MetallurgicalDocument14 pagesMineral Processing and MetallurgicalJoel CuevaNo ratings yet

- Processing and Recycling in Mining andDocument2 pagesProcessing and Recycling in Mining andHenockNo ratings yet

- Acid Leaching of Oxide-Sulfide Copper Ore Prior The Flotation - A Way For An Increased Metal RecoveryDocument6 pagesAcid Leaching of Oxide-Sulfide Copper Ore Prior The Flotation - A Way For An Increased Metal RecoveryJay patelNo ratings yet

- Rеcycling Of Mining And Metallurgicall Wastes At Devnja Waste Treatment PlantDocument22 pagesRеcycling Of Mining And Metallurgicall Wastes At Devnja Waste Treatment PlantGeorgi SavovNo ratings yet

- Pengantar Teknik Pengolahan MineralDocument87 pagesPengantar Teknik Pengolahan MineralFajarRizki100% (1)

- A New Process For The Thermal Refining of Zinc: A Case Study of Technology Development at MintekDocument8 pagesA New Process For The Thermal Refining of Zinc: A Case Study of Technology Development at Mintekyessdey naylea carhuachin condorNo ratings yet

- CNOG PresentationDocument28 pagesCNOG PresentationAlwin Abreu BarretoNo ratings yet

- Universidad Nacional de Cajamarca Facultad de IngenieríaDocument27 pagesUniversidad Nacional de Cajamarca Facultad de IngenieríaElmer Ocas TelloNo ratings yet

- Resume Process Engineer May 2013Document5 pagesResume Process Engineer May 2013Manolo Sallo ValenzuelaNo ratings yet

- Coal Mining: Ing. M.Sc. Marco Antonio Ardila BDocument15 pagesCoal Mining: Ing. M.Sc. Marco Antonio Ardila BLuis CarlosNo ratings yet

- Eng-Study The Position of Test Points in Cement Production-Raid Tarik Al-KhateebDocument8 pagesEng-Study The Position of Test Points in Cement Production-Raid Tarik Al-KhateebImpact JournalsNo ratings yet

- FYP ProposalDocument4 pagesFYP Proposalabd ullahNo ratings yet

- (Part 7) 1001 Solved Engineering Fundamentals Problems-Michael LindeburgDocument8 pages(Part 7) 1001 Solved Engineering Fundamentals Problems-Michael LindeburgDlorah OalZepolNo ratings yet

- A K Suri Leaching AlakalineDocument37 pagesA K Suri Leaching AlakalineSutanwi LahiriNo ratings yet

- Coal Mining: Ing. M.Sc. Marco Antonio Ardila BDocument15 pagesCoal Mining: Ing. M.Sc. Marco Antonio Ardila BLina Fernanda GómezNo ratings yet

- 28 Mar 2018 153204923JRLEGMNXPFR-PardrehiLimestoneDocument12 pages28 Mar 2018 153204923JRLEGMNXPFR-PardrehiLimestoneDesu MihretuNo ratings yet

- SGS MIN 2001 04 Cyanide Management by SART en 11 09Document7 pagesSGS MIN 2001 04 Cyanide Management by SART en 11 09Jon CastilloNo ratings yet

- Reference Manual (Tech) (Diploma-Be) PDFDocument254 pagesReference Manual (Tech) (Diploma-Be) PDFAnaruzzaman SheikhNo ratings yet

- The Production of Electrolytic Manganese in AfricaDocument15 pagesThe Production of Electrolytic Manganese in AfricalmelwynNo ratings yet

- Foundry ReportDocument7 pagesFoundry Reportmcdonald juma0% (1)

- Desenho Da USINA NAMIBIADocument10 pagesDesenho Da USINA NAMIBIApHNo ratings yet

- Safety and Health in Iron and Steel Industry: Faculty In-Charge: ASHWIN C ADocument7 pagesSafety and Health in Iron and Steel Industry: Faculty In-Charge: ASHWIN C ArameshNo ratings yet

- MinDiv31 NigMiningIndustry31Document25 pagesMinDiv31 NigMiningIndustry31Irmiya Samson AmokaNo ratings yet

- Mercury PresentationDocument42 pagesMercury Presentationpejal5284100% (4)

- Recent Operation and Environmental Control in The Kennecott SmelterDocument17 pagesRecent Operation and Environmental Control in The Kennecott SmelterHat CopterNo ratings yet

- Presentation Premiatec Brochure Eng 2018Document18 pagesPresentation Premiatec Brochure Eng 2018Georgi SavovNo ratings yet

- Request For Proposal Water Well Drilling v2Document9 pagesRequest For Proposal Water Well Drilling v2elnaqa176No ratings yet

- Chrome Report 4Document38 pagesChrome Report 4ahmedkhidryagoub100% (1)

- Minerals ProcessingDocument5 pagesMinerals ProcessingaghilifNo ratings yet

- TiTaN ProfileDocument81 pagesTiTaN Profilemanikantan3003No ratings yet

- 68 Ferronickel Slag Usesand Environment 68Document15 pages68 Ferronickel Slag Usesand Environment 68Agus TriyonoNo ratings yet

- Come To Where The Copper Is - Modern Ore Mining in Chile: Report by Arne Kristoffer Bayer, Reik Michael Winkel, GermanyDocument4 pagesCome To Where The Copper Is - Modern Ore Mining in Chile: Report by Arne Kristoffer Bayer, Reik Michael Winkel, Germanydr chatti hanumantha raoNo ratings yet

- Leaching and Kinetics Studies On Processing of Abu-Ghalaga Ilmenite OreDocument9 pagesLeaching and Kinetics Studies On Processing of Abu-Ghalaga Ilmenite OreAnnisa MaulidiaNo ratings yet

- Almaun F1C113044Document25 pagesAlmaun F1C113044Almaun MaunNo ratings yet

- Analytical Instrumentation For Copper Pyrometallurgy: Challenges and OpportunitiesDocument6 pagesAnalytical Instrumentation For Copper Pyrometallurgy: Challenges and OpportunitiesAutomatizacion UdecNo ratings yet

- Geometalurgy - ITB 281115Document30 pagesGeometalurgy - ITB 281115Kevin MusterNo ratings yet

- Advances in Gold ProcessingDocument9 pagesAdvances in Gold Processingjavicol70No ratings yet

- Study To Improve The Breaking Strength of The No-BDocument7 pagesStudy To Improve The Breaking Strength of The No-BGuna MNo ratings yet

- EAF Stainless Steel Dust ProcessingDocument13 pagesEAF Stainless Steel Dust Processingmd 80No ratings yet

- Mintekbulletin 148Document4 pagesMintekbulletin 148mushava nyokaNo ratings yet

- Khyati Tor PresnetationDocument20 pagesKhyati Tor PresnetationVishal JainNo ratings yet

- Equipment Selection For High Selective Excavation Surface Coal MiningDocument16 pagesEquipment Selection For High Selective Excavation Surface Coal MiningAlejandra MirandaNo ratings yet

- Trimex Beach Sand Beneficiation PlantDocument6 pagesTrimex Beach Sand Beneficiation PlantSrikanth BammhideNo ratings yet

- Maximising The Recovery of Useful Metal From Ores: The ChallengeDocument21 pagesMaximising The Recovery of Useful Metal From Ores: The ChallengeDeneshVijayNo ratings yet

- Final Year Project Thesis Guide: School of Advanced Manufacturing and Mechanical EngineeringDocument18 pagesFinal Year Project Thesis Guide: School of Advanced Manufacturing and Mechanical EngineeringSuseendaran BabuNo ratings yet

- Gold Ore PresentationDocument44 pagesGold Ore PresentationMukti AwanNo ratings yet

- Ocet ProspectusDocument84 pagesOcet ProspectusAnkur Singh0% (1)

- MSC - AccountingDocument3 pagesMSC - AccountingDownloadingNo ratings yet

- MSC in MicrobiologyDocument28 pagesMSC in MicrobiologyKIST College100% (1)

- B's ProspectDocument59 pagesB's ProspectRai Tahir NawazishNo ratings yet

- UCT Student Fees Handbook 2016Document132 pagesUCT Student Fees Handbook 2016LukeMin100% (1)

- Manonmaniam Sundaranar University Tirunelveli M.A. (English)Document10 pagesManonmaniam Sundaranar University Tirunelveli M.A. (English)Sri NavinNo ratings yet

- PU Brochure 2024-25Document6 pagesPU Brochure 2024-25lungumtendereNo ratings yet

- SOP SampleDocument5 pagesSOP SampleTGS /// AyanNo ratings yet

- University of Essex Online Undergraduate ProspectusDocument18 pagesUniversity of Essex Online Undergraduate ProspectusRema RomanNo ratings yet

- Pssit, 2021-25Document16 pagesPssit, 2021-25Sachin KhotNo ratings yet

- Electrical Engineering GuideDocument5 pagesElectrical Engineering GuideMedrouaNo ratings yet

- Magna Carta For Public School TeacherDocument14 pagesMagna Carta For Public School TeacherJhunmark BayangNo ratings yet

- Postgraduate Design and Creative Tech UpdatedDocument72 pagesPostgraduate Design and Creative Tech UpdatedGloria Isabel Betancur AyalaNo ratings yet

- Significance of Picture Books To Memory LevelDocument33 pagesSignificance of Picture Books To Memory LevelNathalie Aira GarvidaNo ratings yet

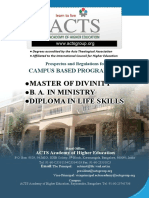

- Acts AcademyDocument12 pagesActs Academyjairaj321No ratings yet

- Edibon Presentation: All Edibon Products and Facilities Part 3. ProductsDocument117 pagesEdibon Presentation: All Edibon Products and Facilities Part 3. ProductsDaud Simon ANo ratings yet

- Combine SoftwareDocument20 pagesCombine SoftwareKing Of Devil 345No ratings yet

- 2017 Postgraduate Prospectus InteractiveDocument70 pages2017 Postgraduate Prospectus InteractivejesseNo ratings yet

- Government of Andhra PradeshDocument10 pagesGovernment of Andhra Pradeshmrraee472950% (2)

- 1master Your Master - AO - 2022Document13 pages1master Your Master - AO - 2022iamzellerNo ratings yet

- UK Skilled Worker VisaDocument16 pagesUK Skilled Worker VisaVinodh KrishnaNo ratings yet

- By: Jonalyn C. GalvezDocument60 pagesBy: Jonalyn C. GalvezvernaNo ratings yet

- CV in EnglishDocument1 pageCV in EnglishMohamed YousefNo ratings yet

- Call DSU 2023-2024Document51 pagesCall DSU 2023-2024khaing khantNo ratings yet

- Draft Policy Dual, Double and Joint Degree Programs July 2022Document11 pagesDraft Policy Dual, Double and Joint Degree Programs July 2022Dr. Iftikhar AliNo ratings yet

- Great Grads 2019Document11 pagesGreat Grads 2019CCNY CommunicationsNo ratings yet

- BITS Pilani BSC Computer Science BrochureDocument20 pagesBITS Pilani BSC Computer Science BrochureSuraj MadhavNo ratings yet

- DAAD - WISE Internships PDFDocument3 pagesDAAD - WISE Internships PDFAshwin KrishnanNo ratings yet

- Advertisement No. GBU-03/2021: Important Note For All PostsDocument4 pagesAdvertisement No. GBU-03/2021: Important Note For All PostsHOD Electrical DegreeNo ratings yet

- 22 SssDocument675 pages22 Sssjoel enciso enekeNo ratings yet