Professional Documents

Culture Documents

ITP&Procedure

Uploaded by

rajkbhatiaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ITP&Procedure

Uploaded by

rajkbhatiaCopyright:

Available Formats

(e ENGINEERS

s@;al fclldlc5 (t.:,tJ INDIA LIMITED

(a-m'i'f (A Govl of India Undertaking)

DUAL FEED CRACKER UNIT & ASSOCIATED UNIT PROJECT

OPaL, DAREJ. BHARUCH, GUJARAT

Ref: 6987-LEPClilNST-01l19-42/LETI '313

Date: 9th June 2011

Mis Samsung Engineering,

Dahej Petrochemical Complex,

Dahej.

./', .....

.,.. ..'\

. . '\

Sub: - Dual Feed Cracker and Associated Units, Dahej Petrochemical Complex

_ Construction procedure & ITP for Instrumentation work.

Dear Sir,

Please refer your . letter no SE-EIL-L-1287 dtd 06.05.2011 approval of construction

procedure for installation and ITP for Instrument works.

Please find enclosed herewith the above documents duly reviewed and approved for

implementation for the subject work.

Further you are requested to submit construction procedure & ITP for balance job like Field bus,

PSVetc.

Thanking you,

Very truly yours,

Enclo. : As above

INCHR

fI9. Je

I Q.\tQC.. Ie..

.. : 4.':

Regd Office: Engineers fudia Bhavan, 1 Bhikaiji Cama Place, New Delhi-II 0066

Visit us at: www.engineersindia.com

CM

so

. - " ., ..

ONGC Petro additions limited

SEZ, Dahej, Gujarat, India

DAHEJ PETROCHEMICAL

COMPLEX

Dual Feed Cracker Unit

& Associated Units

CONSTRUCTION PROCEDURE

FOR

INSTRUMENT WORK

Ell

JOB NO. 6987

Page: I of 21

Reason for Issue I Remark Prepared Checked Approved

Contract No. I Po. No. :

ENGINEERING

DIVISION

SAMSUNG

ENGINEERING

Doc No: &SE-OO-W-PE-0058

Linde Project No.:

Linde Project Code:

Samsung Project

No.:

Sanisung Project

Code:

Item Name.:

3110 A9NK

DAHEJ

SC 2252

OPal DFCU &

AU

Company Doc. No.: 6987-LEPC1-SE-OO-CN-PE-0058

I ,.

Dahej Petrochemical Complex DFCU &AU

Page 20f 21

6987-LEPCl-SE-00-CN-PE-0058

Construction Procedure for Instrument

Issue: 02

work

REVISION HISTORY

REV DATE DESCRIPTION

01 04-06-2011

Letter nO.SE-EIL-L-1254&1262 dated 23.05.2011, ElL

Comments incorporated and re-submitted.

* Notes:

This page records all revisions on the specification.

Issued for

~

00 23.05.2011 Review &

c ; / ~ .

Nis(.., ..... ~ -s

Approval

Rev. DATE Purpose

Prepared by

_l

Checked hy Approved by Approved by

J

SECL SECL SECL ElL

- -

Dabej Petrocbemical Complex DFCU &AU PROJECT Page 30f2,

6987-LEPCI-SE-CN-PE-0058

Instrument work procedure

Rev.: 01

-

. CONTENTS

PAGE

1 . ----------------------------------------------------------------------------------- 3

1.1 Scope of Application ----:.----------------------------------------------------------- 3

1.2 Codes and Standards ------------------------------------------------------------ 3

1 .3 R efe re n ces ---------------------------------------------------------------------------- 3

2. I S T f\L-L-f\ T ION W 0 F{ K S ------------------------------------------------------------ 3

2.1 General Requirements ------------------------------------------------------------- 3

2.2 Be n ch T est ---------------------------------------------------------------------- 4

2.3 Equipment in Control Room ------------------------------------------------- 7

2.4 I nstrum e nts I nstallation -------------------------------------------------------- 7

2.5 Main Cable Way(Duct) ------------------------------------------------------- 7

2.6 Perforated Cable Tray ------------------------------------------------"------ 9

2.7 Cabling and Wiring ---------------------------------------------------------- 10

2.8 Pressure Piping and Tubing . --------------------------------------,,;---------- 11

2. 9 Air Supply Tubing' ---------------------------------------------------------- 12

2.10 Steam Tracing 12

3. INST f\LL-f\ TION f\ND TEST ----------------------------------- 13

3.1 Inspection on Receipt and Storage -------------------------------------------- 13

3.2 Inspection during the Execution of the Works ------------------------------- 13

3.3 Control Equipment Installation Inspection ------------------------------------- 13

3.4 Instrument Installation Inspection ---------------------------------------------- 13

3.5 I nstrument Wiring Test -------------------------------------------------------------- 15

3.6 Pressure Piping and Tubing Test ----------------------------------------------- 15

3.7 Air Supply Piping Test ------------------------------------------------------------- 16

3.8 Steam Tracing Tubing Test -------------------------------------------------------- 17

4. LOOP AND FUNCTION TEST ---------------------------------------------------------- 17

4.1 Field Check and Test Preparation ---------------------------------------------- 17

4.2 Loop Test ---------------------------------------------------------------------------- 18

I

,

04.06.2011 I

Issued For

I

Approval

Nt'sWs

Date Purpose

Prepared Checked Approved

by SECL by SECL by SECL

- -

Dahej Petrochemical Complex DFCU &AU PROJECT Page 40[2,

6987-LEPC l-SE-CN-PE-0058

Instrument work procedure

Rev.: 01

.

1. GENERAL

1.1 Scope of Application

1.1.1 This specification covers the general requirements for the installation work, inspection

and test of instrument and control equipment during execution.

1.1.2 The following installation work includes in this specification:

(1) Bench Test

(2) Control Equipment including DCS

(3) Instrument Installation

(4) Main Cable Way(Cable Duct)

(5) Perforated Cable Tray

(6) Cabling and Wiring

(7) Pressure Piping and Tubing

(8) Air Supply Tubing

(9) Steam Tracing

1.2 Codes and Standards

The installation of instrument and control equipment shall conform to the requirements of the

applicable codes and standards stated on the succeeding paragraphs and the references.

1.3 References

1.3.1 The following documents shall be applied as an integral part of the

requirements of this specification

(1) Drawings for Construction of Instrumentation and Control System

(2) Instrument Specification

(3) Instrument Hook-up Drawing

(4) Instrument Wiring & Tubing Connection Detail

(5) Installation Standards Instrument Mounting Details

1.3.2 In the event of conflict between the documents and drawings the order of precedence

shall be as indicated in Section 1.3.1

2. INSTALLATION WORKS

2.1 General Requirements

2.1.1 All materials shall be received, handled, and stored in a careful and prudent manner to

the components they incorporate.

2.1.2 The installation work and materials shall conform to the specified documents and

drawings.

The alternatives shall be allowed only after ElL's approval.

2.1.3 The materials used for the work shall be cleaned prior to assembling.

After completion of the work, foreign matter such as rust, scale, etc. shall be removed.

04.06.2011

Issued For

Approval

Date Purpose

Prepared

by SECL

Checked

by SECL

Approved

by SECL

Approved

by ElL

1 J

~

Dahej Petrochemical Complex DFCU & AU PROJECT Page $of2'

6987-LEPCl-SE-CN-PE-0058

Instrument work procedure

Rev.: 01

- -

2.1.4 All screw threads shall be machined by a threading machine.

2.1.5 Pipes, tubes and conduits shall be cut mechanically at right angles. However, the cutting

other than by the mechanical shall be subject to ElL's approval.

2.1.6 Pipes, tubes and conduits shall be reamed and cleaned before installation.

2.1.7 Unless stated, Teflon tape shall be used for sealing of all threaded joints.

2.1.8 During construction, temporary openings of equipment, conduits, tubes, cables, etc. shall

be plugged and/or sealed to prevent entry of moisture and dust.

2.1.9 Supports shall be installed on concrete walls, steel structures, etc.

No supports shall be installed on process equipment, insulated pipes, and location

subject to vibration, high temperature or corrosive fluids

2.1.10 Unless otherwise specified, threaded connections shall not be welded.

2.2 Bench Test

2.2.1 This test is for calibration and is undertaken at the workshop

2.2.2 As the strict performance tests of instruments are to be made at the manufacturer's

shop, emphasis shall be placed upon zero and/or span checks of them rather than

accuracy.

The results of each completed test should be recorded on the appropriate calibration

sheet and witnessed by the responsible engineer.

2.2.3 Prior to the test, confirm if the utilities such as air, electrical power, etc. are under

normal conditions.

2.2.4 After completion of the tests, the instrument should be drained and, if necessary, blown

through with clean and oil-free dry air. After testing and draining, all connections and

entries should be temporarily sealed to prevent subsequent ingress of moisture and dirt.

2.2.5 The instrument to be tested should be mounted in the correct plane on a rigid and

vibration-free stand of structure.

2.2.6 Bench test procedures shall be as follows:

(1) Flow Instrument

1) D/P Transmitter

The transmitters shall be calibrated against standard water or mercury

column manometer at 0-25-50-75-100% of span.

2) Turbine and positive displacement meters

04.06.2011

Issued For

Approval

Date Purpose

Prepared

by SECL

Checked

by SECL

Approved

by SECL

.

, ,

~

Dahej Petrochemical Complex DFCU &AU PROJECT Page 60f21

6987-LEPCl-SE-CN-PE-0058

Instrument work procedure

Rev.: 01

04.06.2011

.

G) The meters shall be checked by mechanical operability.

@ The characteristic of converter shall be confirmed using a

pulse-synthesizer.

3) Rotameter

All transmitting and indicating rotameters in which the float is not visible

sh!311 be calibrated by'manually positioning the float and adjusting the

indicator or transmitter output to the correct value at 0-25-50-75-100% of-

span. ~

4) Flow Switch

The action shall be checked by moving the paddle of float.

(2) Level Instrument

1) Displace Type Level Instrument

G) The instruments shall be calibrated by filling the chamber with clean

water and using clean plastic tubing connected at the bottom drain as a

gauge glass. Check calibration at 0-25-50-75-100% of span.

Reset the specific gravity adjustment to the operating conditions and

recheck zero after calibration.

@ Internal type shall be calibrated with the help of weights simulating at

~ 0-25-50-75-100% of span.

2) Capacitance Type Level Instrument

The instrument shall be put into water of bath, and the action shall be

checked.

In case of using plastic bucket, grounding shall be considered.

3) Tank Gauging System

The dimension or length of the float and wire shall be checked in accordance ,J

with vendor's drawing.

4) Float Type level Switch

The switches shall be checked by removing the side outlet plug, filling the float

chamber with water and observing the float action and the switch action.

5) DIP Transmitter

. The instruments shall be calibrated like DIP flow instruments.

(3) Pressure Instrument

1) Pressure Transmitter ~

The instruments shall be calibrated at 0-25-50-75-100% of range with a hand

pump calibrator or using dry air or nitrogen as a source of pressure.

2) Pressure Switch

The instruments shall be calibrated with a precision calibration gauge or

manometer with hand pump or using dry air or nitrogen as a source of

pressure.

3) Pressure Gauge

The instrument shall be zero-adjusted .

. - .4) Draft Gauge

Issued For

Approval I

I

Date Purpose

Prepared

by SECL

Checked

by SECL

Approved

by SECL

Approved -I

by ElL

Dahej Petrochemical Complex DFCU & AU PROJECT Page :;'of2t

6987-LEPCI-SE-CN-PE-0058

Instrument work procedure

Rev.: 01

.

The instrument shall be zero-adjusted.

5) DIP Gauge .

The instruments shall be checked against standard water or mercury at

0-25-50-75-100% of range. A precision calibration gauge shall be used to

check.

(4) Temperature Instrument

1) Temperature Tra.nsmitter Gb

CD The instruments for TIC shall calibrated at 0-25-50-75-100% of range using DC

voltage standard. A precision calibrator shall be used to check the

transmitted signal.

@ The instruments for RTD shall be calibrated at 0-25-50-75-100% of range

using a precision resistance. .

2) Filled Type Temperature Instrument

The instruments shall be calibrated at the ambient temperature-adjusted

using precision mercury gauge.

3) Temperature Switch :

The instruments shall be calibrated at 0-25-50-75-100% of range using a

temperature controlled bath and set at proper value.

4) Thermocouple and RTD

The sensor shall be checked there is no open circuit with circuit

tester and the output value corresponding the ambient temperature shall be

checked mV for thermocouple, resistance for RTD respectively using precise

multi tester.

(5) Control Valve

1) The valves shall be set at the installed condition using a chain block or pulley

at the shop for its size is bellow 4". However, its size is above 4" valves would

be stroke tested only at shop and calibration will be done at field side after

piping installation as following manner.

2) All diaphragm or piston operated control valves shall be pneumatically

stroked using a pressure regulator, test gauge and DC power supply etc.

3) The following items shall be checked and calibrated.

CD Valve action including solenoid valve

Travel indicator

Positioned calibration

@ Stroking time

Limit switch function

Failure position

4) Accessories such as hand wheel, booster, relay, lockup valve, etc. shall be

operationally checked.

04.06.2011: __ __ st:--=- ..

Prepared Checked Approved

Date Purpose

by SECL by SECL by SECL

.

Dahej Petrochemical Complex DFCU &AU PROJECT Page 8"0[2'

6987-LEPC1-SE-CN-PE-tlO58

Instrument work procedure

Rev.: 01

2.3 Equipment in Control Room

2.3.1 The equipment installation shall be done based on this specification, "PLAN" DWG, and

"Instrument Wiring Connection List", and other relevant drawings.

2.3.2 Before installation of equipment, the control rqom shall be adequately cleaned.

And then the floor shall be protected temporarily with a suitable material.

2.3.3 The equipment, after completion of installation, shall be covered with a proper material.

And adhesive tape shall not be affixed directly on the equipment.

2.3.4 Channel base of the panels shall be fixed firmly and leveled horizontally.

2.3.5 Panels shall be mounted from those of center in case where there is a lot of panels.

2.3.6 Panels shall be correct-mounted horizontally, vertically using the specified liners.

2.3.7 Upper and front side of the panels shall be correct-mounted in places.

2.3.8 Panels, channel base and panel to panel shall be arranged correctly.

2.4 Instrument Installation

2.4.1 General

(1) Instruments shall not be interfered with their function, operation and maintenance.

(2) Instruments shall be installed without any interference at the time of installing,

removing them.

(3) Instruments shall be installed and protected against high temperature,

humidity, corrosive gas and dust.

(4) Instrument and its accessories for construction shall apply a standardized goods.

(5) Instrument shall be installed in a place where there is no vibration. Otherwise shall

take a measure to avoid the vibration.

(6) When the welding work are performed, instrument shall be protected against

electric spark and welding current before the works for safety.

2.4.2 Field Instrument and Equipment

I

04.06.2011

,

i

i

i

Date

I

(1) The installation of field instruments and equipment shall be done based on this

specification, "PLAN" DWG, and "Instrument Wiring Connection List", and other

relevant drawings.

(2) All field instruments and equipment shall be located so that the function of them is

not affected and they are accessible from grade, platforms, walkways, etc.

However, the use of a portable ladder or a rolling platform is permitted in case of

Issued For I

'htQ

i

Approval

.Ull.,.... t

!--.

N;s a/.s

i

I

Prepared Checked Approved I Approved !

I

i

Purpose

I

!

I

by SECL by SECL

i

by SECL by ElL i

, '

-

Dabej Petrocbemical Complex DFCU & AU PROJECT Page 10f2,.

6987-LEPCI-SE-CN-PE-0058

Instrument work procedure

Rev.: 0]

the instruments and valves such as a line-mounted instruments and first block

valves for instruments.

(3) Location subject to dust, excessive vibration, corrosion, and radiant heat shall be

avoided in locating the instruments.

(4) In general, instruments shall be mounted on the specified stanchion.

2.4.3 Instrument to be installed on the shall be as follows:

(1) Locate the stanchion on the designated place

(2) The stanchion shall be supported enough as specified

(3) Top side of the stanchion shall be blinded.

(4) A surface of the capillary tubes shall be protected from exterior harm.

(5) If the instrument relocation is required, it shall be shown on the drawing after

ElL's confirmation,

2.4.4 Instrument to be installed on a tower

(1) Bolts, nuts and gaskets for connection shall be used as specified.

(2) Maintenance work of instrument shall not be interfered under the hot or cold

insulation materials of process piping or equipment.

2.4.5 Instrument to be installed on piping line

(1) Instrument to be installed on pipe line such as a orifice plate, Control Valves,

Flowmeters etc. shall be confirmed of the direction of flow & Scale Plate.

(2) The orifice plate shall be correctly installed, if no tab, it will be necessary to

introduce the installation procedure before the works.

(3) The orifice plate shall not be installed before the hydraulic test and flushing works

is completed and then, it shall be installed after confirmation prior to final leak

test

(4) The orifice tap shall be blinded if it is provided as spare tap.

(5) Bolts, nuts and gaskets for connection shall be used as specified in the Drawing.

2.5 Main Cable Way(Cable Duct)

2.5.1 The Main cable way installation shall be done based on this specification, "PLAN" DWG.

and "Instrument Wiring Connection List", and other relevant drawings.

,

2.5.2 Dimension of cable duct shall be confirmed whether it is correct or not.

2.5.3 Distance from the heat source shall be confirmed whether it is enough or not

2.5.4 Connection point shall be entirely done by welding and bolting.

2.5.5 Cable shall be protected from damage due to welding and bending work.

2.5.6 Foreign materials such as oily water, rag, etc. shall be removed from cable duct.

04.06.2011 Issued For ....,/;? I \n

r-______ __

Date Purpose

Prepared Checked

by SECL by SECL

Approved

by SECL

"

. .

Dabej Petrocbemical Complex DFCU & AU PROJECT Page l Q o f 2 ~

6987-LEPCl-SE-CN-PE-0058

Instmment work procedure

Rev.: 01

.

2.5.7 Primary painting inside of cable duct shall be completely done after the welding work.

2.5.8 Separator installed in cable duct shall be made as designed.

2.5.9 The cable duct shall be routed considering the location of equipment's and the route of

process pipes. And they shall be supported with rack or bracket and shall be firmly

anchored not to be moved by wind or vibration.

2.5.10 Cable duct shall be strengthened to endure the load passing a person.

2.5.11 Unless otherwise noted, the supporting interval shall be not more than 3 meters.

2.6 Perforated Cable Tray

2.6.1 The tray installation shall be done based on this specification, "PLAN" DWG and

"Instrument Wiring Connection List" and other relevant drawings.

2.6.2 Dimension of tray shall be confirmed whether it is correct or not.

2.6.3 Distance from the heat source and other equipment and eleCtrical tray shall be confirmed

whether it is enough or not.

2.6.4 Connection point shall be entirely done by welding or bolting.

2.6.5 Cable shall be protected from damage due to welding and bending work.

2.6.6 Foreign materials such as oily water, rag, etc. shall be removed from tray.

2.6.7 Support work shall be completed prior to tray installation work, and all damaged points

shall be painted with rust inhibiting paints

2.6.8 Tray shall be finished smoothly: They shall be free of unnecessary protrusions

2.6.9 After tray installation, the welded portion shall be covered with zinc paint or other

protective means where stipulated by the project specification.

2.9.10 Tray support interval shall not be exceed maximum 2 meter.

2.9.11 For support, material shall be used after blasting and applying primer paint coat. After

support fabrication, intermediate and final paint shall be applied at site.

04.06.2011: Issued For

Approval

Nt'SW.S 9f ~ ~

----------+---=------"--'---+----cc-------:-----i----:----"---,----t-----::--""'-----:---

Prepared Checked Approved Approved

by SECL by SECL by SECL by ElL

Date Purpose

~

Dabej Petrocbemical Complex DFCU & AU PROJECT Page I, 0[2,

6987-LEPC1-SE-CN-PE-0058

Instrument work procedure

Rev.: 01

.

2.7 Cabling and Wiring

2.7.1 The cabling and wiring shall be done based on this specification, "PLAN" DWG, and

"Instruments Wiring Connection List", and other relevant drawings.

2.7.2 In laying cables and wires, special care shall be taken to avoid any damages on cables

and wires.

2.7.3 Wires shallnot be spliced in other places than the specified point.

2.7.4 Cables installed in vertical cable tray shall be fastened at proper points.

2.7.5 Bending radius of cables shall be not less than 6 times of its outside diameter.

2.7.6 After laying of cables and wires, they shall be cut with some margin in length in both

ends.

2.7.7 Cables in cable tray shall be laid in parallel and straightly as far as possible.

2.7.8 The stripping of multi cables for wiring shall be done after clamping the cable.

2.7.9 When connecting the wires to the terminal block of instruments, junction boxes and

panels, the compression terminal shall be used.

2.7.10 Shield wires shall be grounded only at the one point.

2.7.11 Left over cables on the drum should be updated and suitably marked on the drum.

2.7.12 Cable work

(1) The cable shall not be twisted when it is being pulled from the drum.

(2) The cable work shall be carefully worked to avoid the damage on insulator of the

cable.

(3) The length of cable shall be enough prepared for the termination and maintenance

work.

(4) The electric power and electronic line shall be separated as specified on drawing so

as to be protected from the noise.

(5) The cable connection work in the cable tray shall be prohibited

(6) The cable inside of the cable .tray or pit shall be clearly arranged.

(7) Shield wire inside of the panel shall be only 1 point grounded.

(8) Wiring of the intrinsically safe circuit shall be independently installed with the

blue color and protected from the others.

(9) Joints shall be made only at terminals in instruments or approved equipment. No

, intermediate joints shall be made on cable trays.

(10) Cable shall be drawn from the drums allocated on the cable list. A record shall be

Issued For

04.06.2011, A I

pprova

Date Purpose

/--------------t--=--""-----i-----

Prepared Checked

by SECL by SECL

Approved

by SECL

Approved

by ElL

Dabej Petrochemical Complex DFCU & AU PROJECT Page 12.0[2.

-

6987-LEPCl-SE-CN-PE-0058

Instrument work procedure

-

kept of actual cut length.

2.7.13 Signal wiring work

(1) The signal wiring shall be arranged as shown on the drawings.

(2) The materials specified on drawings shall be used.

Rev.: 01

(3) The wiring route shall avoid an adverse effect from a.heat source and not be under

the process piping and equipment which are covered by the hot or cold insulation

materials.

(4) The wiring shall be arranged or supported to avoid the vibration and thermal

expansion of process piping and equipment.

(5) Wiring shall avoid an adverse effect from power cables.

(6) Sealing method shall be conformed to the specified drawings.

(7) Grounding method shall be conformed to the specified drawings.

2.8 Pressure Pipe and Tubing

2.8.1 The instrument pressure piping and tubing shall be done based on this specification,

"Instrument Piping Hook-up Detail", and other relevant drawings.

2.8.2 The lines instruments and process lines/equipment's shall be short as far as

possible.

2.8.3 Cold bending shall be applied. However hot bending may be employed subject to

approval of ElL. Bending radius shall generally be not less than 5 times of the

pipe outside diameter.

2.8.4 All block valves except equalizing valves shall be closed after installation of

pressure lead lines.

2.8.5 The lined shall be 100mm remote from adjacent structure, equipment and piping.

2.8.6 Whenever cutting or welding is necessary for rearrangement of the pressure lead line

after installation, the lines shall be removed from the instruments.

2.8.7 The proper space allowance for insulation and/or steam tracing between the lead lines

and equipment's & process pipe lines shall be considered.

2.8.8 All high and/or low pressure piping components and instruments shall be inspected prior

to assembling the lines.

2.8.9 The lines shall not be supported by instruments.

2.8.10 Welding shall be only made by welders who have been qualified as specified in the

related documents.

2.8.11 The materials specified on drawings shall be used.

2.8.12 The elevation and direction of pressure tapes and instruments shall be correct as

shown on the drawings.

2.8.13 Seal pot and/or condensate pot shall be assembled in the same of the specified

elevation.

2.8.14 The lines shall be slopped as specified on instrument hook-up drawing.

Ground lug for welding machine shall not be connected to the instrument stanchion

!

Issued For

stc

04.06.2011 !

Approval

Nish::d$

I

!

Date

I

Purpose

Prepared Checked

J

Approved Approved

by SECL by SECL by SECL by ElL

, ,

~

Dabej Petrocbemical Complex DFCU &AU PROJECT Page

13

0n

t

6987-LEPCl-SE-CN-PE-0058

Instrument work procedure

Rev.: 01

-

2.9 Air Supply Tubing

2.9.1 The air tubing shall be done based on this specification, "PLAN" DWG, and

"Instrument "Connection Detail", and other relevant drawings.

2.9.2 The work includes tubing from air header to each control valves.

2.9.3 The tube shall be supported by perforated tray ..

2.9.4 Fittings for each tubing run shall be minimized.

2.9.5 Bending radius of tubes sha'lI be more than 5 times the outside diameter of the

tubes.

2.9.6 The cutting section of the tubing shall be reamed.

2.9.7 The seal tape shall be used for thread connection.

2.9.8 The tubing route shall avoid an adverse effect from a heat source (keep 150mm

minimum distance) and not be under the process piping and equipment which are

covered by hot and cold insulation materials.

2.9.9 The tubing shall be arranged or supported to avoid the vibration and thermal

expansion of process piping and equipment.

2.9.10 The tubing shall be used as specified and pulled arranged as shown on the drawings.

2.10 Steam Tracing

2.10.1 The steam tracing shall be done based on this specification, "Instrument Steam Tracing

"PLAN" drawing and other relevant drawings.

2.10.2 The instruments shall be traced with considering the convenience of their mounting and

dismounting.

2.10.3 If the pipe shall run straight more than 20 meters, U-Ioop shall be put in the pipe for

thermal expansion.

2.10.4 Condensate pot in the steam line shall not be traced.

2.10.5 The materials and size specified on the drawings shall be used.

2.10.6 Tracing tubing shall be arranged closely to the heating zone.

2.10.7 "U" type pocket shall not be made during the tracing work.

2.10.8 The root valve(1 st block valve) shall be easily accessible.

04.06.2011. ;

Issued Fot

~

c ; / ~ .

~ ~

Approval

Nis\"; ... d.s

Date Purpose

Prepared Checked Approved Approved

!

by SECL by SECL by SECL by ElL

:

Dahej Petrochemical Complex DFCU & AU PROJECT . Page

6987-LEPC 1-SE-CN-PE-0058

Instrument work procedure

Rev.: 01

- -

3. INSTALLATION INSPECTION AND TEST

3.1 Inspection on Receipt and Storage

3.1.1 Instrument equipment received on site shall be visually inspected for damage

and shortages.

3.1.2. Instrument equipment shall be stored in accordance with the vendor's recommendation.

and protected against adverse weather conditions.

3.1.3 Equipment shall be examined on receipt into the main warehouse to confirm that they

are correctly tagged and meet with the specification of purchaser order.

3.1.4 Modular and packaged equipment shall be checked to confirm that the structure, cable

and piping runs do not conflict with equipment on adjacent modules or units. Access for

commissioning and maintenance shall be checked.

3.2 Inspection during the execution of the works

All of the inspection shall be performed during the execution of the works unless otherwise

specified to be done after completion of work, if required, shall be kept all the evidence

such as a picture and drawings.

3.2.1 underground work

3.2.2 work to be covered in the wall.

3.2.3 work to be covered in the building

3.2.4 'work to be covered in the insulation materials

3.2.5 others necessary to maintain the work history.

3.3 Control Equipment Installation Inspection(Control Panel, PLC, DCS, etc.}

3.3.1 Panels shall be located in place and fixed firmly in accordance with the related

drawings.

3.3.2 The panels shall be correct-mounted vertically.

3.3.3 The surface of panels shall be clean and have not been damaged.

3.4 Instrument Installation Inspection

3.4.1 Visual Inspection Prior to Installation

04.06.2011

Date

The inline instruments and instruments mounted on equipment shall be checked prior to

installation as it is difficult to confirm the specification or re-install the instruments after

installation. The following visual inspection shall be done.

Issued For

if

Approval

Purpose

Prepared Checked

I

Approved Approved

by SECL by SECL

I

by SECL by ElL

Dabej Petrocbemical Complex DFCU & AU PROJECT Page

6987-LEPCl-SE-CN-PE-0058

Instrument work procedure

Rev.: 01

04.06.2011

Date

.

A. Flow Instrument

(1) Orifice Plate

Each orifice plate shall be checked and confirmed for Tag No., flatness, freedom

from adhesive materials, specification of gaskets, cleanness, correct bore size,

plate thickness, stamp on tab, flow direction and flatness.

(2) Flow Nozzle I Venture Tube

Each flow nozzle I venture tube shall be checked and confirmed for Tag No.,

damage, cleanness, face to face dimension and inside diameter.

(3) Pitot Tube

Each pitot tube shall be checked and confirmed for Tag No., damage, flow direction,

and insertion length.

(4) Rotameter

CD Where the float of rotameter is not visible, the action shall be checked by

positioning the float manually.

@ To be checked that the proper float is correctly installed, and that the float

moves freely.

Cleanness shall be checked

(5) Turbine and Positive Displacement Meters

Each meter shall be checked for Tag No., damage, cleanness, flow direction.

(6) Flow Switch

Each meter shall be checked for Tag No., damage, cleanness, flow direction.

B. Level Instrument

(1) Displace Type Level Instrument

1) Stiffeners shall be removed.

2) Direction of indicators or transmitters shall be confirmed.

(2) Capacitance Type Level Instrument

Direction of transmitters shall be confirmed.

(3) Tank Gauge System

Float and measuring tape shall be verified.

(4) Level Gauge

The center to center length shall be checked according to specifications and

vendor's drawing

C. Temperature Instrument

(1) Thermocouple/RTD

Insertion length and outside diameter shall be checked.

(2) Thermometer

1) The instruments may not be calibrated but dial pointer shall be adjusted to the

known ambient temperature.

2) Insertion length and outside diameter shall be checked.

Issued For

;?-.

Approval

---------

I

Purpose

Prepared Checked Approved Approved

by SECL by SECL by SECL by ElL

, '

~

Dahej Petrochemical Complex DFCU &AU PROJECT Page l ~ o f 2 '

6987-LEPCI-SE-CN-PE-OOS8

Instrument work procedure

Rev.: 0]

.

D. Control Valve

Visual Inspection of valve body inside and flow direction shall be done.

3.4.2 Instruments shall not be interfered with their function, operation and maintenance.

3.4.3 Instruments are installed according to the materials shown on the related drawings.

3.4.4 Instruments are correct-mounted horizontally, vertically or at the specified angle.

3.4.5 Instruments are cleaned and have not been damaged.

3.4.6 The terminal and indicating direction of transmitters and switches shall be

checked.

3.5. Instrument Wiring Test

3.5.1 Continuity Test

(1) Use low voltage apparatus such as testers, buzzer or telephones.

(2) Disconnect the wires from the terminal blocks to avoid excessive voltage to the

instruments and to prevent the bypass circuits.

(3) Confirm that the identification of cables and wiring is as shown on the drawings.

3.5.2 Insulation Resistance Test

Insulation resistance test shall be performed after the continuity test.

(1) Used "Meager Tester"(lnsulation resistance tester) of rated voltage 500V or 250V

meager

(2) Disconnect the wires from the terminal blocks after continuity test, and the measure

the insulation resistance between a wire and ground.

(3) Check that the measured values are greater than 100 Mohm except compensation

lead wire for thermocouples as a 5 Mohm.

(4) When specified by the manufacture of apparatuses, the value shall be governed.

(5) Reconnect the wires to terminal blocks after electric energy charged in the wire is

discharged to the ground.

3.5.3 Ground Resistance Test

(1) Grounding resistance meters shall be used.

(2) The measured value shall be less than the specified.

(3) When the grounding resistance value is specified on the special circuits such as

intrinsic safety circuits, the value shall be governed.

3.6 Pressure Piping and Tubing Test

3.6.1 Unless otherwise stated, the test shall be performed with blocking of the

lines from the instruments

3,6,2 Instruments with an operating pressure less than 900# shall be pneumatically tested.

I

04.06.2011 i

i

Date I

Issued For

Approval

Purpose

Prepared

by SECL

Checked

by SECL

Approved

by SECL

Approved

by ElL

Dabej Petrochemical Complex DFCU & AU PROJECT Page llfof2t

6987-LEPCl-SE-CN-PE-0058

Instrument work procedure

Rev.: 01

- -

Instruments with an operating pressure more than 900# and equal shall be

pneumatically and/or hydro statically tested. .

(1) Pneumatic Test

1) Test fluid: Nitrogen, Air

2) Test pressure (the maximum working pressure times)

G) 1.25 for less than 900#.

1.1 for more than 900# & equal.

3) After pressurizing up to test pressure for 5 minutes, pressure piping and tubing

shall not have any pressure change. During the test, the leakage from pressure

piping and tubing shall be checked by soap water.

(2) Hydrostatic Test

1 ) Test fluid : Water

2) Test pressure shall be 1.5 times the maximum working pressure.

3) After feeding of fresh water up to test pressure for 3 minutes, the pressure

piping and tubing shall not have any pressure. During the test, the pressure

decreasing of the lines shall be checked by pressure gauge indication.

<Notes> 1. Pressurization of system shall be done slowly for safety.

2. The test for analyzer piping shall be performed without

disconnection of the lines from analyzers. The test method shall be

done according to process pipe line, pressure pinging and tubing.

3. All piping and tubing system shall be cleaned by air blowing or

water flushing before and/or after the test.

; 3.7 Air Supply Tubing Test

3.7.1 Continuity test and flushing

(1) Continuity test shall be done after flushing of the main header.

(2) Tube itself shall be tested after disconnecting from the instrument.

3.7.2 Leak test

(1) Leak test shall be done after continuity test.

(2) The pressure of air source shall be maintained as specified.

(3) Leak test shall be checked by well mixed soap water.

(4) The roof valve(1st valve) shall be completely opened before testing.

(5) The air shall be used as the test fluid.

(6) The working pressure shall be considered as the test pressure.

(7) After pressurizing up to test pressure for 3 minutes, piping lines shall not have any

pressure change. During the test, the leakage from piping shall be checked by

soap water.

3.7.3 Cleaning Check

04.06.2011 I

Issued For

y=-h-

Approval

t-

Date

I

Purpose

Prepared Checked Approved Approved

by SECL by SECL by SECL by ElL

-

Dabej Petrocbemical Complex DFCU & AU PROJECT Page I gof2fl

6987-I,.EPC l-SE-CN-PE-0058

Instrument work procedure

Rev.: 01

-

(1) The instrument air shall be used as the test fluid.

(2) The working pressure shall be considered as the test pressure.

(3) Blowing out for cleaning shall be performed according to the following procedure.

1) Disconnect lines ahead the individual instrument filter.

2) Open the take-off valve on the main header.

3) Open and shut the stop valve of individual instrument and stop valves in main

header.

4) Repeat above step 1) to 3) until any matter is not found on the white paper

<Note> The blowing shall be done sequentially from instrument air header to

instruments.

3.8 Steam Tracing Tubing Test

3.8.1 Basically, the procedure shall conform to Section 3.6

3.8.2 The steam used for steam tracing shall be practically used for pressure and leak test.

3.8.3 The tubing shall not have any pressure change.

3.8.4 Tracing tubing shall be arranged as shown on the drawings.

3.8.6 No extremely crushed parts by bending shall be found on the heat tubing.

4. LOOP AND FUNCTION TEST

4.1 Field Check and Calibration

Prior to starting of check and calibration of each instrument, the following confirmation shall

be carried out.

4.1.1 Electric Power Source

First,

- If the electric power source energizes normally

- If the voltage is normal

- If the insulation is normal

- If the terminals have been tightened certainly.

In these case, main switch of instrument power source shall be cut off. Second,

- If converter linverter system is normal.

- If the right voltage is supplied.

- If the take-over system is normally functioned each other

(mechanical contractor)

- If the back-up time of each battery is more than holding up time.

<Notes> 1. Dummy load may be considered for this test.

In this case, main switch of switchboards shall be cut off.

2. Refer to "Vendor's instruction manual".

4.1.2 Instrument Air Source

i

Issued For

.

1-

I

04.06.2011 .j

Approval

. I

-_.

Prepared

I

Checked

I

Approved

Date

i

Purpose

Approved

i

by SECl by SECl by SECl by Ell

-

Dabej Petrochemical Complex DFCU & AU PROJECT Page 1,0[2,

6987-LEPC I-SE-CN-PE-0058

Instrument work procedure

Rev.: 01

.

-

(1) Instrument Air Source

The following items shall be confirmed carefully:

1) Loading/unloading of compressor

2) Starting stand-by compressor Refer to "Vendor's Instruction Manual".

(2) Supply of Instrument Air

Upon completion of various kinds of tests, the required supply air pressure of each

kind of instrument shall be confirmed and setting of the pressure regulator (air set)

shall be made. .

4.1.3 Outline of Field Check and Calibration

Check and calibration of the following equipment shall be in accordance with vendor's

standard procedure.

(1) DCS operator console

(2) DCS cabinet

(3) Control panel and rack in control room

(4) PLC

(5) Local panel supplied by package vendor

(6) Power distribution board

(7) Analyzers including Gas-chromatograph

4.2 Loop Test

After each component of a control loop has been calibrated individually, an operational test of

the individual loop shall be carried out.

4.2.1 DCS

(,1) Functional Test

Each loop shall be operated to simulate actual operation from transmitter to final

control element. The complete loop as well as each component in the loop shall

be checked for proper operation and control action (direcUreverse).

(2) Calibration Check

0% of scale for each transmitter shall be verified and calibrated on DCS console.

(3) Action Check

The action of switches and valves shall be checked on DCS console.

(4) Alarm Check

Alarm point shall be confirmed at the above function test.

4.2.2 SIS/ESD and Sequence Control System

04.06.2011

Date

(1) The operational confirmation for input signals, from field instruments to the system,

shall be done at the final output end.

(2) If the operational confirmation of an loop has already been done and an input to

SIS/ESD and sequence system is duplicate to alarm system, it is permissible to

check input to system without operational confirmation from field instruments.

(3) The stroking time of the on-off valve shall be measured using a stop watch.

Issued For

Approval

Purpose

Prepared

by SECl

Checked

by SECl

Approved

by SECl

Approved

by Ell

- -

Dahej Petrochemical Complex DFCU & AU PROJECT Page 2J)of2t .

6987-LEPCl-SE-CN-PE-0058

Instrument work procedure

Rev.: 01

.

4.2.3 Field Signal Input

04.06.2011

(1) Flow Instrument

1) DIP Transmitter

CD The instruments shall be calibrated using a portable signal generator or

HART communicator.

@ 00% of full scale shall be verified on DCS.

@ Hard-wired alarms for the loop shall be confirmed at console.

2) Turbine Meter and PID Meter

0-25-50-75-100% offull scale shall be verified on DCS by the simulated signal

such as pulse or mA generator.

3) Flow Switch

Alarms on the DCS or the console shall be confirmed by giving open or closed

signals at the terminal of the instruments.

(2) Level Instrument

1). Displace Type and Capacitance Type

CD The loopsshall be tested using a potable Millie ampere simulator

connected to the terminal of the instrument.

@ 0-25-50-75-100% offull scale shall be verified on DCS .

.&c..

@ Hard-wired alarms for the loop shall be confirmed at console.

2) Tank Gauge System

Zero point shall be verified on DCS raising the float electrically.

(3) Pressure Instrument

1) Pressure Transmitter

CD The instruments shall be calibrated using a portable signal generator or

HART communicator.

@ 0-25-50-75-100% of full scale shall be verified on DCS.

&

@ Hard-wired alarms for the loop shall be confirmed at console.

2) Pressure Switch

Alarms on the DCS or the enunciator console shall be confirmed by giving

open or closed signals at the terminal of the instruments.

(4) Temperature Instrument

1) Temperature Transmitter

Issued For

Approval

CD The loops shall be tested using a potable milliampere simulator

connected to the terminal of the instrument.

@ 0-25-50-75-100% of full scale shall be verified on DCS.

@ Hard-wired alarms for the loop shall be confirmed at enunciator console.

---.... -

Prepared I Checked Approved

by SECL

Approved

by ElL

Date Purpose

by SECL by SECL

-

Dahej Petrochemical Complex DFCU & AU PROJECT Page 2,0[2,

6987 -LEPCl--SE--CN-PE-0058 Instrument work procedure

Rev.: 01

APPENDIX:

04.06.2011

Date

-

2) Thermocouple and RTD

<D Thermocouple loops shall be tested using a potable mill volt simulator

connected to the terminal of the element. RTD loops shall be tested using

a resistance simulator connected to the terminal of the element.

of full scale shall be verified on DCS.

@ Alarms for the loop shall be confirmed at enunciator console.

3) Temperature Switch

Alarms on the DCS or the console shall be confirmed by giving open or closed

signals at the terminal of the instruments.

(5) Control Valve

1) The following items shall be verified by giving signal by DCS and/or PLC.

<D Valve action (smooth)

@ Travel of full scale)

@ Limit switch action (to be confirmed on DCS by answer back)

@ Solenoid valve action

Air and electrical failure position

2) If the control valve has a solenoid valve and the test is impossible, this test

may be performed at the same time off the operational confirmation of

interlock system or sequence system.

1. ITP for Instrument,

2. Calibration Reports

3. Inspection Record Sheets

Issued For

Approval

Purpose

Prepared

by SECL

Checked

by SECL

Approved

bySECL

DAHEJPETROCHEMICAL

e)

COlVIPLEX

Dual Feed Cracker Unit

ONGC Petro additions Limited

& Associated Units

ElL

SEZ, Dahej, Gujarat, India

JOB NO. 6987

Page: I of 4

INSPECTION AND TEST PLAN

02 04-Jul1e-2011

01 n-May-2011

Dalc

0-

-.:! ...

. .

'. .

Contract No PO No.:

I t '."llractor noc. No.:

I &SE-OO-Q-PQ-042

L_.

FOR

INSTRUMENTATION

For Approval

For Re\'icw & Approval

Rc,lsnn 1(1)" IsSlIC Rcmark

ENGINEERING

DIVISION

SAMSUNG

ENGINEERING

Prcpared

Linde Project No.:

Linde Project Code:

Samsung Project No.:

Samsung Project Code:

Item No.:

l.,mpany Doc. No.:

Y.K.Park

Y.K.Park

Chccked :\ppnwcd

3110 A9NK

DAHEJ

SC 2252

OPaL DFCU & AU

6987-LEPC I-SE-OO-QC-PQ-042

Dahej Petrochemical Complex DFCU &AU

Page 2 of4

6987-LEPC 1-SE-00-QC-PQ-042

INSPECTION AND TEST PLAN FOR

Issue: 02

INSTRUMENTATION

REVISION HISTORY

REV DATE DESCRIPTION

01 04-June-2011

Letter no.SE-EIL-L-1254&1262 dated 23.05.2011, ElL

Comments incorporated and re-submitted.

* Notes:

This page records all revisions on the specification.

23-05-2011

Date

Issued for

Approval

Purpose

Prepared by

SECL

Checked by

SECL

Appro\'cd by ElL

I

I

Dahe.i Petrochemical Complex DFCU & AU Page 3 of4

,()X7-1.1:PC I-S E-OO-QC-PQ-042

INSPECTION AND TEST PLAN

Issue: OL

INSTRUMENTATION

L ............. _ ... ___ .

0' In'p"tion T."

I nspectionffest

Reference Document Remarks

Report Format

I M.ATERIAL RECEIVING IMIR H H IIMIR

.--------

- Calibration should be bench tested

CALIBRATION basically but where bench test is not

2.1 Transmitters INC-CAL-OO I suitable such as flow element, control

'1 '1 S . I

INC-CAL-002 valve above 4" etc., t1eld calibration

2

I wltC les

IIR W V/RC -Instrument Data Sheet

2.:> Thermocouple/RTD INC-CAL-003 would be adopted.

2.4 Control Valves INC-CAL-004 - Gauges will "0" adjusted but ifnot

2.5 Gauges(Pressure/Temperature) No Record possible to calibrate, that gauge will be

substituted by new ones.

I.UC /\L PANEL

r ["()NTROL ROOM EQUIPMENT

I-RIB Equipment & Wiring Layout

4 "Jl BOX IINC-INSP-OO 1

.5 Cable Duct INC-INSP-002

(j

PERFORATED TRAY INC-INSP-002

7

I IIR

IIR

I/R

IIR

I/R

I H

H

H

W

W

W

W

W

W

V/RC

I-Instrument Main Cable Plan

Main Cable Way

-Instrument Main Cable Plan

-Instrument Wiring Plan

-Instrument Air Tubing Plan

-Inspection Connection List

Partial inspection request is acceptable

Inspection should be done before cable

pulling or tube laying on tray

Inspection should be requested after

rack & JB both side termination done

MULTI-CABLE INC-INSP-003 " """d 8.1 + 8.2

7 I C,blo p"mng INC-INSP-004 -I"pootion bo q

) INC-INSP-005 In,'mmo.' W;ri.g PI,. . altho b"oq",,'od afto"B

(C.",;"",,,Ii.," a .0. W :I.","mo., W;".g & T"b .. g -1.'pOO"0.' ,;do ",m;.atod

>----------+-,;, N G L CoCA B LEV IRC . Co o"; eo Dotail & .. "rumo.'

I

X J H.I Cable Pulling

{ X.2 Cable Termination

_____ _ (Continuity/Insulation)

INC-INSP-004

INC-INSP-OOS

IIR

IIR

W

W

Issued for I I /"\ ... .. :A' :;;;;>'

Approval

01 04-06-20 II

Rev.

Date

Purpose Prepared by SECL Checked by SECL Approved by SECL Approved by ElL

Dahe.i Petrochemical Complex DFCU & AU Page 4 of 4

.

E

6987-LEPC I-SE-00-QC-PQ-042 INSPECTION AND TEST PLAN INSTRUMENTATION Issue: 02-

-----'1NSTRUMENT

9.1 Stanchion

9 I 9.2 Instrument Installation

9 . .1 Pressure Piping & Tubing

9.4 Others(such as Steam Tracing)

LEi\K TEST

10 I 10.1 Pressure Piping/Tubing

INC-INSP-006 I

fNC-fNSP-007 I

-Instrument Wiring Plan

IIR I H H

I -Piping Arrangement(if needed)

-Instrument Hook-up Detail

-Steam Tracing Plan

f/R I W

I V/RC I -Instrument Data Sheet

-Instrument Air Supply Tubing Plan

-Instrument Calibration Record

____ ________ +-__________ -+ ____ +-__

II I I.OOP TEST INC-INSP-008 I f/R I H H

I -Instrument Termination Test Report

-Other Logic/Control Diagram as

required

NOTE

I Stanchion location should be decided

with the coordination with ElL

The aclditional rei'erence drawing and/or document may be required while inspectionitest if necessary other than listed above Reference Document.

PARTICIPATIENT

SC - Sub Contractor

SS - Samsung Engineering & Construction Co., Ltd.

EI L - Engineering India Limited

LEGEND

I - Responsible to request/undertake the inspection/test

R - Responsible to generate/maintain the inspection/test record

V - Verify/Review of InspectionfTest Record

W - Witness of InspectionfTest(lf not il! attendance of specified time, inspection/test may proceed

RC - Random check: may request the test for few %(Iess than 10%) or items among tested items for

verification.

H - Hold InspectionfTest till SECLIEIL attend(may not proceed inspection/test by themselves)

[0'-- 04-06-'011 I""d foc

Approval ,,).';;t ... .J. < If ."

Date I

Rev. Purpose Prepared by SECL Checked by SECL I Approved by SECL I Approved by ElL

Owner PMC

DAHEJ PETROCHEMleAL COMPLEX

Contractor

II

Dual Feed Cracker Unit

.-

SAMSUNG

=:

& Associated Units

ENGINEERING

OPaL ElL

-

CALIBRATION REPORT

(TRANSMITTERS)

Report No.: Calibration Date:

Tag No.:

Eng. Spec. No.:

Tag Description

Range on Spec.:

Location I Area:

1. Instrument data

Function: Range:

Manufacturer: Test Voltage:

Type I Model No.:

/iTem

p

Serial No.:

r(/)

2. Visual Checking

" if>

No.

ITEM DECRIPTION OK

1I!Aj'

REMARKS

1 Accessories(Block Valve, Cable Entry Blocking, etc.)

A b:J

2 Instrument check against data sheet

II

3 Instrument checked for damage

,,)

4 Instrument tag number attached to instrument

,--) J

5 Calibration tag or sticker attached to instrument

Ac"-.

3. Calibration Results .

ACTUAL INPUT

FINALmA % ERROR(FINAL)

% INPUT

Rising . Falling Rising Falling

0%

25%

J

50%

1

75%

r

V" " "t'

h"'I.

100%

"

//)

_.-r... .) ,!

pr .'

4. Test Equipment

Description Manufacturer I Model Serial No. Calibration Expiry Date

Remarks:

.-....... __ ... _ ... __ ................ -................. _ ...... _-._-_ ...... _ ....... __ ......... -.... _ ....... ............. __ ........................ _ .......... _-_.-._.-_ .... _._---_._-----_ ..... _ ... _.-_._. __ .. -. __ .. _ .. __ ............... _.---.. _--

........................................... -. .................... __ .... -..... _ ..... -.. --.. _ ...... ....... -........ . ........... _ ......... .................. -............ _ ....... _ ..... __.. _._ ... _ ........... -._-_ ........ -.--_ ............. . .......... _ ................. _ ..... ............ .. ..... -.....

Company Sub-Contractor Samsung

EWOPaL

Name

N'Sh",d..s

Signature

cntQ

Date

'-"

j{(dl\

Ot., - Iu If\.( - 20 It

Form No.: INC-CAL-001

i

Owner PMC

DAHEJ PETROCHEMICAL

Contractor

COMPLEX

-

SAMSUNG

(I.1M)

Dual Feed Cracker Unit

ENGINEERING

&-

& Associated Units

OP::l1 Ell

CALIBRATION REPORT

(SWITCHES)

Report No.: Calibration Date:

Tag No,:

Eng. Spec. No.:

Tag Description:

Set point on Spec.:

Location I Area:

1. Instrument data

Function: Range:

Manufacturer: T

((-

,tage:

,

Type r Model No.: b' nve ..

--

!

1/

/1

Serial No.: /' T

,r

2. Visual Check

""-

No.

ITEM DECRIPTION

,"'

",-oJ! I..INO

"

N/A

REMARKS

1 Accessories(Block Valve, Cable Entry

2 Instrument check against data sheet

/rb 1

'''''

3 Instrument checked for damage

,""H l.

4 Instrument tag number attached

5 Calibration tag or. sticker attached

3. Calibration Results

{.

As Left

Set Point RiSing!

a '

I '"" ,

mead Band Rising Falling Dead Band

\

)

(

- : M

\V'

'= z,r

.d if

4. Test Equipment

Description Manufacturer f Model Serial No. Calibration Expiry Date

Remarks:

....................... -.... _ .............. -............... -......... -........................................................... _ ..................... _-............ _ ............ -.-....... -..... -... -............... _ ............. -.... _ ....................... _ ....... _ ..

.......................................................................................................................... .................... _ ......................................... _ ....................................................................................................

............... ....................................................................................

"

.... . ....................................................................................................................................................

Company Sub-Contractor Samsung EIUOPaL

Name

VAL.

Signature

?dQ. RP../)

- -

Date

04- Jc..AlfU - 2.011

Form No.: INC-CAL-002

-

PMC

DAHEJ PETROCHEMICAL COMPLEX

Contractor

II

Dual Feed Cracker Unit

-

SAMSUN.G

.

& Associated Units

ENGINEERING

L

OPaL ElL

CALI BRA TION REPORT

(Thermocouple/RTD)

Report No.: Calibration Date:

Tag No.:

Eng. Spec. No.:

Tag Description:

Range on Spec.:

Location! Area:

1. Instrument data

Function: ge:

c

".I

Manufacturer:

i 'V. It e:

{I

Type I Model No.: Am n "' p.:

Serial No.:

2. Visual Check

;ti-

No.

ITEM DECRIPTION

NO NIA

REMARKS

1 Accessories(Union, Cable Entry Blocking, etc./, /"'\, ) t"#

2 Instrument checK against data sheet

"J'J

3 Instrument checked for damage

4 Instrument tag number attached to v

5 Calibration tag or sticker attached 'Y

3. Calibration Results

: . .:::ss

Measured Value Error

Input

As Found As Left %

c fC&P" c Q/Mv

c

Q/Mv

Ambient

\..J

Ij)j

?' ,

URV

"

l/'

,,'

4. Test Equipment

Description Manufacturer I Model Serial No. Calibration Expiry Date

Remarks:

........... __ ............... _ .... -.. _ ............. -.... _ ... _ ... __ ......... _ ... _ ................................................. _ ..................................... __ ._ ................... _ ... _ ......... _ .... _ ................. _ .......... __........ _-.. -._ ........ -

............................................... __ .......................................... -............................................................ - ......... _ ..... __ ...... -... _ .. _ .......... -.... _ ... _ ............ _ ..... -.................................... -.... -..................... -

.Ji ................................................................................................................ ............ . ................................................................. _ .................... -................. -.......................................................................

Company Sub-Contractor Samsung

i

EIUOPaL

Name

Nisl".,.d5

Signature

_MJ.r-vAL

-

q1g\ \\

Date

'j'aw. - 2.0',

- Form No.: INC-CAL-003

Tag No.:

COMPLEX

Dual Fel!d Cracker Unit

& Associated Units

CALIBRATION REPORT

(CONTROL VALVE I ON-OFF VALVE)

Eng. Spec. No.:

Contractor

SAMSUNG

ENGINEERING

Tag Description: Air Supply Press.: _________ _

Location I Area:

1. Valve data

Manufacturer:

Type I Model No.:

2. V isual Checking

S. No.

ITEM DECRIPTION

1 Accessories Status(I/P Converter, Solenoid, etc.)

2 Valve check against data sheet

3 Cable entry and air connection blocking check

4 Valve flow direction correct

./

5 Calibration tag or sticker attached to

Serial No.:

A

OK N, 1/".1'

"-

.I'

'"

"'

"\

,.

i)J

"'I

3.C alibration Results

. INPUT

REMARKS

CLOSING ACTION

TRAVEL %

TRAVEL % lIP Conv.

% mA As Found As Left

As Left As Found As Left As. Left

0%

<;:

b

V

..,..

25%

/

50%

(C

75%

1<" ,/

-

100%

STROKE TIME: Air Fail Action:

ACCESSORIES FAIL FUNCTION OK NOT OK

SOLENOID A

SOLENOID B

LIMIT SWITCH CLOSE

LIMIT SWITCH OPEN

LOOK-UP DEVICE

OTHER

4. Test Equipment:

ERROR %

As Left

Description Manufacturer I Model Serial No. Calibration Expiry Date

Remarks:

Company Sun-Contractor

Name

Signature

Date

Form No.: INC-CAL-004

DAHEJ PETROCHEMICAL COMPLEX

.,

SAMSUNG

(ilIIt11PIl

Dual Feed Cracker Unit

ENGINEERING

& Associated Units

INSPECTION & TEST REPORT

.

(PANEL I JUNCTION BOX)

.

Report No.: Inspection Date:

Tag No.:

Ref. Spec.lDWG No.:

Name

Location I Area:

Panel I Junction Box Installation Check list

No. CHECK ITEMS

11hA

SAT.

UN

N/A Remarks

SAT.

1 Labelling I Identification correct

2 Check mechanical damage

A

'':::/

3 Check panel leveled properly and stand in a row

4 Check paint condition

/,,',\V

5 Tblllllllc:ltivi peripherals good condition

,"1/

6 Check for accessibility and correct

'''\,;:

7 door opening is smooth and not object

8 Spare entries plugged

9 ICheck internals for cleanliness

10 Check panel against drawing, Specification

11 Check manual operation

push button, Lamp, etc.

Jft' Ar'

'=/:;/)'

"V ..

Remarks: .

-..... _ ...... -.. _ .......... _-...... __........ -_ ........ --..... _ ................ _ .......... _.--_ .. _ ... _ ...... _. __ ...... __ . __ .. _ ............. _--... __ .......... _._._--_ ..... -. __.. _ ....... - ..... _ .. _._._ ..... _. __ ... _--_ .. _--

__ _ ........... _ _ .................................. __ __ n _ .................... _ _ _ ............................ _ .......................... _ ......... _ ................. __ _

.................................................................................................................. _ ................... _ ......................... _ .................................... _ ......................................................................... -_ .. __ ..... _ ...

Company Sub-Contractor Samsung EIUOPaL

Name

Nts "'c.olJ'

Signature

,.

Date

- 04 - jo "'l- 2.11 -

"

Fnrm Nn . INl.-INSP-001

DAHEJ PETROCHEMICAL COMPLEX

.

Dual.Feed Cracker Unit .,

SAMSUNG

-

ENGINEERING

& Associated Units

INSPECTION & TEST REPORT

.

(CABLE DUCT I PERFORATED TRAY)

.

Report No.: Inspection Date:

. Location I Area:

Ref. Spec'/DWG No.:

Cable Duct Installation Check List

No. CHECK ITEMS SAT.

UN

N/A Remarks

SAT.

Cable duct size and layout as per approved drawing

/)A

Support and hanger installed properly

!...VLh

Bending radious acceptable

,V/

Cable duct is free from mechanical damage

b'V

Joint plates correctly installed with proper bolt &

{Qi

....

Perforated Tray Installation .

Tray size and layout as

Tr is properlysu!-,!-,vi \

a

Spacing from hot

Spacing from

\

Joint plates correctly bolt & nuts

Welded portion is properly zinc painted

IWelded portion is properly zinc painted

Remarks:

_ .. __ ..................... __ ................ -............ -_ ............................ -........ _ .............. _--......................................... -_ .. -... _--..................... -.. _ ... __ ........ __ ..... -_._ ... -....... --.-........ _--_ ... _ .... _ ....

......... -_ .................... _-_ ................ -.......................................................... -....................... .............................. -..................... ................ -..... -............ _ .......... _ ........................... _._ .. _-.. -

.. _ ............ -................................................................................................ _ ............. __ ................... _ ... _ ................................................................................ _ ............. - .. _ ............ _ ......... - ....... -....

Company Sub-Contractor Samsung ElL/OPal

Name

N,s

Signature

-

Date

Q -4 - jCAIIV - 2-o!l

9

l61 II

Form No : INC-INSP-002

DAHEJ PETROCHEMICAL COMPLEX

(I'B'W

Dual Feed Cracker Unit

.-

SAMSUNG

& Associated Units

ENGINEERING

INSPECTION & TEST REPORT

.

(INSTRUMENT CABLE)

Report No.:

Inspection Date:

JB No. I Panel No.

Ref. Spec.!DWG No.:

From:

To:

Drum No:

Cable(Multi-Cable) Installation Check List

Cable size:

No. CHECK ITEMS

/)

SAT.

UN

N/A Remarks

SAT.

1 Cable trench status(Tile Brick, Sand, Warning Tape, etc.)

2 Cable duct bank status ,'{/j

3 Cable route and cable transit assembly status

h

V

4 Cable different voltage level segregated, dressed

#'

5 Cable size and type as per cable schedule

/()j

'V

6 Cab'le physically not damaged

7

ICable tag is correct.

"'"

t

V

./11

=<-!y;

Remarks:

...... _ ...... -......... _-.. - ........ _ ............ _ ... _ ...................... -...... _ .... __ ................... _-._-_. __ ............ _._ ................ _---_.-._ ... -._ .. _ .......... _ .. _ .. _--_ ........ _ ... _ ......... -..........

_ ....... -.......... -... __.......................... -_................. -........................... _ ...... _ ........... __ ._-...... _._ ..... _ .. _ ... -..... _ .. --_._. __....... -._ .. _ .... _._... __ ._-_ .......... -........ -................... _--_ ... _ ..

............. _ ........................... . ............................................................ _-_........................ _ ......................................................... _ .................................... -... _ ... _ ........ _ .......... __.. _ ...........

Company SUb-Contractor Samsung EIUOPaL

Name

Nt's \., 5

Signature

Date

o li - 1't.t "'" - 20 \I '11 s{ \\

Form No.: INC-INSP-003

DAHEJ PETROCHEMICAL

-

- -

('Bij

COMPLEX

.,

SAMSUNG

ENGINEERING

Dual Feed Cracker Unit

INSPECTION & TEST REPORT

(INSTRUMENT WIRING)

-

r---

Report No.:

Test Date: Page:

JB or Local Panel No:

1. Visual Checking Drum No: Cable Size

No ITEM DECRIPTION OK NO NfA Remarks

1 Bending Radious Status

2 Labelling f Numbering f Ferruling

3 Earth or sheild wire connection correct

4 Cable gland suitable for area classification

5 CablelWire length is long enough to fress from stress

6 CablelWire is tied properly

7 Cable tag is correct

8 Terminal lug and bolt tightened

2. Test Results

FIELD INSTR. JBfLOCAL PNL

CABLE

CONTROL ROOM CONTIN- INSULATION(MQ)

No TAG NO. TIM NO. WIRE NO. TERM

NO,

PANEL WIRE NO.

UITYOK CORE TO CORE TO CORE TO

(+ OR-) fCOLOR NO. NO. fCOLORA

OR NOT

CORE ARMOUR SCREEN

,!l II'#]t

"-

I'V;"

').

./

&.

!,

/'n

WI'

1#

) ,

,

..

!J

N

j'

\

tf

\

/.

7')..

:i'

IF

D '

..

t (

1#' /.?\

'-.. /1

/-/A

'Y"

Continued

Company Sub-Contractor Samsung EIUOPaL

Name 1--.1; 0:::. l,..." d. c: 1\1\1\ LU

Signature

Date

nJ.t:''Tt'.J1A1

..... ;::

W bt 1\

\.

-

Form No.: INC-INSP-004

DAHEJ PETROCHEMICAL

COMPLEX

.,

SAMSUNG

ENGINEERING

Dual Feed Cracker Unit

INSPECTION & TEST REPORT

- -

(INSTRUMENT WIRING)

Report No.: Test Date: Page:

2. Test Results Drum No: Cable Size

FIELD INSTR. JBfLOCAL PNL

CABLE

CONTROL ROOM CONTI INSULA TION(MQ)

No. TAG NO. TfM NO. WIRE NO. TERM PANEL WIRE NO. TERM

N-UITY

CORE TO CORE TO CORE TO

(+ OR-) fCOLOR NO.

NO,

NO. fCOLOR NO.

OKOR

CORE ARMOUR SCREEN

i'>...

;

'#'A

/Jl

""'-

{II

"

"", 'V "

A ,,:V

I, "

lI}

r-......'v

j'

'\

,

111

'P'

<

V

S

r-

/!

\

f

\

x

I/I?

/ ......

;'

t""

,p' ..;'

!

.<;(/./

Company Sub-Contractor Samsung

k

Name

S

Signature

-t\<h\ WL.

Date

';.,J.t'-:' T"uw - 2-011

Form No.: INC-INSP-005\

Report No.:

DAHEJ PETROCHEMICAL COMPLEX

Dual Feed Cracker Unit

& Associated Units

INSPECTION & TEST REPORT

(INSTRUMENT)

Inspection Date:

SAMSUNG

ENGINEERING

Tag No.: Hook-up DWG No.: ________ _

Field Instrument Installation Check List

Case

c

o

:.c

u

c

2

en

c

OJ

E

2

iii

c

CHECK ITEMS

Stachion is free from vibration

Fixed properly on floor or structure A

Galvinizing condition /'U'2

Sunshade installed in place of required(direct sunlight) " V),

Name plate / Labelling /Identification tag is '.;:;:vI'

Mount on location as per plan drawing V/

Location is suitable for accessiblity and!(...LO}- V

Instrument flow direction is correct (FIe. (II'" A COntrol Valve)

Isolation valve is i ,r! unused tapping pluged.

Tapping O'!""LCn,Ul' PipinnlJ!Hhinn is correct

'W ."'" 2'

Gasket,bolt-nut&MOC

Correct size of no missing bolt.

III

in

.c

Impulse slop is correct as per hookup drawing.

Material of per drawing.

Correct size and materi;1 for steam tracing if required.

Check proper glanding(gland size/type) and termination. Unused entries

plugged&unused wires are terminated. No exposed armour/wire at point of gland .

o

o1l Wiring,earthing connection as per drawing.

U

lugs/sleeves &ferrules are proper and termination tightened.

OJ

iii

Extra cable loop,cable marking is provided near instrument.

[shield wire is cut&insulated to avoid grounding.

Remarks:

Sub-Contractor Samsung

Name

Signature

Date

SAT. UN N/A Remarks

SAT.

\ f3!.1

0PaL

-

Form No. INC-INSP-006

DAHEJ PETROCHEMICAL COMPLEX

SAMSUNG

Dual..Feed .Cracker Unit

.,

W

ENGINEERING

& Associated Units

INSPECTION & TEST REPORT

-

(PIPEITUBING)

-

Report No.: Insp./ Test Date: T est Duration:

Area / Location Ref. Spec. / DWG. No.

I." Inspect:

II I::' ld lid LU II ;LlUIi Test

HYDROSTATIC TEST PNEUMATIC TEST

No. TAG No. SUPPORT MATERIAL TEST TEST RESULT TEST TEST RESULT

TEST

REMARKS

& FLUID PRESS PRESS FLUID PRESS PRESS

RESULT

RATING I (kg/cm

2

G) (kg/cm

2

G) (kQ/cm

2

G) (kg/cm2G)

f fA

e V/A

"-

{f jt

I'

....... /

,

/AY

....,.,

"-

'-.

/,.

''\ "-

w

fI'

} V

"-

"J

'"

/"\",

"'

"-

\ ."-

'"

.#

"- "'-

."""

"-

'"

"'"

... 'V

\ \

L \ 1/

[If

}

[

P'

...."".

lW

'---

J

FLUID A = AIR ,N = N2 W=WATER

Remarks:

.... __............. _ ........... _-_._-................... -.. _._._ ................... _ .... -.. _ ......... -.................. _ ........... -.. _--_._ .. _._ ....... -.. _ ................. -_ .. _ ........... _._ ... _ ...... - ..

_ .............. -....... _ ............... _._ ................................................. -............................. _ ...... _ ... _ .. __ ... __ .... _.-................ __ ..... -....... _ ....... _ .. _ ......... __ .. -

.................... _ ... _ ............................................................................... _ ................................. _ ....... -...... -.................. -..... __ .......... _ ......... -.......................................

.... _._ ................. _ ............................................. _ ........ _._ ................. _ ............................................ _-._ ... -........... _ .................................. -_ ........................ -... _ .

L-omf-'ol Sllh-r.lmtractor . vdlnsung EIl)OPaL

Name

Ni.sL.""d ('

!\rt\, \UL

Signature

9:1r.:::L

Qate

OJt- '2011

'-'"

Form No.: INC-INSP-007

\ 1

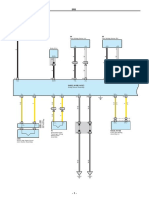

2 DAHEJ -

Dual Feed .Cracker .Unlt _ mGINmlNG

& & ASSOCiated Units

INSPECTION & TEST REPORT

(LOOP TEST)

Date:

Report No:

Loop No.

o Digital Input/Output

Type

o Proximity Switch o Switch 0 Push Button

o Solenoid Valve

Indication/Com m and

o DCS/ESD Command

o Close 0 Start

o Open 0 Stop

Status

OOk o Not OK

o Transmitter

Type

o Flow

OLevel

.Range:

Eng.Unit

OPressure

OTemperature

-------

o Control Valve 0 ON/OFF Valve

Control Valve

o AlarmlTrip

Status

OOk

ON/OFF Valve

o Others

o Not OK

o Not OK

DCS Command Des Command Valve Position

% mA

0

25

50

75

100

Remarks:

Risin

Fail Position

o Fail Close

o Fail Open

Stroke Time:

o Fail Lock

.---- . Ihlr"' IhieD n"Q

sec.

You might also like

- ITP - 003 - Rotating Equipment - IFRDocument3 pagesITP - 003 - Rotating Equipment - IFRMari Belajar100% (1)

- PPR Pipe Method Statement For Pipe and Fitting Installation and Testing Commissioning PDFDocument14 pagesPPR Pipe Method Statement For Pipe and Fitting Installation and Testing Commissioning PDFBuraq Aircondition Cont & Gen Maint LLC BuraqNo ratings yet

- Hydrotest Procedure For PipingDocument4 pagesHydrotest Procedure For Pipingsuria qaqcNo ratings yet

- QCF301 Hydro Test PackDocument1 pageQCF301 Hydro Test Packminhnn0% (1)

- QCP 10 Hydrotest and Flushing ProcedureDocument15 pagesQCP 10 Hydrotest and Flushing Procedureคุณพ่อน้อง บิ๊กบอสNo ratings yet

- 2539-00-ITP-012 - 0 - ITP For Plastic Piping PDFDocument17 pages2539-00-ITP-012 - 0 - ITP For Plastic Piping PDFdang2172014100% (1)

- ITP Elektrical InstrumentDocument17 pagesITP Elektrical InstrumentsswahyudiNo ratings yet

- Site Inspection and Test Plan For Tie-In Works: Subcontrac TorDocument24 pagesSite Inspection and Test Plan For Tie-In Works: Subcontrac Torprabu palaniswamyNo ratings yet