Professional Documents

Culture Documents

Sizing Steam Pipes & Steam Velocities

Uploaded by

Macarthur B. MonsantoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sizing Steam Pipes & Steam Velocities

Uploaded by

Macarthur B. MonsantoCopyright:

Available Formats

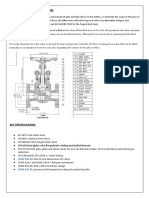

Sizing Steam Pipes (lb/h)

Steam is a compressible gas where the capacity of the pipe line depends on the

size of the pipes and the steam pressure. This table can be used for fast

sizing of steam pipes dimensions

This table can be used for fast calculation of steam pipes. 80 ft/sec is in general a recommended steam velocity.

Capacity (lb/hour)

Steam

Pressure

Velocity

(psi)

(ft/sec)

10

20

30

40

60

Pipe Size (inch)

1/2"

3/4"

1"

1 1/4" 1 1/2"

2"

2 1/2"

3"

4"

5"

6"

8"

10"

12"

50

12

26

45

70

100

190

280

410

760

1250

1770

3100

5000

7100

80

19

45

75

115

170

300

490

710

1250

1800

2700

5200

7600

11000

120

29

60

110

175

245

460

700

1000

1800

2900

4000

7500

12000

16500

50

15

35

55

88

130

240

365

550

950

1500

2200

3770

6160

8500

80

24

52

95

150

210

380

600

900

1500

2400

3300

5900

9700

13000

120

35

72

135

210

330

590

850

1250

2200

3400

4800

9000

14400

20500

50

21

47

82

123

185

210

520

740

1340

1980

2900

5300

8000

11500

80

32

70

120

190

260

520

810

1100

1900

3100

4500

8400

13200

18300

120

50

105

190

300

440

840

1250

1720

3100

4850

6750

1300

19800

28000

50

26

56

100

160

230

420

650

950

1650

2600

3650

6500

10500

14500

80

42

94

155

250

360

655

950

1460

2700

3900

5600 10700 16500

23500

120

62

130

240

370

570

990

1550

2100

3950

6100

8700 16000 25000

35000

50

32

75

120

190

260

505

790

1100

1900

3100

4200

12800

18000

80

51

110

195

300

445

840

1250

1800

3120

4900

6800 13400 20300

28300

120

75

160

290

460

660

1100

1900

2700

4700

7500 11000 19400 30500

42500

50

43

95

160

250

360

650

1000

1470

2700

3900

24000

8200

5700 10700 16500

80

100

120

150

200

80

65

140

250

400

600

1000

1650

2400

4400

6500

9400 17500 27200

38500

120

102

240

410

610

950

1660

2600

3800

6500 10300 14700 26400 41000

58000

50

53

120

215

315

460

870

1300

1900

3200

5200

7000 13700 21200

29500

80

83

190

320

500

730

1300

2100

3000

5000

8400 12200 21000 33800

47500

120

130

290

500

750

1100

1900

3000

4200

7800 12000 17500 30600 51600

71700

50

63

130

240

360

570

980

1550

2100

4000

8800 16300 26500

35500

80

102

240

400

610

950

1660

2550

3700

6400 10200 14600 26000 41000

57300

120

150

350

600

900

1370

2400

3700

5000

9100 15000 21600 38000 61500

86300

50

74

160

290

440

660

1100

1850

2600

4600

7000 10500 18600 29200

41000

80

120

270

450

710

1030

1800

2800

4150

7200 11600 16500 29200 48000

73800

120

175

400

680

1060

1520

2850

4300

6500 10700 17500 26000 44300 70200

97700

50

90

208

340

550

820

1380

2230

3220

5500

8800 12900 22000 35600

50000

80

145

320

570

900

1250

2200

3400

4900

8500 14000 20000 35500 57500

79800

120

215

450

850

1280

1890

3400

5300

7500 13400 20600 30000 55500 85500 120000

50

110

265

450

680

1020

1780

2800

4120

80

180

410

700

1100

1560

2910

4400

6600 11000 18000 26600 46000 72300 100000

120

250

600

1100

1630

2400

4350

6800

9400 16900 25900 37000 70600 109000 152000

6100

7100 11500 16300 28500 45300

64000

Pipe Sizing - Sizing steam and condensate pipes - pressure loss, recommended

velocity, capacity and more

Steam and Condensate - Steam & condensate properties - capacities, pipe sizing,

systems configuration and more

Pressure Drop in Steam Pipes - Steam pipes and pressure drop diagrams - imperial and

metric units

Recommended Velocities in Steam Systems - The steam velocity in a steam distribution

system should be within certain limits to avoid excessive wear and tear

Sizing Steam Pipes (kg/h) - Steam is a compressible gas where the mass flow capacity

of the pipe lines depends on the steam pressure. This table, where pressure is in bar,

velocity in m/s and capacity in kg/h, is suitable for sizing steam pipes

Steam Heating Processes - Load Calculating - Calculating the amount of steam in nonflow batch and continuous flow heating processes

Steam Pipe Pressure drop Calculator - Calculate pressure drop in steam distribution

pipe lines

Steam Trap Selection Guide - A steam trap selection guide - Float & Thermostatic,

Inverted Bucket, Bimetal Thermostatic, Impulse and Thermodynamic Disc steam traps

Steam and Condensate Loads in Heating Systems - Calculating steam and condensate

loads in steam heated systems

STEAM VELOCITIES FOR PIPING DISTRIBUTION

The steam velocities or speeds below are commonly recommended as acceptable for steam distribution

systems:

Velocity

Steam System

(m/s)

(ft/s)

Saturated Steam medium and low

pressure

25 - 40

82 - 131

Saturated Steam - high pressure

30-40

99 - 131

Saturated Steam at peak load

< 50

< 164

Steam and Water mix

< 25

< 82

Superheated Steam

35 - 100

100 - 300

Saturated steam - low pressure - is common for heating services and secondary process

pipes.

Saturated steam - high pressure - is common in powerhouse, boiler and main process

lines.

Superheated steam is common in power generation and turbine plants.

You might also like

- Pipe Sizing for Optimal Steam FlowDocument6 pagesPipe Sizing for Optimal Steam Flowferdie14No ratings yet

- Once Through BoilerDocument9 pagesOnce Through Boilerbhuvi_patu12No ratings yet

- Construction Parts of BoilerDocument5 pagesConstruction Parts of BoilerMdParbhezNo ratings yet

- LPG Energy IntegrationDocument6 pagesLPG Energy IntegrationBandaru KiranNo ratings yet

- TurboDocument8 pagesTurboKorichiKarimNo ratings yet

- Toolbox4Planning - Basic Concept of Civil - Structure Engineering Work Flow For Schedule DevelopmentDocument1 pageToolbox4Planning - Basic Concept of Civil - Structure Engineering Work Flow For Schedule DevelopmentMuslimNo ratings yet

- PETRONAS' Malaysia RAPID Steam Craker Complex - TOYODocument3 pagesPETRONAS' Malaysia RAPID Steam Craker Complex - TOYOKitty JoyceNo ratings yet

- King Hussein Airport Expansion Project Quality Control LogDocument3 pagesKing Hussein Airport Expansion Project Quality Control LogAmran MohammedNo ratings yet

- CJ Project Activity ScheduleDocument3 pagesCJ Project Activity ScheduleWisnu Setiawan100% (1)

- Energies 10 00205Document19 pagesEnergies 10 00205radanpetricaNo ratings yet

- What Is Carry Over and Carry Under at The Boiler DrumDocument12 pagesWhat Is Carry Over and Carry Under at The Boiler Drumabdulyunus_amirNo ratings yet

- Design Review of AbsorbersDocument46 pagesDesign Review of AbsorbersAngelik MoralesNo ratings yet

- Definition & Types of Reboilers - A. Thermosiphon - : Reboiler CircuitsDocument2 pagesDefinition & Types of Reboilers - A. Thermosiphon - : Reboiler CircuitsWade ColemanNo ratings yet

- Functional Test: FT-Packaged Boiler and Boiler System Including HW Pumps 1 & 2Document7 pagesFunctional Test: FT-Packaged Boiler and Boiler System Including HW Pumps 1 & 2vin ssNo ratings yet

- Teg ContactorDocument4 pagesTeg ContactorrepentinezNo ratings yet

- Korf BrochureDocument1 pageKorf Brochurelhphong021191No ratings yet

- FlareDocument39 pagesFlareMuhammad Tahir RazaNo ratings yet

- At M/S Jindal Steel &power Limited: For More ProjectsDocument26 pagesAt M/S Jindal Steel &power Limited: For More ProjectsvasqueznvNo ratings yet

- Ethylene Plant Planning StudyDocument8 pagesEthylene Plant Planning StudyAngelica Rosario Flores LecoñaNo ratings yet

- Integrated Amine Degreasing Schedule 30mar2018Document1 pageIntegrated Amine Degreasing Schedule 30mar2018KhairulNo ratings yet

- ITR B StatusDocument8 pagesITR B StatusPazhamalai RajanNo ratings yet

- Primavera P6 Lookahead Filters in 40 StepsDocument8 pagesPrimavera P6 Lookahead Filters in 40 StepshichemokokNo ratings yet

- Hydrogen Production Flow Diagram. 2Document1 pageHydrogen Production Flow Diagram. 2DumarTorresNo ratings yet

- JERP Brief ProcessDocument14 pagesJERP Brief Processbikas_sahaNo ratings yet

- 13 - Oxygen Removal From Boiler WaterDocument12 pages13 - Oxygen Removal From Boiler Waterarunkumar23101100% (1)

- Gas Sweetening Processes and ApplicationsDocument6 pagesGas Sweetening Processes and ApplicationsEdwin AguilarNo ratings yet

- SMR Hydrogen Generators-Technologies and Producers 2009Document28 pagesSMR Hydrogen Generators-Technologies and Producers 2009Zoran JuricNo ratings yet

- Improved Level Control of A Feed Water ValveDocument7 pagesImproved Level Control of A Feed Water ValveAli Bari100% (1)

- What Are The Types of HRSGDocument2 pagesWhat Are The Types of HRSGThiruvengadamNo ratings yet

- FGP WPMP OverviewDocument15 pagesFGP WPMP OverviewyazardNo ratings yet

- Oil Facility: Main ProcessDocument1 pageOil Facility: Main ProcessRaghavan VenkatramanNo ratings yet

- 3800-210-710-01-q Rev 1 Chemical Cleaning and Steam Blowing SRQDocument28 pages3800-210-710-01-q Rev 1 Chemical Cleaning and Steam Blowing SRQEslam ShiblNo ratings yet

- O&Msec2 Heat & Material BalanceDocument8 pagesO&Msec2 Heat & Material Balanceugun87No ratings yet

- 2016 - Thermal Performance Calculation and Analysis of Heat Transfer Tube in Super Open Rack VaporizerDocument10 pages2016 - Thermal Performance Calculation and Analysis of Heat Transfer Tube in Super Open Rack VaporizerLong Nguyễn HoàngNo ratings yet

- Alkali Boil Out Procedure - Rev-1Document10 pagesAlkali Boil Out Procedure - Rev-1vahab shaikNo ratings yet

- Boiler Operation Made Easy - Procedure For Starting and Stopping A Boiler PDFDocument13 pagesBoiler Operation Made Easy - Procedure For Starting and Stopping A Boiler PDFDavid WilliamsNo ratings yet

- Irri Kwale Gas PipelineDocument7 pagesIrri Kwale Gas PipelineEfosaUwaifoNo ratings yet

- Yanbu Refinery Tank Farm Process DescriptionDocument9 pagesYanbu Refinery Tank Farm Process DescriptionJanakiraman MalligaNo ratings yet

- Boiler Chemical Cleaning ProcedureDocument20 pagesBoiler Chemical Cleaning ProcedureHandoko AurelNo ratings yet

- Flash Skim Vessel Descr.Document5 pagesFlash Skim Vessel Descr.vanashley1No ratings yet

- Document Submission Status: FOR APPROVAL: Vung Ang 1 Thermal Power Plant 2 X 600Mw Lot M4A Cooling Water System (Bop)Document10 pagesDocument Submission Status: FOR APPROVAL: Vung Ang 1 Thermal Power Plant 2 X 600Mw Lot M4A Cooling Water System (Bop)khang10182No ratings yet

- Typical EfW Plant Commissioning Plan Feb 2010Document176 pagesTypical EfW Plant Commissioning Plan Feb 2010mbetts6304No ratings yet

- 50 MMSCFD Low BTU Gas Combined Cycle Power PlantDocument42 pages50 MMSCFD Low BTU Gas Combined Cycle Power PlantShaikh BilalNo ratings yet

- Level 3 - Project Schedule - Gambat South EWT ProjectDocument8 pagesLevel 3 - Project Schedule - Gambat South EWT ProjectAli Mohsin100% (1)

- HRSG Water Chemistry and Inspection OverviewDocument5 pagesHRSG Water Chemistry and Inspection OverviewRahul ChoubeyNo ratings yet

- Air Coolers Versus Shell-And-tube Water CoolersDocument8 pagesAir Coolers Versus Shell-And-tube Water CoolersDefenceDog67% (3)

- Boilers Basic Components (Att. VIII)Document28 pagesBoilers Basic Components (Att. VIII)Vijay RajNo ratings yet

- ENGINEERING DESIGN GUIDELINES Boiler Systems Rev1.3web PDFDocument29 pagesENGINEERING DESIGN GUIDELINES Boiler Systems Rev1.3web PDFMohsen KadivarNo ratings yet

- Estimate Subsonic Flare Tip Pressure Drop With Graph Derived CorrelationDocument3 pagesEstimate Subsonic Flare Tip Pressure Drop With Graph Derived CorrelationbtjajadiNo ratings yet

- Penjelasan TLEsDocument28 pagesPenjelasan TLEsFauzi IhsanNo ratings yet

- Mechanical Engineer CVDocument3 pagesMechanical Engineer CVRaj AryanNo ratings yet

- Korf Hydraulic ReportDocument10 pagesKorf Hydraulic ReportMuthuKumar ArunachalamNo ratings yet

- SAMSUNG SEM-9471E - Process Design Manual - Health and Design Safety Specification Rev0 2004Document7 pagesSAMSUNG SEM-9471E - Process Design Manual - Health and Design Safety Specification Rev0 2004d_mazieroNo ratings yet

- Installing Conda PackageDocument4 pagesInstalling Conda Packagepolaris44No ratings yet

- Globe Valve Bs 1873 and Api 602: ASME B16.10Document7 pagesGlobe Valve Bs 1873 and Api 602: ASME B16.10swapnil PATILNo ratings yet

- Velocity of Water in PipeDocument4 pagesVelocity of Water in Pipeabidch143100% (1)

- As A Rule of Thumb The Following Velocities Can Be Used in Design of Piping and Pumping Systems For WaterDocument2 pagesAs A Rule of Thumb The Following Velocities Can Be Used in Design of Piping and Pumping Systems For WaterbhupsjangirNo ratings yet

- Fluid Pipping - 21-30Document10 pagesFluid Pipping - 21-30andytuorNo ratings yet

- Steam Distribution System Design GuideDocument70 pagesSteam Distribution System Design GuideMohamed RiyaazNo ratings yet

- Propane Gas and Liquefied GasDocument10 pagesPropane Gas and Liquefied GasJ.SIVIRANo ratings yet

- Dow Chemicals. Review of AminesDocument48 pagesDow Chemicals. Review of AminesEloy SanzNo ratings yet

- Electrolytic Flow CellDocument0 pagesElectrolytic Flow CellMacarthur B. MonsantoNo ratings yet

- Dow Chemicals. Review of AminesDocument48 pagesDow Chemicals. Review of AminesEloy SanzNo ratings yet

- Cyanogenic Glycosides in Bitter Apricot KernelsDocument8 pagesCyanogenic Glycosides in Bitter Apricot KernelsMacarthur B. MonsantoNo ratings yet

- Cyanogenic Glycosides in Bitter Apricot KernelsDocument8 pagesCyanogenic Glycosides in Bitter Apricot KernelsMacarthur B. MonsantoNo ratings yet

- Alkaline Acid Food ChartDocument16 pagesAlkaline Acid Food ChartRyan Livingston67% (3)

- Cyanogenic Glycosides in Bitter Apricot KernelsDocument8 pagesCyanogenic Glycosides in Bitter Apricot KernelsMacarthur B. MonsantoNo ratings yet

- Ultra Fine Grinding - A Practical Alternative To OxidativeDocument21 pagesUltra Fine Grinding - A Practical Alternative To OxidativeSarah PerezNo ratings yet

- Dynamic Simulation of Gold Recovery ProcessesDocument13 pagesDynamic Simulation of Gold Recovery ProcessesMacarthur B. MonsantoNo ratings yet

- ANTI-FRICTION - Test Report of 4 Ball Test From Chinese Academy SciencesDocument3 pagesANTI-FRICTION - Test Report of 4 Ball Test From Chinese Academy SciencesMacarthur B. MonsantoNo ratings yet

- Black UreaDocument20 pagesBlack UreaMacarthur B. Monsanto0% (1)

- Dynamic Simulation of Gold Recovery ProcessesDocument13 pagesDynamic Simulation of Gold Recovery ProcessesMacarthur B. MonsantoNo ratings yet

- Effect of Additive On The Viscosity Index of LubeoilDocument6 pagesEffect of Additive On The Viscosity Index of LubeoilMacarthur B. MonsantoNo ratings yet

- Bucket Elevator Owners ManualDocument87 pagesBucket Elevator Owners ManualMacarthur B. Monsanto100% (1)

- Advanced Wastewater Treatment Technology - Mech Vapor RecompressionDocument42 pagesAdvanced Wastewater Treatment Technology - Mech Vapor RecompressionMacarthur B. Monsanto100% (1)

- CWSF Combustion Testing For Oil-Fired BoilerDocument15 pagesCWSF Combustion Testing For Oil-Fired BoilerMacarthur B. MonsantoNo ratings yet

- Air Pollution Control Systems For BoilerDocument122 pagesAir Pollution Control Systems For BoilerMacarthur B. MonsantoNo ratings yet

- SO2 ControlDocument5 pagesSO2 ControlMacarthur B. MonsantoNo ratings yet

- Process For Recovering Lube Oil Base Stocks From Used Motor Oil FormulationsDocument19 pagesProcess For Recovering Lube Oil Base Stocks From Used Motor Oil FormulationsMacarthur B. MonsantoNo ratings yet

- SO2 ControlDocument5 pagesSO2 ControlMacarthur B. MonsantoNo ratings yet

- Parabolic Trough Solar PlantsDocument16 pagesParabolic Trough Solar PlantsMacarthur B. Monsanto100% (1)

- Active Freeze DryingDocument3 pagesActive Freeze DryingMacarthur B. MonsantoNo ratings yet

- Method of Re Refining Used Lubricating Oil & Salt Bath RefiningDocument35 pagesMethod of Re Refining Used Lubricating Oil & Salt Bath RefiningMacarthur B. MonsantoNo ratings yet

- Engineering - Handbook of Steam Power PlantDocument302 pagesEngineering - Handbook of Steam Power PlantShailendra Pratap SinghNo ratings yet

- Thermal Power Plant PresentationDocument46 pagesThermal Power Plant PresentationMacarthur B. MonsantoNo ratings yet

- Cable NomenclatureDocument5 pagesCable NomenclatureSushantGore100% (1)

- CTD 05-2008 enDocument303 pagesCTD 05-2008 enRodger LeonNo ratings yet

- Boiler ParameterDocument2 pagesBoiler ParameterFieNo ratings yet

- Experiment 4: Chemical Equilibrium: Lab ReportDocument2 pagesExperiment 4: Chemical Equilibrium: Lab ReportNhật Tân Võ VươngNo ratings yet

- Alcor Atf Super - enDocument2 pagesAlcor Atf Super - enronaldNo ratings yet

- Topic 2 SimpleDistillationDocument52 pagesTopic 2 SimpleDistillationJA NableNo ratings yet

- MPI Architectural Painting Manual: Guide Specification Revision - September 2012 Section 09900 Painting Page 1 of 28Document28 pagesMPI Architectural Painting Manual: Guide Specification Revision - September 2012 Section 09900 Painting Page 1 of 28Alsayed DiabNo ratings yet

- 05.09.21 OSR - CO-SC Jee Adv 2020 P1 GTA-28 (P-I) QPDocument17 pages05.09.21 OSR - CO-SC Jee Adv 2020 P1 GTA-28 (P-I) QPRahul RanjanNo ratings yet

- Chapter 16Document55 pagesChapter 16Khalil AlluhaybiNo ratings yet

- MS 1539 PT3 2003 Portable Fire Extinguisher PDFDocument31 pagesMS 1539 PT3 2003 Portable Fire Extinguisher PDFLee GP100% (3)

- General Chemistry II Module on Intermolecular ForcesDocument5 pagesGeneral Chemistry II Module on Intermolecular ForcesJerry De Leon TaayNo ratings yet

- Global Warming and Climate ChangeDocument101 pagesGlobal Warming and Climate Changes selva prakashNo ratings yet

- CARBOXYLIC ACID Derivatives - Salts and ReactionsDocument6 pagesCARBOXYLIC ACID Derivatives - Salts and ReactionsmarcelompassosNo ratings yet

- Introduction and Bravais LatticesDocument17 pagesIntroduction and Bravais LatticesBilal BarutNo ratings yet

- Bulletin Nov 08 Conformal Coating Failure MechanismsDocument2 pagesBulletin Nov 08 Conformal Coating Failure MechanismsLee Hitchens100% (2)

- BS en 10136-2019Document16 pagesBS en 10136-2019Martijn GrootNo ratings yet

- Tabla de Colores Winsor & NewtonDocument8 pagesTabla de Colores Winsor & NewtonArq Copy ChorrillosNo ratings yet

- Code All Item RohanDocument127 pagesCode All Item RohanKapooNo ratings yet

- Samuela Lahai - WSJ-DemandDocument3 pagesSamuela Lahai - WSJ-DemandSamuela LahaiNo ratings yet

- The Solid State Class 12 MCQs Questions With AnswersDocument19 pagesThe Solid State Class 12 MCQs Questions With AnswersRohit Chavariya100% (1)

- Catalog: PrefaceDocument155 pagesCatalog: PrefaceTalita Yasmin TalitaNo ratings yet

- Fresh Cut FruitsDocument25 pagesFresh Cut FruitsMuhammad FaisalNo ratings yet

- G 21 - 96 R02 - RzixDocument5 pagesG 21 - 96 R02 - RzixjayakumarNo ratings yet

- Compost Tea Manual PDFDocument38 pagesCompost Tea Manual PDFbaspipsNo ratings yet

- Minfm54307 Astm A131 Grade ADocument6 pagesMinfm54307 Astm A131 Grade AEmerson IpialesNo ratings yet

- MS-26 Vii: Asphalt - FM - Indd 7 7/9/11 2:57 PMDocument5 pagesMS-26 Vii: Asphalt - FM - Indd 7 7/9/11 2:57 PMChristineNyambeNo ratings yet

- VMP Manual PDFDocument106 pagesVMP Manual PDFkikiNo ratings yet

- Biological Safety CabinetsDocument5 pagesBiological Safety CabinetsAhmed Ali AssafNo ratings yet

- QO390-SS200025 Technical Sheet (Actuated On Off Valve & RESDVForel Bronang)Document2 pagesQO390-SS200025 Technical Sheet (Actuated On Off Valve & RESDVForel Bronang)Iqbal MatondangNo ratings yet

- Gis 18-013Document22 pagesGis 18-013Dinesh NadarNo ratings yet