Professional Documents

Culture Documents

9A01404 Fluid Mechanics & Hydraulic Machinery

Uploaded by

sivabharathamurthyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9A01404 Fluid Mechanics & Hydraulic Machinery

Uploaded by

sivabharathamurthyCopyright:

Available Formats

Code: 9A01404

1

FLUID MECHANICS AND HYDRAULIC MACHINERY

(Mechanical Engineering)

B.Tech II Year II Semester (R09) Regular & Supplementary Examinations, April / MAY 2012

Time: 3 hours Answer any FIVE questions All questions carry equal marks ***** 1

Max Marks: 70

Two large fixed parallel planes are 12 mm apart. The space between the surfaces is filled with oil of 2 2 viscosity 0.972 N.s/m . A flat thin plate 0.25 m area moves through the oil at a velocity of 0.3 m/s. Find the drag force when the plate is equidistant from both the planes and when the thin plate is at a distance of 4 mm from one of the plane surfaces. Explain Bernoullis theorem. Also list the assumptions. A pipe 200 m long slopes down at 1 in 100 and tapers from 600 mm diameter at the higher end to 300 mm at the lower end and carrier 100 lps of oil (G = 0.8). It the pressure gauge at the higher end reads 2 60 KN/m . Find velocities at the two ends and pressure at the lower end. The following data is related to an orifice meter. Diameter of the pipe = 240 mm Diameter of the orifice = 120 mm G of oil = 0.88. Reading of differential manometer = 400 mm of mercury, C d = 0.65. Find the rate of flow of oil. A jet of water moving at 20 m/s impinges on a symmetrical curved vane shaped to deflect the jet 0 0 through 120 (i.e. the vane angles and are each equal to 30 ). If the vane is moving at 5 m/s, find the angle of the jet so that there is no shock at inlet. Also determine the absolute velocity of exit in magnitude and direction, and the work done. Explain hydro electric power station with a neat sketch. What is meant by geometric similarity? Explain the term cavitation with respect to turbines. A Pelton wheel has to be designed for the following data: Power to be developed = 6000 kw. Net head available = 300 m, speed = 550 r.p.m. Ratio of jet diameter to wheel diameter = 1/10, and overall efficiency = 85%. Find the number of jets, diameter of the jet, diameter of the wheel and the quantity of water required. Explain the term NPSH. Explain indicator diagram.

2 (a) (b)

5 6 (a) (b) 7

8 (a) (b)

*****

Code: 9A01404

2

FLUID MECHANICS AND HYDRAULIC MACHINERY

(Mechanical Engineering)

B.Tech II Year II Semester (R09) Regular & Supplementary Examinations, April / MAY 2012

Time: 3 hours Answer any FIVE questions All questions carry equal marks ***** 1

Max Marks: 70

A metal plate 1.25 m x 1.25 m x 6 mm thick and weighing 90 N is placed midway in the 24 mm gap between the two vertical plane surfaces. The gap is filled with an oil of specific gravity 0.85 and dynamic viscosity 3 N s/m2. Find the force required to lift the plate with a constant velocity of 0.15 m/s. Explain Eulers theorem. In a pipe of 90 mm diameter water is flowing with a mean velocity of 2 m/s and at a gauge pressure of 350 kN/m2. Determine the total head, if the pipe is 8 m above the datum line. Neglect friction. Determine the rate of flow of water through a pipe 300 mm diameter placed in an inclined position where a venturimeter is inserted having a throat. of 150 mm. The difference of pressure between the main and throat is measured by a liquid of G = 0.7 in an inverted U tube which gives a reading of 260 mm. The loss of head between the main and throat is 0.3 times the kinetic head of the pipe. Show that the efficiency of a free jet striking normally a series of flat plates mounted on the periphery of a wheel never exceeds 50%. Explain the various types of hydro electric power stations. Explain specific quantities of hydraulic turbines. What is water hammer? Explain with respect to a turbine. Give the classification of turbines in detail. Find the power required to drive a centrifugal pump which delivers 40 lps to a height of 20 m. through a 150 mm dia. and 100 m long pipeline. The overall efficiency of pump is 70% and Darcys f = 0.06 for the pipeline. Assume inlet losses in suction pipe equal to 0. 33m.

2 (a) (b)

5 6 (a) (b) 7 8

*****

Code: 9A01404

3

FLUID MECHANICS AND HYDRAULIC MACHINERY

(Mechanical Engineering)

B.Tech II Year II Semester (R09) Regular & Supplementary Examinations, April / MAY 2012

Time: 3 hours Answer any FIVE questions All questions carry equal marks ***** 1 (a) (b) 2

Max Marks: 70

Give a complete classification of different types of manometers (do not give sketches) mentioning the conditions for which each type of manometer is suitable. Derive the expressions for the pressure intensity inside a droplet, a soap bubble and a liquid jet. A pipe line carrying oil ( G = 0.8 ) changes in diameter from 300 mm at position 1 to 600 mm diameter at position 2, which is 5 m. at a higher level. If the pressures at positions 1 and 2 are 100 2 2 kN/m and 60 kN/m respectively and the discharge is 300 lps, find loss of head and direction of flow. What is the significance of upper and lower critical Reynoldss numbers. A differential manometer is connected between the inlet and throat sections of a venture meter. Show that the manometer reading is unaltered whatever be the inclination of the venturimeter. A jet of water 50 mm in diameter having a velocity of 20 m/s, strikes normally a flat smooth plate. Determine the thrust on the plate if the plate is at rest and if the plate if the plate is moving in the same direction as the jet with a velocity of 8 m/s. Also find the work done per second on the plate and the efficiency of the jet when the plate is moving. Explain the various elements of hydro electric power station with sketches. What are the various characteristic curves of a turbine? What is the necessity of characteristic curves? An inward flow reaction turbine discharges radially and the velocity of flow is constant and equal to the velocity of discharge from the turbine. Show that the hydraulic efficiency can be expressed by

3 (a) (b)

5 6

Where and 8

are respectively the guide vane angle and wheel vane angle at inlet.

Explain the classification of centrifugal pumps. Explain the working of a centrifugal pump.

*****

Code: 9A01404

4

FLUID MECHANICS AND HYDRAULIC MACHINERY

(Mechanical Engineering)

B.Tech II Year II Semester (R09) Regular & Supplementary Examinations, April / MAY 2012

Time: 3 hours Answer any FIVE questions All questions carry equal marks

Max Marks: 70

*****

1 (a) (b) Explain U-Tube manometers. A fluid has an absolute viscosity of 0.048 Pa- s and a specific gravity of 0.913. For flow of such a fluid over a solid flat surface, the velocity at a point 75 mm away from the surface is 1.125 m/s. calculate the shear stresses at the solid boundary and also at the points 25 mm, 50 mm and 75 mm away from the surface in normal direction, if the velocity distribution across the surface is linear, parabolic with vertex at the point 75 mm away from the surface. Gasoline (G = 0.8) is flowing upwards through a vertical pipeline which tapers from 300 mm to 150 mm dia. A gas line mercury differential manometer is connected between 300 mm and 150 mm pipe section to measure the rate of flow. The distance between the manometer tappings is 1 m and gauge reading is 500 mm of mercury. Find differential gauge reading in terms of gasoline head. Also find the rate of flow. Neglect friction and other losses. Derive Darcy Weisbach equation and give its significance. What is flow nozzle? Explain. The rotor of an inward flow hydraulic turbine has a diameter over the tips of the blades of 1 m. The diameter at the bottom of the blade is 0.6 m. The speed is 300 r.p.m. the water is supplied 0 through fixed values at 10 to the tangent to the outer circumference of the rotor, the velocity of water being 10 m/s. Find the blade angle at entry and exit, so that the water may enter and leave the moving blades without shock, the water leaves the blades with the velocity entirely radial and equal to 3.5 m/s. Also find the velocity of water relative to the blades at the inlet. Explain the various types of hydroelectric power stations. What are unit quantities? Explain any two characteristic curves of a turbine. The following data were obtained from a test on a pelton wheel. Head at the base of the nozzle = 32 3 m discharge of the nozzle = 0.18 m /s. Area of the jet = 7500 sq. mm. Power available at the shaft = 44 KW mechanical efficiency = 94 % Calculate the power lost in the nozzle, in the runner and in mechanical friction. Explain the working of a reciprocating pump in detail.

3 (a) (b) 4

5 6 (a) (b) 7

*****

You might also like

- Powershift TransmissionsDocument27 pagesPowershift TransmissionsJonathanDavidDeLosSantosAdornoNo ratings yet

- GRC Fiori End User Guide Final - V2Document75 pagesGRC Fiori End User Guide Final - V2Subhash BharmappaNo ratings yet

- Learning Resource Management Made SimpleDocument12 pagesLearning Resource Management Made SimpleJosenia ConstantinoNo ratings yet

- 9A01404 Fluid Mechanics & Hydraulic MachineryDocument4 pages9A01404 Fluid Mechanics & Hydraulic MachinerysivabharathamurthyNo ratings yet

- FM Question Model 2Document8 pagesFM Question Model 2aadhanNo ratings yet

- 9A01308 Fluid Mechanics & Hydraulic MachineryDocument4 pages9A01308 Fluid Mechanics & Hydraulic MachinerysivabharathamurthyNo ratings yet

- 9A01402 Hydraulics and Hydraulic MachineryDocument4 pages9A01402 Hydraulics and Hydraulic MachinerysivabharathamurthyNo ratings yet

- 9a01308-Fluid Mechanics & Hydraulic MachineryDocument4 pages9a01308-Fluid Mechanics & Hydraulic MachinerysivabharathamurthyNo ratings yet

- Rr210201 Hydraulics and Hydraulic MachineryDocument8 pagesRr210201 Hydraulics and Hydraulic MachinerySRINIVASA RAO GANTANo ratings yet

- FM &HM Old PapersDocument4 pagesFM &HM Old Paperssai leenaNo ratings yet

- II B. Tech I Semester, Supplementary Examinations, May - 2012 Fluid Mechanics & Hydraulic MachinesDocument44 pagesII B. Tech I Semester, Supplementary Examinations, May - 2012 Fluid Mechanics & Hydraulic MachineshvrkNo ratings yet

- Jntuworld: R09 Set No. 2Document9 pagesJntuworld: R09 Set No. 2saiteja1234No ratings yet

- 9A01308 Fluid Mechanics and Hydraulic MachineryDocument4 pages9A01308 Fluid Mechanics and Hydraulic MachinerysivabharathamurthyNo ratings yet

- Ii Mid FM&HMDocument8 pagesIi Mid FM&HMSrinivas RaghavanNo ratings yet

- Fluid Mechanics and Hydraulic MachineryDocument8 pagesFluid Mechanics and Hydraulic MachineryDhanush RagavNo ratings yet

- 14 MarksDocument4 pages14 MarksmohanNo ratings yet

- 9A01304 Fluid MechanicsDocument4 pages9A01304 Fluid MechanicssivabharathamurthyNo ratings yet

- (Richard M. Felder Ronald W. Rousseau) ElementaryDocument4 pages(Richard M. Felder Ronald W. Rousseau) ElementaryTeeTeeXdNo ratings yet

- 9A01304 Fluid MechanicsDocument4 pages9A01304 Fluid MechanicssivabharathamurthyNo ratings yet

- II B. Tech I Semester Regular Examinations, March – 2014 FLUID MECHANICS AND HYDRALICS MACHINESDocument4 pagesII B. Tech I Semester Regular Examinations, March – 2014 FLUID MECHANICS AND HYDRALICS MACHINESkalikadeviNo ratings yet

- 9A01304 Fluid MechanicsDocument4 pages9A01304 Fluid MechanicssivabharathamurthyNo ratings yet

- FLUID MECHANICS & HYDRAULIC MACHINERY - PDF SyllabusDocument4 pagesFLUID MECHANICS & HYDRAULIC MACHINERY - PDF SyllabusShareef KhanNo ratings yet

- Hydraulic Machinery and Systems Jntu Model Paper WWW Student Yogi Com 100113195214 Phpapp01Document8 pagesHydraulic Machinery and Systems Jntu Model Paper WWW Student Yogi Com 100113195214 Phpapp01Nitish ShresthaNo ratings yet

- Mechanics of Fluids r05220302Document8 pagesMechanics of Fluids r05220302Nizam Institute of Engineering and Technology LibraryNo ratings yet

- Department of Mechanical Engineering Fluid Mechanics (QUESTION BANK)Document5 pagesDepartment of Mechanical Engineering Fluid Mechanics (QUESTION BANK)Zohaib ShahidNo ratings yet

- JNTU Fluid Mechanics Exam QuestionsDocument9 pagesJNTU Fluid Mechanics Exam QuestionsnvemanNo ratings yet

- Fluid Mechanics and Hydraulic Machinery (Electrical and Electronics Engineering)Document7 pagesFluid Mechanics and Hydraulic Machinery (Electrical and Electronics Engineering)29viswa12No ratings yet

- MEC222 - 5 Fluid Mechanics QP - Amrita UniversityDocument4 pagesMEC222 - 5 Fluid Mechanics QP - Amrita UniversityAkshay RajanNo ratings yet

- Rr210201 Hydraulics and Hydraulic MachineryDocument8 pagesRr210201 Hydraulics and Hydraulic MachinerySrinivasa Rao GNo ratings yet

- Fluid Mechanics and Machinery Question Paper AnalysisDocument4 pagesFluid Mechanics and Machinery Question Paper Analysissanthoshm2k810No ratings yet

- Images - MEQP - 08 - R05310302 HYDRAULIC MACHINERY AND SYSTEMS PDFDocument8 pagesImages - MEQP - 08 - R05310302 HYDRAULIC MACHINERY AND SYSTEMS PDFvishnu chaudharyNo ratings yet

- MFHM I-Mid QB II Sem A y 2014-15Document3 pagesMFHM I-Mid QB II Sem A y 2014-15john_raju17No ratings yet

- Fluid Mechanics Exam Questions and AnswersDocument54 pagesFluid Mechanics Exam Questions and AnswersSony RamaNo ratings yet

- Hydraulic Machinery Systems Exam QuestionsDocument4 pagesHydraulic Machinery Systems Exam QuestionswirelessandlessNo ratings yet

- Aalim Muhammed Salegh College of Engineering Department of Mechanical EngineeringDocument6 pagesAalim Muhammed Salegh College of Engineering Department of Mechanical EngineeringMaran ElangovanNo ratings yet

- R7210202 Fluid Mechanics & Hydraulic MachineryDocument1 pageR7210202 Fluid Mechanics & Hydraulic MachinerysivabharathamurthyNo ratings yet

- CE253Document3 pagesCE253Maxwell RejilNo ratings yet

- Nr-310302-Hydraulic Machinery and SystemsDocument8 pagesNr-310302-Hydraulic Machinery and SystemsSrinivasa Rao GNo ratings yet

- B.Tech. II Year II Semester Regular Examinations, May, 2017: Subject Code 5CE08Document2 pagesB.Tech. II Year II Semester Regular Examinations, May, 2017: Subject Code 5CE08Md zakirNo ratings yet

- R5210106 Fluid MechanicsDocument1 pageR5210106 Fluid MechanicssivabharathamurthyNo ratings yet

- Question Paper Code:: (10×2 20 Marks)Document3 pagesQuestion Paper Code:: (10×2 20 Marks)Keesanth Geetha ChandrasekaranNo ratings yet

- Gujarat Technological University: InstructionsDocument2 pagesGujarat Technological University: InstructionsMital PatelNo ratings yet

- Important Questions CE 6451 Fluid MechanicsDocument4 pagesImportant Questions CE 6451 Fluid Mechanicsommech2020No ratings yet

- Fluid Mechanics QP - Amrita UniversityDocument3 pagesFluid Mechanics QP - Amrita UniversityAkshay RajanNo ratings yet

- FMHM Regular Jntu Question Papers 2008Document8 pagesFMHM Regular Jntu Question Papers 2008anjaneyulud100% (1)

- Fluid Machinery II Seme2 2006Document2 pagesFluid Machinery II Seme2 2006Arindam MisraNo ratings yet

- FM AssignDocument5 pagesFM AssignEkantha MoorthyNo ratings yet

- A-PDF Merger DEMO: Purchase FromDocument66 pagesA-PDF Merger DEMO: Purchase Frommanju0806No ratings yet

- Fluid Mechanics and Machines (MME-243) RCS (Makeup)Document3 pagesFluid Mechanics and Machines (MME-243) RCS (Makeup)sherryhhNo ratings yet

- AQ Fluid Machinery-1Document3 pagesAQ Fluid Machinery-1Sourabh BelladNo ratings yet

- Fluid mechanics and hydraulics machines exam questionsDocument8 pagesFluid mechanics and hydraulics machines exam questionsNitin GuptaNo ratings yet

- MFHM Code No: 07A3EC02Document2 pagesMFHM Code No: 07A3EC02rafikhanpathanNo ratings yet

- Fluid Power EngineeringDocument4 pagesFluid Power EngineeringrameshsagapariyaNo ratings yet

- 9A01402 Hydraulics & Hydraulic MachineryDocument4 pages9A01402 Hydraulics & Hydraulic MachinerysivabharathamurthyNo ratings yet

- Gojan School of Business and Technology: Department of Aeronautical EngineeringDocument7 pagesGojan School of Business and Technology: Department of Aeronautical EngineeringRameez FaroukNo ratings yet

- Tutorial QN 6-10Document6 pagesTutorial QN 6-10clarence limNo ratings yet

- Rr220301 Mechanics of FluidsDocument8 pagesRr220301 Mechanics of Fluidslibrarian_abitNo ratings yet

- r05220302 Mechanics of FluidsDocument8 pagesr05220302 Mechanics of FluidsSRINIVASA RAO GANTANo ratings yet

- Fluid Mechanics Exam QuestionsDocument11 pagesFluid Mechanics Exam QuestionsShesha Prakash M NNo ratings yet

- Modern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlFrom EverandModern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlNo ratings yet

- 9A13701 Robotics and AutomationDocument4 pages9A13701 Robotics and AutomationsivabharathamurthyNo ratings yet

- SSC Telugu (FL) (AP)Document232 pagesSSC Telugu (FL) (AP)sivabharathamurthyNo ratings yet

- SSC Social Textbook (AP)Document100 pagesSSC Social Textbook (AP)sivabharathamurthyNo ratings yet

- Control Systems (CS) Notes As Per JntuaDocument203 pagesControl Systems (CS) Notes As Per Jntuasivabharathamurthy100% (3)

- 07A4EC01 Environmental StudiesDocument1 page07A4EC01 Environmental StudiessivabharathamurthyNo ratings yet

- 9A05707 Software Project ManagementDocument4 pages9A05707 Software Project ManagementsivabharathamurthyNo ratings yet

- R5410201 Neural Networks & Fuzzy LogicDocument1 pageR5410201 Neural Networks & Fuzzy LogicsivabharathamurthyNo ratings yet

- R7410506 Mobile ComputingDocument1 pageR7410506 Mobile ComputingsivabharathamurthyNo ratings yet

- R7410407 Operating SystemsDocument1 pageR7410407 Operating SystemssivabharathamurthyNo ratings yet

- R7310306 Heat TransferDocument1 pageR7310306 Heat Transfersivabharathamurthy100% (1)

- R7312301 Transport Phenomena in BioprocessesDocument1 pageR7312301 Transport Phenomena in BioprocessessivabharathamurthyNo ratings yet

- R7311506 Operating SystemsDocument1 pageR7311506 Operating SystemssivabharathamurthyNo ratings yet

- Code: R7311306: (Electronics & Control Engineering)Document1 pageCode: R7311306: (Electronics & Control Engineering)sivabharathamurthyNo ratings yet

- R7311205 Distributed DatabasesDocument1 pageR7311205 Distributed DatabasessivabharathamurthyNo ratings yet

- R7310506 Design & Analysis of AlgorithmsDocument1 pageR7310506 Design & Analysis of AlgorithmssivabharathamurthyNo ratings yet

- R7311006 Process Control InstrumentationDocument1 pageR7311006 Process Control InstrumentationsivabharathamurthyNo ratings yet

- R7310406 Digital CommunicationsDocument1 pageR7310406 Digital CommunicationssivabharathamurthyNo ratings yet

- 9A10505 Principles of CommunicationsDocument4 pages9A10505 Principles of CommunicationssivabharathamurthyNo ratings yet

- R7310206 Linear Systems AnalysisDocument1 pageR7310206 Linear Systems AnalysissivabharathamurthyNo ratings yet

- R5310204 Power ElectronicsDocument1 pageR5310204 Power ElectronicssivabharathamurthyNo ratings yet

- R5310406 Digital CommunicationsDocument1 pageR5310406 Digital CommunicationssivabharathamurthyNo ratings yet

- R7310106 Engineering GeologyDocument1 pageR7310106 Engineering GeologysivabharathamurthyNo ratings yet

- 9A15502 Digital System DesignDocument4 pages9A15502 Digital System Designsivabharathamurthy100% (1)

- 9A23501 Heat Transfer in BioprocessesDocument4 pages9A23501 Heat Transfer in BioprocessessivabharathamurthyNo ratings yet

- 9A14503 Principles of Machine DesignDocument8 pages9A14503 Principles of Machine DesignsivabharathamurthyNo ratings yet

- 9A05505 Operating SystemsDocument4 pages9A05505 Operating SystemssivabharathamurthyNo ratings yet

- 9A21506 Mechanisms & Mechanical DesignDocument8 pages9A21506 Mechanisms & Mechanical DesignsivabharathamurthyNo ratings yet

- 9A04504 Digital IC ApplicationsDocument4 pages9A04504 Digital IC ApplicationssivabharathamurthyNo ratings yet

- 9A02505 Electrical Machines-IIIDocument4 pages9A02505 Electrical Machines-IIIsivabharathamurthyNo ratings yet

- 9A03505 Heat TransferDocument4 pages9A03505 Heat TransfersivabharathamurthyNo ratings yet

- NETWORK ANALYSIS Chap.8 TWO PORT NETWORK & NETWORK FUNCTIONS PDFDocument34 pagesNETWORK ANALYSIS Chap.8 TWO PORT NETWORK & NETWORK FUNCTIONS PDFsudarshan poojaryNo ratings yet

- General Ledger Senior Accountant in Charlotte NC Resume Diana ShipeDocument1 pageGeneral Ledger Senior Accountant in Charlotte NC Resume Diana ShipeDianaShipeNo ratings yet

- KernelDocument326 pagesKernelSkyezine Via Kit FoxNo ratings yet

- 3., 4., & 9. RBXC Catalogue Local 2015Document16 pages3., 4., & 9. RBXC Catalogue Local 2015Nilesh RanadeviNo ratings yet

- Fundamentals 2014Document959 pagesFundamentals 2014Angelo Vittorio VettorazziNo ratings yet

- Sample Style GuideDocument5 pagesSample Style Guideapi-282547722No ratings yet

- 01 U3 Ws 1 Force DiagramsDocument4 pages01 U3 Ws 1 Force Diagramsapi-197108354No ratings yet

- Volvo 850 GLT Owners Manual 1993Document176 pagesVolvo 850 GLT Owners Manual 1993jpaulorosado2186No ratings yet

- Mathcad - Ampacity CalculationDocument76 pagesMathcad - Ampacity CalculationAlex Ribeiro100% (4)

- Auto Temp II Heat Pump: Programmable Thermostat For Single and Multistage Heat Pump SystemsDocument22 pagesAuto Temp II Heat Pump: Programmable Thermostat For Single and Multistage Heat Pump Systemswideband76No ratings yet

- Managing ImapDocument408 pagesManaging ImapPriya RaoNo ratings yet

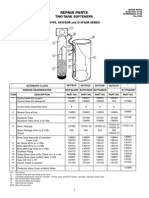

- Star S07FS32DR Water Softener Repair PartsDocument1 pageStar S07FS32DR Water Softener Repair PartsBillNo ratings yet

- Bulletin 1395 Digital DC Drive 1350A & 2250ADocument213 pagesBulletin 1395 Digital DC Drive 1350A & 2250ATulioPenaNo ratings yet

- MPTK Medium Pressure Pump Performance SpecsDocument2 pagesMPTK Medium Pressure Pump Performance SpecssaronandyNo ratings yet

- POSSIBILITIES OF LOW VOLTAGE DC SYSTEMSDocument10 pagesPOSSIBILITIES OF LOW VOLTAGE DC SYSTEMSTTaanNo ratings yet

- Brief Summary of The Original COCOMO ModelDocument5 pagesBrief Summary of The Original COCOMO ModelTirthajit SinhaNo ratings yet

- Pagination script tutorial for PHP MySQL programmersDocument4 pagesPagination script tutorial for PHP MySQL programmersThomas ChinyamaNo ratings yet

- B737-B787 QRH Differences: 787 NNC Includes Emergency DescentDocument13 pagesB737-B787 QRH Differences: 787 NNC Includes Emergency DescentUfuk AydinNo ratings yet

- FlowCon General InstructionDocument4 pagesFlowCon General InstructionGabriel Arriagada UsachNo ratings yet

- FiatDocument56 pagesFiatOmkar ParkarNo ratings yet

- Sitsyll PDFDocument57 pagesSitsyll PDFpreranaNo ratings yet

- Budget EstimatesDocument251 pagesBudget EstimatesMUHAMMAD QASIM RAJPARNo ratings yet

- Nec 2006Document59 pagesNec 2006loots69No ratings yet

- Performance Estimation of Ofdm-Wimax Network: Vishal Sharma & Navneet KaurDocument8 pagesPerformance Estimation of Ofdm-Wimax Network: Vishal Sharma & Navneet KaurTJPRC PublicationsNo ratings yet

- Breaking Shackles of Time: Print vs Digital ReadingDocument2 pagesBreaking Shackles of Time: Print vs Digital ReadingMargarette RoseNo ratings yet

- Method of MomentsDocument114 pagesMethod of MomentsankladhaNo ratings yet

- MyPower S3220&S3320-INSTALLATIONDocument83 pagesMyPower S3220&S3320-INSTALLATIONJorge GonzalesNo ratings yet