Professional Documents

Culture Documents

GP12

Uploaded by

bhushan911Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GP12

Uploaded by

bhushan911Copyright:

Available Formats

GP 12

A Guide to P roper Understanding and Implementation

Contents

What is GP-12? Why GP-12 When to establish GP-12 Pre-Launch Control Plan Ingredients of a good Pre-Launch Control Plan GP-12 Area Set-Up GP-12 Deliverables Documentation Needs for GP-12 What we know works How to make the Process Robust Exit Criteria Recommended Criteria Exit Certificate

What is GP 12 ?

GP-12 Early Production Containment Proc edure A procedure to ens ure quick problem identification, broadcast an d resolution during the early stages of start-up and acceleration A procedure to protec t Customer Assy Plant during the c rucial phases of Launch A procedure that es tablishes clear understanding between Customer and supplier during the initial phases of a program launch

Why GP 12?

To contain quality problems during start-up before it reaches Customer assembly plant To provide a method for immediate problem resolution during start-up To help suppliers bring their processes under control and make them stable To enhance the Production Control Plan with feedback from the Pre Launch Control Plan

When to establish GP 12?

During ALL pre-production Phases!! During the early stages of production builds After all tool moves and maj or changes to tools GP 12 should not be us ed for carry over concerns ; they should be addressed using the Controll ed Shipping Procedure

(3) Key Elements Required to Establish GP12

Pre-Launch Control Plan (PCP)

IT IS NOT A SUBSTITUTE FOR THE PRODUCTION CONTROL PLAN, BUT IS OVER AND ABOVE THE PRODUCTION CONTROL PLAN AND IS USED TO VALIDATE IT A SIGNIFICANT ENHANCEMENT TO THE SUPPLIER S PRODUCTION CONROL PLAN

GP 12 Area Setup (separate from prod.) Boundary Samples/Pics for appearance items (good and bad examples)

Pre-Launch Control Plan

Should take into account all known critical conditions of the part Should take into account most of the potential causes of failure / concern as identified in the PFMEA Should identify additional controls, inspection audits and testing to identify non conformances during production Should use the format as identified in the APQP manual

Ingredients of a good Pre-launch Control Plan

Identifies increased frequency of checking Increased inspection & control items Verification of label accuracy Enhanced process controls using error proofing

GP 12 Area Setup

It is recommended that GP 12 area be off - line in a clearly marked & quarantined area GP 12 inspectors should not be the same as production inspectors GP 12 area should be set at the maximum possible distance from repair/rework area Use optimum lighting When possible utilize work tables that put components in vehicle position

GP 12 Deliverables

Pre-launch Control plan (PCP) GP 12 area established Ship the exact agreed upon quantity Meet all quality expectation as outlined in the print or as communicated by the customer during Pre-launch control plan approval

GP 12 Deliverables

Make sure each container has a green dot (1inch diam.) signed by senior management Close all PRR issued by the assembly plant Meet all Ppk requirement Have a proven Stable process Be able to demonstrate that the proc ess is robust and has rendered the GP 12 area non value added

Documentation Needs for GP 12

Pre-launch control plan Pictures, Corrective and Preventive Action documentation, Communication between shift documentation, Quality Alert Agreed upon inspection criteria, data points and frequency of checking Boundary Sample availability

Documentation Needs for GP 12

Agreed upon exit criteria Requires these signatures : Supplier, Plant Quality Nominee Documentation to enhance inspection criteria, data points and frequency of checking if needed GP 12 exit certificate

What we know Works

Empower People Management Involvement More employee responsibility Focus on results Focus on shared effort and clear communication Make steady progress Focus on the process and not on inspection

How to make the process Robust

Define the inspection criteria, data points and frequency of checking before start Define exit criteria before start of GP 12 Exit criteria should reflect good statistical parameters eg. SPC chart showing process under control, Cpk, Ppk, etc. and not quantity of good parts Update the data points and frequency of checking to reflect reality at the Customer Assy.

Exit Criteria

Meet process capability requirements per recommended criteria or similar Meet all deliverables identified before Apply for Exit Certificate along with all data to back up exit claim

Exit Certificate

FIAT

GP 12 Exit Cer tificate Part Number(s): Part Name: Supplier: Duns Code: Exit Criteria

1. 2. 3. 4. 5. 6. Customer Assembly Plant at full acceleration Enhanced Control Plan Exists Part at saleable Interim status All PRR s pertaining to the supplier process closed Supplier has process under control and process is stable Supplier has met all Ppk and Cpk requirements as outlined in Table 1 and 2 or equivalent 7. Supplier has met all deliverables as outlined in the Agreed Upon Exit Criteria Upon meeting all the above mentioned criteria the supplier shall be issued this certificate. This certificate allows the supplier to exit GP 12 requirements. However, the supplier shall maintain all required controls in place to warranty good quality parts to Customer. Signatures:

You might also like

- Manual Gp12 InglesDocument3 pagesManual Gp12 InglesdyolotzinNo ratings yet

- GP 12Document2 pagesGP 12Antonio Lara100% (8)

- Early Production ContainmentDocument2 pagesEarly Production Containmenttravi9580% (5)

- Apqp GMDocument73 pagesApqp GMpbvrNo ratings yet

- GM 1927-30 QSB AuditDocument38 pagesGM 1927-30 QSB Auditmanune01No ratings yet

- The Basics of PPAPDocument29 pagesThe Basics of PPAPஎன் கருத்துNo ratings yet

- Formel Q Quality Capability Supplier Assessment Guidelines 2005 PDFDocument152 pagesFormel Q Quality Capability Supplier Assessment Guidelines 2005 PDFAntonioNo ratings yet

- GM 1927 36 Group C Elements BIQSDocument52 pagesGM 1927 36 Group C Elements BIQSVanessa GurrolaNo ratings yet

- PPAP FundamentalsDocument21 pagesPPAP FundamentalsRajdeep SinghNo ratings yet

- GM 1927-33 GM Global GP-12 Audit March 13, 2008Document8 pagesGM 1927-33 GM Global GP-12 Audit March 13, 2008Neumar NeumannNo ratings yet

- GM 1927-17 SQ Processes and Measurements Procedure (GP-5)Document39 pagesGM 1927-17 SQ Processes and Measurements Procedure (GP-5)FABRICIO100% (3)

- GM 1927 08 Potential Supplier Assessment (PSA)Document12 pagesGM 1927 08 Potential Supplier Assessment (PSA)Juan Carlos Murillo Larrota100% (1)

- GM 1927 36 Group D Elements BIQSDocument41 pagesGM 1927 36 Group D Elements BIQSVanessa GurrolaNo ratings yet

- APQP / PPAP Checklist - Suppliers: Responsiblility StepDocument8 pagesAPQP / PPAP Checklist - Suppliers: Responsiblility Steprajesh sharmaNo ratings yet

- 2014 09 05 Cqi 19 WebinarDocument66 pages2014 09 05 Cqi 19 WebinarJuan Egara100% (2)

- Cqi 122014Document28 pagesCqi 122014Armando Flores Moreno100% (1)

- Ppap Worksheet (GM 1411) : S Master Status: Lab StatusDocument6 pagesPpap Worksheet (GM 1411) : S Master Status: Lab Statuscong daNo ratings yet

- BIQS Manual Auditoria 2017 PDFDocument168 pagesBIQS Manual Auditoria 2017 PDFJuan Carlos PadillaNo ratings yet

- Q1 2002 Rules Reference Card Q1 Eligibility Q1 2002 Rules Reference Card Q1 Status Codes (Documentation Required To Change)Document6 pagesQ1 2002 Rules Reference Card Q1 Eligibility Q1 2002 Rules Reference Card Q1 Status Codes (Documentation Required To Change)Omnex Inc.100% (1)

- Q1 Rules Ref CardDocument10 pagesQ1 Rules Ref Cardparigomo2No ratings yet

- GM 1927 - Supplier Quality ManualDocument109 pagesGM 1927 - Supplier Quality ManualMostafa Abd El Alem100% (3)

- BIQ-S AuditDocument13 pagesBIQ-S AuditAngie Guerrero100% (1)

- GM1927Document127 pagesGM1927hmp90No ratings yet

- VOLVO APQP-PPAP Deployment Supplier Information 挋嫌挋Document10 pagesVOLVO APQP-PPAP Deployment Supplier Information 挋嫌挋張永松No ratings yet

- GM 1927 Supplier Quality Manual PDFDocument109 pagesGM 1927 Supplier Quality Manual PDFYaisa Marrugo JimenezNo ratings yet

- GM CSR TrainingDocument9 pagesGM CSR TrainingVanessa GurrolaNo ratings yet

- CQI-14, How To Perfom The AssesmentDocument4 pagesCQI-14, How To Perfom The AssesmentJose Cepeda50% (2)

- GP-12 Check SheetsDocument2 pagesGP-12 Check SheetsLam Nguyen100% (4)

- Seminar PPAPDocument17 pagesSeminar PPAPSumit BedekarNo ratings yet

- GM 1927-36 BIQS Training Material (Read-Only)Document115 pagesGM 1927-36 BIQS Training Material (Read-Only)dreyes130No ratings yet

- Advanced Product Quality Planning and Control Plan: Second EditionDocument8 pagesAdvanced Product Quality Planning and Control Plan: Second EditionAnil AhirNo ratings yet

- Vda 6-3Document7 pagesVda 6-3julio_0489No ratings yet

- Service PPAPDocument17 pagesService PPAPCarlos FilioNo ratings yet

- GM 1927-11 APQP Kick Off and SRV Workbook-GMDocument7 pagesGM 1927-11 APQP Kick Off and SRV Workbook-GMJOECOOL67No ratings yet

- VDA6.3 QuestionsDocument17 pagesVDA6.3 QuestionsSónia Queiroz100% (1)

- Aptiv Customer Specific Requirements June 20th 2022Document15 pagesAptiv Customer Specific Requirements June 20th 2022Hosam Elden Mostafa MasaranyNo ratings yet

- PPAP Webinar Core ToolsDocument62 pagesPPAP Webinar Core ToolsDLNo ratings yet

- Q1 2nd EditionDocument20 pagesQ1 2nd EditionAndres Vargas RoldanNo ratings yet

- APQP Workbook TrainingDocument31 pagesAPQP Workbook TrainingFranciscoNo ratings yet

- P!. GM 1927-30 - BIQS Audit v.7.0 2017-04-05Document14 pagesP!. GM 1927-30 - BIQS Audit v.7.0 2017-04-05Duho ConsultoresNo ratings yet

- APQP ENG SiemensDocument12 pagesAPQP ENG SiemensVikash KumarNo ratings yet

- Supplier-QUAL TM 0027-01 PPAP PackageDocument192 pagesSupplier-QUAL TM 0027-01 PPAP Packagesurya bhawan100% (1)

- GM 1927 36 Introduction and Foundational Elements of BIQSDocument46 pagesGM 1927 36 Introduction and Foundational Elements of BIQSErnesto Padilla100% (2)

- Delphi Technologies Customer Specific Requirements: For Use With ISO 9001:2015 and IATF16949:2016Document15 pagesDelphi Technologies Customer Specific Requirements: For Use With ISO 9001:2015 and IATF16949:2016Ram100% (1)

- APQP-PPAP - Workbook ExampleDocument37 pagesAPQP-PPAP - Workbook ExampleVIBHOR50% (2)

- GMs Drill Deep and Wide Example MatrixDocument3 pagesGMs Drill Deep and Wide Example MatrixDavid MorenoNo ratings yet

- Formel Q Capability Process AuditDocument8 pagesFormel Q Capability Process AuditSarguna SundararajanNo ratings yet

- Template Q-Offer v1 2Document25 pagesTemplate Q-Offer v1 2Krishna Mohan T.R100% (1)

- VDA Flyer - 6 5 Product AuditDocument2 pagesVDA Flyer - 6 5 Product AuditEdwin Osogo100% (1)

- GM 1960 - GP9 Procedure March 2005Document10 pagesGM 1960 - GP9 Procedure March 2005vladameerNo ratings yet

- Apqp PDFDocument2 pagesApqp PDFChandru JattiNo ratings yet

- VDA Formel QDocument138 pagesVDA Formel QLuciano Resk100% (7)

- Control Plan 1st Edition - AnalysisDocument9 pagesControl Plan 1st Edition - AnalysisYassin Serhani100% (1)

- APQP - QuestionnaireDocument2 pagesAPQP - QuestionnaireLOGANATHAN V100% (1)

- Apqp Ppap TrainingDocument2 pagesApqp Ppap TrainingAnkur DhirNo ratings yet

- Production Part Approval Process A Complete Guide - 2019 EditionFrom EverandProduction Part Approval Process A Complete Guide - 2019 EditionNo ratings yet

- WT WIAB Reworked CH 3 FullDocument5 pagesWT WIAB Reworked CH 3 Fulljack3314sonyNo ratings yet

- Letter Regarding Neil Green To UHP, District AttorneyDocument4 pagesLetter Regarding Neil Green To UHP, District AttorneyWordofgreenNo ratings yet

- Fillomena, Harrold T.: ObjectiveDocument3 pagesFillomena, Harrold T.: ObjectiveHarrold FillomenaNo ratings yet

- Testamentary Succession CasesDocument69 pagesTestamentary Succession CasesGjenerrick Carlo MateoNo ratings yet

- Narendra Budiman: Professional StatementDocument1 pageNarendra Budiman: Professional StatementPratika SariputriNo ratings yet

- Test Bank For We The People 10th Essentials Edition Benjamin Ginsberg Theodore J Lowi Margaret Weir Caroline J Tolbert Robert J SpitzerDocument15 pagesTest Bank For We The People 10th Essentials Edition Benjamin Ginsberg Theodore J Lowi Margaret Weir Caroline J Tolbert Robert J Spitzeramberleemakegnwjbd100% (14)

- List of Departed Soul For Daily PrayerDocument12 pagesList of Departed Soul For Daily PrayermoreNo ratings yet

- Sailpoint Training Understanding ReportDocument2 pagesSailpoint Training Understanding ReportKunalGuptaNo ratings yet

- Sharmeen Obaid ChinoyDocument5 pagesSharmeen Obaid ChinoyFarhan AliNo ratings yet

- Coorg Chicken CurryDocument1 pageCoorg Chicken CurryAnitha VinukumarNo ratings yet

- UFC 3-270-01 Asphalt Maintenance and Repair (03!15!2001)Document51 pagesUFC 3-270-01 Asphalt Maintenance and Repair (03!15!2001)Bob VinesNo ratings yet

- Disabilities AssignmentDocument8 pagesDisabilities Assignmentapi-427349170No ratings yet

- An Introduction To The Catholic Charismatic RenewalDocument5 pagesAn Introduction To The Catholic Charismatic RenewalNoah0% (1)

- A Brief Ion of OrrisaDocument27 pagesA Brief Ion of Orrisanitin685No ratings yet

- QuickRecharge - Ae Is Launched by Paynet - OneDocument2 pagesQuickRecharge - Ae Is Launched by Paynet - OnePR.comNo ratings yet

- NF79178240335624 ETicketDocument2 pagesNF79178240335624 ETicketridam aroraNo ratings yet

- Report of Apple Success PDFDocument2 pagesReport of Apple Success PDFPTRNo ratings yet

- Kesari Tours and Travel: A Service Project Report OnDocument15 pagesKesari Tours and Travel: A Service Project Report OnShivam Jadhav100% (3)

- Susan Rose's Legal Threat To Myself and The Save Ardmore CoalitionDocument2 pagesSusan Rose's Legal Threat To Myself and The Save Ardmore CoalitionDouglas MuthNo ratings yet

- Basic Accounting Equation Exercises 2Document2 pagesBasic Accounting Equation Exercises 2Ace Joseph TabaderoNo ratings yet

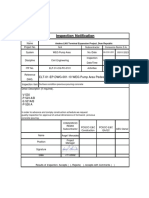

- In-CIV-201 INSPECTION NOTIFICATION Pre-Pouring Concrete WEG Pump Area PedestalsDocument5 pagesIn-CIV-201 INSPECTION NOTIFICATION Pre-Pouring Concrete WEG Pump Area PedestalsPedro PaulinoNo ratings yet

- Developing A Business Plan For Your Vet PracticeDocument7 pagesDeveloping A Business Plan For Your Vet PracticeMujtaba AusafNo ratings yet

- Pulse of The Profession 2013Document14 pagesPulse of The Profession 2013Andy UgohNo ratings yet

- CKA CKAD Candidate Handbook v1.10Document28 pagesCKA CKAD Candidate Handbook v1.10Chiran RavaniNo ratings yet

- Project Driven & Non Project Driven OrganizationsDocument19 pagesProject Driven & Non Project Driven OrganizationsEkhlas Ghani100% (2)

- Christian Biography ResourcesDocument7 pagesChristian Biography ResourcesAzhar QureshiNo ratings yet

- Shipping - Documents - Lpg01Document30 pagesShipping - Documents - Lpg01Romandon RomandonNo ratings yet

- RwservletDocument2 pagesRwservletsallyNo ratings yet

- International PositioningDocument37 pagesInternational PositioningMansi A Kathuria100% (1)

- Day Wise ScheduleDocument4 pagesDay Wise ScheduleadiNo ratings yet