Professional Documents

Culture Documents

Energy Losses in Pipes: Experiment # 4

Uploaded by

محمد جوادOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Energy Losses in Pipes: Experiment # 4

Uploaded by

محمد جوادCopyright:

Available Formats

Experiment # 4

Energy losses in pipes

Objective

To investigate the head losses due to friction in the flow of water through pipe and to determine the associated friction factor. Both variables are to determine in the range of the flow rates and their characteristics identified for both laminar and turbulent flow.

Method

By measurement of the pressure difference between two fixed points in a long straight tube of circular cross-section for steady flows. The range of flow rates will cover both laminar and turbulent floe regimes.

Equipment

In order to complete the demonstration we need a number of pieces of equipment. The F1-10 hydraulics bench which allows us to measure flow by timed volume collection. The F1-18pipe friction apparatus. A stopwatch to allow us to determine the flow rate of water A thermometer A spirit level for setting up the equipment A measuring cylinder for measuring very low flow rates

Apparatus:

The accessory is designed to positioned on the side Channels of the hydraulics bench top channel.

There are two methods of supplying water to the test pipe. For higher flow rates the inlet pipe is connected directly to the bench supply. For the low flow rates inlet pipe is connected to the outlet at the base of the constant head tank and the inlet to the bench is connected to the bench supply. The test section of the pipe is mounted vertically on the rig and is instrumented using two manometers. Water over mercury manometer is used to measure large pressure differentials and pressurized water manometer is used to measure small pressure differentials. When not in use manometer may be isolated using Hoffman clips. Flow through the test section is regulated using a flow control valve should face the volumetric tank. A short length of flexible piping attached to the valve prevents splashing.

Technical data

The following dimensions from the equipment are used in appropriate calculations. If required these values may be checked as part of the experiment procedure and replaced with your own measurement. Length of test pipe Diameter L= 0.500 m d= 0.300 m

And the friction, f, is related to the head-loss by equation h = flv2/2gd Where d is the pipe diameter and, in this experiment, h is measured directly by a manometer which connects to two pressure tapings a distance l apart; v is the mean velocity given in terms of the volume flow rate Q by V= 4Q/d2 The theoretical result for laminar flow is F= 64/Re Where Re=Reynolds number Re= vd / And is the kinematics viscosity. For turbulent flow in the smooth pipe, a well known curve fit to experiment data is given by F= 0.316Re-0.25

Procedure equipment set up

Mount the test rig on the hydraulic bench and, with a spirit level, adjust the feet to ensure that base plate is horizontal and, hence, the manometer is vertical. Check with the demonstrator that the mercury (Hg) manometer is correctly filled; this should not be attempted by student because Hg is hazardous substance. The test rig outlet tube must be held by a clamp to ensure that the outflow point is firmly fixed. This should be above the bench collection tank and should allow enough space for insertion of the measuring cylinders. Join the test rig inlet pipe to the hydraulic bench flow connecter with the pump turned off. Close the bench gate valve open the test rig flow control valve fully and start the pump. Now open the gate valve progressively and run the system until all air is purged. Open the Hoffman clamp and purge any air from the two bleed points at the top of Hg manometer. Attach a Hoffman clamp to each of the two manometer connecting tubes and close them off. With the system fully purged of air, close the bench valve, stop the pump, close the out flow valve and remove Hoffman clamp from water manometer connections. Disconnect test section supply tube and hold high to keep it liquid filled. Connect bench supply tube to header tank inflow, run pump and open bench valve to allow flow when outflow occurs from header tank snap connecter, attach test section supply tube to it ensuring no air entrapped. When out flow occurs from header tank over flow, fully open the outflow control valve.

Procedure- taking a set of results

1. Running high flow rate tests Apply a Hoffman clamp to each of the water manometer connection tubes (essential to prevent a flow path parallel to the test section) Close the test rig flow control valve and take a zero flow reading from Hg manometer, (may not be zero because of the contamination of Hg and / or tube wall.) With the flow control valve fully open measure the head loss h shown by the manometer. Determine the flow rate by timed collection and measure the temperature of collected fluid. The kinematic viscosity of water at atmospheric pressure can then be determined from the table provided in this manual.

2. Running low flow rate test

Repeat procedure given above but using water manometer throughout With the flow control valve fully open measure the head loss h shown by the manometer determine the flow rate by timed collection and measure the temperature of the collected fluid. The kinematic viscosity of water at atmospheric pressure can then be determined from the table provided in theory manual.

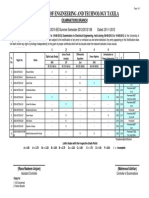

Observations and Calculations:

Test Pipe Length = m Test Pipe Diameter = m Temperature of water = ... OC Kinematic Viscosity = . m2/s

Volume Collected V (m3) Time To collect t (sec) Manometer Reading h1 (m) Manometer Reading h2 (m) Head loss h (m) Flow rate Q Velocity Friction Factor f Reynoldss No Re In f In Re In h In v

(m/s)

Application of theory

Identify the laminar and turbulent flow regimes. What is the critical Reynolds number? Assuming a relationship of the form f= kRen calculate these values from the graph you have plotted and compare these with the accepted values shown in the theory. What is the cumulative effect of the experimental errors on the value of k and n? What is the dependence of head loss upon flow rate in the laminar and turbulent regions of the flow? What is the significance of changes in a temperature in a head loss?

You might also like

- FM05 Pitot Static Tube PDFDocument2 pagesFM05 Pitot Static Tube PDFAnonymous thaRdEcpD100% (2)

- Fluid Flow Measurement Lab: ObjectDocument9 pagesFluid Flow Measurement Lab: ObjectAboodNo ratings yet

- Impact of A Jet Lab ReportDocument3 pagesImpact of A Jet Lab ReportSaiful IslamNo ratings yet

- Lab 4 (Thermofluids Lab)Document32 pagesLab 4 (Thermofluids Lab)Adnan Nanda0% (1)

- AIAA Papers TemplateDocument8 pagesAIAA Papers Templateمحمد جواد100% (1)

- Heat ExchangerDocument17 pagesHeat ExchangerMedariTrinadh100% (2)

- Smartdek Design ManualDocument48 pagesSmartdek Design ManualranddyNo ratings yet

- CE 2020 - Fluid Mechanics LaboratoryDocument67 pagesCE 2020 - Fluid Mechanics LaboratoryMd.Tarequl IslamNo ratings yet

- Lab7-Phelton Turbine Experiment-UpdatedDocument7 pagesLab7-Phelton Turbine Experiment-Updatedtomtoms92No ratings yet

- Centre of Hidrostatic PressureDocument16 pagesCentre of Hidrostatic PressureVanithaa Ponnaiah0% (1)

- Lab Report 4Document7 pagesLab Report 4api-300265822100% (1)

- LAB SHEET For Pelton Wheel 21 Sept 2011Document3 pagesLAB SHEET For Pelton Wheel 21 Sept 2011Mohd FazliNo ratings yet

- Orifice & Free Jet FlowDocument6 pagesOrifice & Free Jet FlowMohamedElkikiNo ratings yet

- Orifice Jet Flow Experiment GuideDocument3 pagesOrifice Jet Flow Experiment GuideshaneshaneshaneshaneNo ratings yet

- Energy Losses in BendsDocument10 pagesEnergy Losses in BendsAngelica Joyce BenitoNo ratings yet

- Lab 4-Friction Losses and Minor LossesDocument7 pagesLab 4-Friction Losses and Minor LossesJJ Sean CruzNo ratings yet

- Bernoulli's TheoremDocument5 pagesBernoulli's TheoremVrushiket PatilNo ratings yet

- Orifice and Free Jet Flow: University of NebraskaDocument8 pagesOrifice and Free Jet Flow: University of NebraskaJemuel Flores100% (1)

- Experiment 3 Reaction TurbineDocument20 pagesExperiment 3 Reaction TurbineAnonymous T7vjZG4ot100% (1)

- Lab Report 2Document16 pagesLab Report 2Limmy Yingran0% (1)

- Determine Floating Body StabilityDocument11 pagesDetermine Floating Body StabilityDember Paul100% (1)

- Flow Demonstration ExperimentDocument5 pagesFlow Demonstration ExperimentVictoria SooknananNo ratings yet

- Flow Meter Demonstration Lab ReportDocument21 pagesFlow Meter Demonstration Lab Reportmhd badhrul bin baharNo ratings yet

- Free VortexDocument3 pagesFree VortexVrushiket Patil67% (3)

- Hydrostatics TrainerDocument2 pagesHydrostatics TrainerJairo Martínez EscobarNo ratings yet

- Calibration of VenturimeterDocument2 pagesCalibration of VenturimeterAhmedElsayedNo ratings yet

- Abstract and Summary Aim and Objectives Theory Apparatus Procedure Result Calculation Discussion Conclusion Recommendations AppendicesDocument18 pagesAbstract and Summary Aim and Objectives Theory Apparatus Procedure Result Calculation Discussion Conclusion Recommendations AppendicesHariz MiorNo ratings yet

- Manning's Roughness Coefficient (N)Document11 pagesManning's Roughness Coefficient (N)Khurram MumtazNo ratings yet

- Impact of JetDocument5 pagesImpact of Jetميسرة33% (3)

- Determination of Discharge by Use of The Pitot TubeDocument2 pagesDetermination of Discharge by Use of The Pitot TubeJoffer Gallamaso100% (4)

- Table of Content DocDocument17 pagesTable of Content DocjjNo ratings yet

- Fluid Mechanics Lab Experiment 2Document8 pagesFluid Mechanics Lab Experiment 2SSShakeelNo ratings yet

- Jet ReactionDocument4 pagesJet ReactionSelva RajNo ratings yet

- Venturimeter and Orifice MeterDocument5 pagesVenturimeter and Orifice MeterVrushiket Patil100% (1)

- Coefficient of Discharge of Weirs Notch TrapezoidalDocument16 pagesCoefficient of Discharge of Weirs Notch TrapezoidalMuhammad FarhanNo ratings yet

- Fluid Mechanics Lab 3.1Document13 pagesFluid Mechanics Lab 3.1mahmoudNo ratings yet

- Flow Rate Measurement Using Venturi, Orifice & RotameterDocument13 pagesFlow Rate Measurement Using Venturi, Orifice & RotameterxxxxxNo ratings yet

- Revised LabDocument18 pagesRevised LabAbu AyemanNo ratings yet

- Flow Coefficients of Orifice and Mouthpiece ExperimentDocument5 pagesFlow Coefficients of Orifice and Mouthpiece ExperimentAshish VermaNo ratings yet

- Pitot Tube ExperimentDocument3 pagesPitot Tube ExperimentinstrutechNo ratings yet

- Flow Through an Orifice - Calculating Discharge, Velocity & Contraction CoefficientsDocument6 pagesFlow Through an Orifice - Calculating Discharge, Velocity & Contraction Coefficientshozipek559950% (2)

- Bernoullis Equation Lab ReportDocument12 pagesBernoullis Equation Lab ReportgeduyoxNo ratings yet

- Impact of A Water JetDocument5 pagesImpact of A Water JetAnirban SardarNo ratings yet

- Exp 2 Flow Visualization 2012Document6 pagesExp 2 Flow Visualization 2012Said Mohd Umar UmarNo ratings yet

- Hydrostatic forces on immersed plane surfacesDocument9 pagesHydrostatic forces on immersed plane surfacesEssam Ahmed Abd MeguidNo ratings yet

- Theory VenturiDocument7 pagesTheory VenturiMahendranath RamakrishnanNo ratings yet

- Energy Losses in Bends and FittingsDocument11 pagesEnergy Losses in Bends and FittingsQuenneBelocura100% (1)

- F9092 - Fluid Properties & Hydrostatics BenchDocument4 pagesF9092 - Fluid Properties & Hydrostatics Benchindra98031No ratings yet

- Bernoulli Theorem DemonstrationDocument27 pagesBernoulli Theorem DemonstrationmanzahuhuNo ratings yet

- V Notch PracticalDocument13 pagesV Notch PracticalAnushaBheenuck0% (2)

- Critical Reynolds Number in Pipe FlowDocument2 pagesCritical Reynolds Number in Pipe FlowHunterTateNo ratings yet

- Energy Losses in Bends & FittingsDocument7 pagesEnergy Losses in Bends & Fittingssamama khan100% (1)

- Stress Concentrations - Lab ReportDocument6 pagesStress Concentrations - Lab ReportArunodha HettiarachchiNo ratings yet

- EXPERIMENT – 6: Obtain Surface Profiles of Free and Forced VorticesDocument3 pagesEXPERIMENT – 6: Obtain Surface Profiles of Free and Forced Vorticesmanoj100% (1)

- 5 Calibration of Triangular NotchDocument8 pages5 Calibration of Triangular Notchkanavan monNo ratings yet

- Page For Main Menu: Typical Results Using The Equipment Below. Return To Lab Experiments PageDocument13 pagesPage For Main Menu: Typical Results Using The Equipment Below. Return To Lab Experiments PagepaniuatuiNo ratings yet

- EXP 7 Pipe FrictionDocument10 pagesEXP 7 Pipe Frictionsiva ramNo ratings yet

- Experiment No 7Document7 pagesExperiment No 7Faizan Ahmed67% (3)

- Mech. Engg. DepartmentDocument37 pagesMech. Engg. DepartmentHamza AhmadNo ratings yet

- MAPUA HYDRAULICS LAB ENERGY LOSSES IN BENDSDocument7 pagesMAPUA HYDRAULICS LAB ENERGY LOSSES IN BENDSJohn Michael Menoza ZapantaNo ratings yet

- Energy Losses in Pipes: Experiment No. - 11Document6 pagesEnergy Losses in Pipes: Experiment No. - 11John Michael Menoza ZapantaNo ratings yet

- HIT Jobs 8 5 17Document2 pagesHIT Jobs 8 5 17محمد جوادNo ratings yet

- Mass Transfer HMTDocument6 pagesMass Transfer HMTمحمد جوادNo ratings yet

- 60 Days To Fit ProgramDocument7 pages60 Days To Fit ProgramJorge Radrusian PiocudaNo ratings yet

- Mass Transfer HMTDocument6 pagesMass Transfer HMTمحمد جوادNo ratings yet

- 60 Days To Fit ProgramDocument7 pages60 Days To Fit ProgramJorge Radrusian PiocudaNo ratings yet

- RP11LDocument18 pagesRP11Lمحمد جوادNo ratings yet

- Application For Apprentice / Artisan Trainee BATCH 2014Document1 pageApplication For Apprentice / Artisan Trainee BATCH 2014محمد جوادNo ratings yet

- Correcting SentencesDocument3 pagesCorrecting Sentencesمحمد جوادNo ratings yet

- 1 Presentation Echometer QRod Quick Rod DesignDocument23 pages1 Presentation Echometer QRod Quick Rod DesignNIno Lenin Yupanqui SanchezNo ratings yet

- Winter 2016 Fee Schedule Grad INTLDocument1 pageWinter 2016 Fee Schedule Grad INTLمحمد جوادNo ratings yet

- PrintDocument2 pagesPrintمحمد جوادNo ratings yet

- PrintDocument2 pagesPrintمحمد جوادNo ratings yet

- Ielts Writing ModuleDocument40 pagesIelts Writing Moduleمحمد جوادNo ratings yet

- Solar RadiationDocument7 pagesSolar Radiation5886552No ratings yet

- 3RefrigerationCycle PDFDocument14 pages3RefrigerationCycle PDFYhn DfNo ratings yet

- Energy Resources and UtilizationDocument34 pagesEnergy Resources and UtilizationHassan Safdar MalikNo ratings yet

- Speed Breaker Power Generation MechanismsDocument32 pagesSpeed Breaker Power Generation MechanismsChetan Tiwary0% (1)

- Solid Works Tutorial-Making Wind Turbine BladeDocument26 pagesSolid Works Tutorial-Making Wind Turbine Bladeمحمد جواد100% (1)

- 2010 EE SummerSemester 2012 E10Document1 page2010 EE SummerSemester 2012 E10محمد جوادNo ratings yet

- RP11LDocument18 pagesRP11Lمحمد جوادNo ratings yet

- Gatsp 1Document9 pagesGatsp 1zbalouch15No ratings yet

- 170 Rotational InertiaDocument3 pages170 Rotational Inertiaمحمد جوادNo ratings yet

- Foreign PolicyDocument11 pagesForeign Policyمحمد جواد0% (1)

- Ref 2 Q#7Document4 pagesRef 2 Q#7محمد جوادNo ratings yet

- PAPA Admission FormDocument1 pagePAPA Admission Formمحمد جوادNo ratings yet

- Development of A Hydro-Mechanical Hydraulic Hybrid Drive Train With Independent Wheel Torque Control For An Urban Passenger VehicleDocument11 pagesDevelopment of A Hydro-Mechanical Hydraulic Hybrid Drive Train With Independent Wheel Torque Control For An Urban Passenger Vehicleمحمد جوادNo ratings yet

- 75-Centrifugal Pump Vibration Caused by Supersynchronous Shaft Instability - DRS&SMPDocument14 pages75-Centrifugal Pump Vibration Caused by Supersynchronous Shaft Instability - DRS&SMPمحمد جوادNo ratings yet

- Tower Bridge: London, EnglandDocument21 pagesTower Bridge: London, Englandمحمد جوادNo ratings yet

- A Text Book On Automobile Chassis and Body Engineering (ADocument58 pagesA Text Book On Automobile Chassis and Body Engineering (Ahunny29100% (2)

- Process Flow ChartDocument22 pagesProcess Flow ChartKumar Ashutosh100% (1)

- 4261 CombustorsDocument29 pages4261 CombustorsLakshman Reddy LuckyNo ratings yet

- TC Cico SuperDocument2 pagesTC Cico SuperHks InfrastructureNo ratings yet

- Shower Tile - Over Tray Installation Guide Wet Area Solutions (Aust) Pty LTDDocument4 pagesShower Tile - Over Tray Installation Guide Wet Area Solutions (Aust) Pty LTDpaulnidNo ratings yet

- FEC Problem Set 1Document4 pagesFEC Problem Set 1Buğra MertolNo ratings yet

- 2020 - 1 s2.0 S0020722520301853 MainDocument20 pages2020 - 1 s2.0 S0020722520301853 MainG DNo ratings yet

- Heavy MetalsDocument841 pagesHeavy MetalsAnonymous EzNMLt0K4CNo ratings yet

- Editable List of Procedure+Document5 pagesEditable List of Procedure+Koya ThangalNo ratings yet

- Bramat2011 ProgramDocument25 pagesBramat2011 Programmtierean100% (1)

- Non-Ferrous Metals and AlloysDocument58 pagesNon-Ferrous Metals and AlloysPradeep Kumar BagadiNo ratings yet

- Onshore: Piping Specification IndexDocument4 pagesOnshore: Piping Specification IndexHoa Bồ Công AnhNo ratings yet

- Manual-De-Usuario Deshumidificador PDFDocument18 pagesManual-De-Usuario Deshumidificador PDFSoyManuNo ratings yet

- 2kw Installation ManualDocument22 pages2kw Installation ManualGratian RealNo ratings yet

- Functionally Graded MaterialsDocument16 pagesFunctionally Graded MaterialsPradeepkumar Chikkamath100% (1)

- Day 2 200 ItemsDocument25 pagesDay 2 200 ItemsRobert DelfinNo ratings yet

- Meaning and Concept of Small Scale IndustryDocument14 pagesMeaning and Concept of Small Scale IndustryVijay SinghNo ratings yet

- Firecel General Catalogue - 100-4Document32 pagesFirecel General Catalogue - 100-4dinesh_kp7647No ratings yet

- Chap 4 Wastewater Effluent Treatment Plant ETP Operation Manual FactsheetDocument2 pagesChap 4 Wastewater Effluent Treatment Plant ETP Operation Manual FactsheetAhmedNo ratings yet

- LG EcoV DX PDFDocument62 pagesLG EcoV DX PDFAnonymous THUA6AsJ100% (1)

- Group 5 Part 2Document22 pagesGroup 5 Part 2Prila Sarmiento AbejoNo ratings yet

- Fosroc Conbextra Sureflow 100 BrochureDocument4 pagesFosroc Conbextra Sureflow 100 BrochurejasonNo ratings yet

- TYFTY Qs BankDocument7 pagesTYFTY Qs BankgurusamyNo ratings yet

- HVAC Pumping Solutions GuideDocument27 pagesHVAC Pumping Solutions Guideமுத்து குமார்No ratings yet

- Steel Tube Scale Exfoliation ResistanceDocument11 pagesSteel Tube Scale Exfoliation Resistancednageshm4n244No ratings yet

- Semi-Structural Surfacings Provide Flexible Top LayersDocument2 pagesSemi-Structural Surfacings Provide Flexible Top Layersgimanu100% (1)

- Method statement for box culvert constructionDocument10 pagesMethod statement for box culvert constructionTAMILNo ratings yet

- Sikadur 30 PDFDocument5 pagesSikadur 30 PDFDarwin SyahputraNo ratings yet