Professional Documents

Culture Documents

Fusible Dev 15RS128 Rev 0110

Uploaded by

Ali YusufOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fusible Dev 15RS128 Rev 0110

Uploaded by

Ali YusufCopyright:

Available Formats

Fusible Devices

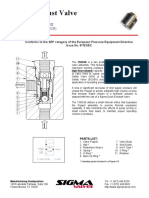

Fusible Valves - 3-Way Block & Bleed (Pop-Top)

1/2" FEMALE NPT, 3-WAY NO, 6,000 PSI MAX Model 15RS128 Standard Service; 15RS129 NACE (H2S); 15RS164 Arctic

Conforms to the CE Category IV of the European Pressure Equipment Directive Issue Certificate No. 97/23/EC

The 15RS128/129/164 Fusible Valve is a two position, threeway normally open Block & Bleed, Temperature Sensitive flow control device. When intense heat or close proximity to a fire causes the valve temperature to exceed the eutectic melting point, valve springs (Items 5, 6, and 16) decompress moving Poppet (Item 15) to block inlet supply pressure and vent downstream (receiving circuit) pressure out the Exhaust port. Fusible Valves are used to close safety valve actuators to isolate potential fuel sources from fire. Fusible Valves are available in the following temperatures: 158oF, 184F, 203oF, 255oF and 281oF.

PARTS LIST:

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. Retainer Copper Ring * O Ring * Valve Body Spring * Spring * Extension O Ring * Back Up Ring * Socket Set Screw * Eutectic Element 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. O Ring * Cup Seal TFE O Ring * Seat Block Spring * Valve Plunger Sub Connector O Ring * Pop Top Cap Retainer

* Indicates parts included in a Repair Kit

1420 Lakeside Parkway Suite 109 Flower Mound, TX 75028

Tel: +1 (972) 446 8250 Fax: +1 (972) 446 8642 http://www.sigma-valves.com

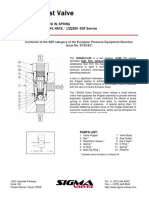

Sigma Model Number 15RS128/129/164

1/2" FEMALE NPT, 3-WAY NO, 6,000 PSI MAX

Product Specifications

Flow Control Application: Normally Open Control Function: Three-Way (Block & Bleed) - Pop Top Pressure Rating Body (Control Ports): 6,000 PSI maximum (413 bar) Media Service: Hydraulic Fluid Melt Temperature : 158o F. 184 203o F. 255o F. 281o F.

Connection Size (Body): 1/2-14 Female N.P.T. Supply, Valve, Exhaust Orifice: 7/16 Diameter Cv Factor: 3.00

Wetted Component Material (Metal): 316 Stainless Steel and 17-4PH SS Seal Material: Viton and Teflon Mounting: Line Mount (Standard) Weight: 10 Lbs. Operating Temperature: -20 F to +250 F (-29 C to +121 C) Arctic Service -55 F Overall Dimensions: 7-3/4 Height x 2-1/2 O.D (19.68 cm Height x 6.35 cm ) Installation and Maintenance Instructions: Install between the interface valve and the actuator. This is done by threading the pipe or fitting from the control system into the port labeled Supply. The piping from the actuator is threaded into the port labeled Valve. The piping from the hydraulic fluid reservoir is threaded into the port labeled Exhaust. If the temperature in the area of the valve exceeds the rated temperature, the valve will open and the control system will trigger an exhaust of the hydraulic fluid from the actuator through the exhaust port. Sigma recommends the use of appropriate thread sealant for each port connection. Shelf Position Port Status Supply Instrument supply pressure open to valve port Valve Outlet pressure to receiving control circuit (closed to exhaust port) Exhaust Depressurizes receiving control circuit upon actuation

While this information is presented in good faith and believed to be accurate, Sigma Valves does not guarantee satisfactory results from reliance upon such information. Nothing contained herein is to be constructed as a warranty or guarantee, expressed or implied, regarding the performance, merchantability, and fitness with respect to the products. Sigma Valves reserves the right, without notice, to alter or improve the designs or specifications of the products described herein.

You might also like

- Clock of Destiny Book-1Document46 pagesClock of Destiny Book-1Bass Mcm87% (15)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- CAT Pumps Service ManualDocument8 pagesCAT Pumps Service ManualAnonymous alQXB11EgQNo ratings yet

- Mechanics of Materials 7th Edition Beer Johnson Chapter 6Document134 pagesMechanics of Materials 7th Edition Beer Johnson Chapter 6Riston Smith95% (96)

- COACHING TOOLS Mod4 TGOROWDocument6 pagesCOACHING TOOLS Mod4 TGOROWZoltan GZoltanNo ratings yet

- Valves Grese NDocument92 pagesValves Grese NYair Alexis Muñoz Rojas100% (1)

- Dekker V Weida Amicus Brief by 17 AGsDocument35 pagesDekker V Weida Amicus Brief by 17 AGsSarah WeaverNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Control Valve FundamentalsDocument241 pagesControl Valve FundamentalsHarpreet SutdharNo ratings yet

- PRV Oil Safety Valve Henry 5600Document3 pagesPRV Oil Safety Valve Henry 5600pm2013No ratings yet

- Pneumatic Control ValvesDocument59 pagesPneumatic Control Valvespatil_raaj7234No ratings yet

- Kpolovie and Obilor PDFDocument26 pagesKpolovie and Obilor PDFMandalikaNo ratings yet

- ValvesDocument44 pagesValvesأحمد محمد قدريNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Information Security Master PlanDocument6 pagesInformation Security Master PlanMarubadi Rudra Shylesh Kumar100% (2)

- Es Acv M115F M1115FDocument4 pagesEs Acv M115F M1115FWattsNo ratings yet

- CAMERON France S.A.S: Front SheetDocument24 pagesCAMERON France S.A.S: Front SheetkrishnsgkNo ratings yet

- Astm C119-16Document8 pagesAstm C119-16Manuel Antonio Santos Vargas100% (2)

- Quick Exhaust Valve 13QS38 - 39Document2 pagesQuick Exhaust Valve 13QS38 - 39simplementemoiNo ratings yet

- Datasheet 4075 4475 High Temp Valve 0111 Rev1Document6 pagesDatasheet 4075 4475 High Temp Valve 0111 Rev1nricquartNo ratings yet

- Caleffi: Solar Pump Stations For Solar Heating SystemsDocument4 pagesCaleffi: Solar Pump Stations For Solar Heating SystemsKonstantaras YiannisNo ratings yet

- Quick Exh Valves 13QS1 Rev 0110Document2 pagesQuick Exh Valves 13QS1 Rev 0110136339No ratings yet

- FunctionalSafety V7666Document12 pagesFunctionalSafety V7666rufino.perea.2No ratings yet

- Mooney Flowgrid Slam Shut 1 Inch Valve: GE Oil & GasDocument12 pagesMooney Flowgrid Slam Shut 1 Inch Valve: GE Oil & GasCarlos TarquinoNo ratings yet

- Series EMVII-6400SS Installation InstructionsDocument4 pagesSeries EMVII-6400SS Installation InstructionsWattsNo ratings yet

- ASCO Info Filter Canada PDFDocument8 pagesASCO Info Filter Canada PDFdicicaNo ratings yet

- Type 1805P Pilot-Operated Relief ValveDocument8 pagesType 1805P Pilot-Operated Relief ValveJOMAGUESNo ratings yet

- Quick Exh Valves 13QS40 - 41 - 80 Rev 0110Document2 pagesQuick Exh Valves 13QS40 - 41 - 80 Rev 0110khaldoun samiNo ratings yet

- Sur - Flo Turbine MeterDocument40 pagesSur - Flo Turbine MeterCheng HuangNo ratings yet

- Air Eliminators 13WS WHS-Technical InformationDocument2 pagesAir Eliminators 13WS WHS-Technical Informationsugandaraj522No ratings yet

- Katalog p310 - 07Document7 pagesKatalog p310 - 07agustinusidNo ratings yet

- 14 400E 6DC Final Valvula BermadDocument4 pages14 400E 6DC Final Valvula Bermadmax_powerNo ratings yet

- CROWN Esd Brochure Usa 3 2Document4 pagesCROWN Esd Brochure Usa 3 2Ahmed Ayman Yassin100% (1)

- Catalogo Regulador Mooney Product00288 Manual Slam Shut 2 PLG y 4plgDocument20 pagesCatalogo Regulador Mooney Product00288 Manual Slam Shut 2 PLG y 4plgluis_d_mNo ratings yet

- F110-14, F1110-14 Specification SheetDocument6 pagesF110-14, F1110-14 Specification SheetWattsNo ratings yet

- Valve Proving SystemDocument6 pagesValve Proving SystemKyle JonesNo ratings yet

- 52 32 Convertible Namur Solenoid Valve Model 51424 51424Lw 51424is PDFDocument7 pages52 32 Convertible Namur Solenoid Valve Model 51424 51424Lw 51424is PDFysr3eeNo ratings yet

- Electri RelifDocument18 pagesElectri Relifsuleman247No ratings yet

- PVR-108-2 Fueling Model SheetDocument2 pagesPVR-108-2 Fueling Model SheetLetycia RosalesNo ratings yet

- Fluids Entry HBV Cetop 7 & 8 Series 101109Document12 pagesFluids Entry HBV Cetop 7 & 8 Series 101109Enhtuwshin BarkhasbadiNo ratings yet

- 01072Document4 pages01072윤병택No ratings yet

- Container Valve RGS-MAM-12-3C - Rv04Document3 pagesContainer Valve RGS-MAM-12-3C - Rv04Diego PinedaNo ratings yet

- SIT630 Installation InstructionsDocument2 pagesSIT630 Installation Instructionsmelisa63No ratings yet

- VALVULA DE SOLENOIDE HS7 BulletinDocument4 pagesVALVULA DE SOLENOIDE HS7 BulletinJoséMarcanoNo ratings yet

- FM-200 Alpha Series SystemsDocument6 pagesFM-200 Alpha Series SystemsGurusumiNo ratings yet

- SCMS 7035Document5 pagesSCMS 7035Jose Manuel CastroNo ratings yet

- M110-14, M1110-14 Specification SheetDocument6 pagesM110-14, M1110-14 Specification SheetWattsNo ratings yet

- 08-Conv Valves Product InfoDocument18 pages08-Conv Valves Product Infoakrk777No ratings yet

- Multimatic Deluge Valve A4Document6 pagesMultimatic Deluge Valve A4Lenin Rajaah AlaganNo ratings yet

- Convertidor Mechanical S108KDocument8 pagesConvertidor Mechanical S108KALBERTONo ratings yet

- Accessory Hot Gas BypassDocument4 pagesAccessory Hot Gas BypassRidwan PramudyaNo ratings yet

- Bomba Manual Hoja InstruccionesDocument72 pagesBomba Manual Hoja InstruccionesJulio ValderramaNo ratings yet

- Free Fall Valve Pg1-11Document12 pagesFree Fall Valve Pg1-11Roshan ShanmughanNo ratings yet

- 846 00 GB 0310Document8 pages846 00 GB 0310AlienshowNo ratings yet

- Trampadevapor Flotador y TermostaticaDocument9 pagesTrampadevapor Flotador y TermostaticaLuis Gutiérrez AlvarezNo ratings yet

- IOM 19 SeriesDocument6 pagesIOM 19 SeriesUmen AryanNo ratings yet

- Valvulas de Seguridad Hansen PDFDocument4 pagesValvulas de Seguridad Hansen PDFLuis ReinoNo ratings yet

- TC02 DigitalDocument17 pagesTC02 DigitalNebojsa CekicNo ratings yet

- Model 210 Digital Electro-Hydraulic Set Stop - PDF-, AttachmentDocument4 pagesModel 210 Digital Electro-Hydraulic Set Stop - PDF-, AttachmentMohd HassanudinNo ratings yet

- Diaphragm ValveDocument10 pagesDiaphragm Valveshganesh81No ratings yet

- Bulletin 1301Document8 pagesBulletin 1301Syed Haris Bin AkhterNo ratings yet

- Mustang Series M115-3 (Globe), M1115-3 (Angle) Specification SheetDocument7 pagesMustang Series M115-3 (Globe), M1115-3 (Angle) Specification SheetWattsNo ratings yet

- Sigma Valve 3 WayDocument2 pagesSigma Valve 3 WayRahimNo ratings yet

- NIMCO CV3000sDocument16 pagesNIMCO CV3000sBruno SamaeianNo ratings yet

- Blow Down Control ValveDocument2 pagesBlow Down Control ValveAmruth Babu V TNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Vortex ManualDocument89 pagesVortex ManualAli YusufNo ratings yet

- 008 Choke ValveDocument3 pages008 Choke Valveyukos100% (1)

- Can-Lite Model 250: Ignition TorchDocument1 pageCan-Lite Model 250: Ignition TorchAli YusufNo ratings yet

- Piping AnalysisDocument3 pagesPiping AnalysisAli YusufNo ratings yet

- Internship (1) FinalDocument12 pagesInternship (1) FinalManak Jain50% (2)

- 8A L31 Phiếu BTDocument7 pages8A L31 Phiếu BTviennhuNo ratings yet

- High Intermediate 2 Workbook AnswerDocument23 pagesHigh Intermediate 2 Workbook AnswernikwNo ratings yet

- Unit 6B - PassiveDocument18 pagesUnit 6B - PassiveDavid EstrellaNo ratings yet

- Flange CheckDocument6 pagesFlange CheckMohd. Fadhil JamirinNo ratings yet

- Datasheet of STS 6000K H1 GCADocument1 pageDatasheet of STS 6000K H1 GCAHome AutomatingNo ratings yet

- Computer Science HandbookDocument50 pagesComputer Science HandbookdivineamunegaNo ratings yet

- Promoting The Conservation and Use of Under Utilized and Neglected Crops. 12 - TefDocument52 pagesPromoting The Conservation and Use of Under Utilized and Neglected Crops. 12 - TefEduardo Antonio Molinari NovoaNo ratings yet

- Test 1801 New Holland TS100 DieselDocument5 pagesTest 1801 New Holland TS100 DieselAPENTOMOTIKI WEST GREECENo ratings yet

- "Prayagraj ": Destination Visit ReportDocument5 pages"Prayagraj ": Destination Visit ReportswetaNo ratings yet

- Growth Kinetic Models For Microalgae Cultivation A ReviewDocument16 pagesGrowth Kinetic Models For Microalgae Cultivation A ReviewJesús Eduardo De la CruzNo ratings yet

- 20 Ijrerd-C153Document9 pages20 Ijrerd-C153Akmaruddin Bin JofriNo ratings yet

- MBA 2nd Sem SyllabusDocument6 pagesMBA 2nd Sem SyllabusMohammad Ameen Ul HaqNo ratings yet

- 1Document14 pages1Cecille GuillermoNo ratings yet

- First Aid Transportation of The InjuredDocument30 pagesFirst Aid Transportation of The InjuredMuhammad Naveed Akhtar100% (1)

- Marketing Plan Nokia - Advanced MarketingDocument8 pagesMarketing Plan Nokia - Advanced MarketingAnoop KeshariNo ratings yet

- Study of Employees Performance Appraisal System in Hindustan Unilever LimitedDocument9 pagesStudy of Employees Performance Appraisal System in Hindustan Unilever LimitedSimranjitNo ratings yet

- Nugent 2010 Chapter 3Document13 pagesNugent 2010 Chapter 3Ingrid BobosNo ratings yet

- Demand, Supply, and Market EquilibriumDocument15 pagesDemand, Supply, and Market EquilibriumAnonymous HBQ86kNo ratings yet

- Term Paper A and CDocument9 pagesTerm Paper A and CKishaloy NathNo ratings yet

- Study of Subsonic Wind Tunnel and Its Calibration: Pratik V. DedhiaDocument8 pagesStudy of Subsonic Wind Tunnel and Its Calibration: Pratik V. DedhiaPratikDedhia99No ratings yet

- HSG 2023 KeyDocument36 pagesHSG 2023 Keyle827010No ratings yet